Vast offers precision aluminium surface finishing with anodising, hardcoats, powder coating, and electropolishing for durable corrosion-resistant results.

Product Overview

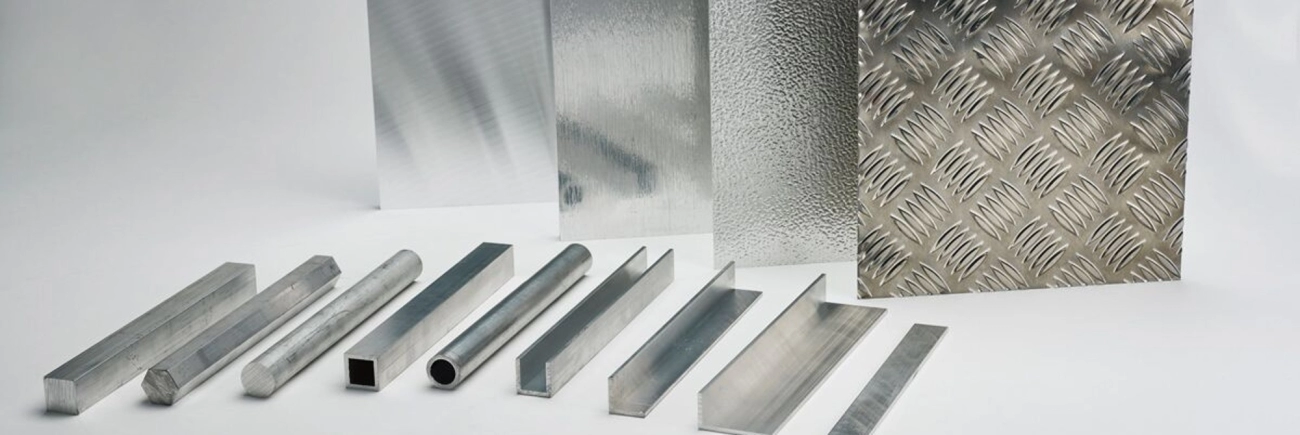

Vast Aluminium Surface Finishing provides precision-engineered treatments that enhance the durability, appearance, and performance of aluminium parts. Our advanced finishing solutions cater to a wide range of applications—from architectural panels and automotive parts to aerospace components and electronics. By combining proven processes with cutting-edge technology, Vast ensures every aluminium surface meets strict quality and functional standards. Whether you need corrosion-resistant protection, improved aesthetics, or specialised functional coatings, Vast delivers consistent, reliable results tailored to your project’s requirements.

Key Features of Aluminium Surface Finishing

Our aluminium surface finishing offers a range of features designed to improve performance, appearance, and compliance for applications in the United Kingdom:

| Feature | Description |

|---|---|

| Corrosion Resistance | Hard anodising and chemical conversion coatings protect parts in harsh environments, enhancing lifespan. |

| Aesthetic Versatility | Options such as mechanical polishing, brushing, and powder coating provide matte, satin, or high-gloss finishes to suit any design. |

| Functional Enhancements | Add-ons such as non-stick PTFE infusions, electrical insulation layers, and wear-resistant hardcoats improve part functionality. |

| Eco-Compliant Processes | We utilise chromate-free conversion coatings and low-VOC powder coatings that meet strict environmental regulations in the United Kingdom. |

| Scalability | From one-off prototypes to full production runs, we maintain strict surface roughness control and consistent quality. |

These features ensure your aluminium parts are durable, attractive, and compliant with industry standards. For precision-machined components requiring top-quality finishing, combining our services with our precision turning parts manufacturing capabilities guarantees exceptional quality and finish.

Available Finishing Processes

Our aluminium surface finishing options encompass a wide range of treatments designed to meet both functional and aesthetic needs:

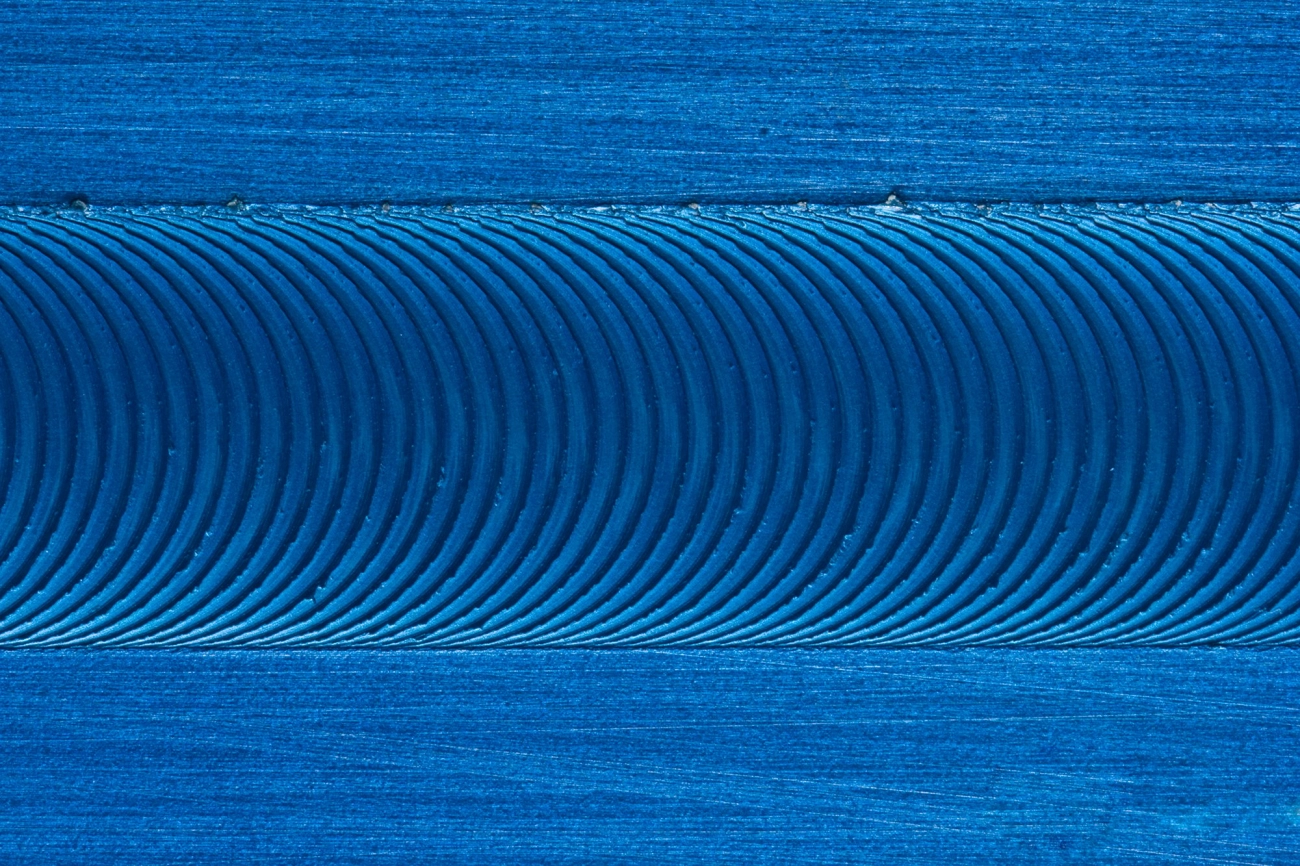

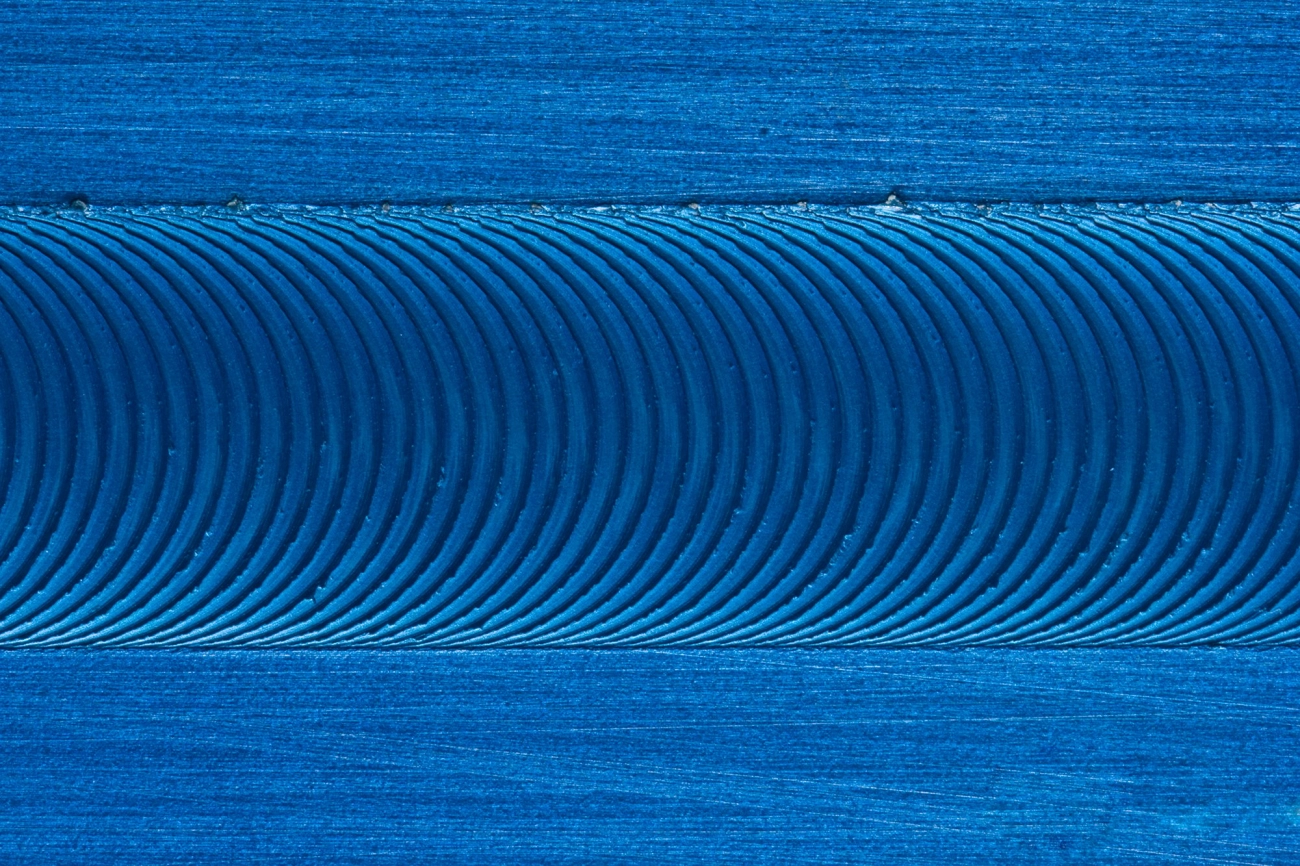

- Anodising: Including Type II sulphuric acid anodising and Type III hardcoat anodising, we offer coatings from 5 to 50 µm thickness. All processes comply with MIL-A-8625 standards, ensuring excellent corrosion resistance and durability.

- Powder Coating: We use high-quality thermoset polyester and epoxy powder blends certified to AAMA 2604/2605 for long-lasting colour and corrosion protection.

- Electropolishing: This process reduces surface roughness (Ra) by up to 80%, making it ideal for sanitary applications and parts with decorative appeal.

- Mechanical FinishingOptions such as Scotch-Brite brushing, bead blasting, and vibratory tumbling provide satin, matte, or textured finishes tailored to your requirements.

- Chemical Conversion CoatingsAlodine and Iridite treatments offer trivalent chromium passivation, enhancing corrosion resistance without the use of chromates.

- PVD & Specialised CoatingsFor ultra-hard surfaces, select from titanium nitride (TiN), diamond-like carbon (DLC), and ceramic infusions that improve wear resistance and create unique visual effects.

These finishing processes ensure versatility for a broad range of applications, from architectural aluminium to high-precision components. For parts requiring tight dimensional tolerances, our close collaboration with advanced machining services guarantees consistent finishes that complement precision machining capabilities. You can learn more about our expertise in high-precision components on the high-precision CNC machining services page.

Technical Specifications of Aluminium Surface Finishing

Here is a clear comparison of key aluminium surface finishing options — anodising, powder coating, and electropolishing — covering thickness, hardness, salt spray resistance, colour options, and maximum part size:

| Feature | Anodising (Type II & III) | Powder Coating (Polyester/Epoxy) | Electropolishing |

|---|---|---|---|

| Thickness | 5–50 µm (MIL-A-8625 Compliant) | 40–80 µm | Surface smoothing only |

| Hardness | 40–60 HRC (Type III Hardcoat) | Moderate, impact-resistant | No coating; bright, smooth surface |

| Salt Spray Resistance | Up to 1000+ hours (Type III) | 500–1500 hours (AAMA 2605) | Minimal corrosion protection |

| Colour Options | Clear, black, custom tints | Full RAL spectrum | Natural metallic finish |

| Max Part Size | Up to 120″ length (custom sizes possible) | Large panels and parts | Limited by equipment size |

Highlights:

- Anodising offers a hard, corrosion-resistant barrier with colour options and MIL-A-8625 certification, great for harsh environments.

- Powder coating delivers thick, colourful, and durable finishes with excellent weather resistance, perfect for architectural and automotive parts.

- Electropolishing is ideal for achieving ultra-smooth, clean finishes mainly for decorative and sanitary applications but less corrosion protection.

For precise dimensional control, surface roughness, and finishing consistency, these specifications ensure the right finish for your aluminium component’s needs. We also recommend reviewing our guide on precision grinding to complement your finishing process for superior results.

Applications of Aluminium Surface Finishing

Our aluminium surface finishing is ideal for a wide range of industries thanks to its durability and adaptability. In architecture, it enhances curtain walls, cladding, and metal façades with corrosion-resistant and visually appealing finishes. The automotive sector benefits from precision finishes on trim, wheels, and body parts that improve aesthetics and wear resistance. Aerospace applications demand high-strength coatings for structural brackets and interior fittings, meeting strict safety and performance standards. Marine environments use our finishing for hull fittings and railings to withstand harsh conditions and saltwater corrosion. Electronics manufacturers rely on these finishes to optimise heat sinks and enclosures for better thermal management and electrical insulation. For projects requiring custom aluminium finishing, our processes deliver consistent quality across all these applications.

Explore related capabilities linked to precision metalwork like our comprehensive guide to milling cutter types and their applications to understand how aluminium components fit into broader manufacturing workflows.

Quality Assurance

Our aluminium surface finishing process is backed by an in-house ISO 17025 accredited lab, ensuring precise measurement of coating thickness, adhesion, and gloss levels. We use real-time process monitoring with SPC (Statistical Process Control) software to maintain consistent quality throughout production. Every batch comes with full traceability through lot-coded certificates of conformance, giving you confidence that your finished aluminium components meet exact standards. This rigorous quality control sets us apart in delivering reliable, high-performance finishes for all your applications.

Sustainability in Aluminium Surface Finishing

We take sustainability seriously in our aluminium surface finishing processes. Our anodising lines use zero-discharge water recycling systems to minimise environmental impact while maintaining high-quality finishes. Powder coating overspray is captured and recovered at rates greater than 98%, reducing waste and conserving materials. Plus, we partner with certified aluminium recyclers to ensure any scrap or off-spec material is reprocessed responsibly. This approach helps us deliver eco-friendly surface treatments without compromising performance or durability.

Lead Times & MOQ

We understand the need for quick turnaround and flexibility in order size. Prototypes can be delivered within 3–5 working days, allowing you to test and refine your designs quickly. Once approved, production runs typically ship within 7–14 days, ensuring you meet your project deadlines without delay. There’s no minimum order quantity, making our aluminium surface finishing services ideal whether you’re ordering a single custom part or large batches. Plus, we offer volume pricing tiers to give you cost savings as your order size grows.

Request for Quotation

To get started with your aluminium surface finishing project, submit your STEP or IGES drawings with detailed finish callouts. We’ll review your specifications and provide design-for-manufacturing feedback within 24 hours. This quick turnaround helps you optimise your parts for coating durability, appearance, and functionality before production begins.

For best results, ensure your drawings clearly specify the type of finish needed, such as anodising, powder coating, or electropolishing. This clarity helps us align your requirements with the most suitable processes and meet your project timelines efficiently.

If you’re looking for customised aluminium finishing solutions that fit your precision manufacturing needs, check out our expert custom manufacturing services for more details.