Compare 1018 vs 4140 steel strength machinability cost and best uses with our detailed alloy selection guide.

1018 Steel: What It Is and Why It Matters

When engineers compare 1018 vs 4140, 1018 is the go‑to low carbon “workhorse” mild steel: cheap, easy to machine, easy to weld, and predictable.

Chemical Composition of AISI 1018

AISI 1018 steel is a plain, low carbon steel with very limited alloying.

| Element | Typical Range (wt%) |

|---|---|

| Carbon (C) | 0.15 – 0.20 |

| Manganese (Mn) | 0.60 – 0.90 |

| Phosphorus (P) | ≤ 0.04 |

| Sulfur (S) | ≤ 0.05 |

| Iron (Fe) | Balance |

Key point: Low carbon = excellent ductility, weldability, and machinability, but limited hardenability compared with 4140 chromoly alloy.

Mechanical Properties of 1018 (Typical, As‑Rolled/Cold Drawn)

Values vary by form and condition, but typical ranges:

| Property | Typical Value |

|---|---|

| Tensile strength | ~ 440 – 500 MPa (64 – 73 ksi) |

| Yield strength | ~ 370 – 415 MPa (54 – 60 ksi) |

| Elongation | ~ 15 – 25% |

| Hardness | ~ 120 – 170 HB |

| Modulus of Elasticity | ~ 205 GPa (29,700 ksi) |

Performance profile:

- Moderate strength vs alloy steels

- High ductility and Good impact toughness

- Stable and predictable for General fabrication

Workability, Machinability, and Weldability

Compared to 4140 vs 1018 machinability, 1018 is usually easier and more forgiving.

- Machinability (B1112 basis): ~ 70–80%

- Operates well on standard tooling

- Suitable for turning, milling, drilling, tapping

- Weldability:

- Excellent with GMAW/MIG, GTAW/TIG, SMAW

- Usually no preheating required for typical sections

- Compatible with common mild steel fillers (e.g., ER70S‑6)

- Forming/Bending:

- Bends easily when cold

- Low risk of cracking during forming or rolling

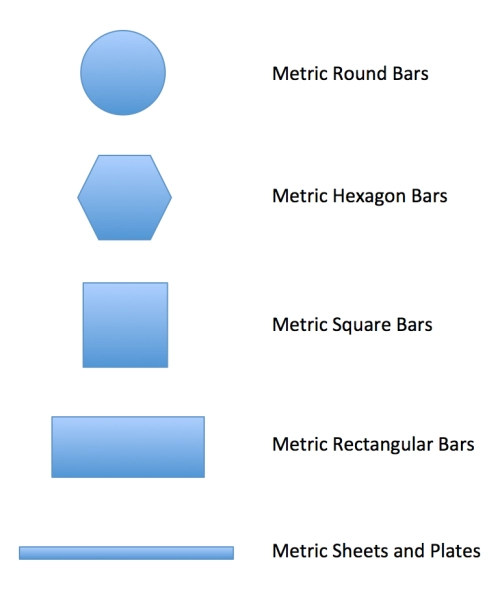

Common Forms and Supply Options for 1018

I stock and source 1018 mild steel Available globally in standard and custom formats:

- Bars: rounds, squares, flats, hex (hot rolled & cold drawn)

- Plates & sheets: hot rolled, pickled & oiled, cold rolled

- Structural shapes: Limited; for pure structural purposes, we often use other structural grades

- Condition options:

- Hot rolled

- Cold finished (better surface and tighter tolerance)

- Peeled/turned and ground for shafting

We support:

- Cut‑to‑length

- Saw cutting, precision cutting

- Mill certs and full traceability on request

When 1018 Mild Steel Is the Right Choice

Choose 1018 over 4140 alloy steel when:

- Loads are low to moderate and not fatigue‑critical

- Cost and availability matter more than maximum strength

- You need easy machining and welding with minimal fuss

- Parts will be case hardened rather than through‑hardened

- You want tight dimensional control via cold‑finished bar

Typical 1018 steel applications include:

- Brackets, plates, base frames

- Light shafts, pins, bushings (non‑critical)

- Welded fabrications and structural components

- Machined fittings, spacers, jigs, and fixtures

If you’re unsure whether 1018 vs 4140 is safer for your load and duty cycle, I usually start with your required yield strength, fatigue life, and budget and size the section from there before recommending the grade.

What Is 4140 Steel?

4140 steel (AISI 4140, “chromoly” steel) is a medium‑carbon chromium‑molybdenum alloy steel. Compared with 1018 mild steel, 4140 gives you much higher strength, hardenability, and fatigue resistance while still being machinable and reasonably weldable when handled correctly.

Chemical Composition & Alloying Elements in 4140

Typical composition (wt%):

| Element | 4140 Range (approx.) | What It Does |

|---|---|---|

| C | 0.38 – 0.43% | Base strength, hardenability |

| Mn | 0.75 – 1.00% | Strength, toughness, deoxidation |

| Cr | 0.80 – 1.10% | Wear resistance, depth of hardness |

| Mo | 0.15 – 0.25% | High-temperature strength, toughness |

| Si | 0.15 – 0.35% | Strength, deoxidation |

| P, S | ≤ 0.035% | Kept low for toughness |

Those Cr-Mo additions are the big difference versus 1018 and are why we call 4140 a chromium molybdenum alloy (chromoly) steel.

Mechanical Properties & Strength Profile of 4140

Properties vary a lot with heat treatment. Typical ranges:

| Condition | Yield strength (MPa) | Tensile Strength (MPa) | Hardness (HB) |

|---|---|---|---|

| Annealed | 415 – 655 | 655 – 895 | ~ 187 – 217 |

| Quenched & Tempered | 655 – 1030+ | 850 – 1250+ | ~ 248 – 320 |

Key points:

- Much stronger than 1018 at the same size

- Can be tailored from tough/ductile to very high strength with proper tempering

- Good strength-to-weight for shafts, gears, and high‑load parts

If you care about how strength connects to machining accuracy, it pairs well with tight‑tolerance processes like milled steel machining where precision and stability really matter (see our guide on what milled steel is and how it’s machined).

Hardenability, Toughness & Fatigue Resistance

Why 4140 is a “go‑to” high‑strength alloy:

- Excellent hardenability

- Through‑hardens in thicker sections versus simple carbon steels

- Uniform properties across the cross‑section

- Good toughness

- With correct tempering, resists impact and shock loads

- Lower risk of brittle fracture versus some higher‑carbon alloys

- Strong fatigue resistance

- Ideal for Rotating shafts, axles, spindles, gears

- Handles cyclic loads far better than 1018

Available Forms, Conditions & Treatments for 4140

You’ll commonly find 4140 in:

- Forms

- Round bar, hex bar, flat bar, plate

- Forgings, pre‑machined blanks, tubing

- Common delivery conditions

- Annealed (soft, easier to machine, then heat treat later)

- Normalized

- Quenched & tempered (QT) To specific hardness (e.g. 28–32 HRC, 32–36 HRC)

- Typical treatments

- Quench & temper for strength

- Induction hardening on surfaces (e.g. bearing journals)

- Nitriding for wear and fatigue resistance

When 4140 Alloy Steel Is the Better Choice

Choose 4140 vs 1018 when:

- The part sees high loads, torque, or shock

(shafts, gears, couplings, spindles, tool holders) - You need higher fatigue life and long‑term durability

- You need hard, wear‑resistant surfaces but still want a tough core

- The cost of failure is high (downtime, safety, warranty risk)

- You want to reduce section size/weight without sacrificing strength

In short:

Use 1018 for low‑stress, general fabrication.

Step up to 4140 when strength, hardenability, and fatigue resistance are critical to your design or your customer’s uptime.

1018 vs 4140: Side‑by‑Side Comparison

Both grades are solid choices, but they solve different problems. Here’s the quick, practical breakdown.

Tensile Strength & Yield Strength: 1018 vs 4140

Typical room‑temperature values (round bar, approximate):

| Property | 1018 (as‑rolled) | 4140 Annealed | 4140 Q&T ~28–32 HRC | 4140 Q&T ~38–42 HRC |

|---|---|---|---|---|

| Tensile strength (MPa) | ~440–480 | ~655–745 | ~930–1030 | ~1100–1250 |

| Yield strength (MPa) | ~320–350 | ~415–450 | ~760–860 | ~900–1050 |

- If you’re under 300 MPa working stress, 1018 is usually enough.

- For high load, shock, or safety‑critical parts, 4140 is the safer bet.

Hardness & Wear Resistance: 1018 vs 4140

| Grade / Condition | Typical Hardness | Wear Performance |

|---|---|---|

| 1018, as‑rolled | ~120–170 HB | Low |

| 1018, carburised case | Surface up to ~58–62 HRC | Good surface wear, soft core |

| 4140, annealed | ~187–217 HB | Medium |

| 4140, Q&T 28–32 HRC | ~275–300 HB | High |

| 4140, Q&T 38–42 HRC | ~340–390 HB | Very high |

- Use 1018 where wear is low or you plan cheap surface hardening only.

- Use 4140 where continuous wear, impact, and fatigue matter.

Machinability & Weldability: 1018 vs 4140

Machinability (relative to free‑cutting steel = 100):

| Grade | Machinability Rating | Notes |

|---|---|---|

| 1018 | ~70–78 | Very easy to machine |

| 4140 Annealed | ~65 | OK with correct tooling |

| 4140 Q&T | 40–60 (drops as HRC rises) | Needs rigid setup, sharp tools |

Weldability:

- 1018:

- Excellent weldability with MIG, TIG, stick.

- No preheat for most thicknesses.

- 4140:

- Preheat (typically 150–300°C) and controlled cooling required.

- Higher risk of cracking, needs low‑hydrogen process and proper filler.

If your process is weld‑heavy and shop skills vary, 1018 is lower risk. For precision machining of hard parts, 4140 works fine if you control tools, speeds, and coolant—similar to what’s needed in precision CNC machining of hard materials as discussed in our ceramic CNC machining guide.

Heat Treatment Response & Hardenability: 1018 vs 4140

- 1018 steel (AISI 1018):

- Very low carbon (~0.18% C) = not through‑hardening.

- Only useful heat treatment: carburising / case hardening + quench.

- 4140 chromoly alloy (chromium molybdenum steel 4140):

- Medium carbon (~0.40% C) + Cr + Mo = high hardenability.

- Responds extremely well to:

- Normalising

- Quench and temper (Q&T)

- Induction hardening

- Can achieve a wide range of strength and hardness profiles.

If you need through‑hardened shafts, gears, or bolts, 4140 wins every time.

Cost, Availability & Sourcing

| Factor | 1018 Steel | 4140 Steel |

|---|---|---|

| Raw material cost | Lower | Higher (alloy additions) |

| Availability | Very common | Very common in bar, less in shapes |

| Minimum order | Lower | Sometimes higher for special states |

- 1018 is usually the lowest cost option for mild steel vs alloy steel.

- 4140 costs more, but one 4140 part can replace a larger or heavier 1018 design, which may reduce total system cost.

Corrosion Resistance & Surface Treatment

Both are plain / low‑alloy steels with poor corrosion resistance:

- Neither is “stainless”; both will rust without protection.

- Typical protection methods:

- Painting or powder coating

- Zinc plating, phosphating, black oxide

- Oil / grease for internal or temporary protection

For parts that must withstand harsh environments, plan surface treatment regardless of 1018 vs 4140.

Weight, Tolerance & Dimensional Stability

Density is almost identical:

| Property | 1018 | 4140 |

|---|---|---|

| Density (g/cm³) | ~7.87 | ~7.85 |

Weight difference is negligible at component level.

Main differences:

- 1018:

- More ductile, more forgiving during forming.

- Less distortion during welding.

- 4140:

- More prone to movement during heavy machining and heat treatment.

- Requires stress-relieving to maintain tight tolerances on long shafts or thick sections.

For Tight tolerance, heat-treated parts, it’s critical to combine proper heat-treatment control with reliable material testing and traceability—exactly the type of support we bundle with our projects, aligned with the best practices outlined in our comprehensive material testing guide.

In simple terms:

- 1018 = easy to machine, easy to weld, cheap, for low–medium stress.

- 4140 = strong, hard, fatigue‑resistant, but requires more process control.

Applications: Where 1018 Shines versus Where 4140 Excels (1018 versus 4140 / 1018 and 4140)

Optimal applications for 1018 mild steel in general fabrication

AISI 1018 mild steel is my preferred choice when you need easy machining, easy welding, and low cost:

- Brackets, frames, base plates, and fixtures

- Jigs, simple tooling blocks, alignment plates

- Pins, bushings, spacers, sleeves with low to moderate loads

- Welded fabrications, support structures, light machine parts

- Shafts and couplings where strength requirements are modest and failure isn’t critical

If your main objectives are good dimensional accuracy, clean machining, and reliable welding, 1018 is usually the most intelligent and cost-effective choice.

Optimal applications for 4140 alloy steel in high‑stress components

4140 chromoly alloy (chromium molybdenum steel) is used when strength, fatigue resistance, and toughness matter:

- High‑load shafts, axles, spindles, and drive components

- Gears, sprockets, couplings, and high‑torque transmission parts

- Heavy clamping components, press parts, and high‑strength fasteners

- Wear parts that benefit from quench‑and‑temper or induction hardening

Wherever failure could be costly or dangerous, 4140 is generally a better choice than 1018.

Automotive and transportation: use cases for 1018 versus 4140

In automotive and transport, you will often see both types of

- 1018steel in the same platform:

- 4140: brackets, tabs, light mounts, non-critical weldments, interior structures, low-load linkages

: steering and suspension links, drive shafts, yokes, gear components, hubs, high-load pins, performance parts If the part bears, motion, torque, or impact , 4140 typically prevails. If it only requires, shape and stiffness.

, 1018 helps to reduce costs.

Industrial machinery, tooling, and oilfield: applications prioritising 4140 Industrial and oilfield users heavily rely on 4140 because of its:

- strength and fatigue life

- Hydraulic cylinder rods, tie rods, press rams vertical machining centre)

- Tool holders, collets, and spindle components (often machined on a

- Drill collars, subs, rotary components, and downhole tools

Heavy machine shafts, couplings, gear blanks, and flanges.

Structural, brackets, and low‑load parts: 1018‑first applications

For general structural work and light duty parts, I default to 1018:

- Welded frames, racks, tables, and guards

- Bracketry, mounting plates, hinge plates, and tabs

- Light supports, housings, covers, and non‑pressurised manifolds

It welds cleanly, distorts less than higher‑carbon steels, and keeps material costs under control.

Hybrid strategies: mixing 1018 and 4140 in the same system

A practical, cost‑driven approach is to mix 1018 and 4140 in one assembly:

- Use 4140 for high‑stress components (shafts, gears, load‑bearing pins, wear points)

- Use 1018 for support, alignment, and mounting (frames, brackets, plates, non‑critical spacers)

This way you pay for 4140 only where its strength, wear resistance, and fatigue performance actually matter, while 1018 keeps project budgets and lead times in check.

Fabrication Guide for 1018 vs 4140

Machining 1018: Speeds, Feeds, Tooling

AISI 1018 mild steel is very forgiving to machine. It cuts cleanly, holds size well, and is ideal for CNC prototypes and general production.

Basic tips for machining 1018:

- Tooling:

- HSS works for low‑volume; carbide for higher speed and long runs.

- Use sharp, positive‑rake tools to avoid built‑up edge.

- Cutting speeds (rough guide):

- HSS: 25–35 m/min (80–120 SFM)

- Carbide: 120–180 m/min (400–600 SFM)

- Feeds & DOC:

- Roughing: 0.15–0.35 mm/rev feed, 2–4 mm depth of cut

- Finishing: 0.05–0.15 mm/rev, 0.5–1.5 mm DOC

- Coolant:

- Use flood coolant for better tool life and surface finish.

- Dry cutting is possible but watch heat and built‑up edge.

For high‑tolerance CNC projects, I usually handle 1018 on the same high‑speed lines we use for precision aerospace CNC machining services, just with more aggressive feeds.

Machining 4140: Annealed vs Quenched & Tempered

4140 chromoly alloy (chromium molybdenum steel 4140) machines very differently depending on condition.

4140 annealed (~HB 197):

- Easier to machine than hardened, but still tougher than 1018.

- Cutting speeds:

- HSS: 15–25 m/min (50–80 SFM)

- Carbide: 90–150 m/min (300–500 SFM)

- Use rigid setups, sharp carbide, and constant coolant.

4140 quenched & tempered (QT, HB 248–302+):

- Much harder, higher tool wear, needs more control.

- Cutting speeds (carbide): 60–110 m/min (200–360 SFM)

- Use:

- Strong, negative‑rake carbide inserts

- Small DOC and moderate feeds

- Plenty of coolant or high‑pressure through‑tool coolant

- Avoid chatter: maximise rigidity, minimise tool overhang.

If you’re new to machining 4140 QT, start conservative on speed, then tune for tool life and surface finish.

Welding 1018: Processes and Filler Choices

1018 welding is straightforward and very forgiving.

Best processes:

- MIG (GMAW): Fast, easy, great for structural and brackets.

- TIG (GTAW): For cleaner, cosmetic, or precision welds.

- Stick (SMAW): Good for field work and thicker sections.

Fillers:

- MIG: ER70S‑6 solid wire

- TIG: ER70S‑2 / ER70S‑6 rod

- Stick: E6010/E6011 for root, E7018 for structural work

No preheat needed for typical thicknesses. Just keep:

- Clean base metal (remove mill scale, oil, rust)

- Reasonable interpass temperatures to avoid distortion.

Welding 4140: Preheat, Post‑Heat, Cracking Control

4140 alloy steel is not weld‑like‑1018 material. It’s hardenable and prone to cracking if you treat it like mild steel.

Key rules:

- Preheat:

- Typical: 150–315°C (300–600°F) depending on thickness and restraint.

- Thicker and higher strength (QT) needs higher preheat.

- Interpass temp:

- Hold between 200–315°C (400–600°F) to manage cooling rate.

- Post‑weld heat:

- Slow cool in insulation or an oven.

- For critical parts, stress‑relieve at 550–650°C (1020–1200°F).

Filler metals:

- For structural/repair: low hydrogen fillers like E8018‑B2, ER80S‑D2, or 4130/4140‑type rods.

- Always use low‑hydrogen practice (dry rods, clean joint).

If you can’t control preheat/post‑heat, redesign the part, or switch the welded area to 1018 where possible.

Heat Treatment of 4140: Quench & Temper Basics

4140 is a classic heat treatable alloy steel. You use quench‑and‑temper to tune strength vs toughness.

Typical Q&T workflow:

- Normalize (optional): 870–925°C (1600–1700°F), air cool to refine grain.

- Austenitise: ~830–870°C (1525–1600°F).

- Quench: Oil quench (common). For small sections, polymer or water can be used with care.

- Temper:

- 200–300°C (390–570°F): very high hardness, lower toughness.

- 400–600°C (750–1110°F): balanced strength/toughness, common for shafts and gears.

- 600–675°C (1110–1250°F): lower strength, high toughness.

Always match hardness/strength level to real loads; over‑hardening 4140 is a common fatigue failure trap.

Case Hardening 1018: Carburising Options

1018 has low carbon, so through‑hardening is weak – but it excels at case hardening.

Carburising options:

- Pack or gas carburising:

- 900–950°C (1650–1750°F), carbon‑rich atmosphere.

- Case depth usually 0.5–1.5 mm, depending on time.

- Follow with oil quench + temper for a hard shell with a tough core.

- Carbonitriding (for smaller parts):

- Adds nitrogen + carbon; useful for wear‑resistant small components.

Use case‑hardened 1018 for pins, bushings, low‑load gears, and wear faces that need a hard skin but not full‑section strength.

Forming, Bending, and Cutting: 1018 vs 4140

Forming & bending:

- 1018:

- Excellent formability.

- Cold bending, rolling, and forming are easy with minimal cracking.

- Great for brackets, frames, and formed sections.

- 4140:

- Annealed: formable, but needs higher force than 1018.

- QT: limited cold forming; cracking risk. Hot forming is safer.

Cutting:

- 1018:

- Saws, laser, plasma, and waterjet cut cleanly.

- CO₂ lasers work well for standard plate and sheet.

- Ideal for custom sheet parts and car sheet metal repair components.

- 4140:

- Tougher on blades; use quality bandsaw blades and slower speed.

- For QT 4140, waterjet or high‑power laser is preferred to reduce HAZ hardness.

In practice, I push 1018 for formed and welded structures, and lean on 4140 where machining, heat treatment, and long‑term fatigue performance matter most.

1018 vs 4140: Pros and Cons for Real‑World Projects

When I choose between AISI 1018 steel and 4140 chromoly alloy, I always start from what the part actually needs – not from what looks “strongest” on paper.

Advantages and Disadvantages of 1018 Steel

Pros of 1018 mild steel

- Excellent machinability – very forgiving, high 1018 machinability rating, ideal for long production runs.

- Easy welding – minimal preheat, compatible with common filler wires, simple for fabrication shops.

- Good for forming – bending, cold forming, and stamping are all easier than with 4140.

- Low cost & widely available – a go‑to structural steel 1018 for brackets, plates, and general fabrication.

- Stable and predictable – low carbon means low risk of cracking and residual stress.

Cons of 1018 steel

- Low strength and hardness – lower steel tensile strength 1018 and yield strength than 4140.

- Limited heat treatment response – you can case harden 1018, but not through-harden like 4140.

- Poor wear resistance – not ideal for sliding, rotating, or impact-loaded wear surfaces.

- Lower fatigue resistance – not suited for highly cyclic or shock-loaded parts without oversizing.

Use 1018 when your part is simple, lightly loaded, or when cost and ease of fabrication matter more than maximum strength.

Advantages and Disadvantages of 4140 Steel

Pros of 4140 alloy steel

- High strength – significantly higher mechanical properties of 4140 steel (tensile and yield) than 1018.

- Great hardenability – responds very well to quenched and tempered 4140 bar and induction hardening.

- High wear resistance – especially in 4140 normalised vs quenched and tempered conditions.

- Good fatigue resistance – ideal for alloy steel for gears and shafts, spindles, axles, and tools.

- Better toughness when treated correctly – strong yet not brittle if heat treated properly.

Cons of 4140 steel

- Harder to machine – especially at higher hardness; requires good tooling and cutting strategy.

- More demanding to weld – requires preheating, controlled cooling, and often post-weld heat treatment.

- Higher material cost – more expensive than 1018, plus additional costs for heat treatment.

- Less forgiving – mistakes in machining, welding, or heat treatment can lead to cracking or distortion.

Use 4140 when your part experiences real loads, torque, impact, or long-term fatigue – for example in automotive, oilfield, and heavy machinery.

Over-Engineering 4140 vs Under-Engineering 1018

This is the trap I see most:

- Over-engineering with 4140

- Using 4140 where 1018 mild steel would work fine wastes money on material and heat treatment.

- Parts can be harder to machine and weld, increasing lead time and scrap risk.

- Under-engineering with 1018

- Using 1018 where you really need 4140 fatigue resistance or higher strength can cause:

- Premature wear

- Bending or permanent deformation

- Cracking or fatigue failure in service

- Using 1018 where you really need 4140 fatigue resistance or higher strength can cause:

The smart move is to match the alloy to actual load, life expectancy, and safety requirements, similar to how you’d balance strength and weight when choosing between metals in an aluminium vs titanium weight comparison.

How Load, Fatigue, and Budget Drive the Choice

When I select between 1018 vs 4140, I look at four things:

- Static load

- Low to moderate load, lots of safety margin → 1018 steel is usually enough.

- High load, torque, or bending stress → lean towards 4140 chromoly alloy.

- Fatigue and shock

- Rare or low‑cycle loading → 1018 can work.

- Continuous cyclic loading, impact, or vibration → 4140 is safer.

- Wear conditions

- Little to no wear, or sacrificial parts → 1018 is fine.

- Sliding contact, gear meshing, or rotating shafts → 4140 wear resistance wins.

- Budget and process capability

- Tight cost targets, basic workshop equipment, simple welds → 1018.

- Higher budget, access to heat treatment and better machining → 4140.

Quick Decision Checklist: 1018 or 4140?

Use this as a quick filter when deciding 1018 vs 4140:

Choose 1018 if:

- The part is mainly structural, bracket, fixture, or low‑load.

- You need easy machining and welding.

- You’re working to a strict budget and high volume.

- Little or no heat treatment is planned.

Choose 4140 if:

- The part is a shaft, gear, spindle, axle, coupler, or high‑stress pin.

- You need high tensile strength and yield strength, with good fatigue life.

- You require Heat-treatable 4140 steel for hardness and wear resistance.

- Safety, long life, and reliability matter more than lowest cost.

If you’re between the two, I usually start with 1018 for low‑risk parts and step up to 4140 once the design moves into critical, rotating, or high‑load territory.

Frequently Asked Questions About 1018 vs 4140 (1018 and 4140)

Is 4140 stronger than 1018 in typical applications?

Yes. In most real‑world parts, 4140 chromoly alloy is significantly stronger than AISI 1018 mild steel.

- 1018 (as-rolled): tensile ~440–480 MPa, yield ~250–320 MPa

- 4140 (quenched & tempered): tensile 850–1100+ MPa, yield 700–900+ MPa

If you’re seeing high load, impact, or fatigue, 4140 is usually the safer choice.

Can 1018 be heat treated like 4140?

No. 1018 is low‑carbon mild steel, so it won’t through‑harden like 4140.

- 1018: can be case hardened / carburised for a hard skin and soft core

- 4140: can be through‑hardened by quench & temper to a wide hardness range

Use 1018 when you want an easy‑to‑form base with optional surface hardening, and 4140 when you need true

Why Buy 1018 vs 4140 Steel from a Specialist Supplier (1018 and 4140)

When you’re choosing between 1018 vs 4140 for real projects, who you buy from matters almost as much as the grade itself. I treat 1018 mild steel and 4140 chromoly alloy as core, high‑value products, not commodity stock.

Quality, Certifications & Mill Traceability

For both AISI 1018 steel and 4140 alloy steel, I lock in:

- Full mill certs (MTCs) with heat numbers and chemical composition

- Mechanical property reports (tensile strength, yield strength, hardness)

- Clear traceability from mill → warehouse → your PO

- Material that meets ASTM, AISI, SAE and EN specifications where required

That means when you compare 1018 vs 4140 mechanical properties, you’re working with certified data, not guesswork.

Stock Range, Cutting & Heat‑Treat Services

I keep a wide range of:

- 1018 and 4140 in round bar, flat bar, plate, block, tube

- Standard and close‑tolerance sizes for CNC and machining shops

On top of that, we can:

- Cut‑to‑size for quick production

- Supply 4140 in annealed, normalised, or quenched and tempered (QT)

- Arrange heat treatment (quench & temper, stress relief, or case hardening for 1018) so parts go straight to machining

If you’re running a tight machining workflow, you’ll likely benefit from our experience with CNC precision engineering and tolerance control, similar to what’s covered in this practical CNC precision engineering guide with processes and applications.

Technical Support from Metallurgists & Engineers

Choosing between 1018 vs 4140 isn’t just about strength charts. My team can help you:

- Pick the right grade based on load, fatigue, and budget

- Decide between 4140 normalised vs quenched and tempered

- Tune machinability, weldability, and heat treatment to your process

- Avoid over‑engineering with 4140 or under‑spec’ing with 1018

You get real feedback from people who live in the world of alloy steel for gears and shafts, fixtures, brackets, and high‑stress parts.

How to Request Quotes, Samples & Data Sheets

To move quickly on 1018 vs 4140:

- Send your material list (grade, size, quantity, condition: as-rolled, annealed, QT).

- Tell us your end use (e.g., shaft, gear, bracket, tooling) so we can verify the grade.

- Request:

- Price quote + lead time

- Mill certificates and data sheets for 1018 and/or 4140

- Small samples or short bars if you want to test machining or welding first

Once we know your specifications and schedule, we can arrange the right 1018 or 4140 with the appropriate treatments so it integrates into your process seamlessly.

Related Steel Comparisons and Resources – 1018 vs 4140

If you’re choosing between 1018 vs 4140, you’ll usually want to compare them against a few other core grades and have quick reference data on hand. I keep it simple and practical.

1018 vs 1045 and Other Carbon Steel Grade Comparisons

For general fabrication and turned parts, most shops are really comparing these three:

| Grade | Type | Typical Use Case |

|---|---|---|

| 1018 | Low carbon / mild steel | Brackets, fixtures, shafts, weldments |

| 1045 | Medium carbon | Stronger pins, axles, basic shafts |

| 4140 | Alloy steel (Cr‑Mo) | High‑load shafts, gears, tooling |

Quick rule of thumb:

- 1018 – easiest to weld and machine, lowest strength.

- 1045 – middle ground, can be heat treated, more strength.

- 4140 – highest strength and hardenability in this group, for demanding parts.

4140 vs Other Alloy Steels for Gears and Shafts

For gears, spindle shafts, and drive components, the real battle is 4140 vs other alloy steels like 4130, 4340, or case‑hardening grades.

| Grade | Key Benefit | Typical Part |

|---|---|---|

| 4140 | Good mix of strength + toughness | Transmission shafts, couplings |

| 4340 | Higher toughness, deeper hardening | Heavy‑duty gears, axles |

| 4130 | Easier to weld, slightly lower strength | Roll cages, frames |

If you’re running precision CNC machining on these alloys, a strong process setup like in a dedicated CNC machine operations workflow helps you hold tight tolerances, especially on hardened 4140.

Reference Charts for Steel Tensile and Yield Strength

You should always have quick tensile and yield strength charts available for design checks and customer quotes.

Typical design‑level values (approximate, for quick comparison):

| Grade / Condition | Yield strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| 1018 (cold drawn) | ~370–420 | ~440–480 |

| 1045 (normalized) | ~380–415 | ~570–625 |

| 4140 (QT, ~30–32 HRC) | ~655–860 | ~850–1030 |

| 4140 (QT, ~38–42 HRC) | ~950–1100+ | ~1100–1300+ |

Use these as a screening tool only; final design must follow actual mill certs and standards.

Downloadable 1018 vs 4140 Comparison Tools and PDFs

For buyers, engineers, and machinists, I always recommend keeping:

- 1‑page 1018 vs 4140 comparison sheet

- Chemical composition

- Typical mechanical properties

- Machinability, weldability, heat‑treat response

- Process cheat sheets

- Machining feeds/speeds by hardness range

- Preheat/temper guidelines for 4140

- Case‑hardening notes for 1018

Bundle these as downloadable PDFs so your team can check material selection, machining strategy, and heat‑treat decisions in seconds instead of hunting through specs.

For more advanced alloys or high‑temp environments (aerospace, energy), it also helps to cross‑reference our high‑temperature alloy insights so you know when standard steels like 1018/4140 are no longer sufficient: high-temperature alloy insights and applications.