Discover the die cast aluminum process for precision lightweight parts offering strength corrosion resistance and cost efficiency in manufacturing.

If you’re involved in manufacturing or engineering, you already know that choosing the right materials and processes can make or break a project. Die cast aluminum stands out as a game-changer—offering precision, lightweight strength, and cost-efficiency all in one package. Whether you’re prototyping in the Midwest or scaling production coast to coast, understanding the aluminum die casting process unlocks huge advantages: faster lead times, durable parts, and designs that traditional methods just can’t match. Ready to see why die cast aluminum powers everything from automotive components to advanced electronics? Let’s dive in and explore how this versatile metal can transform your next project.

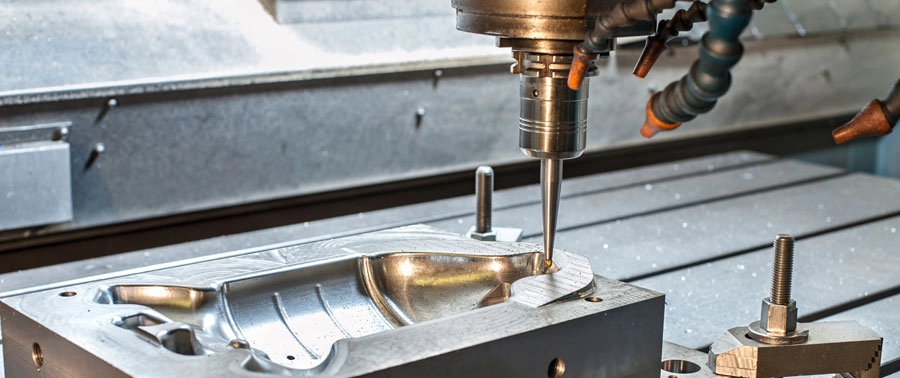

The Die Cast Aluminum Process From Molten Metal to Precision Parts

Die cast aluminum starts as molten metal heated to precise temperatures, ready for high-pressure injection into steel molds. This core process uses specialized machines that force liquid aluminum alloy into detailed aluminum mold cavities under intense pressure. The result is precise, repeatable parts with excellent surface finish and dimensional accuracy.

Core Mechanics High Pressure Injection and Mold Design

High-pressure die casting relies on injecting molten aluminum rapidly into closed molds. These molds are carefully designed with cooling channels and venting systems to ensure quick solidification and minimal defects. The mold design directly impacts part quality and cycle times, allowing complex shapes with fine details that traditional casting methods can’t efficiently produce.

Key Equipment and Alloy Selection

The process requires robust die casting machines capable of generating the pressures needed for detailed casting. Choosing the right aluminum die casting alloys is critical; common options balance fluidity, strength, and corrosion resistance. Selecting the proper alloy ensures mechanical properties match the application, whether lightweight automotive parts or durable industrial components.

Cycle Times and Scalability

One of die cast aluminum’s strengths is rapid production cycles, typically lasting seconds to a few minutes per part. This fast turnaround enables high-volume manufacturing without sacrificing precision. Scalability is straightforward thanks to automation and repeatable mold performance, making die cast aluminum ideal for both small runs and mass production.

Unmatched Benefits of Die Cast Aluminum Lightweight Strength Meets Cost Efficiency

Die cast aluminum offers a unique mix of lightweight strength and cost-effectiveness that’s hard to beat. This metal is significantly lighter than steel but still delivers excellent durability and high structural integrity. For U.S. manufacturers and customers alike, this translates into parts that are easier to handle, reduce overall product weight, and improve fuel efficiency in automotive or aerospace applications—all while keeping costs down.

Mechanical and Physical Advantages

- High Strength-to-Weight Ratio: Ideal for parts needing strength without the bulk.

- Corrosion Resistance: Perfect for long-lasting components exposed to weather or harsh environments.

- Thermal Conductivity: Helps in applications needing quick heat dissipation like electronics.

- Precision and Consistency: Die casting tolerances ensure parts fit perfectly every time.

Economic and Environmental Edges

- Cost Efficiency: Faster production cycles reduce labor and overhead expenses.

- Material Savings: Less scrap compared to other metal forming methods.

- Recyclability: Aluminum die casting alloys are recyclable, supporting green manufacturing efforts.

- Energy Efficient: Lower melting points mean less energy use during production.

Design Flexibility for Complex Geometries

One standout benefit is how die cast aluminum handles intricate designs. Complex shapes, thin walls, and consistent wall thicknesses are achievable without sacrificing strength. This design freedom allows engineers to optimize parts for performance and appearance, cutting down assembly time by reducing the need for extra components or machining.

In the U.S. market, these benefits align perfectly with industries pushing for lightweight, durable, and affordable solutions—making die cast aluminum a smart choice for modern manufacturing.

Real World Applications Where Die Cast Aluminum Excels

Die cast aluminum plays a huge role across multiple industries thanks to its strength, lightweight nature, and cost efficiency. Here’s where it really shines:

Automotive and Transportation

Aluminum die casting is a go-to for making precision aluminum components like engine blocks, transmission cases, and lightweight frames. The combination of corrosion-resistant castings and high-pressure die casting delivers parts that help improve fuel efficiency and durability in cars, trucks, and even electric vehicles.

Aerospace Electronics and Consumer Goods

In aerospace, die cast aluminum parts meet tight tolerances and strict weight limits, which are critical for performance and safety. It’s also widely used in electronics housings and consumer products where durability and heat dissipation matter—think laptops, smartphones, and power tools.

Industrial and Marine Uses

Die cast aluminum is tough enough for industrial equipment parts that require both strength and corrosion resistance. In the marine industry, its lightweight metal parts stand up well to saltwater conditions, making it ideal for boat components and marine hardware.

This wide range of applications highlights why aluminum die casting alloys remain a trusted choice across sectors looking for efficient, durable, and precise metal parts.

Design and Troubleshooting Guide for Flawless Die Cast Aluminum Parts

Getting die cast aluminum parts right takes smart design and knowing how to handle common issues. Here are some key points to keep in mind.

Essential Design Considerations

- Wall Thickness: Keep walls uniform. Thin walls save weight but too thin can cause defects.

- Draft Angles: Include proper draft angles for easier mold release, reducing surface marks and defects.

- Ribs and Bosses: Use ribs to add strength without extra weight. Bosses should have fillets to avoid stress points.

- Gate Location: Position gates to ensure smooth metal flow, avoiding air pockets or cold shuts.

- Tolerances: Design with realistic die casting tolerances in mind to avoid costly rework.

Common Challenges and Solutions

- Porosity: Often from trapped gas. Minimize by optimizing mold venting and controlling injection speed.

- Surface Defects: Such as roughness or die lines. Use proper mold maintenance and aluminum die casting alloys suited for the finish.

- Warping: Occurs from uneven cooling. Avoid by balancing wall thickness and mold temperature control.

- Cold Shuts: Metal flows meet imperfectly. Improve by adjusting injection pressure or gate design.

Integrating with Secondary Processes

Once the casting is done, many parts need secondary steps like CNC die casting finishing, machining, or coatings. Early collaboration between design and finishing teams helps avoid complications and ensures the part meets all specs without extra cost.

Applying these best practices helps produce high-quality, precision aluminum components that meet your project needs reliably and efficiently.

Choosing a Die Cast Aluminum Partner What to Look for in US Manufacturing

Finding the right partner for your die cast aluminum needs can make all the difference in quality, delivery, and overall cost. Here’s what to focus on when choosing a US-based manufacturer:

Quality Certifications and Capabilities

- Look for partners with ISO 9001 or other industry certifications ensuring consistent quality.

- Verify their experience with high-pressure die casting and working with various aluminum die casting alloys.

- Check if they offer in-house testing and quality control to meet tight die casting tolerances.

- Advanced equipment like modern aluminum mold design and CNC finishing tools signal precision capabilities.

Cost Factors and Local Sourcing Benefits

- US-based manufacturers can save you time and shipping costs compared to overseas suppliers.

- Local sourcing reduces lead times and improves communication throughout the project.

- Transparent pricing with no hidden fees or unexpected tariffs gives more control over your budget.

- Partnering domestically means easier collaboration on design tweaks, prototypes, and revisions.

Why Vast Stands Out

- Vast brings years of experience producing precision aluminum components that meet the toughest standards.

- Emphasizing sustainability, Vast uses recyclable die cast metal to align with eco-conscious manufacturing.

- With an all-American workforce and modern equipment, Vast delivers lightweight metal parts on time and within spec.

- Their team works closely with clients to handle design challenges and integrate secondary processes seamlessly.

Choosing Vast means you get a reliable partner committed to quality, cost efficiency, and speedy delivery in the US die cast aluminum industry.