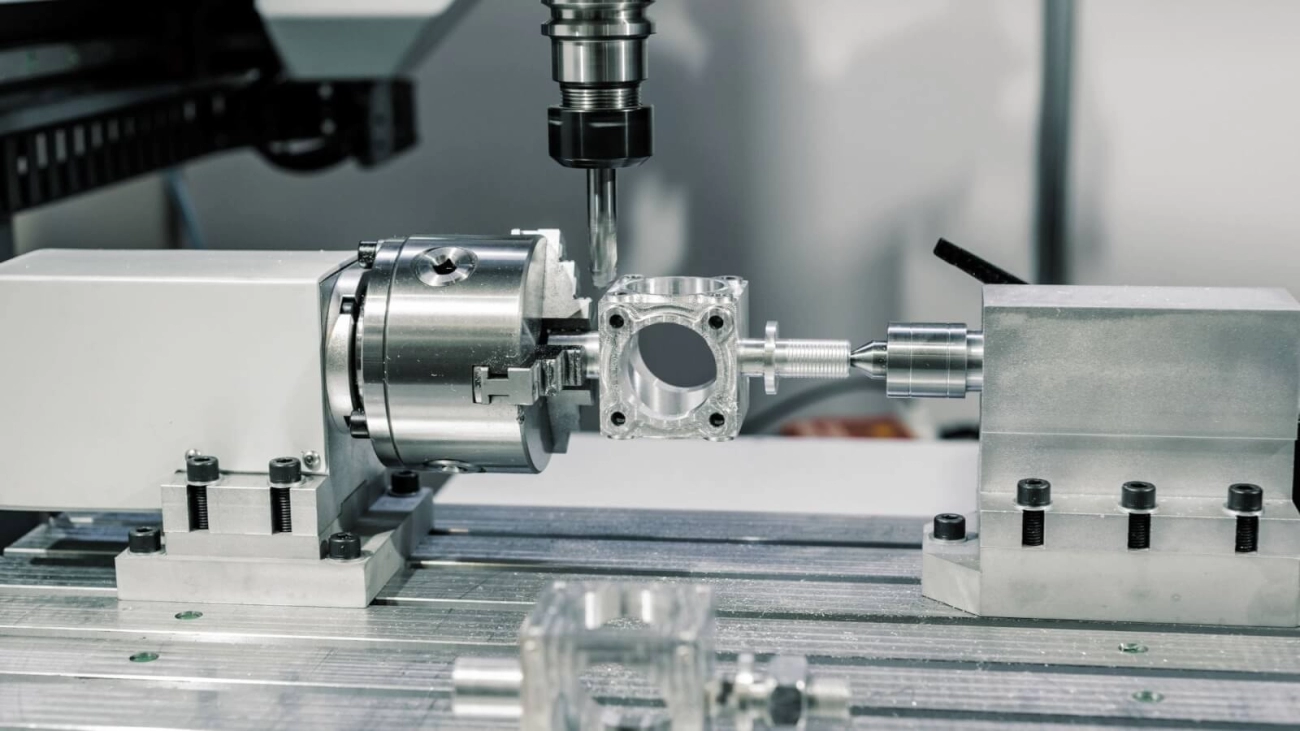

Discover expert tips and techniques for CNC milling precision achieving tolerances under 0.005mm for aerospace, medical, and prototyping needs.

In high-stakes manufacturing, CNC milling precision isn’t just a goal—it’s a game-changer. Whether you’re crafting aerospace components or medical devices, hitting tolerances within ±0.0025mm can be the difference between flawless parts and costly reworks. If you’ve ever wrestled with inconsistent finishes or unexplained dimension errors, you’re not alone. In this guide, you’ll discover exactly what defines precision in CNC milling, how it’s measured, and the proven techniques that turn theoretical accuracy into real-world results. Ready to unlock precision that sets your projects apart? Let’s get started.

Core Principles of Precision in CNC Milling

When you think about CNC milling precision, what usually worries you? Is it how tight the tolerances can get? Or maybe how consistently your parts will meet exact specifications? Getting precision right is crucial—whether you’re making aerospace components or tight tolerance prototypes.

At its core, precision in CNC milling is about accuracy, repeatability, and control. Here’s what that means:

- Accuracy: How close the finished part matches the design dimensions. This depends on machine calibration, tool quality, and programming.

- Repeatability: The ability to produce the same part multiple times with minimal variation. This ensures every batch meets your standards.

- Control: Managing cutting parameters, tool paths, and machine movements to avoid errors or vibration.

A few core principles make all this possible:

- Stable machine construction: Heavy, rigid frames reduce vibration and deflection, which is key for sharp edges and tight details.

- Precision spindle and axes: Whether it’s a 3-axis or advanced 5-axis milling setup, the spindle speed and movement precision influence cutting smoothness and accuracy.

- Advanced software: CAD/CAM programmes optimise tool paths and G-code, helping achieve sharper cuts and efficient material removal.

Understanding these basics helps you appreciate why precision CNC machining tolerances can reach thousandths of an inch. It all comes down to combining the right machine, smart programming, and careful control over every step of the milling process.

Anatomy of a Precision CNC Mill

Understanding CNC milling precision starts with knowing the key parts of the machine that impact accuracy. At the heart of it is the spindle, which holds and spins the cutting tool. A precise spindle speed and minimal runout here are essential for tight tolerance prototyping and high-quality finishes.

Next, the linear guides and ball screws control the movement of the cutting head and workpiece. These components must have minimal play and vibration reduction to maintain consistent positioning during multi-axis CNC operations. This is especially important for 5-axis milling accuracy, where small movements add up.

The machine frame plays a big role too—it needs to be rigid and stable to minimise deflection. Even slight frame movements can throw off precision.

Then, there’s the control system, which reads and executes the G-code, translating digital designs from CAD/CAM software into real-world cuts. A well-tuned control system ensures smooth operation and accurate path following.

All these parts work together to meet the high standards required in industries like aerospace CNC parts and medical device milling, where precision isn’t just a bonus—it’s a requirement.

How Precision is Measured and Achieved

Measuring and achieving CNC milling precision comes down to understanding both the tools and processes involved. Precision is typically evaluated by how closely the finished part matches the intended design, often defined within tight tolerance prototyping limits. These tolerances can range from a few thousandths of an inch to even microns, depending on the application.

Here’s how precision is usually measured and maintained:

- Dimensional AccuracyUsing high-accuracy measuring tools like coordinate measuring machines (CMMs), laser scanners, or callipers, machinists verify that dimensions align with the CAD model within specified tolerances.

- Surface FinishPrecision isn’t just about size; the surface texture matters. Smooth finishes reduce friction and wear, especially in fields like aerospace CNC parts or medical device milling.

- Repeatability and ConsistencyThe machine’s ability to produce the same part repeatedly with minimal deviation speaks to its precision. This is influenced by factors like multi-axis CNC operations and the stability of the CNC mill spindle speed.

- Machine CalibrationRegular calibration ensures the CNC machine’s movements are true to programme commands, preventing drift that would harm precision.

- Software and ProgrammingUsing advanced CAD/CAM for milling precision helps optimise G-code for smoother tool paths and better control, which directly impacts the finished product’s accuracy.

In short, CNC milling precision is achieved by keeping strict control over machine operations, software, and physical measurements, helping ensure every part meets exact design requirements.

Techniques and Best Practices for Achieving Superior CNC Milling Precision

Machine Setup and Calibration

Getting superior CNC milling precision starts with proper machine setup and calibration. Here’s what I focus on to keep everything dialled in:

- Level the Machine: Make sure your CNC mill is perfectly level. Even a slight tilt can cause inconsistencies and impact tight tolerance prototyping.

- Check Spindle Alignment: The spindle needs to be aligned correctly to avoid runout, which affects 5-axis milling accuracy and surface finish.

- Tighten and Inspect Tool Holders: Worn or loose tool holders can cause vibration, reducing precision. Regularly inspect and replace if needed.

- Use Calibration Tools: Running periodic calibration tests with dial indicators or laser measurement systems helps maintain positioning accuracy.

- Set Correct Zero Points: Establish and verify your workpiece zero points consistently to avoid errors during multi-axis CNC operations.

- Control Vibration: Install vibration dampeners or pads to minimise vibrations that compromise milling precision, especially when working at high spindle speeds.

By routinely performing these setup and calibration steps, you’ll get consistent precision CNC machining tolerances every run. This solid foundation is key no matter what material or complexity you’re working with.

Programming and Operation Tips for CNC Milling Precision

Getting the programming and operation right is crucial for achieving top CNC milling precision. Here’s how to dial it in:

- Optimize G-codeWrite clean, efficient G-code to reduce unnecessary tool moves. Smooth code improves spindle speed control and keeps your milling tight and consistent.

- Use CAD/CAM SoftwareInvest in good CAD/CAM tools that help you translate designs into precise tool paths. This minimises errors and boosts 5-axis milling accuracy.

- Set Proper Feed Rates and SpeedsBalancing spindle speed and feed rate reduces vibration and tool wear. Adjust these based on material type and cutter specs for tight tolerance prototyping.

- Apply Multi-axis CNC Operations ThoughtfullyWhen working with complex parts, use multi-axis capabilities effectively to maintain precision without extra setups or realignment.

- Dry Run SimulationsAlways run simulations before actual milling. This catches potential mistakes early and ensures your programme runs smoothly on the machine.

- Regularly Update Software and FirmwareKeeping your machine’s control systems updated helps implement the latest precision improvements and bug fixes.

Following these programming and operation tips will help keep every CNC mill job on point—essential for delivering precision parts that meet strict standards, whether for aerospace CNC parts or medical device milling.

Material and Environmental Factors

Material choice and the surrounding environment play a big role in achieving top CNC milling precision. Different materials behave differently under cutting conditions, so understanding how your material responds is crucial for tight tolerance prototyping and 5-axis milling accuracy.

Here’s what to consider:

- Material Hardness and StabilityHarder materials like titanium or hardened steel require slower spindle speeds and more careful tool paths to reduce tool wear and maintain precision. Softer materials can deform, so clamping and support are key.

- Thermal ExpansionTemperature changes affect both the material and the machine. Metals expand or contract with heat, which can throw off tight precision specifications. Keeping your machining area climate-controlled helps avoid these shifts.

- Humidity and DustHigh humidity can cause materials like wood or composites to absorb moisture and change shape. Dust and debris build-up can affect machine accuracy and wear down tools faster.

- Vibration ReductionExternal vibrations from other machines or poor foundations interfere with precision CNC machining tolerances. Using vibration-dampening mounts and ensuring your CNC mill is on a solid base boosts accuracy.

- Coolant and LubricationProper coolant use prevents overheating and tool wear, which keeps the machine running smoothly and the workpiece consistent.

Keeping a close eye on these factors and adapting your setup helps maintain consistent precision, no matter the material or conditions. This is especially important for high-stakes applications like aerospace CNC parts or medical device milling where accuracy is everything.

Real World Applications Where CNC Milling Precision Drives Innovation

Industry Highlights

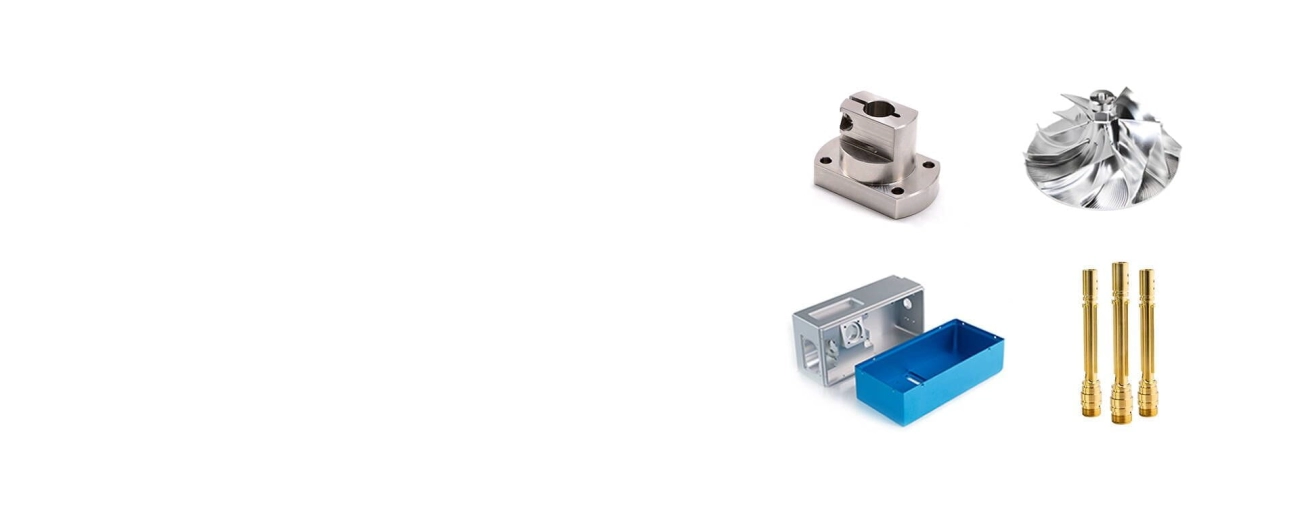

CNC milling precision is a game changer across several key industries here in the United Kingdom. Let’s look at where tight tolerances and accuracy really matter:

- Aerospace parts for aircraft and spacecraft demand extremely tight tolerances. Even the smallest deviation can affect safety and performance. Precision CNC milling ensures components fit perfectly and function reliably under stress.

- Medical Devices Milling precision is critical in making medical implants, surgical tools, and diagnostic equipment. Accuracy helps create parts that meet strict regulatory standards and improve patient outcomes.

- Automotive High-precision CNC milling supports the production of engine components and transmission parts where reliability and durability are vital. It helps manufacturers meet performance goals and reduce waste.

- Electronics Small, intricate parts for electronic devices require multi-axis CNC operations with excellent spindle speed control. This makes sure every piece fits perfectly, keeping devices slim and functional.

- Defense Precision CNC machining supports the manufacture of complex weapons systems and support gear. Here, extreme accuracy is essential for mission-critical components.

Across these industries, the demand for precision CNC machining tolerances drives innovation. Manufacturers invest in 5-axis milling accuracy, vibration reduction techniques, and CAD/CAM software to keep improving quality and efficiency. It’s clear: businesses focused on precision CNC milling achieve better product performance and competitive advantage.

Case Study from vast

At vast, precision in CNC milling is at the heart of everything we do. One standout example involves a partner in the aerospace industry needing tight tolerance prototyping for complex parts. By leveraging our expertise in 5-axis milling accuracy and advanced CAD/CAM for milling precision, we delivered components that met their strict specifications without delays.

We focused on vibration reduction in CNC operations and optimised spindle speed to maintain consistent quality throughout the project. This approach ensured every piece stayed within precision CNC machining tolerances critical to aerospace safety.

The result? Our client achieved a smoother production process with reduced waste and improved part performance. This case showcases how applying precise CNC milling techniques drives innovation and reliability in industries where every micron counts.

Real World Applications Where CNC Milling Precision Drives Innovation Emerging Trends

The demand for cnc milling precision is growing rapidly, especially as industries push for tighter tolerances and more complex parts. Here are some emerging trends shaping the future:

- Increased use of 5-axis milling accuracyMulti-axis CNC operations allow for more complex shapes in a single setup, reducing errors and improving precision.

- Integration of CAD/CAM for milling precisionAdvanced software helps optimise tool paths and G-code, making it easier to achieve tight tolerance prototyping goals consistently.

- Smart machine monitoring and vibration reductionSensors track spindle speed and machine health in real-time, reducing vibrations that could impair accuracy and extending tool life.

- Focus on lightweight and complex aerospace CNC partsAerospace and medical device milling require exceptional precision. Emerging materials and advanced CNC processes support this need.

- Automation and AI in CNC millingAI-driven adjustments during production enhance precision by predicting tool wear and compensating on the fly.

- Sustainable machining practicesAs the market shifts towards eco-friendly solutions, precision CNC milling is adopting energy-efficient machines and smarter cooling methods.

These trends ensure that precision CNC machining tolerances continue to tighten, helping manufacturers stay ahead in competitive markets.

Common Challenges in CNC Milling Precision and How to Overcome Them

Identifying Pitfalls

When working with CNC milling precision, several common pitfalls can cause issues with accuracy and quality. Being aware of these challenges is the first step to overcoming them:

- Tool Wear and BreakageWorn or broken cutting tools can lead to inconsistent cuts and reduced precision. Regular inspection and replacement are key to maintaining tight tolerance prototyping.

- Vibration and Machine StabilityVibrations during milling can cause deviations in part dimensions. Proper machine maintenance and vibration reduction techniques help keep 5-axis milling accuracy on point.

- Inaccurate Machine CalibrationIf your CNC mill isn’t properly calibrated, the precision will suffer. Consistent machine setup checks and calibration ensure the spindle speed, axis movements, and feedback systems are accurate.

- Poor Programming and G-code ErrorsMistakes in G-code or inefficient programming can lead to rough cuts or misalignment. Using CAD/CAM for milling precision and optimising G-code improves results.

- Material InconsistenciesVariations in the material’s hardness or composition affect milling precision. Selecting quality raw materials and understanding how they respond during machining is critical.

- Environmental FactorsTemperature changes and shop-floor vibrations can impact CNC milling precision. Controlling the milling environment by minimising drafts and stabilising humidity helps maintain accuracy.

Recognising these pitfalls early allows you to take practical steps before problems escalate. The right mix of machine care, smart programming, and environmental control significantly boosts CNC milling precision outcomes.

Troubleshooting Guide for CNC Milling Precision

Even with the best setup, precision issues can pop up during CNC milling. Here’s a quick guide to spotting and fixing common problems that affect accuracy and tight tolerance prototyping:

1. Inconsistent Tolerances

- Cause: Tool wear, backlash in machine axes, or poor calibration.

- Fix: Regularly inspect and replace worn tools. Run machine calibration checks and adjust backlash compensation as needed.

2. Surface Finish Problems

- Cause: Excessive vibration, incorrect spindle speed, or feed rate.

- Fix: Reduce spindle speed or feed rate. Check for loose machine parts and use vibration reduction techniques to stabilise cutting.

3. Dimensional Inaccuracies

- Cause: Thermal expansion, improper fixturing, or material warping.

- Fix: Use proper clamping methods, allow the machine to reach stable operating temperature, and select materials resistant to deformation under machining stress.

4. Tool Deflection

- Cause: Using longer or thinner tools at high cutting forces.

- Fix: Opt for shorter, stiffer tools and adjust cutting parameters to reduce load on the tool.

5. Program Errors

- Cause: G-code mistakes or CAM file issues.

- Fix: Double-check CAD/CAM outputs and perform dry runs. Utilise G-code optimisation techniques to ensure smooth machine motion.

Addressing these areas usually restores the precision expected from high-quality CNC mills, including complex multi-axis CNC operations. Keeping a close eye on these factors helps you maintain the tight milling accuracy needed for aerospace CNC parts, medical device milling, and other demanding applications.

When to Scale From Prototype to Production

Moving from prototype to full production in CNC milling precision is a big step, and timing it right is key to keeping quality tight and costs in check. Here’s what to watch for before you scale up:

- Consistent Precision: Make sure your prototype meets the exact precision CNC machining tolerances required. If you’re hitting those tight tolerance prototyping goals reliably, it’s a good sign to consider production.

- Process Stability: The process should be stable and repeatable. Any trial error in programming, machine setup, or material handling needs to be ironed out first. This includes fine-tuning G-code optimisation techniques and spindle speed settings for steady results.

- Material and Environmental Control: Confirm your material choice and environmental factors like temperature and vibration reduction in CNC machines are controlled enough for high-volume runs. Variations here can affect precision across batches.

- Cost Efficiency: Production tooling and cycle times should be optimised. Scaling too early can cause expensive rework or scrap if milling accuracy drops.

- Quality Control Systems: Have strong inspection and quality control processes in place. Regular checks ensure multi-axis CNC operations consistently produce aerospace CNC parts or medical device milling components without defects.

When these boxes are checked, transitioning to production becomes less risky and more cost-effective. It’s about balancing precision needs with production realities — helping you grow without sacrificing the quality that sets your parts apart.

Choosing the Right Partner for Precision CNC Milling Why Vast Stands Out

Evaluating Providers

When it comes to precision CNC milling, picking the right partner can make all the difference. It’s not just about finding a service that claims tight tolerance prototyping or 5-axis milling accuracy—it’s about finding one that actually delivers consistently and understands your specific needs.

Here’s what I look for when evaluating CNC milling providers:

- Experience with precision CNC machining tolerances: Providers need a proven track record of working with tight tolerances in industries like aerospace or medical device milling. This shows they can handle complex, high-accuracy projects.

- Advanced equipment and technology: The best shops use modern CNC mills with strong vibration reduction and spindle speed control to ensure every cut is precise. Multi-axis CNC operations are a big plus for more detailed work.

- Skilled programming expertise: Look for teams that use CAD/CAM for milling precision and optimise G-code efficiently. Programming impacts how accurate and repeatable the milling will be.

- Quality control processes: Regular machine setup, calibration, and thorough inspection procedures are key to maintaining precision over entire production runs.

- Responsive communication and support: You want a partner who is easy to reach, understands your project goals, and can provide updates or address issues quickly.

At Vast, these factors come together to give you confidence in every part we produce. Our focus on precision and customer collaboration sets us apart and ensures your project succeeds.

Choosing the Right Partner for Precision CNC Milling Why Vast Stands Out

Vast’s Precision Edge

When it comes to CNC milling precision, Vast brings a clear advantage. They focus on delivering tight tolerance prototyping and manufacturing with consistent accuracy, making them a top choice across industries like aerospace and medical device milling.

Here’s what sets Vast apart:

- Advanced Multi-axis CNC operations: Vast uses state-of-the-art 5-axis milling technology to achieve complex shapes with exceptional accuracy.

- Optimised CNC mill spindle speed and vibration control: These reduce errors and extend tool life, ensuring every part meets precise specifications.

- Expert CAD/CAM integration: Their programming experts leverage G-code optimisation techniques to fine-tune every cut for maximum precision.

- Strict quality control: Vast regularly measures precision CNC machining tolerances throughout production, guaranteeing consistent results batch after batch.

- Experience with critical industries: Their background with aerospace CNC parts and medical device milling means they understand the demands of tight tolerance prototyping.

If precision is your priority, Vast’s combination of technology and expertise ensures your project hits the mark every time.

Choosing the Right Partner for Precision CNC Milling Why Vast Stands Out

Getting Started with Vast

Starting your project with Vast means tapping into years of experience in precision CNC milling, especially for the United Kingdom market. We understand the importance of tight tolerance prototyping and the demands of industries requiring 5-axis milling accuracy, like aerospace and medical device milling.

Here’s how easy it is to get started with Vast:

- Initial Consultation: We listen to your project needs and help define achievable precision CNC machining tolerances.

- Tailored Solutions: Utilizing the latest CAD/CAM for milling precision, we customise machining strategies that fit your timeline and budget.

- Transparent Quotes: Upfront pricing helps you plan without surprises.

- Collaborative Process: From programming to finishing, we keep you involved, ensuring CNC mill spindle speed and vibration reduction techniques meet your quality standards.

- Rapid Prototyping to Production: Whether you need tight tolerance prototyping or full-scale manufacturing, Vast offers scalable solutions.

Choosing Vast means you get more than just a service provider—you get a partner committed to the accuracy and quality your projects demand. Reach out today to see how Vast can help your next CNC milling project meet and exceed precision expectations.