Discover what a pump house is, its design types, functions, and maintenance tips for efficient water system management in homes and industries.

What Exactly Is a Pump House: Core Definition and Purpose

A pump house is a protective building designed to house essential pumping equipment such as pumps, motors, control panels, and piping systems. Its main role is to safeguard this equipment from weather, debris, and vandalism while ensuring smooth and reliable water flow. Additionally, a pump house helps maintain compliance with safety and environmental regulations, protecting both the system and the people around it.

Pump houses are crucial in various applications—from supplying water in residential areas to managing large-scale industrial or municipal water systems. They create a controlled environment that optimises pump performance and extends equipment life.

Here’s a quick comparison to clarify how a pump house differs from related structures:

| Feature | Pump House | Well House | Pumping Station |

|---|---|---|---|

| Main Use | Protects pumps & controls | Covers well head & basic controls | Large-scale water transfer & treatment |

| Scale | Residential to industrial | Mostly residential or small farms | Municipal, industrial |

| Equipment Housed | Pumps, motors, electrical controls | Well pumps, simple controls | Multiple pumps, filtration, valves |

| Purpose | Reliable water distribution | Water access & protection | High-capacity water management |

| Complexity | Moderate to high | Low to moderate | High |

Understanding this helps when deciding the right solution for your water system needs, whether you’re managing a backyard well or a city’s water supply.

Anatomy of a Pump House Essential Components and How They Work

A pump house is more than just a shelter—it’s a carefully designed system where several parts come together to keep water flowing smoothly. The core components include pumps and motors, control systems, as well as piping and ventilation.

Pumps and Motors are the heart of any pump house. The most common types you’ll see are centrifugal pumps, which use spinning action to move water, and submersible pumps, which sit underwater and push water up. Choosing the right pump affects how efficiently your system runs, so it’s key to match pump size and type to your water needs to save energy and avoid overworking the motor.

Control Systems and Electricals include components like PLC (Programmable Logic Controllers) and RTU (Remote Terminal Units). These are the brains behind automation, helping to optimise pump operation, monitor performance, and reduce energy costs. Modern pump houses may use these systems for seamless automatic control, making sure everything runs reliably without manual intervention.

Piping, Valves, and Ventilation keep water moving safely and efficiently. Well-designed piping directs flow correctly, while valves allow for easy control or shutoff when needed. Good ventilation prevents build-up of harmful gases and overheating inside the enclosure. Poor ventilation is a common pitfall that can cause equipment failures and costly downtime, so it’s critical for pump houses, especially those housing motors and electrical parts.

In , a well-built pump house combines these elements to protect equipment, regulate flow, and maintain long-term reliability. Understanding what each part does helps you make smarter decisions on design, maintenance, and upgrades.

Types of Pump Houses From Backyard Basics to Industrial Powerhouses

Pump houses come in all shapes and sizes, depending on their use and location. Here’s a quick look at the main types you’ll find:

- Residential Well Pump Houses These are small-scale structures designed to protect well pumps in homes. They often blend smoothly with local architecture, keeping the equipment safe while maintaining the look of your yard. They’re usually simple, cost-effective, and built to handle basic water supply needs.

- Municipal and Irrigation Stations These are much larger, serving cities or agricultural lands. Municipal pump houses support city water utilities, pumping water to homes and businesses reliably. Irrigation pump buildings handle high volumes for farms and green spaces. They’re designed to meet strict safety and efficiency standards.

- Specialized Pump Houses Some pump houses serve unique roles such as wastewater lift stations, fire suppression systems, or cooling water pump houses in industrial settings. Each type has specific features tailored to handle those particular tasks, like corrosion resistance or redundant backup systems.

- Prefab vs Custom Builds Prefabricated pump houses offer quick installation and cost savings but might fall short on customization or site-specific needs. Custom-built pump houses allow for tailored designs, ideal for complex systems or specific architectural requirements, though they usually take more time and budget.

Choosing the right pump house means balancing your needs, budget, and the environment where it will operate. Whether you’re looking for a modest well house for home use or an industrial pumping station, understanding these types makes planning easier.

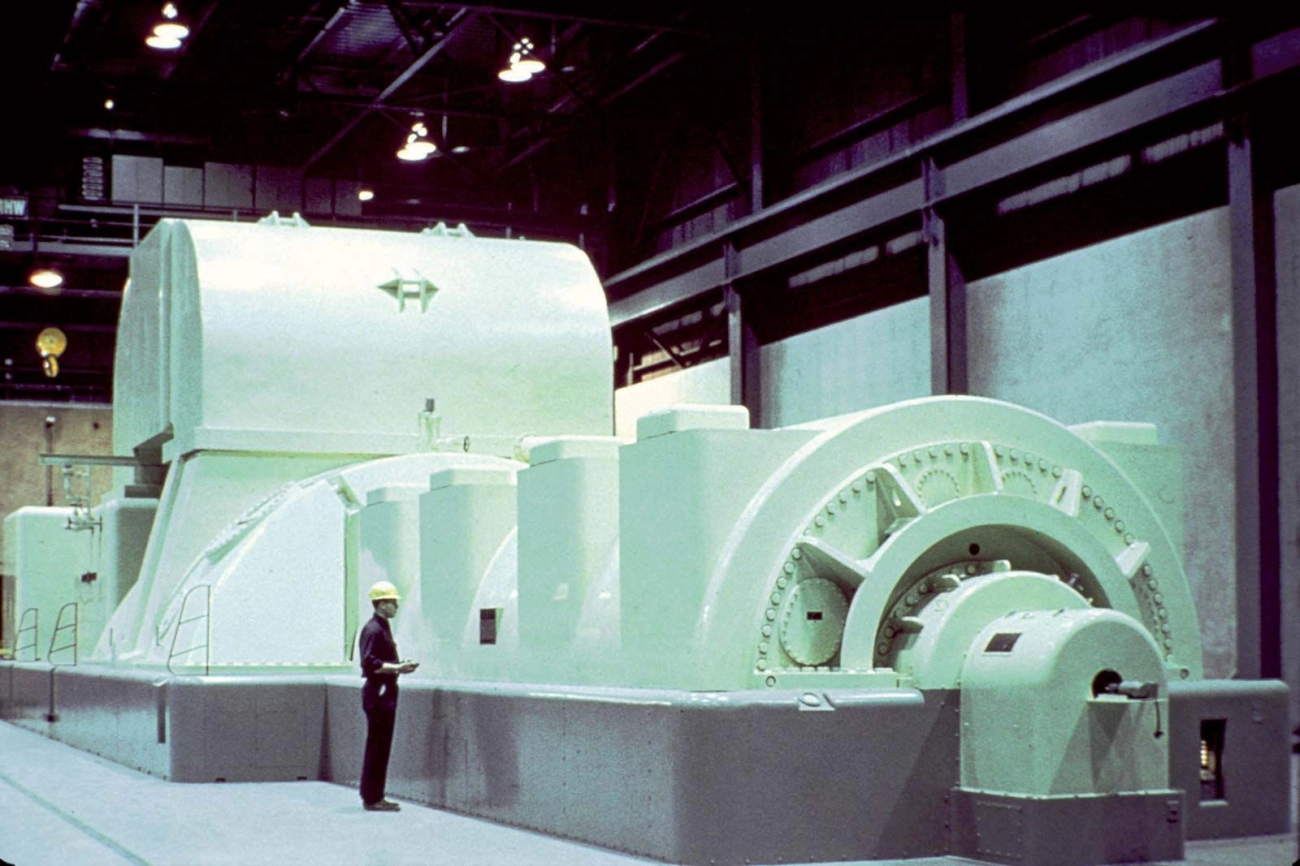

Historical Evolution From Steam Powered Relics to Modern Marvels

Pump houses have come a long way since their early days in the 19th century. Back then, they were mostly steam-powered, bulky structures that housed huge engines used to move water for farming, cities, and industry. These steam pump houses were vital but inefficient and required constant attention.

The big shift came with the rise of electric pumps in the early 20th century. Electric motors replaced steam engines, making pump houses smaller, cleaner, and easier to manage. This change coincided with the growth of Britain’s water infrastructure, including municipal water supply and irrigation systems.

Later advancements like submersible pumps revolutionised pump house designs further. These pumps sit underwater, improving efficiency and reducing noise. They are now a standard in residential well houses and large wastewater lift stations alike.

Today’s pump houses reflect this history with durable materials, automation tech, and eco-friendly designs focused on energy savings and reliability. Knowing this timeline helps us appreciate how modern water pump enclosures blend power, safety, and smart control—all tailored for today’s UK infrastructure needs.

Building and Designing Your Pump House Practical Steps and Best Practices

When building a pump house, the first thing to consider is sizing and site selection. Make sure you calculate the space needed for all equipment, including pumps, motors, controls, and piping. Keep clearances in mind, especially following NFPA codes, to allow for proper maintenance and safety access.

Next up is materials and construction. Common choices include concrete for durability, or polyethylene for lightweight, weather-resistant options. Pick materials that hold up well against your local climate—whether it’s humid, hot, or freezing cold. This ensures your pump house stays solid year-round.

Don’t forget about regulations and permits. Depending on where you are, you’ll need to comply with UK EPA guidelines, local zoning laws, and any residential restrictions. Getting permits upfront avoids headaches down the road.

Here’s a simple step-by-step build process with rough cost basics:

- Plan and design layout

- Obtain permits

- Prepare foundation

- Construct walls and roof

- Install pumps, motors, controls, and piping

- Connect electrical and control systems

- Final inspection and testing

Costs typically range from a few thousand pounds for a small residential pump house to tens of thousands for larger or custom builds.

Case study: A homeowner in a suburban neighbourhood blended their pump house into their backyard by using a small, brick enclosure with a sloped roof matching their home style. This design kept the structure low profile while meeting all operational needs and local codes, proving that practical can also look good.

In short, careful planning with the right materials and compliance will get you a durable, efficient pump house that fits your property and water systems perfectly.

Maintenance Essentials Keeping Your Pump House Running Smoothly

To keep your pump house reliable, regular maintenance is a must. Here’s a quick checklist to stay on top of things:

- Routine Inspections: Check pumps, motors, and piping for any signs of wear or leaks.

- Cleaning Strainers: Remove debris regularly to prevent clogs that can reduce water flow.

- Electrical Checks: Inspect wiring, control panels, and switches to avoid unexpected failures.

If you run into problems, these are common issues and how to handle them:

- Motor Burnout: Often caused by overheating or poor ventilation—make sure your pump house has proper airflow and that motors aren’t overloaded.

- Pipe Leaks: Look for drips or wet spots and fix loose fittings or corroded pipes immediately.

For long-term reliability, consider smart upgrades like:

- Remote Monitoring Systems: These track pump performance and send alerts if something goes wrong, saving you time and preventing costly downtime.

By sticking to these maintenance basics, your pump house will run smoothly and last longer, ensuring a steady water flow whenever you need it.

Why Choose Vast for Your Pump House Needs Innovation Meets Reliability

When it comes to pump houses, Vast stands out by combining innovation with reliable performance. We specialise in modular, customisable enclosures designed to fit your specific needs, whether residential, municipal, or industrial. Our impact-resistant designs ensure your equipment stays protected from harsh weather and accidental damage, keeping your water systems running smoothly.

Expertise You Can Trust

- Modular pump shelters that simplify installation and allow easy upgrades

- Custom builds tailored to your site and system requirements

- Durable materials built to withstand local climates and regulations

Key Benefits

- Faster installs save you time and labour costs

- Cost-effective solutions without cutting corners on quality

- Seamless integration with your landscape or existing facilities for better aesthetics

- Enhanced energy efficiency with advanced pump control systems included

Customer Success

We’ve helped numerous customers improve water reliability and reduce downtime. One recent project saw a suburban community upgrade their well pump house with our modular enclosure, cutting installation time by 40% and reducing maintenance calls by half. That’s the kind of results you can expect with Vast.

Choosing Vast means getting a durable, efficient, and smart pump house solution designed with your local needs in mind.