Discover the essentials of thread profiles including geometry types, machining techniques, and standards for precision engineering and manufacturing.

Understanding Thread Profile Geometry

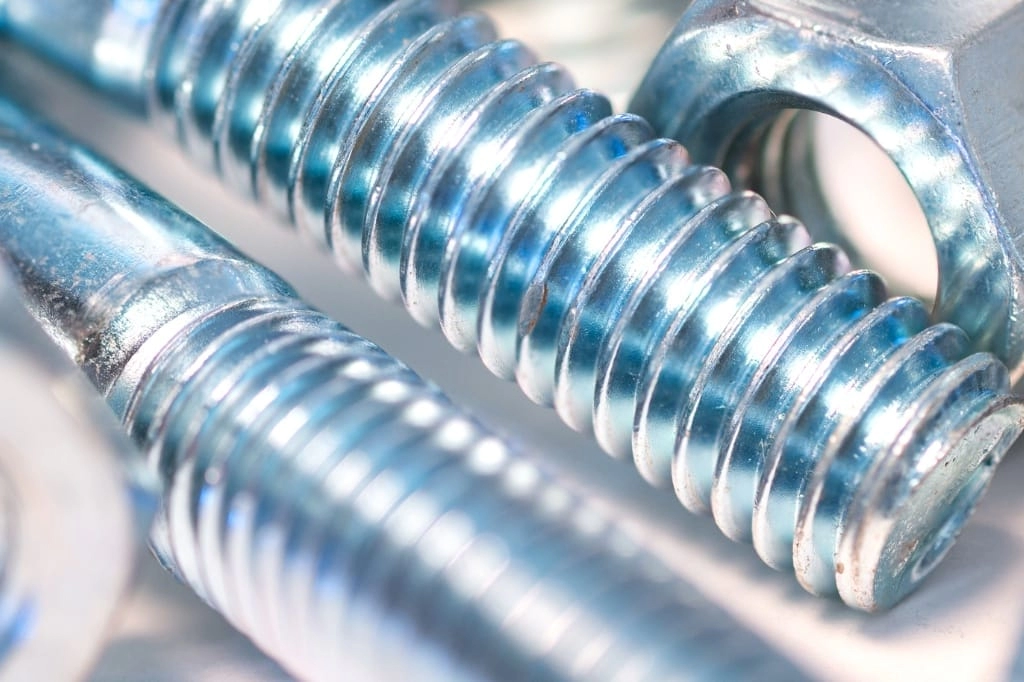

If you’ve ever struggled with a bolt that won’t fit or stripped threads, getting the basics of thread profile geometry can save you headaches. Thread profiles define the shape and size of the threads on screws, bolts, or nuts, affecting strength, fit, and function.

Core Elements of Thread Profile

Here are the main parts you need to know:

| Element | Description |

|---|---|

| Major Diameter | The largest diameter of the external thread (outside of the bolt) |

| Minor Diameter | The smallest diameter inside the threads (root of the thread) |

| Pitch | Distance between two adjacent thread peaks measured parallel to the axis |

| Flank Angle | The angle between the thread sides (or flanks) |

| Root and Crest Flats | The flat or rounded sections at the bottom (root) and top (crest) of threads |

Visualizing Thread Profiles

To picture this, imagine a basic V-profile thread:

- The major diameter is the broadest circle.

- The minor diameter sits where the “valleys” between threads lie.

- The pitch is the spacing between each “peak” or crest.

- The flanks slope at a set angle shaping the thread’s strength.

External threads (like on bolts) and internal threads (like in nuts) mirror each other but have different clearance and fit requirements.

Key Calculations to Know

- Pitch Diameter: An important theoretical diameter that lies between the major and minor diameters. It’s where thread engagement theoretically occurs.

- Pitch Diameter Formula: Typically for metric threads:[

d_2 = D – frac{0.6495 times p}{2}

]where (d_2) is pitch diameter, (D) is major diameter, and (p) is pitch. - Helix Angle: Defines how the thread “twists” around the axis. It affects load distribution and friction.

Common Pitfalls

One frequent cause of thread failure is confusing allowance and tolerance:

- Allowance is the intentional space or clearance between mating threads.

- Tolerance is the acceptable size variation during manufacturing.

If allowance and tolerance aren’t correctly accounted for, threads can be too tight, causing stripping or too loose, leading to poor load transfer.

In short: Proper fit controls thread life and performance.

Mastering these basics sets you up for understanding different thread profiles and machining techniques. Next, we’ll look at the types of thread profiles and when to use each.

Types of Thread Profiles

Thread profiles come in different shapes, each designed for specific uses like fastening, power transmission, or sealing. Here’s a quick look at the main types you’ll encounter:

| Profile Type | Thread Angle | Strength | Best Use | Notes |

|---|---|---|---|---|

| Symmetric V-Threads | 60° | Moderate | General fastening | Common in ISO Metric & UTS; easy to machine; pros: versatility, cons: more prone to wear |

| Buttress Threads | Asymmetrical | High in one direction | High pressure, heavy loads | Ideal for packaging, heavy machinery; strong on one flank only |

| Acme and Trapezoidal | 29° (Acme) / varies | Good efficiency | Leadscrews, motion control | Square-like shape; smooth motion and power transmission |

| Specialized Threads | Varies | Varies | Pipe connections & compact fits | NPT (tapered) used for pipes; Stub Acme for tight spaces |

Overview

- Symmetric V-Threads: These have a 60-degree angle and are the most common in the United Kingdom and international (ISO metric) markets. They offer balanced strength and easy manufacturing but can wear faster under heavy loads.

- Buttress Threads: Shaped asymmetrically to handle loads primarily in one direction, making them perfect for high-pressure packaging and heavy-duty applications. The asymmetric design adds strength where needed.

- Acme and Trapezoidal Threads: These profiles resemble square threads but are easier to machine. They excel in leadscrews and other motion control where efficiency and smooth linear movement are essential.

- Specialized Threads: Examples include NPT, which is tapered and widely used for sealing pipe joints, and Stub Acme, which shortens the thread height for compact fittings without sacrificing strength.

This snapshot should help you pick the right thread profile for your application, balancing strength, fit, and manufacturing needs.

Standards and Specifications

When it comes to thread profiles, knowing the right standards and specifications is key—especially here in the United Kingdom and for global projects.

Global Benchmarks

- ISO 68-1: The go-to for metric threads worldwide. Defines basic profile geometry for ISO metric threads.

- ASME B1.1: Covers Unified Thread Standard (UTS) inch threads, popular in the United Kingdom for bolts, nuts, and fasteners.

Tolerance Classes and Their Impact

Threads come in classes ranging from 1A (loose fit) to 3A (tight interference fit). The class you select affects:

- How easily parts fit together

- Load handling and strength

- Risk of stripping or galling

| Class | Fit Type | Typical Use |

|---|---|---|

| 1A | Loose fit | Quick assembly, low precision |

| 2A | Standard fit | Most general applications |

| 3A | Tight fit | High strength critical parts |

Tools for Verification

Quality control relies on:

- Thread gauges to quickly check go/no-go fits

- Profile templates for detailed shape verification

- Advanced methods like optical and laser scanning ensure precise thread form.

Local UK Preferences

- The UK favours Unified Thread Standard (UTS) with inch sizes over metric.

- Imperial units dominate, so quick conversion tools are handy on international jobs.

- Being fluent in both helps avoid costly thread mismatches or delays.

Understanding and applying the right standards and tolerances safeguards your threads from misfit issues and guarantees performance across industries.

Machining Thread Profiles Techniques Tools and Best Practices

When it comes to machining thread profiles, there are several effective techniques and tools to consider, depending on your needs—from strength to precision and even custom designs.

Common Machining Methods

- Single Point Cutting on LatheIdeal for simple threads. This method uses a single cutting tool to create threads by moving in sync with the rotating workpiece. Great for steel or aluminium but requires proper speeds and feeds to avoid tool wear or poor finish.

- Thread Rolling and FormingInstead of cutting, this method cold-forms threads by pressing the material. It strengthens the thread by aligning the grain and is common for high-volume production where strong fasteners are needed.

- CNC Milling and Thread MillingCNC allows complex and custom thread profiles. Thread milling machines follow a helical path, which is perfect for tight tolerance internal threads and difficult materials.

- Grinding for Ultra-PrecisionUsed mainly in aerospace or medical sectors, thread grinding offers fine finishes and tight tolerances, ideal when accuracy and surface finish are critical.

Lathe Threading Setup Basics

Setting up your lathe for threading requires attention to detail:

- Choose the correct threading tool shaped for your thread profile (V, Acme, Buttress, etc.).

- Match spindle speed and feed rate to your material. For aluminium, higher speeds and feeds work; steel demands slower rates to protect the tool.

- Use proper lubrication to reduce friction and tool wear.

Thread Milling Advantages

- More flexible for custom threads and fine adjustments.

- Better for internal threads since the milling tool can approach from different angles.

- Less risk of tool breakage compared to single-point threading.

Tools and Software Integration

- Taps, Dies, Inserts – Essential for manual threading and repairs.

- Software like SolidWorks – Supports custom thread profile design and export for CNC programming, enabling exact machining of non-standard threads.

Optimising 3D Printed Threads

- Adjust layer height carefully for thread clarity and fit.

- Avoid chatter with proper print speed adjustments.

- Use vibration damping methods to improve surface finish.

Troubleshooting Common Issues

| Issue | Cause | Solution |

|---|---|---|

| Poor thread fit | Incorrect pitch or diameter | Verify measurements and tooling |

| Tool wear | High speed/feed or poor lubrication | Lower speed, improve coolant |

| Surface roughness | Vibration or dull tool | Use proper tooling, stabilise workpiece |

| Thread stripping | Mismatched tolerances | Review allowance and clearance |

By choosing the right machining technique and setup, and pairing it with the right tools, you can produce strong, accurate threads suitable for a wide range of applications—whether for automotive bolts or custom aerospace fasteners common here in the UK.

Applications and Industry Insights

Thread profiles play a significant role across various industries here in the UK, from automotive to energy and packaging. In automotive manufacturing, precise thread profiles ensure bolts withstand high stress and vibration. Packaging often uses specialised threads for caps and closures that require quick, reliable seals and easy opening. In energy sectors, especially oil and gas, API-standard threads like buttress profiles are common because they handle heavy loads and high pressure without failing.

A great example is the use of custom buttress thread profiles in chemical-resistant closures. These specialised threads significantly improve sealing, reducing leaks and extending product life. This has been a game changer for companies dealing with harsh chemicals and strict safety standards.

We’re also witnessing major shifts with 3D printing entering the threading industry. 3D printing allows for custom threads with tighter tolerances and unique geometries that were previously difficult to machine. Additionally, sustainable materials are becoming more popular, with threads designed to perform well in biodegradable plastics or recycled composites, aligning with the UK’s push for eco-friendly manufacturing.

In short, thread profiles matter more than ever, adapting to new technology and more demanding requirements across industries.