Explore high precision wax injection moulding machines with advanced features, fast cycle times, and energy-efficient designs for investment casting and jewellery.

If you’re involved in precision casting, jewellery making, or advanced manufacturing, you already know that the quality of your wax patterns can make or break your final product. That’s why choosing the right wax injection moulding machine is crucial. These machines don’t just shape wax; they deliver unmatched precision, efficiency, and repeatability that modern industries demand. In this guide, you’ll discover exactly what a wax injection moulding machine is, why it’s a game-changer for investment casting and prototyping, and how to select the perfect model for your production needs. Ready to elevate your manufacturing process? Let’s get started.

What is a Wax Injection Moulding Machine

A wax injection moulding machine is a specialised device used to create detailed wax patterns by injecting melted wax into moulds. These patterns are essential in processes like investment casting, where the wax model is later replaced by metal or other materials. The main purpose of the machine is to produce high-precision wax parts that match complex designs accurately and consistently.

How It Works

The process begins by melting wax inside a heated chamber. Once the wax reaches the right temperature, it is injected under pressure into a closed mould cavity. The mould is held tightly to ensure the wax fills every detail. After injection, the wax cools and solidifies inside the mould. When solid, the mould opens, and the finished wax pattern is ejected for further processing.

Types of Wax Injection Moulding Machines

- Manual Machines

Operated by hand, ideal for small-scale or custom jobs. - Semi-Automatic Machines

Combine manual and automated steps, boosting production speed while maintaining control. - Fully Automatic Machines

Handle the entire injection, cooling, and ejection process automatically for high-volume production.

Key Components

- Wax Melting Chamber

Heats and keeps wax at the right temperature. - Injection Unit

Pressurises and injects the molten wax into the mould. - Mould Clamping System

Holds the mould closed during injection and cooling. - Cooling System

Solidifies the wax pattern quickly and uniformly. - Ejection Mechanism

Removes the finished wax pattern without damage. - Control Panel

Manages temperature, injection speed, pressure, and cycle timing for consistent results.

This combination of parts ensures that wax injection moulding machines produce detailed wax patterns efficiently and with precision, meeting the needs of industries like jewellery, aerospace, and precision engineering.

Applications of Wax Injection Moulding Machines

Wax injection moulding machines are widely used across various industries due to their precision and ability to create complex shapes. Here’s where they excel:

Investment Casting Industry

- Automotive parts such as engine components

- Aerospace parts requiring high accuracy

- Medical devices with precise specifications

- Electronics housings and connectors

Jewellery Manufacturing

- Detailed wax patterns for rings, necklaces, and intricate designs

- Consistent replication of fine details

Precision Components and Prototypes

- Small mechanical parts for testing and production

- Rapid prototyping with high detail and accuracy

Benefits for Complex and High Precision Parts

- Ability to mould intricate shapes that are difficult with other methods

- High repeatability ensures consistent quality

- Smooth surface finishes reduce the need for extra polishing

Key Features to Consider When Choosing a Wax Injection Moulding Machine

Picking the right wax injection moulding machine means focusing on several important factors that affect performance, efficiency, and cost. Here’s what you should look at:

| Feature | What to Consider |

|---|---|

| Injection Pressure & Speed | Higher pressure ensures better mould filling. Speed impacts cycle time and production capacity. |

| Mould Capacity & Size Range | Choose a machine that fits the size and complexity of your wax patterns. Flexibility is key. |

| Automation & Controls | Look for temperature controls, PLC integration, and automation level (manual, semi, fully automatic). This eases operation and improves consistency. |

| Wax Melting & Heating Efficiency | Efficient wax melting systems reduce energy use and cycle times, saving money. |

| Cycle Time & Throughput | Faster cycle times mean higher production rates. Match machine speed with your demand to avoid bottlenecks. |

| Energy Consumption & Environment | Energy-efficient machines lower costs and meet environmental standards. Check for eco-friendly features. |

| Machine Footprint & Customisation | Consider machine size for your workspace. Customisable options let you tailor the machine to your needs. |

These key features help you balance quality, output, and costs for your business. Paying attention to them means you’ll choose the best wax injection moulding machine for your production needs.

Step by Step Guide How Wax Injection Moulding Machines Work

Here’s a straightforward look at how wax injection moulding machines operate, from start to finish:

Wax Melting Process

The wax is first heated in a melting tank until it reaches the right liquid state. This ensures the wax flows easily into the mould without causing defects.

Mould Clamping and Injection Phase

Once the wax is prepared, the machine clamps the mould shut tightly. Then, it injects the melted wax into the mould cavity under controlled pressure and speed to fill every detail.

Cooling and Solidification

After injection, the wax cools inside the mould. This solidifies the wax, forming a precise pattern that matches the mould’s shape exactly.

Mould Opening and Wax Pattern Ejection

When the wax hardens, the mould opens automatically, and ejector pins gently push the finished wax pattern out without damage.

Quality Control Checkpoints

At this stage, operators inspect the wax patterns for defects such as bubbles, incomplete fills, or surface flaws to ensure only top-quality pieces proceed. Adjustments to temperature or injection parameters can be made to maintain consistent quality.

Advantages of Using Wax Injection Moulding Machines

Wax injection moulding machines offer several clear benefits, especially for businesses focused on precision and efficiency.

High precision and repeatability

These machines produce wax patterns with consistent accuracy every time, ideal for detailed parts where exact dimensions are crucial.

Cost-effective for mass production

When large quantities are needed, wax injection moulding reduces your per-unit cost by speeding up production and decreasing manual labour.

Reduced material waste

Because the process is controlled and precise, you only use the wax you need—reducing scrap and saving money.

Improved surface finish and detail accuracy

Wax patterns emerge smooth and finely detailed, which is vital for industries like jewellery and investment casting.

Faster production cycles

Compared to traditional hand carving or moulding, wax injection moulding machines significantly shorten cycle times, enabling you to meet tight deadlines with ease.

Common Challenges and How to Overcome Them

Using a wax injection moulding machine may present some challenges, but understanding how to address them keeps your production smooth and efficient. Here are the most common issues and practical tips to resolve them.

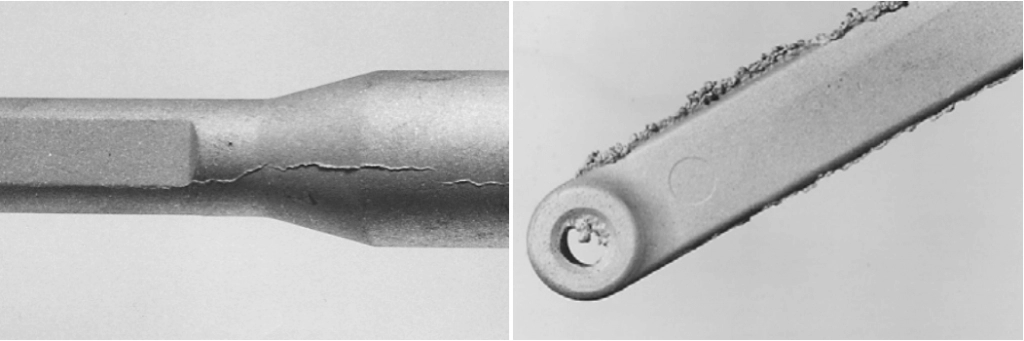

Wax Porosity and Defects

Porosity appears as tiny holes or weak spots in your wax patterns. It often results from trapped air or inconsistent wax temperature.

- Solutions:

- Preheat the mould properly to avoid sudden cooling.

- Adjust injection pressure and speed for a steady flow.

- Use high-quality wax with consistent melting points.

- Apply proper venting in the mould to release trapped air.

Mould Wear and Maintenance

Over time, moulds can wear out or get damaged, leading to poor wax patterns. Regular upkeep extends mould life.

- Maintenance Tips:

- Clean moulds after every run to prevent buildup.

- Inspect moulds regularly for cracks or damage.

- Lubricate mould surfaces where applicable.

- Store moulds in a dry, controlled environment.

Temperature Control Challenges

Maintaining the right temperature for wax melting and mould heating is crucial. Too hot or too cold impacts pattern quality and cycle time.

- How to Manage:

- Use reliable temperature sensors and controllers.

- Monitor temperature consistently during operation.

- Adjust heater settings based on wax type and ambient conditions.

Machine Calibration Guidelines

Incorrect calibration can cause inconsistent injection pressure, cycle times, or mould clamping force. Regular calibration ensures accuracy.

- Calibration Best Practices:

- Follow the manufacturer’s schedule for calibration checks.

- Use calibrated tools to verify pressure and temperature settings.

- Document calibration results for quality tracking.

Troubleshooting Common Faults

Operators often face jams, incomplete injection, or ejection failures. Quick troubleshooting reduces downtime.

- Quick Fixes:

- Check wax viscosity and adjust melting temperature.

- Inspect moulds for blockages or misalignment.

- Verify hydraulic or pneumatic components for leaks or pressure drops.

- Reset control systems if equipment behaves irregularly.

By staying proactive with these tips, you can minimise downtime, produce high-quality wax patterns, and keep your wax injection moulding machine running smoothly.

How to Choose the Right Wax Injection Moulding Machine for Your Business

Selecting the right wax injection moulding machine isn’t just about finding the cheapest option. You need a machine that fits your production needs, budget, and long-term goals. Here’s what to keep in mind:

Assess Production Volume and Speed Requirements

- Low volume or prototypes: A manual or semi-automatic machine may be sufficient.

- High volume production: Consider fully automated machines to enhance throughput and consistency.

Budget Considerations

| Cost Factor | What to Think About |

|---|---|

| Initial Cost | Initial purchase price vs machine features |

| Operation Cost | Energy use, maintenance, and consumables |

| ROI | How quickly the machine pays for itself |

After Sales Support and Warranty

- Fast, reliable support reduces downtime.

- A solid warranty protects your investment.

- Check if the supplier offers training and spare parts.

Supplier Reputation and vast’s Strengths

- Look for established manufacturers with a proven track record.

- Vast stands out for delivering durable machines tailored to various industries.

- Their customer service is known for responsiveness and technical expertise.

Customization and Upgrade Options

- Can the machine be customised for your specific wax types or mould sizes?

- Check if upgrades like PLC integration or automation kits are available to keep up with your growth.

Maintenance and Best Practices for Longevity

Proper maintenance is key to keeping your wax injection moulding machine running smoothly and extending its lifespan. Here’s what you should focus on:

Routine Maintenance Checklist

- Inspect moving parts Regularly to prevent wear and tear.

- Lubricate components like hinges and ejector pins to ensure smooth operation.

- Check seals and hoses Check for leaks or cracks.

- Verify electrical connections and sensors for faults.

- Monitor injection pressure and temperature settings for consistency.

Cleaning Procedures

- Clean the wax melting tanks and channels after every shift to avoid wax buildup.

- Use appropriate solvents to remove stubborn residues without damaging parts.

- Keep moulds and machine surfaces free from dust and debris.

- Schedule deep cleaning periodically depending on production volume.

Wax Type Compatibility and Machine Settings

- Match your wax injection moulding machine settings—such as temperature and injection speed—to the specific type of wax you use.

- Using incompatible wax can cause clogs, porosity, or defects.

- Adjust heating units and cooling times to maintain optimal wax fluidity and solidification.

Safety Protocols and Operator Training

- Train operators on safe machine startup and shutdown procedures.

- Emphasise handling hot components and molten wax carefully.

- Implement lockout/tagout protocols during maintenance.

- Provide personal protective equipment (PPE) like gloves and safety glasses.

- Regularly update training to cover new machines or processes.

Following these maintenance best practices will help ensure reliable performance and reduce downtime for your wax injection moulding machine.

The Future of Wax Injection Moulding Machines

Wax injection moulding machines are evolving rapidly, thanks to new technology and growing industry demands. Automation and AI integration are making these machines smarter. They now offer better process control, predict maintenance needs, and boost production efficiency, which means less downtime and higher quality wax patterns.

Environmentally friendly wax materials are also gaining traction. More companies are using recyclable and bio-based waxes to reduce waste and lower their environmental impact. Machines designed to handle these new wax types help make the process greener without sacrificing precision.

Another big trend is the integration of Industry 4.0. Wax injection moulding machines are becoming part of connected smart factories where data from sensors and PLC systems guide real-time decisions. This connectivity improves traceability, quality control, and overall workflow management, helping UK manufacturers stay competitive and agile.

In short, the future points to cleaner, smarter, and more efficient wax injection moulding machines tailored for high precision and sustainable production.

Why Choose VAST for Your Wax Injection Moulding Machine Needs

When it comes to wax injection moulding machines, Vast VAST stands out in the UK market with a strong product lineup and advanced technology. Here’s why partnering with VAST makes sense:

Extensive Product Range and Technology Leadership

- Offers manual, semi-automatic, and fully automatic wax injection machines.

- Integrates the latest automation and temperature control features.

- Machines built for high precision wax injection moulding and fast cycle times.

Proven Customer Success

- Real-world results from automotive, aerospace, medical, and jewellery industries.

- Case studies show improved product quality, efficiency, and reduced waste.

- Testimonials highlight Vast’s machines as reliable and easy to maintain.

Dedicated After Sales and Technical Support

- Responsive service team based in the UK.

- Fast parts availability, including wax injection moulding machine parts.

- Training and troubleshooting help ensure smooth operation.

Customized Solutions for Every Industry

| Industry | Customization Focus | Benefits |

|---|---|---|

| Jewellery Manufacturing | Fine-detail wax injector capabilities | High-precision wax pattern making |

| Investment Casting | High-capacity machines, automation options | Faster throughput, consistent quality |

| Medical Devices | Cleanroom compatible machines | Safe, contamination-free parts |

| Electronics | Small wax injection moulding machine setups | Compact machines for tight spaces |

Vast tailor-made machines to fit your specific production needs, whether you want to scale up or improve precision.

Choosing Vast means investing in reliable wax injection moulding machines backed by strong support, cutting-edge technology, and industry expertise.