Explore expert wire EDM cut techniques precision parameters materials and troubleshooting for flawless industrial manufacturing results and tight tolerances.

If you’re looking to master wire EDM cut techniques, you’ve landed in the right place. Whether you’re an engineer, machinist, or manufacturing pro, understanding the fine details behind this precision machining method can make or break your project outcomes. Wire EDM isn’t just about slicing metal—it’s about achieving micron-level tolerances, flawless surface finishes, and tackling geometries that traditional machining can’t handle. In this guide, you’ll get straight-to-the-point insights on how wire EDM cut works, key parameters to optimize, and expert tips to unlock perfect cuts every time. Ready to up your precision game? Let’s dive in.

What Is Wire EDM Cutting?

Wire EDM stands for Wire Electrical Discharge Machining, a precise metal cutting process using electrical sparks. It cuts conductive materials by eroding them with rapid, controlled electrical discharges along a thin wire.

Core Components

| Component | Role |

|---|---|

| Wire | Thin, continuously fed—usually brass or molybdenum—to create the spark gap |

| Dielectric fluid | Non-conductive liquid (usually deionized water) to flush away debris and cool the workpiece |

| Spark gap | Microscopic gap where electrical discharges occur, melting and vaporizing metal |

Machine Types

- CNC wire EDM: Fully automated with CAD/CAM control for complex, precise cuts.

- Wire spool: Supplies continuous wire, ensuring smooth, uninterrupted cutting.

- Nozzles: Direct dielectric fluid and wire positioning; adjustable for different cutting needs.

Difference from Conventional EDM

Conventional EDM uses a shaped electrode that erodes the workpiece; Wire EDM uses a continuously moving wire instead. This allows Wire EDM to:

- Cut extremely fine, complex contours.

- Achieve tighter tolerances and thinner kerf width.

- Produce less heat-affected zones, preserving material integrity.

Wire EDM visually looks like a thin wire “slicing” through metal with sparks flying, unlike traditional EDM’s stationary electrode approach.

How Wire EDM Cutting Process Works

Wire EDM cutting starts with programming using CAD/CAM software. Designers create the part’s shape, which is then translated into G-code that guides the machine on how to move the wire precisely.

Next comes the machine setup. You’ll adjust key power settings like current, voltage, and pulse duration, plus the dielectric fluid flow, which cools the wire and flushes away debris. This setup is crucial for a stable spark gap between the wire and the workpiece.

The cutting begins with a roughing pass. Here, the goal is to remove material quickly while maintaining proper wire tension to prevent breakage. This pass shapes the basic profile but leaves a slightly rough surface.

Once the rough cut is done, we run one or more skim cuts. These are slower, finer passes that improve surface finish and tighten tolerances. Skim cuts help reach final dimensions with high precision.

Wire consumption is always monitored during the process. Proper tension and power controls help avoid wire breaks, reducing downtime and keeping cuts clean. Managing wire feed speed and break prevention is key to efficient production on any CNC wire EDM system.

Key Technical Specs to Control in Wire EDM Cut

When it comes to wire EDM cutting, a few technical specs are crucial for stable, precise results. Here’s a quick breakdown:

| Specification | Details |

|---|---|

| Wire Diameter Range | Typically from 0.004″ to 0.013″ (100–330 μm). Thinner wires offer finer cuts but need careful handling. |

| Voltage & Gap Monitoring | Real-time tracking ensures the spark gap stays steady, preventing wire breaks and improving cut quality. |

| Cutting Speed | Depends on the material type and workpiece height. Softer metals cut faster; thicker parts slow the process. |

| Taper Cutting Capability | Wire EDM can handle tapers up to 45°, useful for angled or complex shapes. |

| Max Workpiece Size | Most machines handle parts up to about 20″ thick; exotic metals may require special setups or slower feeds. |

Keeping these specs dialed in helps avoid wire breakage, controls kerf width, and achieves tight EDM tolerances for your precision wire cutting needs.

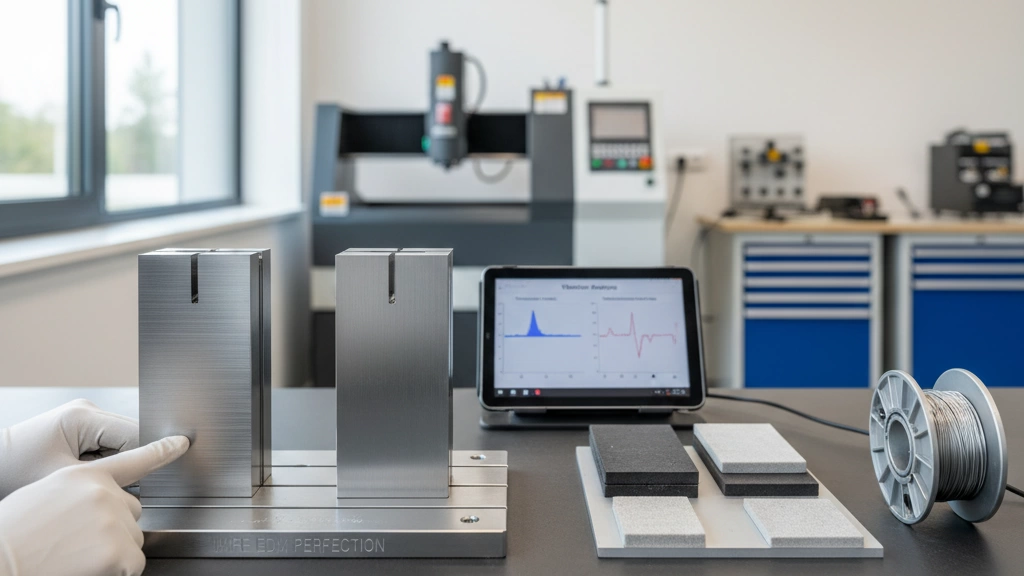

Materials Compatible with Wire EDM

Wire EDM cutting works best with conductive metals, making it versatile for many industries. Common materials include tool steels like D2, A2, and T7, stainless steels such as 17-4PH and 316, as well as aluminum, titanium, copper, brass, and even carbide. It handles a wide range of hardness levels—from soft, annealed metals to hardened steels—without any trouble.

Since Wire EDM relies on electrical discharge, it can’t cut non-conductive materials like plastics or ceramics directly. However, there are hybrid approaches, like coating or special setups, that let you work around those limits in some cases. If your project involves a mix of metals or complex materials, it’s worth discussing with your local wire EDM shop to find the best solution.

Tolerances and Surface Finish Achievements

Wire EDM cuts with incredible precision. Typical corner radius tolerance is around ±0.0002″ (5 μm), and in the best cases, you can get down to ±0.00005″ (0.05 mm). This level of accuracy is why it’s trusted for high-precision parts.

Multi-axis wire EDM machines use skim cuts—very fine finishing passes—to tighten tolerances and improve surface finish. These skim cuts remove just a tiny bit of material after the roughing pass, giving you smoother edges and sharper details.

When it comes to surface finish, wire EDM stands out compared to milling, grinding, and laser cutting. It generally provides a cleaner finish with minimal burrs and a smoother texture. Plus, there’s no mechanical contact, so there’s less chance of distortion or tool marks.

In , wire EDM delivers top-notch tolerances and surface quality, making it ideal for complex parts where precision counts.

Common Applications by Industry

Wire EDM cutting is trusted across many industries because of its precision and versatility. Here’s where it shines most:

- Aerospace: Perfect for making turbine blade cooling holes and fuel system parts where tight tolerances and complex shapes matter.

- Medical: Used for surgical instruments, implant prototypes, and detailed work like recast layer analysis to ensure device safety and performance.

- Tool & Die: Essential in creating extrusion and progressive stamping dies that require sharp edges and excellent surface finish.

- Automotive: Ideal for gearbox splines and injection mold components, delivering high-precision parts that must withstand wear and stress.

- Electronics: Common for manufacturing connectors, heat sinks, and other components that need fine, consistent cuts and tight tolerances.

Wire EDM cutting is a go-to wherever precision and complex geometry meet tough materials.

Advantages of Wire EDM vs Other Micro Cutting Methods

Wire EDM cut stands out when compared to CNC milling, laser cutting, and waterjet for precise micro cutting jobs. Here’s a quick rundown of why Wire EDM often wins:

| Feature | Wire EDM | CNC Milling | Laser Cutting | Waterjet |

|---|---|---|---|---|

| Heat-Affected Zone (HAZ) | Minimal (almost none) | Moderate | High | None |

| Burr Formation | None | Common | Moderate | Minimal |

| Tool Contact | No physical contact | Physical tool contact | No contact | No contact |

| Material Distortion | Very low | Possible due to force | Possible due to heat | Low |

| Adaptability for Sensitive Materials | Excellent (adaptive control) | Limited | Limited | Good |

| Surface Finish Quality | Superior (skimming cuts) | Good | Varies | Moderate |

Why Wire EDM is Great for Heat-Sensitive Materials:

- No direct tool contact means less mechanical stress on parts.

- Adaptive spark control adjusts cutting power to avoid overheating.

- Minimal heat-affected zone prevents warping or changes in metal properties.

For precision parts like medical implants, aerospace components, or tool & die inserts, wire EDM cutting ensures clean edges without the risk of distortion or burrs. In contrast, milling tools can cause mechanical stress, lasers might burn or melt edges, and waterjets can sometimes leave ragged cuts on softer materials.

In short, if your job calls for tight tolerances with a clean finish, especially on hard-to-machine metals, Wire EDM cuts offer a smooth, reliable edge with less post-processing.

Limitations and When Not to Use Wire EDM

Wire EDM cutting works great on many metals, but it’s not the best choice for everything. Here are some situations where you might want to look elsewhere:

- Non-conductive materials: Wire EDM only cuts electrically conductive metals. That means plastics, ceramics, and other non-conductive materials are a no-go.

- Very thick parts: Cutting parts thicker than about 20 inches slows down the process significantly, making it inefficient and costly.

- Simple, low-cost jobs: For basic shapes or low-complexity parts, Wire EDM can be more expensive and slower than other methods like CNC milling or waterjet cutting.

In short, if your project involves non-metals, very thick pieces, or simple cuts without tight tolerances, other cutting methods are usually better suited.

Cost Factors Influencing Wire EDM in 2025

When it comes to wire EDM cutting costs in 2025, several key factors play a role in your final price:

- Material Type and Thickness: Harder or thicker metals take longer to cut and can wear the wire faster, increasing costs. Softer metals like aluminum are quicker to machine, but super-alloys or hardened steels will cost more.

- Number of Skim Cuts: Skim cuts improve surface finish and tolerance but add extra run time. The more skim passes you need, the higher the cost, so it’s good to balance quality vs. budget.

- Setup Time vs. Runtime: Setup includes programming the job (CAD/CAM and G-code), fixturing, and machine calibration. Efficient setups reduce costs, especially for smaller runs. Long runtime jobs raise expenses due to electricity, wire consumption, and fluid use.

- Shop-Specific Algorithms and Rates: Many shops now use proprietary software to optimize wire speed, spark energy, and cut paths. These efficiencies can lower machining time and costs but might factor into pricing differently across vendors.

Knowing these factors helps you budget better and choose the right wire EDM shop to get competitive rates without sacrificing quality.

Troubleshooting Common Wire EDM Defects

When you’re working with wire EDM cut processes, a few common issues like wire vibration and streaks can pop up. These problems mess with your precision and slow you down, but the fixes are usually straightforward.

Wire Vibration Causes and Fixes:

- Causes: Too much wire tension, incorrect wire speed, or unstable spark energy can make the wire vibrate. Also, rough machine setup or worn guides add to the problem.

- Fixes: Adjust wire tension carefully—too tight or too loose causes issues. Optimize wire speed and check the machine’s spark settings. Make sure the wire guides are clean and in good shape.

Streaks on the Workpiece:

- Causes: Uneven spark distribution, dirty dielectric fluid, or worn wire can leave streaks or marks on your part.

- Fixes: Regularly replace or filter dielectric fluid, use fresh wire spools, and check your power settings. Fine-tuning pulse on/off times can smooth out the surface.

Reducing Wire Breakage:

- Wire breaks are costly and frustrating. Most breaks come from improper programming or wire tension problems.

- Double-check your CAD/CAM program for tight corners that may pull the wire too hard.

- Reduce wire tension slightly and slow the feed rate in tricky areas.

- Adjust pulse energy to a lower setting when cutting fragile or thin parts.

By staying on top of these settings and maintenance steps, you can keep your wire EDM cut running smooth with minimal defects. It’s all about balance—right tension, clean dielectric, and well-tuned power make a big difference.

How to Choose a Wire EDM Shop (Checklist)

Picking the right wire EDM shop is key to get quality cuts on time and on budget. Here’s what I look for when choosing a shop:

| Factor | What to Check |

|---|---|

| Machine Brands | Shops using trusted machines like Mitsubishi, Sodick, GF, Fanuc tend to deliver consistent precision. |

| Calibration | Regular calibration ensures stable cutting and tight tolerances. Ask if they document this process. |

| Wire Speed & Dielectric Types | Higher wire speeds boost productivity; look for shops that use quality dielectrics for better surface finish and machine life. |

| Certifications | Look for ISO 9001, AS9100 (for aerospace), or ITAR compliance—these prove quality and compliance with industry standards. |

| Wire Consumption & Efficiency | Efficient wire use lowers cost. Ask about their wire breakage rates and recycling practices. |

| Turnaround Time & Capacity | Choose a shop with enough capacity to meet your deadlines. Check average job lead times and flexibility. |

| Customer Reviews | Look up ratings and testimonials—real feedback reveals reliability and service quality. |

This checklist makes sure your wire EDM job goes smooth from quotes to finished parts without surprises.

Future Trends in Wire EDM Cutting

Wire EDM cutting is evolving fast, especially in the U.S. market where precision and efficiency matter most. Here’s what’s coming next:

- Resin Regeneration in Dielectric FluidsNew dielectric fluids with resin regeneration help reduce waste and lower operating costs. They keep the fluid cleaner longer, improving cut stability and surface finish without frequent changes.

- AI-Optimized Tool Paths and FiltrationArtificial intelligence is stepping in to optimize wire routes and filtration systems automatically. This means smarter cutting paths, fewer wire breaks, and extended machine uptime—saving time and money.

- Thinner Wires (~0.002″) for Faster CuttingThinner molybdenum wires around 0.002″ diameter are getting popular. They offer higher cutting speeds and finer details, perfect for US industries demanding ultra-precision, like aerospace and medical device prototyping.

- Hybrid Additive Manufacturing IntegrationWire EDM is starting to merge with 3D printing and other additive processes. This combo lets manufacturers create complex parts quickly and finish them precisely with EDM cut, streamlining production for advanced components.

These trends show wire EDM cutting becoming smarter, cleaner, and faster—keeping it a top choice for precision industries across the country.