Learn how insert moulding combines metal inserts with plastic for stronger parts with benefits, process steps, and applications explained clearly.

What Is Insert Moulding Demystifying the Basics

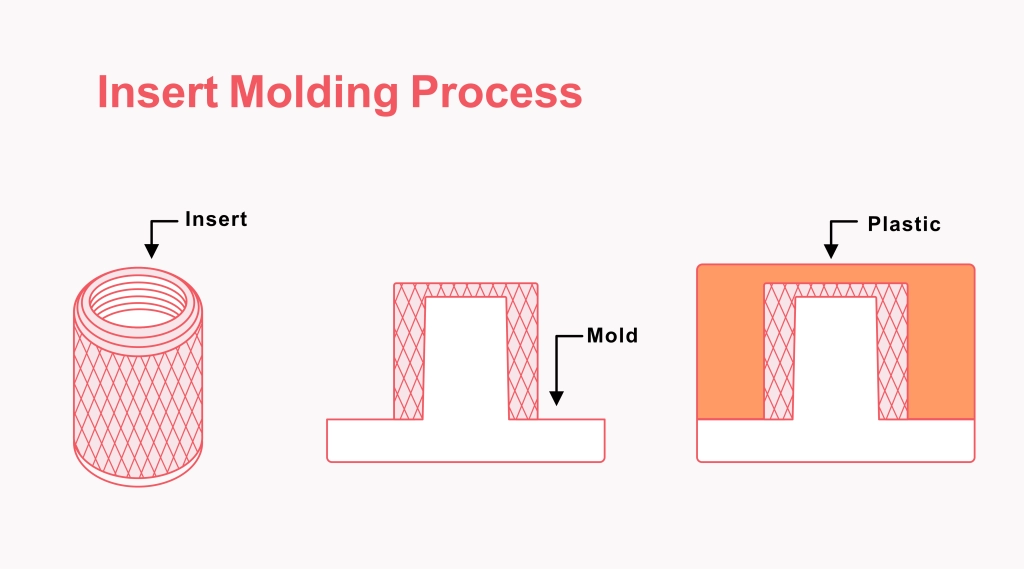

Insert moulding is a specialised manufacturing process where pre-formed inserts—often metal components like threaded inserts—are placed into a mould before injecting plastic around them. Unlike traditional injection moulding, which forms parts solely from plastic, insert moulding creates hybrid parts by combining materials in a single step. This results in stronger, more durable components with integrated features such as metal threads or electrical contacts.

Historically, insert moulding evolved from basic overmoulding techniques used in the automotive and electronics sectors. Its ability to produce complex, multi-material parts efficiently has made it increasingly popular in modern manufacturing. Today, insert moulding delivers cost-effective solutions for industries demanding precision, such as medical devices, consumer goods, and high-performance automotive components. This technique not only enhances mechanical properties but also streamlines assembly, driving its rising adoption worldwide.

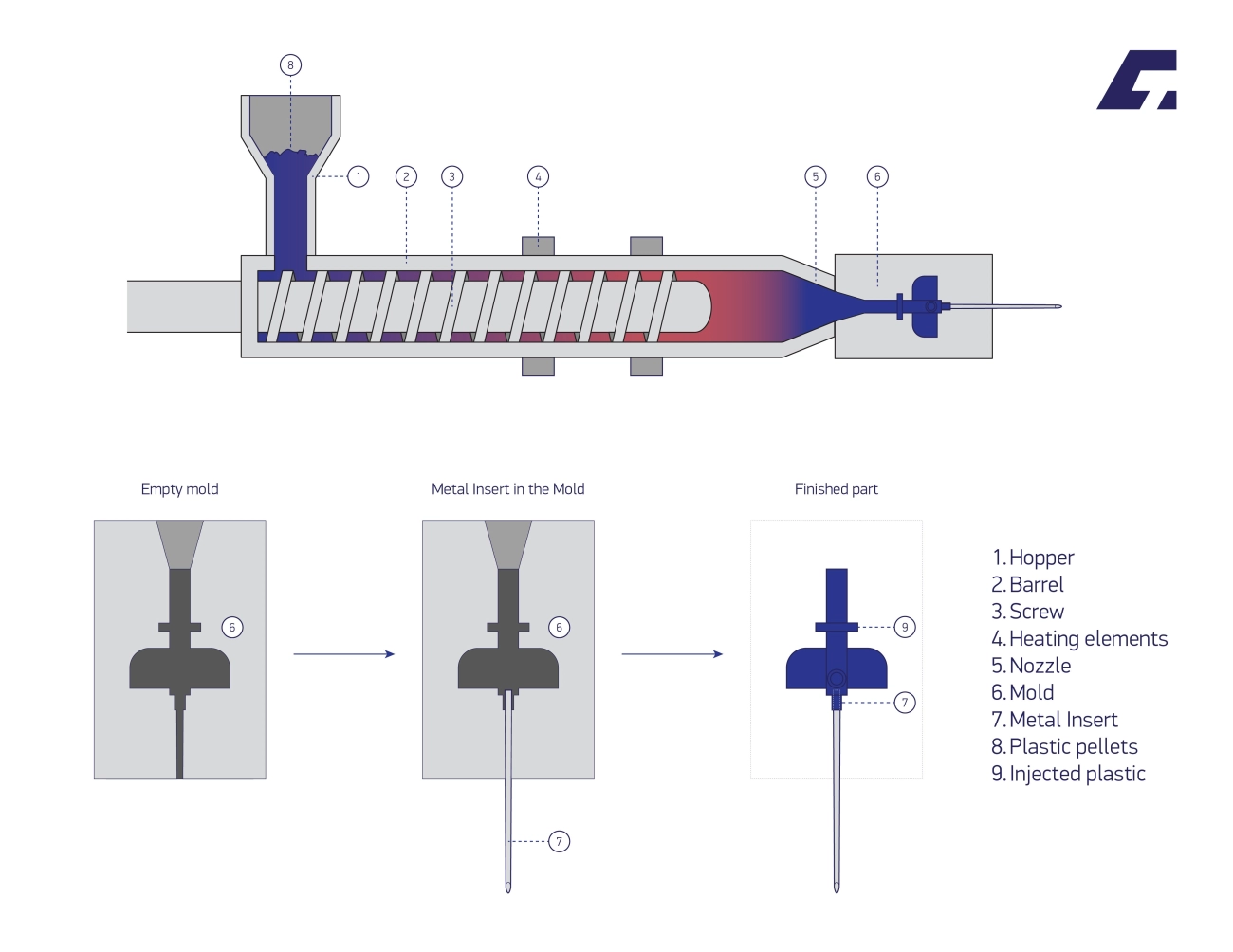

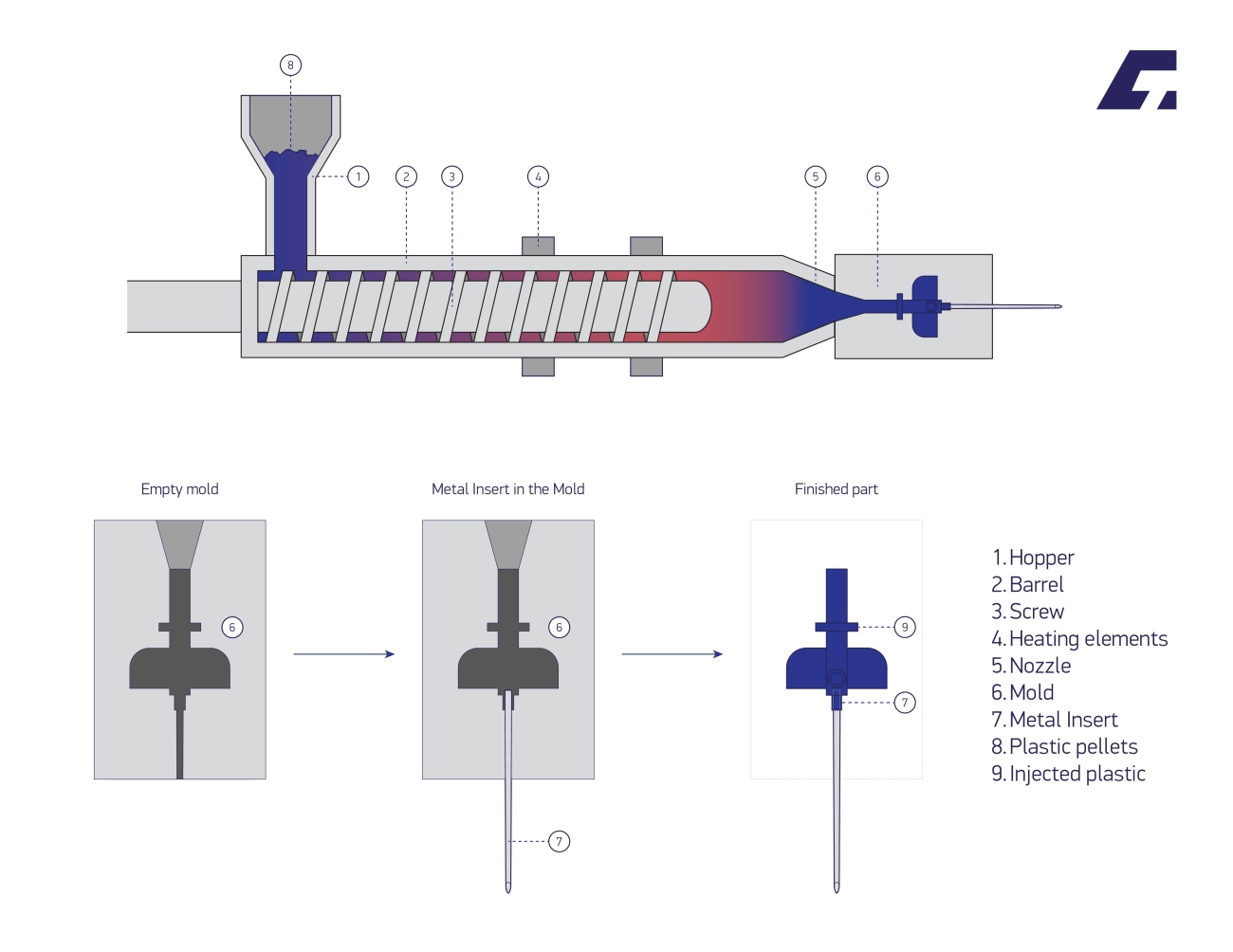

The Insert Moulding Process Step by Step From Concept to Completion

Insert moulding is all about combining materials in a smart way, and understanding the process helps you get the best results. Here’s how it works from start to finish:

Step 1 Insert Preparation and Placement

Before any plastic gets injected, the metal or other inserts are prepared carefully. This includes cleaning, sometimes pre-heating, and making sure inserts like threaded components or other metal parts are perfectly positioned. Precision insert placement techniques are key here, often done manually or with robotic insert loading automation to boost accuracy and speed.

Step 2 Mould Design and Injection

The mould is designed with the exact cavity to fit both the insert and the plastic. After placement, the thermoplastic encapsulation process begins. Plastic is injected around the insert at high pressure, bonding the materials without damaging the insert. This step demands a precise mould design to avoid gaps, weak spots, or insert movement.

Step 3 Cooling, Ejection, and Quality Checks

Once the plastic cools and hardens, the part is ejected from the mould. Then, quality checks follow – verifying insert placement, part dimensions, and mechanical properties. These checks ensure each piece meets specifications, especially for demanding industries like automotive or medical.

Pro Tip from vast Integrating Automation for Scalable Production

For larger scale runs, vast recommends integrating robotic automation for insert loading. This not only speeds up production but keeps consistency tight, reducing human error and boosting overall efficiency. It’s especially handy for cost-effective multi-material parts manufacturing, helping UK manufacturers stay competitive.

By following these steps carefully, insert moulding delivers durable, high-quality hybrid material parts built to last.

Key Advantages of Insert Moulding Why It Outshines Alternatives

Insert moulding stands out because it delivers stronger, more durable parts. By embedding metal or other inserts directly into plastic during the moulding process, you get improved mechanical properties like better load distribution and resistance to wear. This makes parts last longer, which is a big win for industries like automotive and electronics where reliability is key.

Enhanced Mechanical Properties and Durability

- Stronger bond between materials: Insert moulding fuses the insert and plastic, reducing the risk of separation.

- Improved strength: Threaded inserts in plastic parts offer superior load-bearing capacity compared to just moulded holes.

- Higher durability: Parts resist fatigue, shock, and thermal stress better than those made with traditional injection moulding.

Cost and Efficiency Gains

- Reduced assembly steps: Since inserts are moulded in place, you reduce manual labour and assembly costs.

- Minimal post-processing: Fewer finishing steps mean faster production and lower overall costs.

- Automation-friendly: Robotic insert loading automation can scale production while maintaining quality and consistency.

Insert Moulding vs Overmoulding A Head to Head Comparison

| Feature | Insert Moulding | Overmoulding |

|---|---|---|

| Material Integration | Embeds solid inserts (metal/plastic) | Layers one material over another |

| Mechanical Strength | Superior load capacity and stability | Suitable for soft over hard plastics |

| Cost Efficiency | Lower long-term costs through durability | Sometimes cheaper for simple parts |

| Application Flexibility | Ideal for threaded inserts and fasteners | Best for protective or aesthetic coatings |

Insert moulding is usually the better choice when you need strong, durable parts with metal inserts. It’s especially valuable in precision applications where mechanical integrity is non-negotiable.

Design Considerations and Best Practices for Flawless Insert Moulded Parts

Getting insert moulding right starts with smart design choices. Here’s what you need to keep in mind for top-quality results.

Material Compatibility and Selection

- Match your insert material with the plastic to avoid issues like warping or poor bonding. For example, metal insert injection moulding often pairs steel or brass inserts with robust thermoplastics.

- Consider thermal expansion differences to prevent cracks or stress.

- Use corrosion-resistant inserts when exposed to moisture or chemicals.

Common Pitfalls and How to Avoid Them

- Insert movement during moulding: Secure inserts firmly using precision insert placement techniques or robotic insert loading automation.

- Overheating inserts: Choose plastics with suitable melting points and optimise cycle times.

- Poor insert encapsulation: Design moulds that allow complete plastic flow around inserts.

- Stress concentration points: Round edges on inserts and avoid sharp corners in your design.

Vast’s Design Checklist 5 Must-Haves for Optimal Results

- Clear insert placement plan with tight tolerances

- Compatible materials that work well together without stress

- Robust mould design for complete encapsulation and easy ejection

- Automation-ready processes to maintain precision and speed

- Quality control measures including inspection of insert seating and overall part integrity

Following these guidelines helps avoid costly errors and ensures your insert moulded parts deliver on strength, durability, and performance every time.

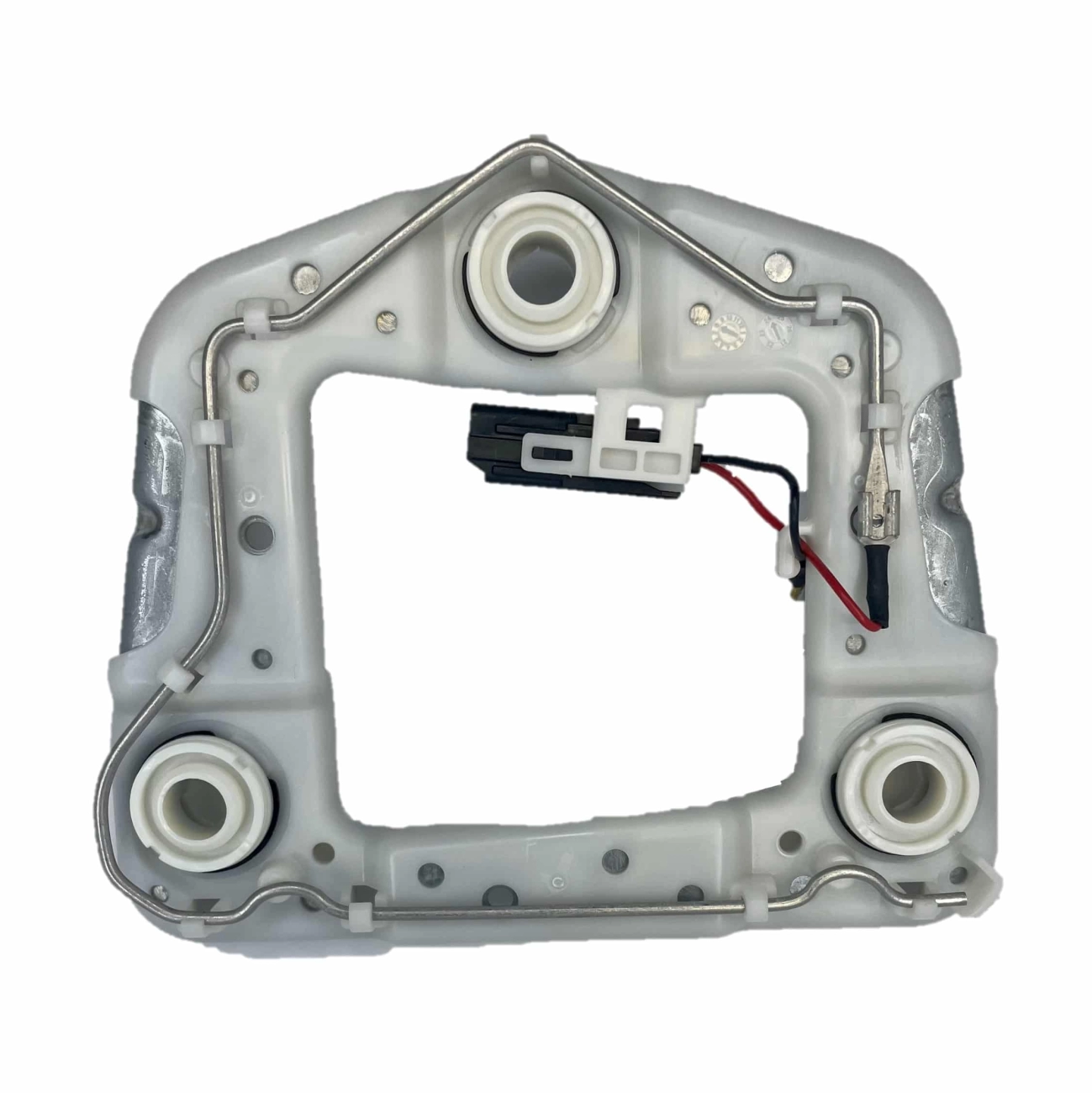

Real World Applications Insert Moulding in Action Across Industries

Insert moulding plays a crucial role in many industries here in the UK, thanks to its ability to combine materials like metal and plastic into one strong, durable part. Let’s look at how it’s making a difference in key sectors.

Automotive and Electronics Fasteners and Housings

In automotive manufacturing, metal insert injection moulding is a game changer. It creates robust threaded inserts in plastic parts used for fastening, improving the strength and longevity of components under stress and heat. Electronics also benefit, with precision insert placement techniques ensuring reliable housings and connectors that protect sensitive circuits.

Medical and Consumer Goods Precision Meets Safety

Insert moulding is also critical for medical devices where safety and accuracy can’t be compromised. The thermoplastic encapsulation process protects metal parts inside surgical tools and devices, meeting strict FDA standards. For everyday consumer goods, this manufacturing method delivers tough, cost-effective multi-material parts that hold up under daily wear.

Case Study How Vast Delivered 20 Percent Stronger Parts for a Tech Client

At Vast, we helped a UK-based tech client improve their product durability by 20% using insert moulding. By integrating automation for precise insert loading, we cut defects and shortened production time. This not only enhanced part strength but also reduced costs – proving that smart design and hybrid material manufacturing really pay off.

Insert moulding is clearly an efficient, reliable choice across industries demanding high performance, and it’s only gaining traction here in the UK market.

Challenges in Insert Moulding and Innovative Solutions from vast

Insert moulding presents its own set of challenges, and at vast, we have addressed these directly to deliver reliable, cost-effective solutions.

Tooling Costs and Scalability Barriers

One major challenge is the initial tooling cost. Custom moulds for insert moulding can be expensive, which can slow down small-batch production. However, vast counters this with intelligent mould design and modular tooling options that distribute costs over multiple runs. Additionally, our robotic insert loading automation accelerates the process, making it easier to scale without significantly increasing labour costs. This balance of efficiency and precision ensures projects stay on track from prototype to mass production.

Sustainability Perspective Eco-Friendly Insert Moulding Practices

Sustainability is more than just a buzzword here. We focus on waste reduction by optimising material usage and recycling scrap from metal insert injection moulding. Our processes prioritise thermoplastics that are easier to recycle and employ eco-friendly encapsulation methods that minimise emissions. By adopting hybrid material manufacturing thoughtfully, we not only enhance part strength but also assist clients in moving towards greener supply chains.

At vast, challenges in insert moulding are opportunities. With advanced technology, sustainable practices, and local expertise, we keep your projects both innovative and practical.

Partnering with vast for Custom Insert Moulding Excellence

When selecting a partner for custom insert moulding, the right choice makes all the difference. At vast, we bring years of experience and a proven track record of delivering high-quality, precision-engineered parts tailored to your requirements. Our ISO-certified process guarantees consistent quality you can rely on, regardless of your project size.

Why Choose vast for Insert Moulding

- ISO Certified Quality: We adhere to strict quality control measures to meet and surpass industry standards, providing you with reliable, defect-free parts.

- Global Reach: Whether you are in the UK or abroad, vast’s manufacturing facilities and supply chain make it easy to receive your parts on time, every time.

- Advanced Automation: Our robotic insert loading and precision moulding techniques help reduce costs while enhancing part consistency and turnaround speed.

- Expertise in Hybrid Material Manufacturing: We specialise in combining metal insert injection moulding with thermoplastic encapsulation, perfect for complex, durable parts.

- Dedicated Support: From initial design advice to post-production, our team works closely with you to ensure your project’s success.

Getting Started Your Path to a Quote

Ready to bring your insert moulding project to life? Here’s how to get started with vast:

- Reach Out: Contact us with your project details and goals.

- Initial Consultation: We’ll discuss design, materials, and volumes to tailor the best approach.

- Quote and Timeline: Expect a clear, detailed estimate coupled with realistic timelines.

- Prototype and Testing: We can produce prototypes to validate your design and performance.

- Scale Production: Once approved, we ramp up with automation and quality checks to meet your delivery needs.

Partner with vast and experience insert moulding excellence backed by proven quality, innovation, and a strong commitment to service.