Discover X4CrNiMo16-5-1 martensitic stainless steel with high strength corrosion resistance and excellent weldability for demanding industrial applications.

Chemical Composition and Microstructure

X4CrNiMo16-5-1, also known as 1.4418 stainless steel, is a low carbon martensitic stainless alloy designed for high strength and corrosion resistance. Its balanced chemical composition includes:

| Element | Content (wt%) | Role |

|---|---|---|

| Chromium | 15.5 – 16.5 | Provides corrosion resistance and hardenability |

| Nickel | 4.5 – 5.5 | Enhances toughness and improves corrosion resistance |

| cURL Too many subrequests. | 0.8 – 1.2 | Boosts pitting corrosion resistance |

| Carbon | ≤ 0.03 | Controls hardness and martensitic transformation |

| Manganese | ≤ 1.0 | Deoxidizer and strength contributor |

| Silicon | ≤ 1.0 | Strengthens and aids oxidation resistance |

This alloy’s microstructure is predominantly tempered martensite, a phase formed through controlled cooling that offers a fine balance between hardness and toughness. Martensitic transformation imparts excellent mechanical strength, while tempering reduces brittleness by allowing controlled carbide precipitation.

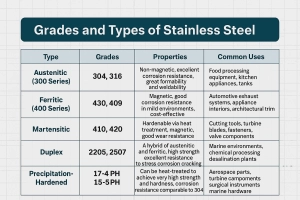

Compared to standard 400-series martensitic stainless steels, such as X46Cr13 (1.4034), X4CrNiMo16-5-1 distinguishes itself with added nickel and molybdenum. These elements enhance corrosion resistance, especially in chloride-rich environments, and improve toughness significantly. This makes it a preferred choice where both high strength and moderate corrosion resistance are critical.

The tempered martensitic phase ensures improved impact behavior under low temperatures, setting X4CrNiMo16-5-1 apart from typical 400-series grades which tend to be more brittle. This makes the alloy suitable for demanding industrial applications requiring reliable performance in harsh service conditions.

Mechanical and Physical Properties of X4CrNiMo16-5-1 Martensitic Stainless Steel

X4CrNiMo16-5-1, also known as 1.4418 stainless steel, offers impressive mechanical strength with tensile strength typically ranging from 850 to 1100 MPa and yield strength between 600 to 850 MPa, meeting EN 10088-3 standards. This makes it a solid choice for applications needing high strength without sacrificing toughness.

When it comes to hardness, it usually falls in the range of 280 to 360 HV, depending on heat treatment. What sets this martensitic stainless steel apart is its good toughness, even at low temperatures—offering reliable cryogenic ductility that many 400-series steels can’t match.

On the thermal and electrical side, X4CrNiMo16-5-1 behaves like typical martensitic steels, with moderate thermal conductivity and electrical resistivity. It’s not designed for high electrical or thermal insulation but performs well under varying temperature conditions.

Here’s a quick comparison with common austenitic grades like 304 and 316 stainless steels to highlight its mechanical edge:

| Property | X4CrNiMo16-5-1 (1.4418) | 304 Austenitic | 316 Austenitic |

|---|---|---|---|

| Tensile Strength (MPa) | 850 – 1100 | 520 – 750 | 520 – 750 |

| Yield Strength (MPa) | 600 – 850 | 210 – 275 | 240 – 290 |

| Hardness (HV) | 280 – 360 | 150 – 200 | 150 – 210 |

| cURL Too many subrequests. | Good | Excellent | Excellent |

| Thermal Conductivity | Moderate (~20 W/m·K) | Lower (~16 W/m·K) | Lower (~16 W/m·K) |

| cURL Too many subrequests. | cURL Too many subrequests. | Low | Low |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.:

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- Tempering: cURL Too many subrequests.

This cycle balances hardness and ductility, ideal for parts needing wear resistance and structural integrity.

Welding Methods and Filler Recommendations

Welding X4CrNiMo16-5-1 requires care to avoid cracking and preserve properties:

- Use TIG (GTAW) or MIG (GMAW) with low hydrogen filler wires.

- Recommended fillers: matching martensitic stainless steel grades or austenitic stainless steel fillers like 308L for better toughness and corrosion resistance.

- Preheat the base metal to 150–200°C to minimize thermal stress.

- Post-weld heat treatment (PWHT) at 600°C for 1 hour restores weld zone hardness and reduces residual stresses.

Machining and Forming Tips

While X4CrNiMo16-5-1 offers good machinability among martensitic steels, follow these tips for best results:

- Use sharp, high-speed tools with plenty of coolant.

- Keep cutting speeds moderate to avoid work hardening.

- For forming, the steel should be annealed before shaping to reduce cracking risk.

- Avoid excessive bending; when necessary, use larger radii.

Processing Parameters Table

| Process | Parameter | Notes |

|---|---|---|

| cURL Too many subrequests. | 1020–1050°C (1870–1920°F) | Hold for 30 minutes |

| cURL Too many subrequests. | Air or oil cooling | Avoid slow cooling |

| cURL Too many subrequests. | 480–620°C (900–1150°F) | 1–2 hours |

| Preheat for Welding | 150–200°C (300–390°F) | Reduces cracking risk |

| PWHT | ~600°C (1110°F) | 1 hour |

| Machining Speed | cURL Too many subrequests. | Use sharp tools and coolant |

| cURL Too many subrequests. | Annealed condition preferred | Use gentle bends, larger radii |

Following these guidelines ensures that X4CrNiMo16-5-1 martensitic stainless steel performs reliably through fabrication and retains its high strength and corrosion resistance in service.

Applications and Case Studies of X4CrNiMo16-5-1 Martensitic Stainless Steel

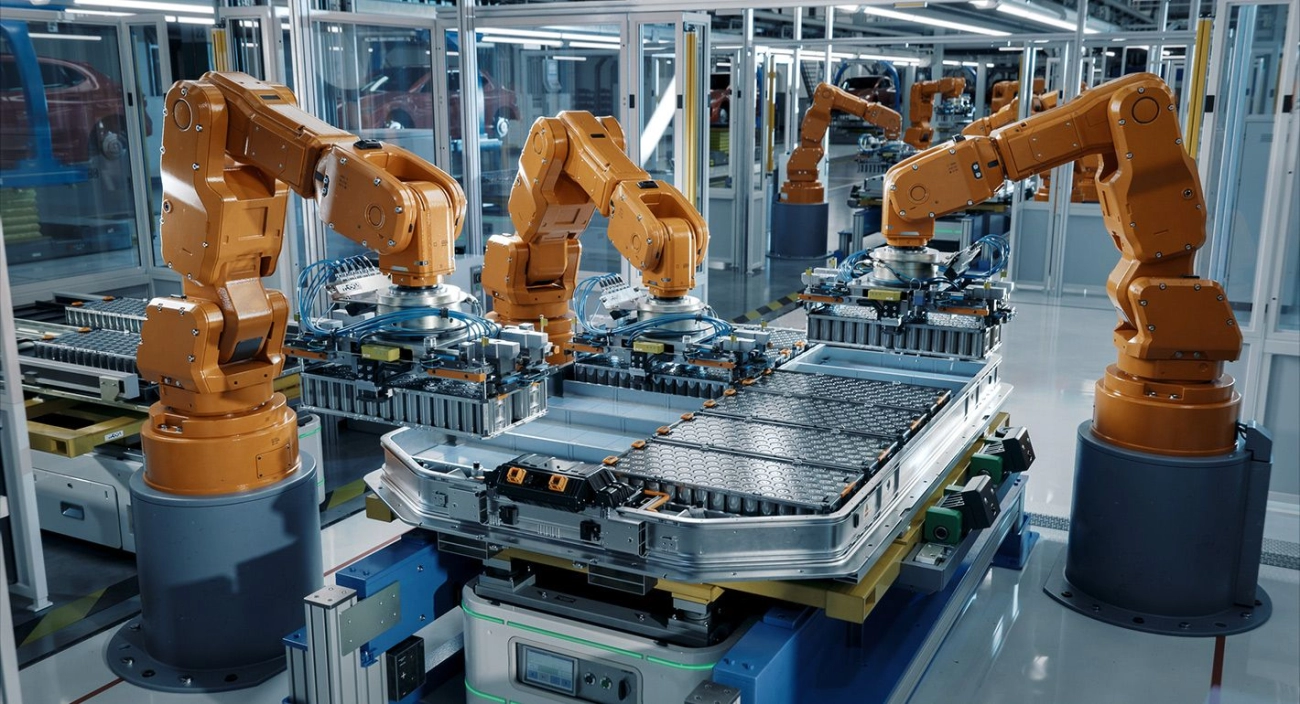

X4CrNiMo16-5-1 martensitic stainless steel is widely used across heavy industries in the U.S., thanks to its strong combination of corrosion resistance and high strength. You’ll often find it in energy sectors for turbine components and shafts, where durability under stress and exposure to harsh environments is critical. In aerospace, it’s favored for landing gear parts and structural elements that demand toughness without excess weight.

cURL Too many subrequests. cURL Too many subrequests. industry, this steel is a go-to for seawater-exposed parts like propeller shafts and pump components, thanks to its solid resistance against seawater corrosion. Mining operations also rely on it for tools and wear-resistant equipment that perform well under abrasive and corrosive conditions.

A notable case study involves a European hydrofoil project cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.