Discover Vast’s expert guide to EDM cutting wire types materials and tips for precision wire EDM machining in aerospace automotive and more industries.

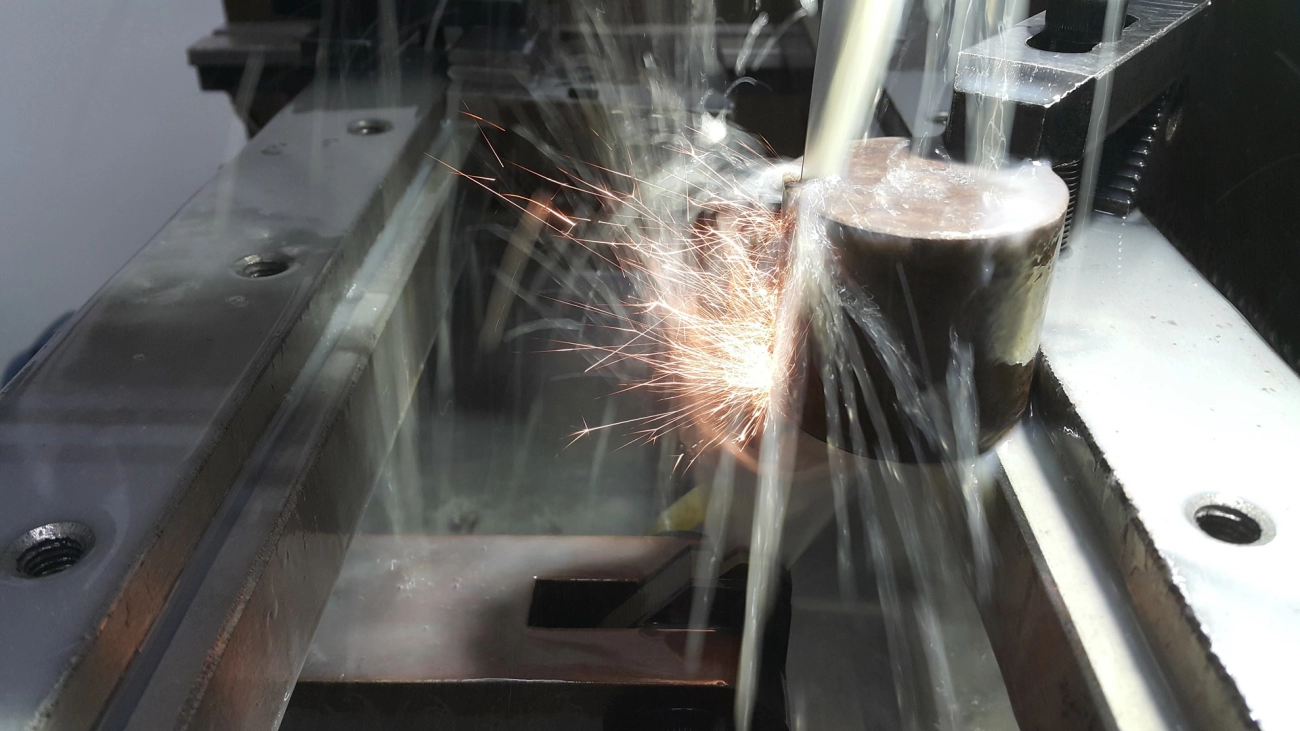

How EDM Cutting Works The Science Behind the Spark

Ever wonder how EDM cutting wire slices through tough metals with such precision? At its core, EDM (electrical discharge machining) uses tiny sparks to erode material without physical contact. Imagine a controlled lightning bolt jumping between a thin wire electrode and the workpiece—it melts and vaporizes the metal bit by bit.

Here’s how it works:

- Spark erosion process: The wire feeds continuously while short electrical bursts create sparks.

- Voltage and intervals: These sparks happen in milliseconds, controlled by voltage gaps that determine spark size.

- Material vaporization: The sparks instantly vaporize tiny sections of the metal, carving out the cut.

Key components making this possible include:

- Wire guides that keep the wire steady and on path.

- Power supply delivering precise electrical pulses.

- Dielectric fluid (usually deionized water) that cools the cut and flushes away debris.

- CNC controls managing multi-axis paths for complex shapes.

Cutting depends on several factors like:

- Voltage gap between wire and workpiece.

- Flush pressure to clean debris.

- Wire feed rates matching material thickness for smooth cuts.

Visualize the wire’s path slicing through a titanium workpiece in our infographic—each spark is a tiny sculptor shaping metal with surgical precision. This is precision wire EDM machining at its finest.

Types of EDM Cutting Wires Materials and Their Unique Properties

When it comes to EDM cutting wire, the right material makes a big difference in cut quality and efficiency. Here’s a quick look at the most common wire types and what sets them apart:

Brass Wires

- Pros: Low cost and widely available

- Uses: General purpose cutting, easy to flush with dielectric fluid

- Cons: Prone to breakage when cutting thicker materials

Molybdenum Wires

- Strengths: High tensile strength and fatigue resistant

- Applications: Aerospace parts and tight tolerance jobs

- Benefits: Cleaner cuts with less wire breakage, ideal for precise, intricate work

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

| cURL Too many subrequests. | cURL Too many subrequests. | Tensile Strength (MPa) | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|---|---|

| cURL Too many subrequests. | 100-300 | cURL Too many subrequests. | cURL Too many subrequests. | Low |

| cURL Too many subrequests. | 150-250 | High | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | 150-200 | Very High | cURL Too many subrequests. | High |

cURL Too many subrequests.

- cURL Too many subrequests. are gaining popularity, offering faster cutting speeds and better wear resistance.

- These are especially useful in cutting hardened steels where traditional wires struggle.

Choosing the right EDM cutting wire material depends on your specific job and budget. Brass works well for everyday jobs, molybdenum suits precision needs, and coated copper tungsten excels in complex or tough applications.

Selecting the Right EDM Cutting Wire Factors for Optimal Performance

Choosing the right EDM cutting wire is key to getting the best results and keeping your process smooth. Here’s what you need to consider:

Material Compatibility

Match your wire to the workpiece material. This helps reduce the recast layer—the thin, hardened layer left after EDM—that can affect finish and strength. For example, molybdenum wire is great for aerospace alloys, while brass works well with softer metals.

Machine Specifications

Make sure your wire choice fits your EDM model. Tension settings matter to avoid wire sagging or breaking during cuts. Some machines handle finer wires better, so check what your CNC wire EDM system supports.

Cost Versus Efficiency

Think about your wire consumption and ROI. If you’re running high-volume jobs, investing in higher quality wires like coated copper tungsten may save you money by reducing breakage and downtime. For low-volume runs, cost-effective brass wire may do the job.

Common Pitfalls to Avoid

- Wire breaks from poor flushing or wrong tension

- Deflection issues on tight internal radii

- Increased wear from incompatible wire and material combos

To help you pick, we offer a free downloadable PDF checklist covering critical selection criteria. Using it ensures you get the right wire for your specific EDM cutting needs and avoid costly downtime.

Applications and Real World Use Cases for EDM Cutting Wire

EDM cutting wires play a huge role across many industries in the U.S., especially where precision and complex shapes matter. In aerospace, for example, turbine blades require extreme accuracy and clean cuts—molybdenum wires are often the go-to because they deliver sharp edges and consistent results. Medical implants benefit from EDM wire erosion too, providing the tight tolerances needed for parts that must fit perfectly inside the body.

The automotive sector uses EDM wires for fine blanking dies, helping produce parts with minimal cleanup. Electronics manufacturers rely on wire EDM to shape delicate components without causing heat damage. Plus, technologies like PCD (polycrystalline diamond) erosion demand wires that can handle hard, abrasive materials while maintaining fine tolerances.

One standout example is a case study using molybdenum wire to create intricate graphite electrodes. This approach cut lead times dramatically and improved overall precision, showing just how effective the right wire material can be for complex jobs.

Compared to milling, waterjet, or laser cutting, EDM wire cutting offers clear benefits:

- No tool wear since the wire doesn’t actually touch the material

- Consistent kerf width for uniform cuts

- No heat-affected zones, preserving the original material properties

Looking ahead, the future of EDM cutting wire includes integrating AI-driven controls for adaptive spark regulation. This means even smarter cuts, less wire breakage, and better overall efficiency tailored to each unique job.

If you’re working with tough metals or need ultra-fine precision, EDM cutting wire remains a top choice—in industries across the board, it’s proven to deliver.

Maintenance and Troubleshooting Maximizing Wire Longevity and Cut Quality

Keeping your EDM cutting wire in top shape is key to getting clean, precise cuts and avoiding costly downtime. Here’s how to maximize wire lifespan and maintain cut quality:

Daily Maintenance Tasks

- Inspect wire tension regularly to prevent sagging and wire breakage.

- Clean wire guides to avoid buildup that can cause deflection or uneven cuts.

- Monitor dielectric fluid conductivity to ensure proper flushing and spark stability.

Common Troubleshooting Tips

- Short circuits often mean the wire path is obstructed or the dielectric isn’t flowing correctly—check for blockages and adjust flush pressure.

- Rough finishes can be caused by worn electrodes or incorrect feed rates—fine-tune cutting parameters and replace wire if needed.

- cURL Too many subrequests. cURL Too many subrequests.

Safety Protocols

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

Pro Tip

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.