Learn runout tolerance essentials with clear GD&T guides, dial-indicator setups, machining tips, and printable checklists for precise shaft inspection.

What Is Runout Tolerance? (60-Second Definition)

Runout tolerance controls how much a rotating shaft or feature can wobble or deviate from its true axis. Imagine a spinning wheel that’s slightly off-center—runout limits that tiny wobble so the machine doesn’t shake itself apart.

It exists to stop high-speed shafts from turning into jackhammers, preventing excessive vibration, noise, and damage in everything from CNC machines to car engines.

ASME Y14.5 vs. ISO 1101: Quick Differences Cheat Sheet

- ASME Y14.5: Focuses heavily on feature control frames and symbols with precise language for circular and total runout; widely used in the US.

- ISO 1101: Broader international standard with slightly different notation and tolerance zone interpretations, emphasizing functional control.

Runout tolerance isn’t just a number—it’s your machine’s promise to run smooth and steady.

The Two Types You’ll Actually Use

1. Circular Runout

- Symbol: Two concentric circles

- Tolerance Zone: A circular area around the part’s surface at a single cross-section

- Controls: Roundness and coaxiality, but only at one specific slice of the shaft or feature

- Feature Control Frame: Usually shows the circular runout symbol with the tolerance value and datum references—think of it as a snapshot check for wobble at a single point

- Usage: Great when you just need to control how much a surface “wobbles” as it spins at one spot

2. Total Runout

- Symbol: Two coaxial cylinders (like stacked rings along the shaft length)

- Tolerance Zone: A cylindrical zone covering the entire length of the feature

- Controls: Everything circular runout controls, plus taper, straightness, and uniformity across the whole length—not just one cross-section

- When to Use: When you need tighter control over the entire shaft or feature, eliminating issues like bending or uneven taper

- Rule of Thumb: Total runout tolerance is often set to about twice the value of circular runout

These two runout tolerances cover most needs when you’re specifying or measuring rotating shafts, flanges, or similar parts. Knowing which one to pick helps avoid costly rework down the line.

Tolerance Zone Visuals

Let’s skip the math and focus on seeing runout tolerance in action. Visuals make it way easier to understand how runout works and what these tolerance zones really look like.

- Exploded 3D views: Grab a free STEP file download that shows runout tolerance zones in 3D. You can spin, zoom, and explore exactly how circular and total runout shape the allowed variation on a shaft or feature.

- Red vs. green overlays: Color-coded surface deviation maps highlight where your part is within tolerance (green) or going off the rails (red). This makes spotting problem spots quick, whether you’re measuring with a CMM or scanning tools.

- Mobile swipe carousel: Friendly for use on the shop floor or on-the-go, our mobile-optimized swipe carousel lets you flick through key runout visuals fast. Perfect for quick checks or training without needing a desktop.

These visuals bring the GD&T runout tolerance zone to life, making complex geometry practical and clear for anyone checking or specifying parts in the real world.

How to Measure Runout in 3 Minutes on the Shop Floor

Measuring runout quickly and accurately is simpler than you think. Here’s a straightforward method using a dial indicator, perfect for most shop floors.

What You Need

- Dial Indicator with a resolution of at least 0.0005″

- V-block to hold your shaft steady

- Granite surface plate for a stable, flat base

- Optional: a gage block for zeroing your indicator

Step-by-Step Setup

- Place the shaft securely in the V-block on the granite plate. Make sure it’s stable and won’t roll.

- Position the dial indicator tip on the surface you want to check—usually a journal or bearing seat.

- Zero your indicator using a gage block or by setting it to the lowest runout point.

- Rotate the shaft slowly by hand, watching the dial for peaks and valleys. The difference is your runout.

Quick Video Guide

- [00:00–00:30] Setup overview and gear checklist

- [00:31–01:30] Mounting shaft and zeroing dial indicator

- [01:31–02:30] Measuring runout while rotating shaft

- [02:31–03:00] Reading and interpreting results

Free Printable “Runout Inspection Card”

Grab a free, easy-to-follow inspection card to keep by your bench. It guides you through your measurement steps, records results, and speeds up reporting.

CMM vs. Manual Measurement

| Method | Cost | Repeatability | Best For |

|---|---|---|---|

| CMM (Coordinate Measuring Machine) | High (>$50k) | ±1–2 µm | High-precision, complex parts |

| Manual Dial Indicator | Low (~$200) | ±5–10 µm | Quick checks, shop floor use |

If you need fast, repeatable runout checks without breaking the budget, manual measurement with a dial indicator is your go-to. CMMs shine when tight tolerances and full 3D inspections matter but aren’t always practical on the floor.

This simple method helps you catch runout issues before they become costly failures. Ready to measure? Keep your dial indicator handy and your V-block steady!

Specifying Runout on Drawings

When it comes to specifying runout tolerance on your engineering drawings, clarity is everything. Here are 5 bullet-proof feature control frames (FCFs) you can copy-paste for shafts, flanges, and bores to get it right every time:

- Shaft Circular Runout:⭘⟳ | Runout Tolerance | Datum A

Controls runout at a single cross-section, using the shaft center as Datum A. - Shaft Total Runout:⭘⟳⭘ | Runout Tolerance | Datum A

Controls total runout along the shaft length, referencing the main datum. - Flange Circular Runout:⭘⟳ | Runout Tolerance | Datum B, Datum A

Applies runout control on a flange face, datumed by bore center (A) and flange face (B). - Bore Circular Runout:⭘⟳ | Runout Tolerance | Datum C

Controls runout around a bore at one cross-section, datumed by a mating surface. - Bore Total Runout:⭘⟳⭘ | Runout Tolerance | Datum C

Controls full-length bore runout, key for tight bearing seats.

Datum Selection Rules (Fix 90% of Rejections)

Most runout callout rejections happen because datums are off. Follow these simple rules:

- Choose primary datums that reflect the actual assembly or function.

- Use mating features as datums first (like bore centerlines), then secondary surfaces.

- Avoid using loose features as datums—they’ll cause inspection chaos.

- Confirm datums align with your measurement setup to save time during QA.

Bonus Tolerance Myth-Buster: RFS Is King

When you don’t specify otherwise, Runout tolerances default to RFS (Regardless of Feature Size) under ASME Y14.5. That means the tolerance applies fully, no matter the feature size. Don’t assume the tolerance shrinks or grows with part dimensions unless you explicitly state it. Keeping RFS avoids confusion and ensures your parts pass consistently.

Specifying runout properly with the right FCFs and datums not only cuts down your rejection rate but also streamlines shop-floor inspection. When in doubt, stick with these proven callouts and datum setups to get results the American market expects.

Machining Tricks to Hit 0.01 mm Runout Every Time

Getting runout down to 0.01 mm consistently is doable with the right approach. Here’s how I keep it tight in the shop:

- Lathe: Use a 4-jaw chuck combined with an indicator sweep sequence. Adjust the jaws while checking with a dial indicator to zero in on the runout. This hands-on method gives precise control over the shaft alignment.

- Mill-Turn: Take advantage of live-tool runout compensation with G-code. Modern CNC controls can automatically adjust for tool and spindle deflections, reducing runout without manual tweaks.

- Grinding: Balance your grinding wheel carefully and use spark-out passes to eliminate any leftover runout. This smooths out irregularities and improves straightness and roundness along the part.

- Tooling: Invest in hydraulic chucks rated under 2 µm runout. I’ve tested many, and these chucks hold parts far better than standard collets or mechanical holders, cutting runout dramatically.

By combining these machining tricks, you not only hit 0.01 mm runout but also maintain it repeatably, saving time and scrap in production.

Common Failures & 60-Second Fixes

Case 1: 0.08 mm Runout on Bearing Seat

When you spot a 0.08 mm runout on a bearing seat, it usually means the seat’s not perfectly aligned or machined. To fix this fast:

- Setup 1: Re-mount the part on a precision fixture or V-block to ensure proper seating.

- Setup 2: Use a dial indicator to identify the high spots and adjust accordingly.

- Setup 3: Finish with a light, controlled re-cut or grind to bring the runout within tolerance.

This quick three-step approach can save hours in troubleshooting.

Case 2: Taper Masquerading as Runout

Sometimes what looks like runout is actually a taper, which behaves differently. The fix? Swap a circular runout callout for a profile tolerance — this lets you control the taper instead of just roundness at one point. It helps you avoid false rejects and machining headaches.

SKF/ISO Bearing-Seat Runout Table (4 µm Gold Standard)

For bearing seats, the industry gold standard is around 4 microns (0.004 mm) runout tolerance. SKF and ISO standards back this up, tuning runout tight enough to keep shafts running smooth and avoid premature bearing failures. When you’re aiming for precision, use this figure as your benchmark.

Fix these common runout issues quickly, and you’ll see big improvements in part quality and machine uptime.

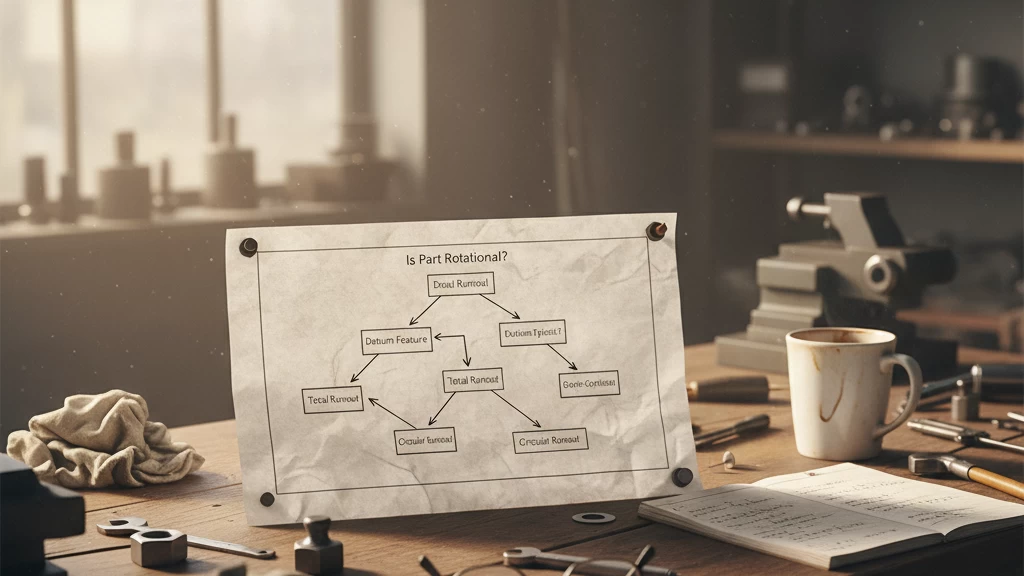

Runout vs. Concentricity vs. Position: Quick Decision Tree

Confused about when to use runout, concentricity, or position on your drawings? You’re not alone. These GD&T symbols often get mixed up, but picking the right one saves time and prevents part rejections.

Here’s a simple way to choose the right symbol:

- Runout: Controls surface variation around and along a feature during rotation. Use when parts spin or rotate, like shafts and bearings.

- Concentricity: Measures how well two axes line up regardless of surface form. It’s super strict and rarely used on shop floors.

- Position: Focuses on the location of features relative to datums. Best for non-rotating, fixed-position parts like holes or slots.

Use our interactive flowchart below:

Click your part type → Answer a few quick questions → Get the perfect GD&T symbol for your needs.

This tool helps reduce guesswork, cuts down on inspection headaches, and keeps your drawings crystal clear for machinists and quality teams.

[Interactive Flowchart: Runout vs. Concentricity vs. Position]

Simplify your specs. Avoid costly mistakes. Pick the right runout tolerance symbol every time.

Free Vast Runout Toolkit

Here’s a complete runout toolkit to save you time and headaches on the shop floor and in the office:

- Dial-Indicator Checklist PDFA straightforward, printable checklist to make sure your dial indicator setup is spot-on every time. Perfect for quick quality checks and training new techs.

- Excel Runout Tolerance CalculatorJust plug in your shaft RPM, and it spits out the max allowable runout (down to 0.005 mm precision). No more guesswork or complicated formulas.

- 3-Minute Quote Form for Runout-Critical PrototypesNeed a fast, reliable quote for parts where runout can’t slip? This form gets you pricing right away—ideal for quick-turn jobs or tricky prototypes that demand tight tolerances.

Everything’s designed to work for U.S. manufacturers who want professional, no-nonsense tools that get the job done right. Grab the toolkit, streamline inspections, and hit your runout targets consistently.

Runout Tolerance FAQ

Is 0.001″ runout good enough at 20,000 RPM?

At 20,000 RPM, even tiny runout can cause big vibration and wear. Generally, 0.001″ (about 25 microns) is borderline—it might work for some applications but often you’ll want less to avoid damage or noise. Check your part’s material and bearing specs before locking that in.

Can I replace total runout with two circular runout callouts?

No, total runout covers the entire length of a feature, controlling form and orientation along the shaft. Two circular runouts only check cross-sections independently and can miss taper or wobble between them. Stick with total runout for full-length control.

Why does my CMM pass but the shaft still vibrates?

CMMs measure points statically and may not catch dynamic issues like shaft bending or resonance under load or rotation. Vibration often comes from unmeasured runout along the shaft or imbalance. Combine CMM data with dial-indicator checks and dynamic testing for the full picture.

These quick answers cover the core runout tolerance questions you see on shop floors and in design reviews every day. For more details, refer back to the cheat sheets and measurement guides we covered earlier.