Discover precision spline shafts with options in involute and straight-sided profiles built for high torque and custom manufacturing needs.

What Are Spline Shafts Core Anatomy and Functionality

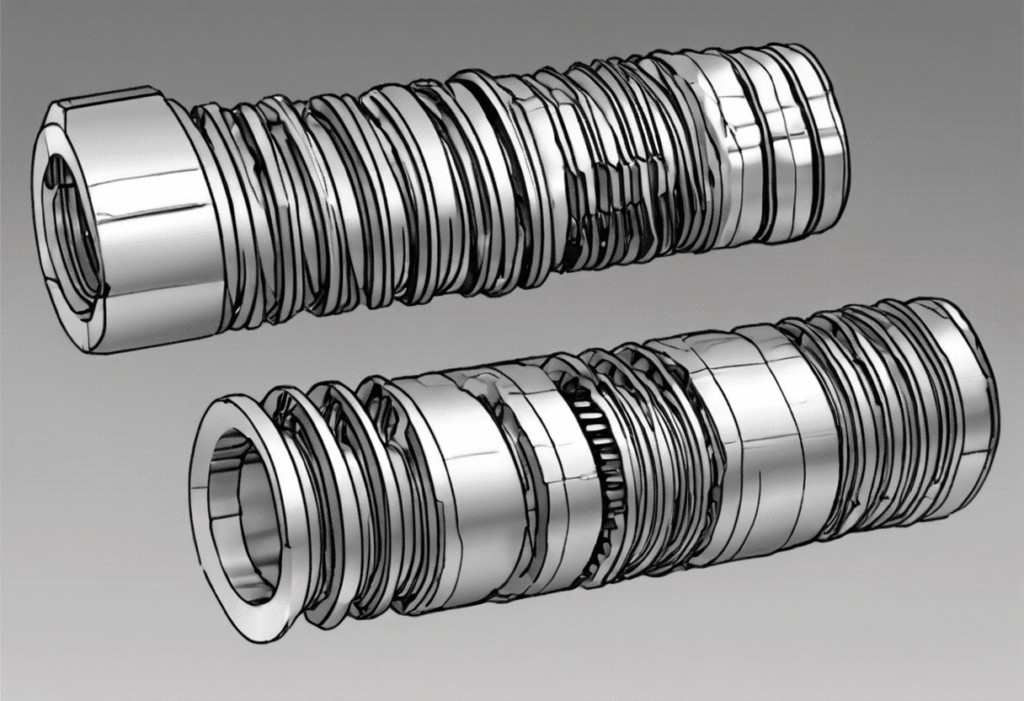

Spline shafts are essential components designed to transfer torque between machinery parts while allowing relative movement along the shaft’s axis. At their core, spline shafts feature a series of ridges or teeth that mesh with grooves on a mating part, like a gear or hub. This interlocking design ensures precise torque transmission and alignment.

Basic Structure

- Shaft Body: The main cylindrical part that provides support and strength.

- Teeth or Splines: Evenly spaced ridges running lengthwise along the shaft.

- Heel and Root: The top (heel) and bottom (root) of each tooth, critical for fit and strength.

- Major and Minor Diameter: The shaft’s outer diameter (including teeth) and the inner base diameter between teeth.

How They Work

The splines engage with corresponding grooves to ensure the shaft rotates the connected component without slipping. This makes them perfect for precise, robust power transmission in demanding equipment.

Visual Aid

Think of the shaft like a key and lock system; the splines are the “teeth” that fit exactly into the corresponding grooves, preventing rotation slippage while allowing sliding if needed.

Vast’s Cold-Formed Spline Shafts

Vast specialises in cold-formed spline shafts—a process that strengthens metal through deformation without heat. This method offers high durability, tight tolerances, and cost-effective production. Cold-formed shafts stand out for their enhanced strength and surface finish, ideal for industries requiring reliable torque transmission.

If you want to explore custom options or get drawings, Vast provides expert support to tailor spline shafts to your exact needs.

Types of Spline Shafts Choosing the Right Profile for Your Needs

Spline shafts come in different profiles, each suited for specific tasks. Picking the right type helps improve performance and durability.

Straight-Sided Splines

- Design: Parallel sides with flat teeth.

- Uses: Common in simple torque transmission, like PTO spline shafts for farm equipment.

- Benefits: Easy to manufacture, good for medium torque loads.

Involute Splines

- Design: Curved tooth profiles that match gear teeth shapes.

- Uses: Widely used in automotive drive splines and heavy-duty gearboxes.

- Benefits: Better load distribution, reduced stress, and smoother torque transfer.

Serrations and Other Variants

- Design: Fine, closely spaced grooves.

- Uses: Often in hydraulic spline couplings and small torque applications.

- Benefits: Compact and able to handle rapid engagement and disengagement.

Comparison Table of Common Spline Shaft Types

| Spline Type | Tooth Shape | Typical Use Cases | Torque Capacity | Manufacturing Ease |

|---|---|---|---|---|

| Straight-Sided | Flat, parallel | PTO shafts, simple drives | Medium | Easy |

| Involute | Curved, gear-like | Automotive, heavy machinery | High | Moderate |

| Serrations | Fine grooves | Hydraulic couplings, small parts | Low to Medium | Moderate |

Choosing the right spline shaft type depends on the torque requirements, space constraints, and manufacturing options. For local United Kingdom businesses, cold-formed spline shafts are a popular choice due to cost-effectiveness and durability.

Manufacturing Spline Shafts Processes Materials and Quality Standards

When it comes to making spline shafts, the process plays a crucial role in durability and performance. Common manufacturing methods include cold forming, broaching, and hobbing. Cold-formed spline shafts are popular because they offer high strength with tight spline shaft tolerances while minimising material waste. Broaching is excellent for precision grooves and straight-sided splines, often used in PTO spline shafts for agriculture and industrial gearboxes. Hobbing typically creates involute splines favoured in automotive drive splines due to their smooth torque transmission.

Material choice is also important. Most spline shafts are made from alloy steels or stainless steel, depending on the application's strength and corrosion requirements. After shaping, finishing processes like grinding and heat treatments improve hardness and wear resistance. Heat treatments—such as carburising or induction hardening—ensure the spline shafts can withstand long-term stress without failure.

At Vast, we specialise in custom spline manufacturing. For a recent case, we worked with a client needing cold-formed, high-torque spline shafts for heavy machinery. By combining precise broaching and careful heat treatment, we delivered parts that exceeded their quality standards and fit perfectly into their hydraulic spline couplings.

No matter your application, understanding these processes and quality checkpoints helps you select spline shafts built to last and perform reliably under tough conditions.

Applications of Spline Shafts From Farm Fields to Factory Floors

Spline shafts play a vital role across many industries, providing reliable torque transmission where it matters most. In industrial settings, you’ll find them in PTO (power take-off) systems, gearboxes, and robotics, where precise movement and power transfer are essential for smooth operation.

In automotive and aerospace, spline shafts are key to connecting drive shafts, transmissions, and control systems, handling high loads and reducing backlash for better performance and safety. Agriculture relies heavily on spline shafts in equipment like tractors and harvesters, especially in hydraulic couplings that require durable, strong torque transmission shafts to endure tough conditions.

Hydraulic spline couplings offer secure power transfer in heavy machinery, making them a preferred choice for construction and farming equipment. The energy sector is also utilising spline shafts, with emerging applications in EV drivetrains where efficient power transfer and compact design are vital, and in renewable energy applications like wind turbines, which demand long-lasting, high-tolerance spline shafts.

Here’s a quick overview of where spline shafts make a difference:

- Industrial: PTO shafts, automated gearboxes, robotic arms

- Automotive and Aerospace: Drive shafts, transmission systems, aircraft controls

- Agriculture and Hydraulics: Tractors, harvesters, hydraulic couplings

- Renewable Energy and Electric Vehicles: Electric vehicle drivetrains, wind turbines

Across these applications, the correct spline shaft type and manufacturing precision ensure durability, reduced wear, and smooth, reliable torque transfer—regardless of the task.

Advantages and Common Challenges in Maximising Spline Shaft Performance

Spline shafts are well-known for their ability to transfer torque efficiently and reliably, making them essential in many mechanical systems. Here’s a quick overview of their main advantages, common challenges, and tips to optimise their performance.

Key Benefits of Spline Shafts

- Torque Transmission: Spline shafts provide a firm grip between connected parts, enabling smooth power transfer without slipping.

- Longevity: Properly designed spline shafts can withstand heavy loads over extended periods with minimal wear.

- Backlash Reduction: The precise fit of splines reduces play between mating parts, enhancing system accuracy and performance.

Common Challenges

| Challenge | Description |

|---|---|

| Misalignment | Can cause uneven wear and premature failure |

| Measurement Errors | Incorrect spline shaft tolerances affect fit and function |

| Failure Modes | Fatigue, wear, and corrosion are typical causes of failure |

Tips to Maximise Performance

- Use Proper Lubrication:Prevents wear and reduces heat buildup in spline interfaces.

- Choose Correct Fit Classes:Match spline tolerances to your application to reduce backlash and avoid binding.

- Regular Inspection:Check for signs of wear, misalignment, or damage to catch issues early.

- Consider Prototyping Services:Partnering with specialists like Vast can help optimise spline designs before full production.

By following these guidelines, you can avoid common pitfalls and extend the life of your spline shafts, ensuring smooth and reliable operation in your equipment.

Sourcing and Maintenance Partnering with Vast for Custom Spline Shaft Solutions

When it comes to buying spline shafts, choosing between custom-made and off-the-shelf options depends on your specific needs. Vast offers both, helping local businesses in the United Kingdom find the right fit quickly. Custom spline manufacturing lets you tailor specifications like spline shaft tolerances, material type, and heat treatments to match your project perfectly. Off-the-shelf spline shafts are great for standard requirements and faster turnaround.

Buying Guide for Spline Shafts

- Custom splines:Best for unique torque transmission shafts or specialised applications like automotive drive splines or hydraulic spline couplings.

- Standard splines:Ideal for common needs, like PTO spline shafts used in farming equipment.

- Material and finish:Check for cold-formed spline shafts or those made via broaching, depending on strength and surface quality needed.

- Tolerance and fit classes:Proper fit matters for smooth operation and minimising wear.

Maintenance Best Practices

Keeping your spline shafts in top shape means regular inspection and timely maintenance. Here’s what works:

- Regular visual checks: Look for wear, deformation, or corrosion.

- Lubrication: Use recommended lubricants to reduce friction and prevent failure.

- Measurement: Check spline shaft tolerances periodically to catch misalignment early.

- Diagnostics: Use vibration analysis or other tools to spot potential problems before they escalate.

Vast Spotlight

At Vast, we pride ourselves on delivering quality spline solutions and excellent customer support. Our extensive prototyping services help test your custom designs before full production. Don’t just take it from us—our UK customers praise our quick turnaround and durable products tailored to their toughest challenges.

Ready to upgrade your torque transmission shafts? Contact Vast today for custom spline shafts built to last.