Explore different end mill types including square, ball nose, and carbide cutters to choose the right CNC milling tool for precision and efficiency.

Core Classifications of End Mills by Geometry and Design

Choosing the right end mill starts with understanding their shapes and uses. Different geometries fit different jobs, and getting this right means better cuts and longer tool life.

Square (Flat) End Mills

These are your go-to for flat surfaces, slots, and roughing work. They excel in steel and aluminium and are great for plunging straight down.

- Pros: Strong for deep cuts and roughing

- Cons: Not ideal for 3D contours or rounded edges

- Spotlight: Vast’s 4-flute square carbide end mills offer excellent high-feed roughing performance, combining durability with precision.

Ball Nose End Mills

Ball nose cutters have a rounded tip perfect for smooth 3D contouring, moulds, and die-making where curves matter.

- Pros: Great for complex curved shapes

- Cons: Slower material removal rates versus flat end mills

- Tip: Pair with high-helix flutes for better chip evacuation on non-ferrous metals like aluminium.

Corner Radius End Mills

These have blended edges that add strength for semi-finishing and high-stress cuts, reducing chipping and extending tool life.

- Pros: Last longer than square end mills under tough conditions

- Cons: Require programming specific to the radius

- Spotlight: Vast offers TiAlN-coated options designed for machining titanium alloys with toughness and heat resistance.

Chamfer and Tapered End Mills

Designed with angled edges, these are perfect for chamfering, countersinking, and edge preparation.

- Pros: Versatile for finishing edges and dies

- Cons: Not suitable for heavy stock removal or roughing work

Roughing vs Finishing End Mills

Roughing end mills feature serrated edges that break chips aggressively to speed up material removal. Finishing end mills have polished flutes for the smoothest surfaces.

| Feature | Roughing End Mills | Finishing End Mills |

|---|---|---|

| Edge Style | Serrated | Smooth Polished |

| Use | Aggressive cuts | Fine surface finishes |

| Typical Flutes | 3-4 | 4-6 |

| Chip Evacuation | High | Moderate |

Flute Count and Helix Angles also play key roles:

- Flutes range from 2-6, balancing chip clearance and cutting speed.

- Helix angles between 45° and 55° improve chip flow and surface finish.

For a quick pick, check out Vast’s geometry selector tool to match your project needs with the perfect end mill design.

Material and Coating Variations Matching End Mills to Your Workpiece

Choosing the right end mill material and coating is key to getting the best results for your specific job. Here’s a quick breakdown of common options we use and their pros and cons:

High-Speed Steel (HSS) vs Solid Carbide

- HSS: Great for general use, especially with lower speeds. It’s more affordable but wears out faster.

- Solid Carbide: Offers more rigidity and can handle high RPMs, making it ideal for tough materials and fast machining, but comes at a higher cost.

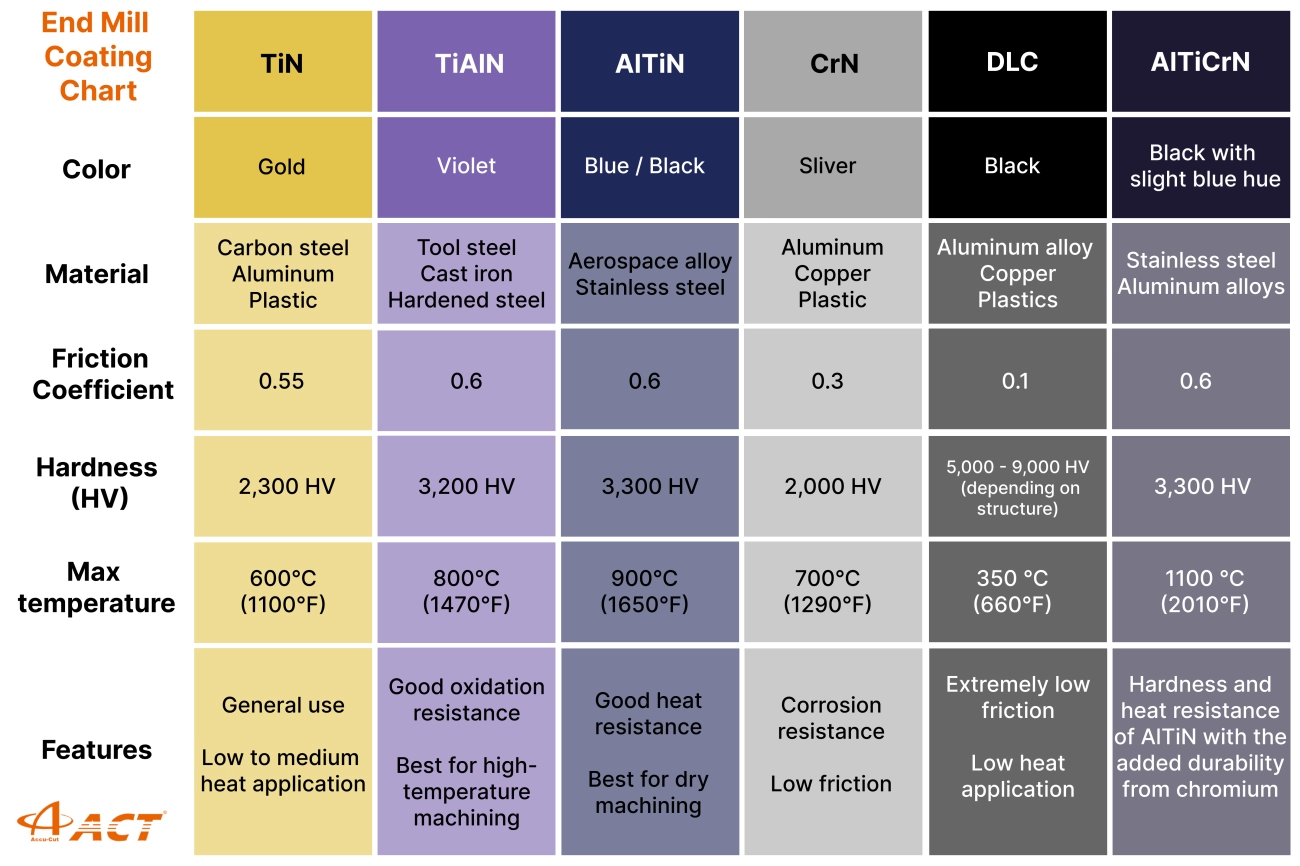

Key Coatings Explained

- TiN (Titanium Nitride): Adds wear resistance and helps tools last longer.

- AlTiN (Aluminium Titanium Nitride): Perfect for high-heat applications like stainless steel or titanium cutting.

- DLC (Diamond-Like Carbon): Great for sticky materials like aluminium, reducing built-up edge.

- PVD coatings: Popular for stainless steel and other tough alloys because they improve tool life and reduce friction.

Flute Count and Helix Angles

- 2-Flute Tools: Best for slots and better chip clearance, especially in softer materials.

- Helix Angles (45°–55°): Help evacuate chips faster and create smoother cuts.

- Upcut vs Downcut: Upcut pulls chips out of the cut, ideal for deep slotting. Downcut pushes chips down, preventing top surface damage—great for laminates and composites.

For beginners, we suggest starting with uncoated HSS end mills. Our starter kits provide a balanced option while you learn the ropes. As you progress, matching coatings and materials to your workpiece can dramatically improve tool life and part quality.

Applications and Real-World Use Cases Across Industries

End mill types play a key role across various industries, tailored to meet specific machining needs.

Automotive and Aerospace

- Ball nose end mills are popular for shaping complex contours in high-strength alloys.

- Roughing end mills handle heavy cuts when machining engine blocks and structural parts.

Mould and Die Making

- Tapered end mills are perfect for deep ribs and angled details.

- Finishing mills deliver mirror-smooth surfaces required for high-quality moulds.

Electronics and Medical

- Micro-diameter end mills are essential for precision tasks like implant components and intricate PCB features.

General CNC Work

- Slotting, profiling, and pocketing jobs benefit from the right flute count and geometry.

- Case study: Using Vast’s carbide end mills helped a workshop reduce cycle times by 30% without sacrificing finish or tool life.

Common Pitfalls and Fixes

- Neglecting the correct helix angle can cause issues with gummy metals like aluminium or stainless steel.

- Choosing the wrong flute count or coating leads to premature wear.

Matching the right end mill type to your application saves time, improves finish, and extends tool life—especially when paired with Vast’s specialised carbide tooling made for the United Kingdom market needs.

How to Select the Perfect End Mill A Step-by-Step Buyers Guide

Choosing the right end mill can seem overwhelming, but breaking it down makes it simple. Here’s how to pick the perfect tool for your job:

Assess Your Needs

Start by thinking about:

- Material hardness: Hard metals need tougher, coated tools. Soft materials allow more tool choices.

- Depth of cut: Deeper cuts require stronger end mills with proper flute design.

- RPM and finish: High speeds and smooth finishes require specific geometries such as ball nose or finishing mills.

If you’re working on complex 3D shapes, ball nose end mills are top choices. For slots or flat surfaces, square end mills are more suitable. Use a decision tree approach: if the workpiece or cut changes, reconsider your tool type.

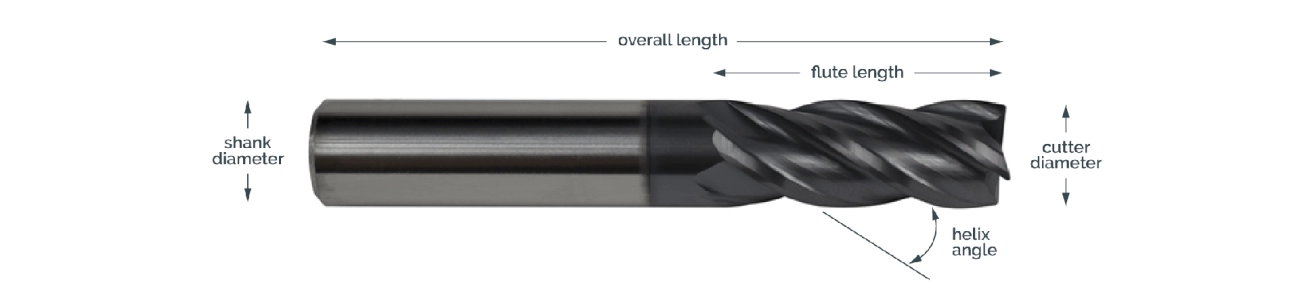

Consider Sizing Factors

- Diameter and length: Larger diameter end mills handle tougher jobs but require more power.

- Shank type: Plain shanks fit standard collets. Weldon shanks provide extra grip for aggressive cuts or vibration-prone setups.

Maintenance and Longevity Tips

Taking care of your end mills extends their lifespan and keeps your cuts clean:

- Use recommended speeds and feeds based on material and tool type.

- Always apply coolant or lubrication to reduce heat and wear.

- Store tools properly to avoid damage or corrosion.

Pro tip: For beginners, start with uncoated HSS end mills to learn the ropes without breaking the bank.

Want help sizing and selecting? Download Vast’s free end mill calculator spreadsheet to match your workpiece and machining needs perfectly.

Elevate Your Machining with Vast End Mills

At Vast, we focus on delivering precision-ground carbide end mills that withstand tough jobs and last twice as long as standard tools. Our commitment to quality means you get better performance and less downtime on every cut.

Top Picks from Vast

- Vast Pro Ball Nose Series – Perfect for 3D contouring and smooth finishes in aerospace and mould making.

- Vast 4-Flute Square End Mills – Great for high-feed roughing with excellent chip evacuation for steel and aluminium.

- Vast Corner Radius End Mills – Built for longer tool life and high-stress semi-finishing applications.

What Customers Say

“Switched to Vast end mills and cut my cycle times nearly in half without sacrificing finish quality.” — Jake M., CNC Operator

“I see way less tool wear with Vast’s carbide options, especially on tough titanium jobs.” — Sarah T., Aerospace Machinist

Ready to level up your machining? Shop Vast end mills now or subscribe for expert tool tips straight to your inbox.

FAQs Answering Common End Mill Questions

What’s the difference between end mills and face mills?

End mills cut on the sides and the tip, perfect for detailed shapes, slots, and pockets. Face mills mainly cut with their flat face, great for removing large amounts of material quickly and creating flat surfaces.

What’s the best end mill for wood?

A 2-flute straight or spiral end mill works best for wood. It clears chips well and reduces burning. Carbide tools are recommended for longer life.

How do I calculate the right flute count for my job? 2-flute: Ideal for slots and softer materials like wood, aluminium. Better chip clearance.

3-4 flute: Great for general purpose milling on harder materials like steel.

5-6 flute: Best for finishing passes where surface finish matters over chip clearance. Use fewer flutes for better chip removal, more flutes for smoother finishes.

Need help choosing the right end mill?

Check our extensive geometry selector tool or download our end mill calculator for precise recommendations tailored to your project.