Discover customisable industrial automation solutions designed to boost efficiency, scalability, and seamless integration for your manufacturing needs.

Understanding Industrial Automation and Its Customisability

Definition of Industrial Automation

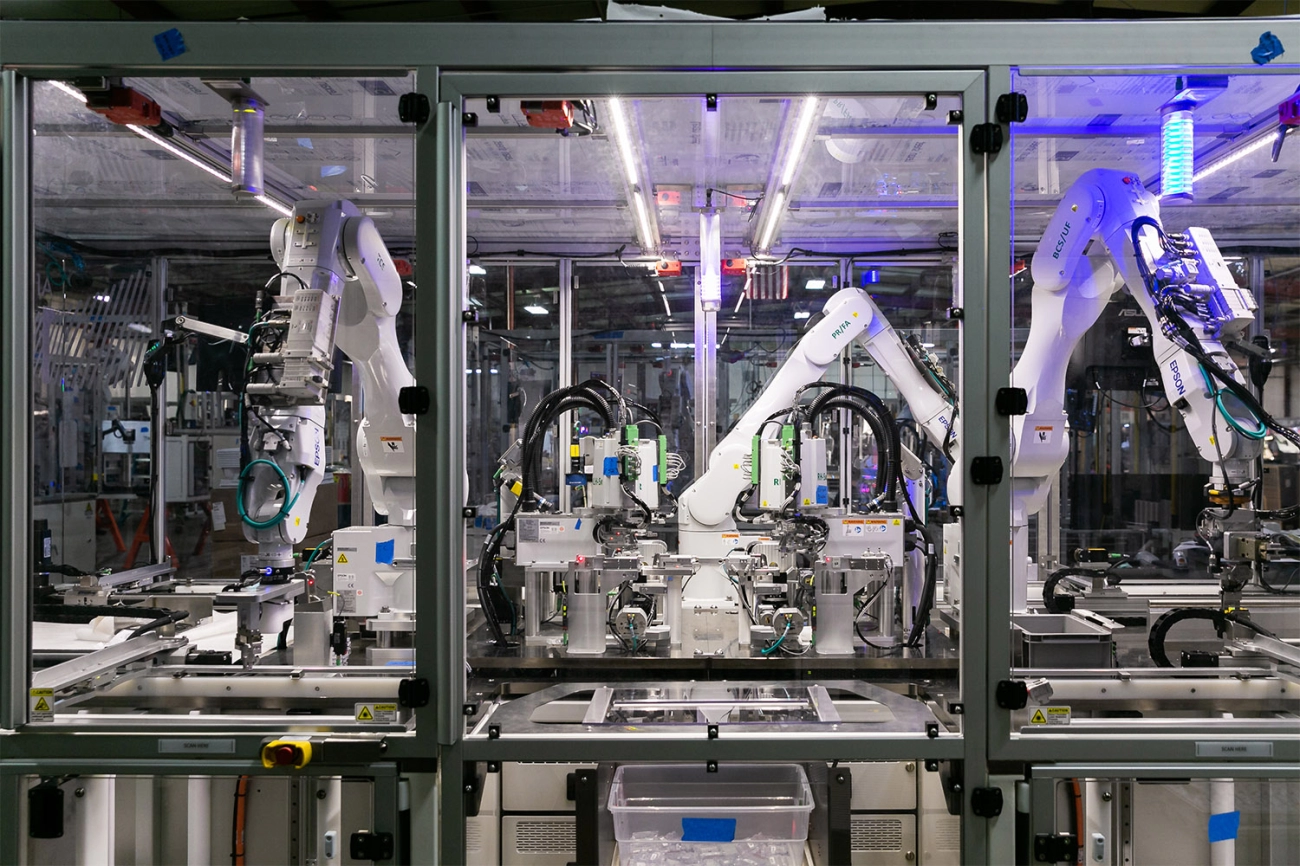

Industrial automation involves using technology to control and operate manufacturing processes with minimal human intervention. This can include machines, control systems, and software working together to improve efficiency, accuracy, and safety in production environments. Automation helps companies reduce errors, increase output, and maintain consistent product quality.

What Makes Automation Solutions Customisable

Customisable industrial automation solutions are designed to adapt to the unique needs of each manufacturing operation. Unlike one-size-fits-all systems, these tailored solutions allow businesses to modify workflows, integrate specific hardware or software, and adjust automation rules to fit their exact processes. The result is a flexible, scalable system that grows and evolves alongside your business goals.

Types of Industrial Automation Solutions

Customisable automation can include several types of technologies working together:

- Hardware: Robots, sensors, actuators, programmable logic controllers (PLCs), and control panels tailored to your production line.

- Software: Industrial automation software for controlling processes, data collection, and analytics, including customisable user interfaces and control algorithms.

- IoT Integration: Leveraging the Industrial Internet of Things (IIoT) to connect machines and devices for real-time monitoring, predictive maintenance, and enhanced decision-making.

Key Components of Customisable Systems

To build an effective customisable automation solution, these components are essential:

- Modular hardware that can be swapped or upgraded easily.

- Flexible software platforms supporting various automation protocols and tailored programming.

- Connectivity tools such as wireless networks or cloud platforms for remote access and data management.

- User interfaces designed for ease of use, enabling quick configuration and control.

- Security features ensuring safe operation and compliance with industry standards.

By understanding these basics, you get a clearer picture of how customizable industrial automation solutions can be the perfect fit for your manufacturing needs.

Why Choose Customisable Industrial Automation Solutions

Customisable industrial automation solutions offer real benefits that fit your unique manufacturing needs. Here’s why they make sense for factories and plants aiming to stay competitive:

Flexibility to Meet Unique Manufacturing Needs

Every operation is different. Tailored automation systems let you customise the setup to match your specific processes, materials, and output goals. This means you get exactly what you need without extra, unnecessary features.

Improved Process Efficiency and Precision

Custom solutions focus on your production line, reducing downtime and errors. Precise control systems push efficiency up while keeping quality consistent—key for industries demanding high standards.

Integration with Existing Infrastructure and Legacy Systems

No need to scrap your current setup. Scalable automation solutions are designed for smooth integration with the systems you already use, preserving your investments and easing the upgrade process.

Scalability and Futureproofing Your Operations

As your business grows or changes, your automation should too. Customisable solutions let you add or modify components easily, making them a solid long-term investment that keeps up with market demands.

Cost Effectiveness Over Time

Though initial costs vary, custom automation often leads to savings by cutting waste, lowering labour costs, and avoiding costly errors. Plus, efficiency gains translate into better margins over time.

Enhanced Data Collection and Analytics for Decision Making

With built-in data capture and smart analytics, these systems provide actionable insights. Access to real-time information helps you make informed decisions quickly, improving production and maintenance planning.

| Benefit | What It Means for Your Business |

|---|---|

| Flexibility | Tailored to your exact processes |

| Efficiency & Precision | Reduced errors, higher throughput |

| Existing Systems Integration | Keeps your current machinery usable |

| Scalability | Grows with your business needs |

| Cost Effectiveness | Lower operational costs over time |

| Data Analytics | Smarter, faster decisions with better visibility |

Choosing customisable industrial automation solutions means you’re investing in a system built around your needs, giving you the flexibility and tools to improve both now and in the future.

Key Features to Look for in Customisable Industrial Automation Solutions

When choosing customisable industrial automation solutions, focus on features that keep your operations efficient, flexible, and secure. Here’s what to prioritise:

| Feature | Why It Matters |

|---|---|

| Modular Design and Interoperability | Easily add or swap components to fit your changing needs and connect seamlessly with other systems. |

| User-Friendly Interface and Control Software | Simple controls reduce training time and help operators manage systems smoothly. |

| Remote Monitoring and Cloud Connectivity | Keep tabs on your equipment from anywhere, enabling quick responses and minimising downtime. |

| Real-Time Data and Predictive Maintenance | Get instant updates and anticipate issues before they cause costly breakdowns. |

| Robust Security Measures | Protect your operations from cyber threats and ensure compliance with industry standards. |

| Support for Various Industrial Protocols and Platforms | Avoid compatibility headaches by using solutions that work with your existing and future systems. |

Choosing automation solutions with these features means you can tailor processes without sacrificing reliability or control. This approach is especially valuable for manufacturers in the United Kingdom seeking scalable, flexible automation that grows with their business.

Industry Use Cases and Applications

Customisable industrial automation solutions fit a wide range of industries across the United Kingdom, helping companies stay efficient and competitive.

Automotive Manufacturing

In automotive plants, tailored automation systems streamline assembly lines, improve precision, and speed up production. Flexible manufacturing automation handles everything from robot integrators to quality checks, keeping vehicle output both fast and reliable.

Food and Beverage Processing

Automation solutions here focus on maintaining hygiene and consistency. Custom systems manage packaging, filling, and labelling processes while adapting to changing product lines and safety standards.

Pharmaceuticals and Healthcare

In pharma, customised control systems ensure precise dosing, strict compliance, and traceable batch tracking. Adaptable automation enables faster product development and helps meet regulatory guidelines efficiently.

Electronics and Semiconductor Production

These industries demand high precision and rapid changeover capabilities. Scalable automation solutions integrate with cleanroom environments and handle delicate electronic components without downtime.

Heavy Industries and Logistics

Heavy industries benefit from robust, industrial IoT automation that handles complex machinery and real-time monitoring. Automation streamlines supply chains and material handling, improving throughput and safety.

Custom Solutions for Small and Medium Enterprises (SMEs)

SMEs often need scalable automation that fits their budget but can grow with them over time. Customised industrial automation solutions provide flexibility, easy integration with existing systems, and targeted support—helping SMEs boost productivity without overspending.

How to Select the Right Customisable Automation Solution Provider

Choosing the right provider for customisable industrial automation solutions starts with understanding your specific operational needs and goals. Take time to identify the processes you want to improve, the level of flexibility required, and any unique challenges your facility faces. This clarity helps you find a partner who can tailor solutions that truly fit your business.

Next, evaluate the vendor’s expertise and track record. Look for providers with a solid history of delivering successful projects in your industry. For example, Vast stands out with its experience in automation system integration and strength in delivering scalable, tailored automation systems for manufacturers in the United Kingdom.

Customization capabilities are key. Verify that the provider offers flexible design options, can integrate with your existing infrastructure, and supports ongoing adjustments as your operation evolves. Good support services, including training and post-implementation assistance, ensure your team can maximise the benefits of the new system without a steep learning curve.

Don’t overlook total cost of ownership (TCO) and return on investment (ROI). A solution might have a higher upfront cost but save money long-term through improved efficiency, reduced downtime, and easier maintenance. Partnering with a provider who is transparent about these factors can make a big difference in your project’s success.

Implementing Customisable Industrial Automation Solutions Best Practices

When rolling out customisable industrial automation solutions, following a clear process is key to success. Here’s how to make implementation smooth and effective:

Planning and Requirement Gathering

Start by understanding your exact needs. Identify what processes you want to automate, the desired outcomes, and any limitations like budget or existing equipment. This foundation ensures the solution is tailored to your operation and avoids costly surprises later.

Collaborative Design and Prototyping

Work closely with your automation provider to design a system that fits your unique requirements. Prototyping lets you test and tweak the setup early, saving time and resources while ensuring the solution works exactly how you want.

Seamless Integration with Existing Systems

Your new automation should connect smoothly with your current infrastructure, including legacy machines and software. This avoids downtime and reduces the learning curve for your team.

Testing Validation and Quality Assurance

Before going live, thorough testing is essential. Validate that all components function correctly, data flows as expected, and any automation sequences perform reliably under real-world conditions.

Continuous Improvement and Upgrades

Industrial automation isn’t a one-and-done deal. Keep monitoring system performance and gather feedback from users. Regular updates and upgrades will keep your automation efficient, scalable, and aligned with evolving business needs.

By following these steps, you can maximise the value and longevity of your customisable industrial automation solutions while avoiding common pitfalls.

Challenges and How to Overcome Them

Implementing customisable industrial automation solutions isn’t without its hurdles. Here’s a quick look at common challenges and how to tackle them.

Managing Complexity and Change

Custom automation systems often involve multiple components and processes. The key is to break down implementation into clear phases. Use solid project management and involve your team early to handle change smoothly.

Integration Issues with Legacy Systems

Older equipment and software can clash with new automation technology. Prioritise solutions that support industrial automation system integration and flexible manufacturing automation. Working with vendors experienced in legacy systems helps avoid costly downtime.

Cost and Budget Constraints

Custom solutions can seem pricey upfront. Focus on scalable automation solutions that grow with your needs and consider the total cost of ownership. Long-term savings from improved efficiency usually outweigh initial costs.

Training and Change Management for Workforce

Your staff needs to adapt to new control systems and software. Provide hands-on training and ongoing support to ease the transition. Clear communication about benefits reduces resistance and builds confidence.

Regulatory Compliance Challenges

Staying compliant is critical, especially in industries like pharmaceuticals or food processing. Choose automation solutions with built-in security measures and compliance support to meet local standards without stress.

The Future of Customisable Industrial Automation

The future of customisable industrial automation is driven by cutting-edge technologies that make systems smarter and more connected. Artificial intelligence (AI) and machine learning play a big role here. They help automation solutions learn from data, anticipate issues before they happen, and optimise processes on the fly. This means your operations can get better over time without needing constant manual tweaks.

Industrial Internet of Things (IIoT) is another game changer. With more devices linking up through IIoT, you get real-time visibility into your entire production line. This increased connectivity powers faster decision-making and smoother coordination between machines, even across different facilities.

Adaptive and self-optimising systems are the next step in automation evolution. These solutions automatically adjust to changing conditions, whether it’s shifting production volumes or raw material variations. This flexibility keeps your manufacturing running efficiently without downtime or manual intervention.

At Vast, we’re focused on bringing these innovations to customisable industrial automation solutions tailored for UK manufacturers. Our vision centres on scalable, flexible systems that integrate AI, IIoT, and adaptive controls to future-proof your operations. By investing in these smart automation tools, businesses can stay competitive, reduce costs, and improve quality in the long run.