Discover the best cutters for lathe use including types, selection tips, and maintenance advice for precision turning and metalworking projects.

Struggling to find the perfect cutter for your lathe? Whether you’re a weekend hobbyist or a seasoned machinist, using the right cutting tool can make all the difference between a clean, precise cut and a frustrating, rough finish. In this guide, you’ll discover how to choose and use lathe cutters that fit your project, material, and machine—boosting your accuracy and efficiency without breaking the bank. Ready to take your turning skills up a notch? Let’s dive into everything you need to know about picking, installing, and maintaining the ideal lathe cutter.

Understanding Lathe Cutters

A cutter for lathe is the tool that actually shapes your workpiece by removing material during the turning process. Simply put, it’s the part of your lathe setup that does the cutting, facing, threading, or boring. These cutters come in different shapes and sizes, but all share the same goal: to produce precise, clean cuts on metal, wood, or plastic.

Purpose of Lathe Cutters

The key purpose of lathe cutters is to transform raw stock into finished parts by shaping the surface accurately according to your project specifications. Whether you want to rough out a block of metal or create intricate threads, the right cutter makes that happen efficiently. Using the proper cutter helps you improve surface finish, extend tool life, and maintain consistent dimensions.

Key Components of Lathe Cutters

Most lathe cutters have a few common components worth noting:

- Cutting Edge: The sharp part that engages the material—can be straight or curved depending on the cutter type.

- Body or Shank: The main structural part held by the lathe tool holder, usually made of high-speed steel (HSS) or carbide.

- Insert (if applicable): Many modern cutters use replaceable carbide inserts for easier maintenance and better wear resistance.

- GeometryThe angle and shape of the cutting edge designed to optimise chip removal and surface finish.

Understanding these basics prepares you to choose the right cutter that fits your lathe and project needs. In the next sections, we’ll explore the most common types of cutters and how to select the perfect one for your workshop.

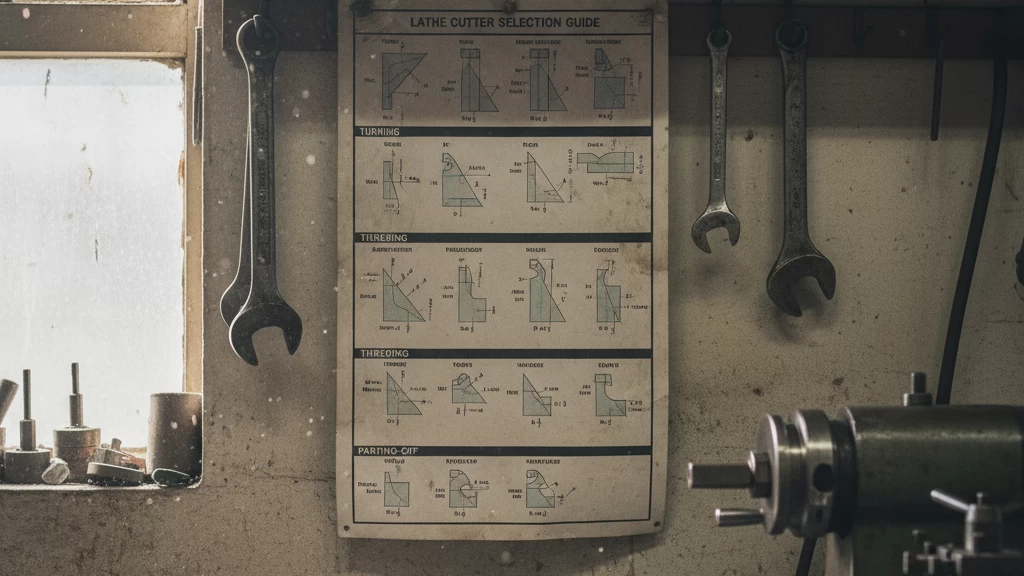

Types of Cutters for Lathes

When working with a lathe, selecting the appropriate cutter for the task is essential. Here’s a quick overview of the main types of cutters for lathe machines and their optimal applications:

| Cutter Type | Purpose | Common Features |

|---|---|---|

| Roughing Tool | Removes large quantities of material | Durable, designed for rapid cutting |

| Finishing Tool | Smooths and refines the surface | Sharp edges, precise cutting |

| Parting Tool | Cuts off (sections) parts | Thin blade, fits into tight spots |

| Threading Tool | Cuts threads on shafts | Special profile, precise angle |

| Boring Tool | Enlarges or finishes holes | Adjustable, often have replaceable tips |

| Form Tool | Shapes specific profiles | Custom shapes, used for repeat patterns |

Roughing tools are your go-to for heavy cuts on tough metals like steel or cast iron. For fine work on softer materials, finishing tools keep your surface smooth and accurate.

If you need to slice off a piece cleanly, the parting tool for lathe is designed for minimal material waste and maximum control. When creating threads, the threading tools lathe offer precise cuts that fit standard thread profiles.

Boring tools are perfect for inside diameters, helping to get a clean round finish or enlarge holes without vibration. Lastly, form tools are mostly custom cutters made for shaping complex profiles in one go—handy for repeated or specialised parts.

Understanding these types helps you pick the right lathe turning tools for better results and less wear on your machine.

How to Select the Perfect Cutter for Your Lathe Setup

Picking the right cutter for your lathe is key to getting clean cuts and saving time. Here’s how to match your cutter with your lathe setup:

- Know Your Lathe Type: Different lathes (manual, CNC, metal, or wood) need different cutters. CNC lathes often require precision lathe inserts or specialised tooling, while manual metal lathes work fine with standard HSS lathe bits or carbide inserts for lathe.

- Consider the Material: The material you’re working on affects cutter choice. Hard metals like stainless steel require carbide inserts for lathe to stay sharp, while softer metals like aluminium can be handled well with HSS lathe bits.

- Size and Geometry Matter: The cutter’s size must fit your lathe’s tool holder. Also, the geometry of the cutter—its shape and angle—affects how smoothly it cuts, especially for threading tools lathe or form tools.

- Budget: Carbide cutters cost more but last longer and perform better on tough materials. HSS cutters are budget-friendly and easy to sharpen but wear out faster.

- Selection Checklist:

- Type of lathe (manual or CNC)

- Material hardness

- Cutter size and compatibility with your lathe tool holders

- Type of operation (roughing, finishing, parting)

- Budget constraints

- Availability of replacement tips or inserts

Using this checklist will help you pick the best cutter for lathe tasks, whether you’re a hobbyist or a professional in the United Kingdom market looking for reliable metal lathe cutters.

Essential Accessories and Setup for Optimal Cutter Performance

To get the best results from your cutter for lathe, having the right accessories and setup is just as important as the cutter itself. Here’s what you should have on hand:

- Tool Posts: A solid tool post holds your lathe cutter steady during operation. Quick-change tool posts let you swap tools fast, boosting productivity and keeping your cuts precise.

- Coolants: Using a good coolant reduces heat and wear on cutters—especially important with carbide inserts or when working with tough metals. Choose a liquid or mist coolant depending on your lathe and material.

- Measuring Tools: Accuracy is king. Digital calipers, micrometers, and dial indicators help you measure your workpiece and adjustments precisely, ensuring your lathe cutter’s performance meets your exact specifications.

- Storage Solutions: Proper storage extends the life of your cutters. Use labelled cases or racks to keep HSS lathe bits, carbide inserts, and threading tools organised and protected from damage or rust.

A well-planned setup with these essentials will help you maintain cutter sharpness, improve cutting quality, and keep your lathe running smoothly for every job.

Step-by-Step Guide: Installing and Using Cutters on Your Lathe

Getting your lathe cutters set up and running smoothly is key to quality work and safety. Here’s a simple step-by-step to help:

Safety Preparation

- Wear PPE: Always use safety glasses, gloves, and hearing protection.

- Power off: Make sure the lathe is turned off before installing or adjusting cutters.

- Clear workspace: Remove any loose tools, chips, or debris around the machine.

- Check tool condition: Inspect your cutter and tool holder for any damage before mounting.

Installing the Cutter

- Choose the right tool holder: Match your cutter with a compatible lathe tool holder or post.

- Secure firmly: Clamp the cutter into the holder tightly to prevent movement during operation.

- Set height correctly: Align the cutter tip with the centreline of the lathe spindle for accurate cuts. Use a height gauge or test cut if unsure.

- Tighten all fasteners: Double-check all bolts and screws to avoid loosening while running.

Basic Operations

- Start slow: Begin with a low spindle speed and shallow cuts to test the setup.

- Feed rate: Adjust feed according to the material and cutter type for a smoother finish.

- Watch for chatter: If you hear or feel vibrations, reduce speed or check cutter rigidity.

- Use coolant: Apply coolant or cutting oil to extend cutter life and reduce heat.

Advanced Operations

- Threading and parting: For threading tools or parting cutters, double-check alignment and use precise depth control.

- Form tools: When using form cutters, slow down to maintain the shape and avoid tool damage.

- CNC setups: For CNC lathes, ensure your cutter paths and programmes are verified before running the machine.

Troubleshooting

- Poor finish: Check cutter sharpness, alignment, and feed rate. Dull tools cause rough cuts.

- Tool breakage: Make sure the toolholder is locked tight and avoid oversized cuts.

- Inaccurate sizing: Verify the height setup and replace any worn tool holders or inserts.

- Overheating: Increase coolant flow or reduce speed/feed to cool down the cutter.

Following these steps keeps your lathe cutting strong and reliable, minimising downtime and boosting your results.

Maintenance and Sharpening

Keeping your cutter for lathe in top shape means regular maintenance and sharpening. Here’s what I recommend for daily care and long-term performance:

- Daily Care: Clean cutters after each use to remove metal chips and coolant residue. Use a soft brush or cloth—avoid harsh chemicals. Inspect the cutting edge for nicks, chips, or wear before and after every job.

- Sharpening Methods:

- For HSS lathe bits, use a bench grinder or sharpening stones. Pay attention to maintaining the correct angle for your tool’s geometry.

- Carbide inserts usually are disposable but some can be honed slightly. Most users replace them once dull.

- Use a proper jig or guide for consistent sharpening, especially for threading tools and form cutters.

- Replacement Indicators:

- Dull, chipped, or uneven cutting edges can cause poor finishes and tool chatter.

- Increased cutting force or unusual noises are signs you need to sharpen or replace the cutter.

- For modular cutters, swapping out worn tips is often easier and more cost-effective than full-tool replacement.

- Modular Cutter Tips: Many modern lathe cutters feature replaceable carbide tips. Keeping a stock of these saves downtime—just switch out the tip when dull, no full tool resharpening required.

Regular maintenance ensures your lathe cutters work efficiently, extend tool life, and keep your projects running smoothly.

Safety Best Practices for Lathe Cutters

Working with lathe cutters means you need to stay sharp—safely. Here’s how to keep yourself and your workshop protected while getting the job done:

Personal Protective Equipment (PPE)

- Safety glasses or face shields to protect against flying chips and debris

- Gloves for handling tools, but avoid wearing them near spinning parts to prevent entanglement

- Hearing protection if your lathe runs loud

- Close-toed shoes to keep feet safe from dropped tools or parts

Machine Safeguards

- Always use lathe guards to shield moving parts

- Keep the tool post tight and secure to prevent cutters from slipping or moving unexpectedly

- Make sure emergency stop buttons are within reach and fully functional before starting

Risk Assessment

- Check your setup for any loose components or damaged cutters before power-up

- Avoid wearing loose clothing, jewellery, or long hair uncovered to prevent catching in the machine

- Plan your cuts considering material, cutter type, and feed speed to avoid overloading the lathe

Emergency Protocols

- Know how to quickly shut off your lathe in case of malfunctions

- Keep a first aid kit accessible in your workspace

- Have a fire extinguisher nearby, especially when working with metal on metal

Sticking to these safety basics will keep your work smooth and your shop accident-free. Your lathe cutters do great work—make sure you do too by staying safe!

Top Recommendations: Best Lathe Cutters for UK Makers in 2025

Looking for the best cutter for lathe in 2025? Here’s a quick rundown of top picks trusted by UK makers, along with a simple buying guide and key features.

| Cutter Type | Recommended Brand/Model | Material | Best For | Key Features |

|---|---|---|---|---|

| Roughing Tool | Kennametal Carbide Inserts | Carbide | Heavy cuts, metal removal | Long life, heat resistant, precise cuts |

| Finishing Tool | SGS HSS Lathe Bits | High-Speed Steel | Smooth finishes | Sharp edges, easy to resharpen |

| Parting Tool | Dorian Tool Parting Blade | Carbide/HSS | Cutting off parts | Thin profile, strong, minimal chatter |

| Threading Tool | Valenite Threading Insert | Carbide | Thread cutting | Accurate thread profiles, durable inserts |

| Boring Tool | Iscar Boring Bar | Carbide | Internal cuts | Adjustable, rigid, good insert options |

| Form Tool | WNT Form Cutters | Carbide | Shaped profiles | Custom shapes, strong carbide tips |

Buying Guide Highlights for Lathe Cutters

- Match cutter type to your project: Pick roughing cutters for fast metal removal and finishing cutters for clean surfaces.

- Material matters: Carbide inserts last longer and handle heat better, while HSS bits are easier and cheaper to sharpen.

- Tool holder compatibility: Ensure your cutter fits your lathe’s tool post or holder.

- Budget: Quality carbide tools cost more initially, but they save time and reduce wear in the long term.

- Precision: Choose inserts or bits with good edge sharpness and consistent geometry.

Why Makers in the United Kingdom Prefer These Brands

- Availability and service are excellent in the United Kingdom for these brands.

- They balance quality, price, and durability well for small workshops and hobbyists alike.

- Many products offer modular tips or inserts, saving money on replacements.

For 2025, focus on carbide inserts if you want durability and performance, especially for CNC lathe tooling. But keep a set of HSS lathe bits handy for quick repairs and simple jobs.

Selecting the right cutter for lathe work helps you stay efficient and achieve accurate results, whether you are a professional or a weekend maker.