Discover anodizing basics, types, and benefits for durable corrosion-resistant aluminum finishes with expert insights and local service options.

What Is Anodizing A Simple Breakdown for Beginners

Anodizing is a popular metal surface treatment widely used to enhance the durability and appearance of aluminum and other metals. In simple terms, it’s an electrochemical process that creates a protective aluminum oxide layer on the surface of the metal. This layer is hard, corrosion-resistant, and can be dyed in various colors, making anodizing both functional and decorative.

The Science Behind Anodizing

At its core, anodizing uses electricity to thicken the natural oxide layer on aluminum. When the metal is submerged in an acid electrolyte bath and an electric current runs through it, oxygen ions combine with aluminum atoms to form a thick, stable aluminum oxide coating. This coating is porous initially, which allows for dyeing or sealing, but once sealed, it becomes a tough, corrosion-resistant barrier.

This process differs from other coatings like paint or plating because the anodized layer is part of the metal itself. That means it won’t chip, peel, or flake, giving you a long-lasting, abrasion-resistant finish.

Why Anodizing Matters in 2025

With growing focus on sustainability and durability in manufacturing, anodizing is more relevant than ever in 2025. It offers:

- Long-lasting protection against rust and wear, reducing the need for frequent replacements.

- Eco-friendly properties since it’s non-toxic and creates less waste than many coating methods.

- Versatility for industries like aerospace, automotive, and architecture that demand both strength and style.

Whether you’re a DIY enthusiast or a professional, understanding anodizing now can help you make smarter choices about metal finishing that last well into the future.

Types of Anodizing Choosing the Right Finish for Your Needs

Anodizing comes in different types, each offering unique benefits depending on what you need. Whether you want better corrosion resistance, a smooth finish, or extra toughness, picking the right anodizing process matters.

Type I Chromic Acid Anodizing

This uses chromic acid to create a thin, corrosion-resistant aluminum oxide layer. It’s great for delicate parts and applications where minimal color change and surface alteration are important. Often chosen for aerospace and military uses thanks to its lightweight finish.

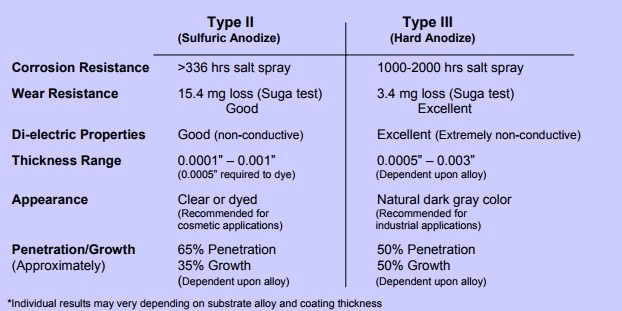

Type II Sulfuric Acid Anodizing

The most common type, using sulfuric acid, produces a thicker oxide layer that’s perfect for general-purpose corrosion resistance and easy dyeing. Many consumer products and architectural anodizing projects rely on this method for both protection and appearance.

Type III Hardcoat Anodizing

Also called hardcoat anodizing, this technique delivers a thick, super durable surface with excellent abrasion resistance. It’s ideal for automotive parts, industrial machinery, and electronics that face tough wear and tear. The hardcoat is much tougher than the usual anodizing finish.

Emerging Variations

New anodizing methods are coming up, including eco-friendly processes and enhanced coatings with better color stability or conductivity. These variations can provide tailored solutions depending on your project’s demands.

DIY vs Professional Anodizing

You can try small anodizing projects yourself with basic kits, especially for Type II finishes. But for consistent quality and especially for Type III hardcoat anodizing, professional services ensure the right process, safety, and best results. Choosing a trusted anodizing expert near you helps avoid common mistakes and ensures your metal parts last longer.

The Step-by-Step Anodizing Process From Prep to Perfection

Anodizing aluminum is a straightforward electrochemical finishing process, but getting great results means following each step carefully. Here’s a simple breakdown to help you understand what goes into producing that tough, corrosion-resistant coating.

Pre-Treatment Essentials

Before anodizing, the aluminum surface must be clean and ready. This usually means:

- Cleaning and Degreasing: Removing oils, dirt, and grease to ensure the coating sticks properly.

- Etching: Lightly roughening the surface to improve adhesion and uniformity.

- Desmutting: Clearing any leftover particles or residue from etching for a smooth finish.

Preparing your metal right is key, especially with Type II sulfuric acid anodizing, where surface quality really impacts the final look and durability.

Core Electrochemical Steps

Once the surface is prepped, the actual anodizing starts:

- Electrolyte BathcURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Aesthetic and Functional Upgrades

Anodizing isn’t just about protection; it also offers a way to dye aluminum parts in various colors that won’t peel or fade easily. From subtle architectural anodizing finishes to vibrant electronics cases, anodizing enhances both function and style. The finish also improves metal surface treatment by reducing glare and creating a uniform look.

Cost and Sustainability Wins

Compared to other surface treatments, anodizing is cost-effective and sustainable. Since it forms a permanent, non-toxic protective layer without heavy paints or coatings, it reduces the need for frequent touch-ups or replacements. For U.S. businesses focused on sustainability and budget, anodizing is a smart choice that saves money and helps the environment over time.

Real-World Applications Where Anodizing Shines

Anodizing is everywhere, making metal parts stronger and better looking across many industries. Here’s where it really stands out:

Industrial Uses

- Aerospace: Aerospace parts get a tough aluminum oxide layer that resists corrosion and wear, which is crucial for safety and performance.

- Automotive: Car makers use anodizing to keep components abrasion-resistant and corrosion-free, especially in engines and trim.

- Electronics: It protects delicate metal surfaces on gadgets and connectors while allowing for dyeing aluminum parts in various colors.

Consumer and Architectural Applications

- Consumer goods: From cookware to sporting equipment, anodizing boosts durability and gives a clean, attractive finish.

- Architectural anodizing: Aluminum panels, window frames, and curtain walls often get this treatment for long-lasting protection and a sleek look that can withstand weather and wear.

Niche Opportunities for Small-Scale Users

- DIY enthusiasts and small businesses use anodizing to customize projects with color finishes or add corrosion resistance.

- It’s ideal for makers crafting metal jewelry, bike parts, or art pieces, who want a professional, durable finish without huge costs.

Anodizing offers flexible solutions whether you’re in a big factory or a local shop, making metal treatment accessible and practical across the board.

Common Challenges and How to Overcome Them

Anodizing isn’t always smooth sailing. Whether you’re working on a small project or a larger industrial job, a few common challenges can come up. Knowing how to handle them helps you get the best results without wasting time or money.

1. Uneven Coating Thickness

- Cause: Inconsistent electrical current or poor surface preparation.

- Fix: Make sure the metal surface is clean and free of oils or dirt before anodizing. Use a steady, well-controlled power supply during electrochemical finishing.

2. Poor Adhesion of the Aluminum Oxide Layer

- Cause: Contamination or improper pre-treatment.

- Fix: Thoroughly clean parts with the right chemicals, and follow proper pre-treatment steps. Rinse parts fully to avoid residue.

3. Color Fading or Inconsistent Dyeing

- Cause: Type II sulfuric acid anodize requires careful dyeing; uneven absorption causes issues.

- Fix: Use high-quality dyes and keep dye baths at consistent temperatures. Testing samples helps before full production.

4. Surface Pitting and Defects

- Cause: Impurities in the metal or bath, or incorrect bath chemistry.

- Fix: Use clean materials, regularly check bath composition, and remove particles promptly.

5. Increased Costs from Rework

- Cause: Mistakes in process control or inexperienced handling.

- Fix: Training and partnering with pro anodizing experts can save money in the long run.

By knowing these pitfalls, you can avoid common headaches and make your anodizing projects shine. When in doubt, reaching out to specialists ensures quality results every time.

Partner with Vast Your Trusted Anodizing Experts

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.