Discover blackening coating for corrosion-resistant, matte black metal finishes with expert insights on types, benefits, and applications.

If you’re dealing with metal surfaces that need toughness and style, blackening coating might just be the game-changer you’ve been searching for. This sleek, black oxide finish not only boosts corrosion resistance but also keeps your metal parts lightweight and dimensionally stable—perfect for everything from automotive components to DIY projects. Whether you’re curious about the science behind the process or wondering how to get that flawless matte black look, this guide will break down everything you need to know about blackening coatings—and why experts trust it for long-lasting, high-performance finishes. Ready to unlock the power of blackening on your next metal project? Let’s dive in!

What Is Blackening Coating Demystifying the Basics

Blackening coating, often called black oxide finish for steel, is a chemical treatment that creates a thin, bonded layer of magnetite (Fe3O4) on the surface of ferrous metals like steel and iron. Unlike painting or traditional plating, which add material on top of the metal, blackening changes the surface itself through a controlled chemical reaction. This conversion coating turns the metal surface black, enhancing its corrosion resistance and giving it a sleek, uniform appearance without altering the part’s dimensions.

The Science Behind Black Oxide Conversion

The process involves submerging metal parts in a hot, alkaline solution containing oxidising agents. This causes the metal’s surface to convert into magnetite, a stable, corrosion-resistant layer. The magnetite layer is ultra-thin—measured in microns—and remains tightly bonded, which improves durability and wear resistance. Since it’s a conversion coating, the metal retains its original texture and strength, unlike thicker coatings like paint.

Key Components and How It Differs from Plating or Painting

- Conversion Process: Blackening chemically converts the metal surface instead of depositing a new layer.

- Thickness: The black oxide layer is much thinner, preserving precise dimensions critical in manufacturing.

- Corrosion Resistance: Offers moderate protection, often enhanced by oil impregnation after treatment.

- Appearance: Produces a uniform matte or semi-gloss black finish without peeling or chipping.

Compared to plating methods like zinc plating or anodising, blackening is typically less bulky and can be more cost-effective for parts that need moderate corrosion protection without sacrifices in form or fit. Painting covers surfaces but doesn’t bond chemically; black oxide becomes part of the metal itself, providing lasting benefits for both aesthetics and function.

Types of Blackening Coatings Hot Mid and Cold Processes Compared

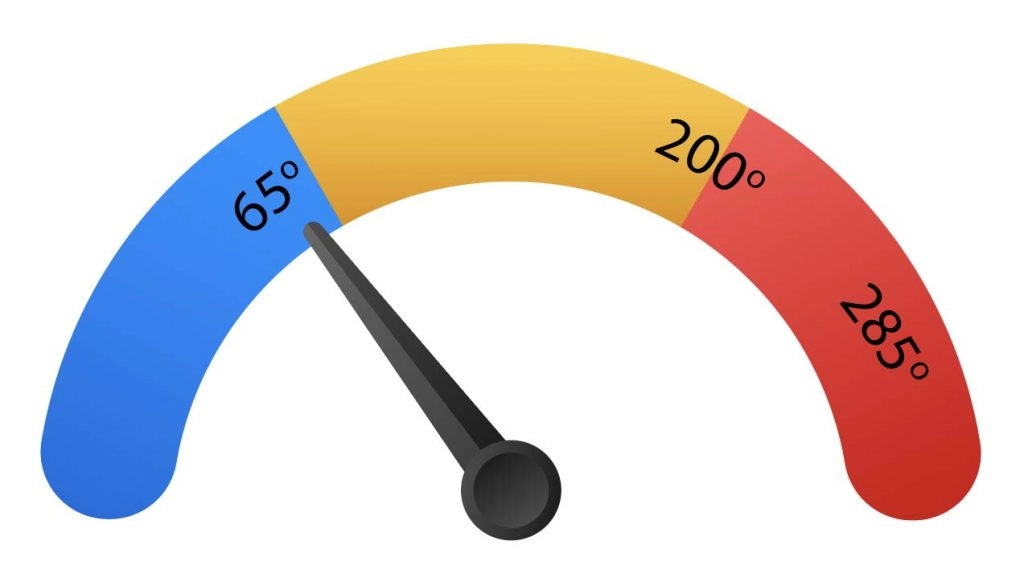

Blackening coatings come in three main types: hot, mid, and cold. Each serves different needs depending on durability, safety, and application.

Hot Black Oxide The Industry Standard for Durability

This is the most common black oxide finish for steel, known for its strong, corrosion-resistant metal coating. The hot blackening process involves immersing parts in a hot chemical bath (around 285°F), creating a tough magnetite conversion coating. It’s ideal for automotive and industrial parts where long-lasting protection is a must.

Mid-Temperature Blackening Safer and Eco Friendly

Mid-temperature blackening works at lower temperatures (around 190–210°F), making it safer and more environmentally friendly. It still offers good corrosion resistance but uses less harsh chemicals and energy. This method suits businesses focused on greener processes and a large volume of parts with solid performance.

Cold Room-Temperature Blackening Ideal for DIY and Touch-Ups

Cold blackening occurs at room temperature, perfect for quick jobs, touch-ups, or small-scale projects. It’s user-friendly, making it popular for gun bluing alternatives and oil-impregnated black finishes done at home or small workshops. While not as durable as hot or mid-temperature methods, it’s a handy and accessible option for maintaining ferrous metal surfaces.

Each type has its place, depending on the balance you need between durability, safety, and ease of use.

Top Benefits of Blackening Coating Why It’s a Game Changer for Metal Parts

Blackening coating offers some strong advantages that make it a preferred choice for metal parts in the United Kingdom market. Here’s why it stands out:

Enhanced Corrosion Resistance and Lubricity

- Corrosion Resistance: The black oxide finish for steel creates a thin, protective magnetite conversion coating that slows rust and wear. Perfect for parts exposed to moisture and tough conditions.

- Lubricity: It improves surface smoothness which reduces friction, making moving parts last longer and work better.

Aesthetic and Functional Advantages

- Sleek Look: The uniform black finish looks clean and professional—great for automotive parts, tools, and architectural hardware where appearance matters.

- Non-Reflective Surface: Useful in firearms and electronics where glare reduction is key.

- Oil-Impregnated FinishMany blackening coatings trap oil on the surface, providing additional moisture protection and a smooth feel.

Cost and Efficiency Advantages

| Benefit | Details |

|---|---|

| Low Cost | Cheaper than plating or anodising |

| Fast Process | Quick application and drying times |

| Eco-Friendly Options | Mid and cold blackening reduce chemical waste |

| Easy Maintenance | Requires less frequent touch-ups |

In short, blackening coating offers a tough, attractive, and cost-effective metal treatment that performs well and looks great across many industries.

Applications of Blackening Coating Across Industries

Blackening coating is widely used across many industries due to its combination of durability, corrosion resistance, and attractive finish. Here’s how different sectors benefit from this versatile surface treatment:

Automotive and Aerospace Precision Under Pressure

In automotive and aerospace, black oxide finish for steel provides a reliable way to protect metal parts without adding bulk. It helps prevent rust in critical components like gears, fasteners, and engine parts, ensuring long-lasting performance under high stress and varying temperatures. The coating enhances wear resistance while maintaining tight tolerances, which is essential for precision.

Tools, Firearms, and Architectural Hardware

Blackening coating is a preferred choice for tools and firearms, offering a tough, corrosion-resistant metal coating that also reduces glare. Gun bluing alternatives such as black oxide are popular because they provide good protection without compromising the metal’s strength. Architectural hardware, such as door handles and locks, also uses blackening coatings for both aesthetic and protective reasons, giving a sleek, oil-impregnated black finish that resists fingerprints and scratches.

Emerging Uses in Electronics and Medical Devices

Recently, black oxide coatings have been adopted in electronics and medical device manufacturing. The mid-temperature blackening benefits include safer application methods suitable for sensitive equipment parts. The magnetite conversion coating can improve electrical grounding and wear resistance without interfering with performance. Additionally, room temperature black oxide DIY options are being explored for small-scale repairs and prototyping in these fields.

Overall, blackening coatings provide value by combining corrosion protection, aesthetic appeal, and functional durability across a broad range of industries in the United Kingdom market.

The Blackening Coating Process Step by Step from Vast Experts

If you’re considering blackening coating for your metal parts, understanding the process can help get the best results. Here’s a simple breakdown from prep to finish, straight from industry experts.

Preparation and Safety Essentials

- Clean the Surface: Start by removing dirt, grease, and rust. Use a degreaser and sometimes a mild acid bath to prep the steel or ferrous metal surface.

- Safety Gear: Always wear gloves, goggles, and protective clothing. Many blackening solutions involve chemicals that can irritate skin or eyes.

- Work in a Ventilated Area: Proper airflow is key because fumes can be harmful, especially with hot or mid-temperature blackening processes.

Application Techniques and Best Practices

- Hot Blackening: Submerge parts in a heated alkaline salt solution at around 285°F to 310°F. This forms a magnetite conversion coating—the hallmark black oxide finish for steel that’s both durable and corrosion-resistant.

- Mid-Temperature Blackening: A gentler process done between 190°F and 210°F. It’s safer and more eco-friendly but still offers a solid black finish and decent protection.

- Cold Blackening: Done at room temperature, usually with spray or dip-on chemicals. It’s perfect for quick touch-ups or DIY projects, but less durable than hot or mid processes.

- Consistent Dwell Time: Keep parts in solution for the recommended time based on the method—too little or too long can affect the coating’s quality.

Post Treatment for Maximum Protection

- Oil or Wax Dip: After blackening, soak or wipe parts with oil to seal the surface. This improves corrosion resistance, adds lubricity, and gives that rich, black look.

- Drying: Allow parts to dry fully to lock in the coating and avoid any moisture that can cause rust.

- Regular Maintenance: Clean and oil coated parts regularly to keep corrosion-resistant metal coatings working long term.

By following these steps, you ensure your black oxide finish is both attractive and hard-wearing—perfect for automotive, firearms, tools, or any ferrous metal surface treatment needs.

Pros, Cons, and Comparisons: Is Blackening Right for Your Project?

Deciding if blackening coating fits your needs means weighing its benefits against any downsides — plus comparing it to other popular finishes like zinc plating or anodising. Here’s a quick rundown to help you decide.

Advantages of Blackening Coating

- Great Corrosion Resistance: The magnetite conversion coating protects steel from rust better than no treatment.

- Improved Lubricity: The oil-impregnated black finish reduces friction, ideal for moving parts.

- Natural Appearance: It gives a sleek black finish without paint or thick coatings.

- Cost-Effective: Generally cheaper than anodising or zinc plating.

- Thin Coating: Retains tight tolerances on precision parts.

- Environmentally Friendly Options: Mid and cold blackening processes reduce hazardous wastes.

Drawbacks

- Limited to Ferrous Metals: Works mostly on steel and iron, not on aluminium or non-ferrous metals.

- Moderate Durability: Not as hard or thick as anodising, which may matter in extreme wear conditions.

- Surface Preparation Needed: Requires clean, well-prepared surfaces to adhere properly.

- Less Protective Alone: Often combined with oil or wax for optimal corrosion resistance, which may diminish over time.

Blackening Coating vs Zinc Plating vs Anodising

| Feature | Blackening Coating | Zinc Plating | Anodising |

|---|---|---|---|

| Metal Compatibility | Steel, iron | Steel, iron, some alloys | Aluminium and some metals |

| Corrosion Resistance | Good (with oil treatment) | Excellent | Excellent |

| Coating Thickness | Very thin | Moderate | Variable, can be thick |

| Surface Finish | Matte black | Shiny silver or black | Colourful, can be dyed |

| Cost | Low | Moderate | Higher |

| Environmental Impact | Low to moderate | Moderate to high | Low |

| Use Case Integrity | Suitable for precision parts | Suitable for steel parts | Ideal for durable aluminium use |

Is Blackening Suitable for You

If you work with steel parts requiring a clean black appearance, corrosion protection, and cost savings, blackening coating is reliable. For aluminium parts or heavy-duty outdoor applications, anodising or zinc plating might be better options. Also, if you prefer a DIY or low-heat method, cold blackening works excellently.

In: Blackening is a versatile, budget-friendly coating suitable for many steel applications—just ensure it matches your project’s metal, wear, and environmental requirements.