Discover what precision casting moulds are, how they work, their types, and advantages for accurate complex manufacturing applications by extensive experts

Understanding Precision Casting Moulds

Precision casting moulds are specialised tools used to create highly detailed and accurate metal parts through the precision casting process. Also known as investment casting moulds, they serve as the exact negative shape in which molten metal is poured to form complex components.

There are several types of precision casting moulds, with the most common being:

- Wax moulds: These are created by injecting wax into a metal mould to form a precise pattern. The wax model is then coated with ceramic to form a shell.

- Ceramic moulds: Used mainly in the shell-building phase, these moulds are made from layers of ceramic slurry and refractory materials that harden around the wax pattern to withstand high temperatures.

Materials commonly used for precision casting moulds include:

- Wax for initial pattern making

- Ceramic materials such as silica, zircon, and alumina for mould shells

- Metal moulds for wax pattern production in high-volume runs

The precision casting process closely links the mould materials and types to the final product quality. Starting with an accurate wax pattern, followed by a durable ceramic shell mould, ensures the fine details and tight tolerances are maintained throughout casting. This method allows complex shapes to be replicated with excellent surface finish and dimensional consistency.

How Precision Casting Moulds Work

Precision casting moulds are at the core of creating detailed, high-quality parts. Here’s a simple step-by-step overview of how they work, from mould creation to the final product:

- Mould CreationThe process usually begins with a wax pattern. This wax pattern is an exact replica of the final part. For ceramic moulds, a ceramic shell is built around the wax. Once hardened, the wax is melted and drained out, leaving a hollow mould.

- Metal PouringMolten metal is poured into the empty mould cavity. Because the mould captures every detail from the wax, the metal fills in all the complex shapes and fine features.

- Cooling and Mould RemovalAfter the metal cools and solidifies, the mould (usually ceramic) is broken away to reveal the raw casting.

- The casting is cleaned, and any excess metal or imperfections are removed. Due to mould accuracy, this step is often minimal.

Why Mould Accuracy Matters

Accuracy in these moulds is critical. Even tiny deviations can affect the fit and function of parts used in aerospace, automotive, or medical fields. Precision moulds ensure:

- Complex ShapesThe moulds can capture intricate designs, thin walls, and complex geometries that are difficult to achieve with other methods.

- Tight TolerancesParts come out very close to the final specifications, reducing the need for additional machining.

In , precision casting moulds play a vital role in delivering parts that meet exact design requirements, saving time and cost during production.

Advantages of Using Precision Casting Moulds

Precision casting moulds offer several key benefits that make them a smart choice for manufacturers in the United Kingdom market.

- High Dimensional Accuracy and Surface Finish: These moulds produce parts with tight tolerances and smooth surfaces straight from the mould, reducing the need for extra finishing work.

- Ability to Produce Complex and Intricate Designs: Precision casting allows for detailed shapes and fine features that other moulding methods struggle with, opening the door to innovative product designs.

- Reduction in Machining and Finishing Time: Since parts come out closer to final specifications, you spend less on machining, saving time and reducing production costs.

- Cost-Effectiveness for Small to Medium Production Runs: Unlike traditional casting methods that require expensive tooling, precision moulds are economical for runs that don’t need mass production but still demand quality.

- Enhanced Material Properties Through Precision Casting: The process improves the structural integrity and performance of materials, resulting in stronger, more reliable parts for industries like aerospace and medical devices.

Using precision casting moulds combines quality, design freedom, and efficiency—ideal for businesses looking to stay competitive without compromising standards.

Applications of Precision Casting Moulds

Precision casting moulds are used across many industries thanks to their ability to produce complex parts with tight tolerances. Here are the key applications where these moulds truly excel:

- Aerospace industryParts such as turbine blades, engine components, and structural parts require extreme accuracy and durability, making precision casting moulds ideal.

- Automotive componentsEngine parts, transmission pieces, and custom metal parts benefit from precise moulds that reduce machining needs and improve performance.

- Medical devices and implants: From surgical instruments to implants, the fine detail and biocompatibility possible with precision casting moulds are critical.

- Consumer electronics: Small, intricate metal components for devices like smartphones and laptops rely on these moulds for consistent quality and smooth finishes.

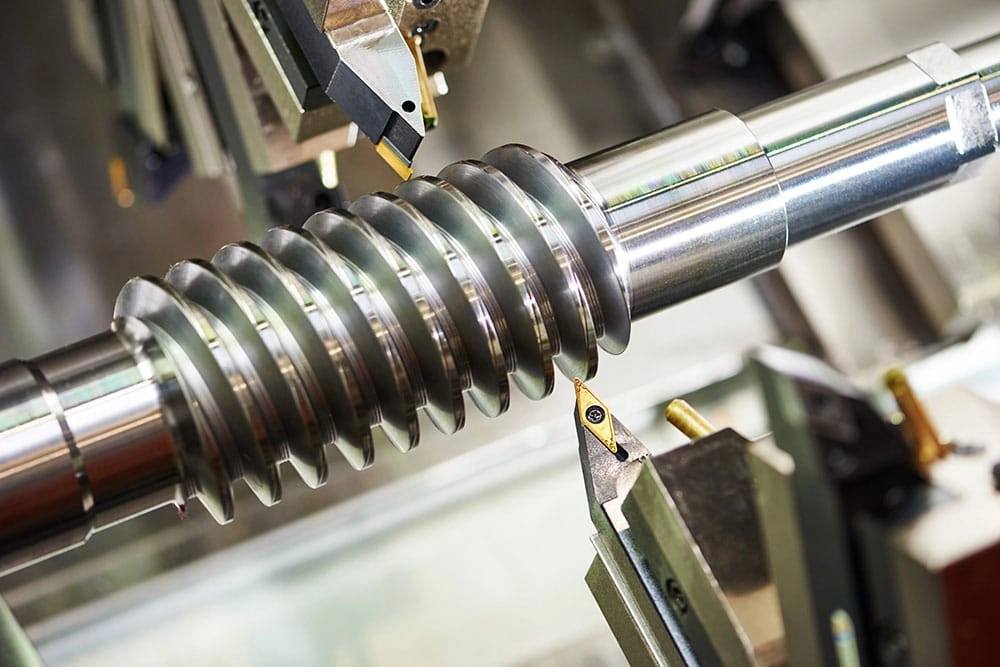

- Industrial machinery parts: Gears, valves, and custom machine parts are made more efficient and reliable through precision casting, reducing wear and extending service life.

Each of these sectors values the accuracy, surface finish, and complexity achievable with custom precision casting moulds, making them a dependable choice for manufacturers focused on quality and efficiency.

Selecting the Right Precision Casting Mould for Your Project

Choosing the right precision casting mould depends on a few key factors:

- Material: Different metals and alloys need moulds made from materials that can handle their melting points and thermal properties. Wax moulds and ceramic moulds are common, but the choice depends on the casting material.

- Complexity: If your design has intricate details or tight tolerances, you’ll need a mould that can capture those features accurately.

- Production Volume: For small to medium runs, investment casting moulds are cost-effective and flexible. Larger volumes might require moulds designed for durability and repeat use.

At Vast, we make sure every mould is designed with your project’s specific needs in mind. Our team works closely with you to:

- Understand your requirements and select appropriate mould materials.

- Customise the mould design to match your product complexity.

- Balance cost and production efficiency to fit your volume needs.

Our consultation process ensures that you get a precise, durable mould that meets your exact specifications without overpaying for features you don’t need. Whether you need a single prototype mould or moulds for a full production run, Vast’s expertise simplifies the process and guarantees quality results.

Maintenance and Longevity of Precision Casting Moulds

Proper care of precision casting moulds is essential to keep them functioning well and extend their lifespan. Here are some best practices for mould maintenance:

- Regular cleaning: Remove any residues after each casting cycle to prevent build-up that can affect surface quality.

- Temperature controlAvoid overheating or rapid cooling to reduce stress and potential cracking.

- InspectionFrequently check for cracks, surface damage, or deformation.

- LubricationUse appropriate mould release agents to protect the mould surface during casting.

Signs your precision casting mould needs replacement include:

- Visible cracks or chips in the mould material

- Loss of dimensional accuracy or surface defects in cast parts

- Frequent sticking of wax or ceramic layers

- Increased cycle times due to mould damage slowing the process

At Vast, we focus on mould durability by using high-quality materials and precision manufacturing techniques. We also provide ongoing support, including condition monitoring and timely repairs, helping you get the most out of your moulds. This approach minimises downtime and keeps your production running smoothly.

Innovations and Trends in Precision Casting Moulds

The precision casting mould industry is evolving rapidly, thanks to new materials and smart designs. Advanced materials and coatings are making moulds tougher and longer-lasting, improving the finish and accuracy of cast parts. These improvements reduce wear and help maintain tight tolerances even after many uses.

3D printing and digital design are game-changers in how precision casting moulds are made. These technologies speed up mould creation, allow for more complex shapes, and offer quick adjustments to designs. This digital approach cuts down lead times and reduces production costs, especially for custom or small-batch jobs.

Environmental concerns are shaping how moulds are designed and manufactured. More sustainable materials and energy-efficient processes are being integrated to reduce waste and emissions. Recycling of wax and ceramic materials used in moulds is becoming more common, supporting greener casting methods.

At Vast, we stay ahead by continuously investing in new technologies and sustainable practices. Our innovation efforts focus on enhancing mould durability, optimising design precision, and reducing environmental impact—helping UK businesses get the best out of precision casting moulds while keeping sustainability in mind.

Why Choose Vast for Your Precision Casting Mould Needs

When it comes to precision casting moulds, Vast stands out with proven expertise and years of hands-on experience. We understand the importance of accuracy and quality in every mould we create, ensuring your project meets the highest standards from start to finish.

Our Strengths

- Expertise: Decades specialising in precision casting moulds for industries across the United Kingdom, including aerospace, automotive, and medical.

- Quality Assurance: All moulds undergo strict inspections and meet industry certifications for reliability and performance.

- Customisation: Tailored mould designs based on your material, complexity, and production volume needs.

- Support: Ongoing technical support and maintenance advice to maximise mould longevity.

What Our Customers Say

| Customer | Industry | Feedback Highlights |

|---|---|---|

| AeroTech Inc. | Aerospace | “Vast delivered precise moulds that minimised finishing work.” |

| MedPlus | Medical Devices | “Their expertise helped us produce complex implants efficiently.” |

| AutoParts UK | Automotive | “Fast turnaround and great communication throughout.” |

Getting Started with Vast

- Consultation: Reach out to discuss your project details and requirements.

- Design & Quote: We provide a clear mould design plan and competitive pricing.

- Production: Once approved, we start mould fabrication using top materials.

- Delivery & Support: Receive your moulds on time with guidance for optimal use.

Choosing Vast means partnering with a reliable United Kingdom-based expert committed to delivering precision casting moulds that help your business succeed.