Discover the benefits and applications of hard anodising for durable, abrasion-resistant aluminium coatings meeting MIL-A-8625 standards.

What Is Hard Anodising? A Deep Dive into the Fundamentals

Hard anodising, also known as Type III anodising or hard coat process, is an electrochemical surface treatment that forms a thick, dense aluminium oxide coating. Unlike natural oxidation, which produces a thin and fragile layer, hard anodising creates a much thicker, abrasion-resistant finish that can reach 25 microns or more.

Core Chemistry and Electrolysis Process

- Electrolyte: Sulphuric acid bath, typically kept cold (32-50°F)

- Process: Aluminium acts as the anode; sulphuric acid electrolyses to form aluminium oxide on the surface

- Temperature: Low temperatures slow reaction, producing a dense, hard coating instead of porous natural oxide

- Voltage & Current: Higher than regular anodising, controlled to avoid burning or uneven coating

Difference from Natural Oxidation

| Feature | Natural Oxide Layer | Hard Anodised Layer (Type III) |

|---|---|---|

| Thickness | 2-5 nanometres | 25-150 microns |

| Durability | Low, easily scratched | Very high, abrasion & wear-resistant |

| Colour | Clear, thin layers | Can be dyed, varies by alloy and process |

Compatible Aluminium Alloys

- Common alloys: 5000 and 6000 series (e.g., 6061, 7075)

- Reason: These alloys form tough oxide layers that bond well and retain hardness

- Less suitable: 1000 series (pure aluminium) due to poor oxide hardness

Colour Effects

- Hard anodising naturally produces a grey to black finish due to the thick oxide layer.

- Dyes and sealing can add colours, but hues depend on alloy and layer thickness.

In , hard anodising builds a tough, wear-resistant aluminium oxide coating using sulphuric acid electrolysis at low temperatures — delivering superior protection and durability compared to natural oxidation.

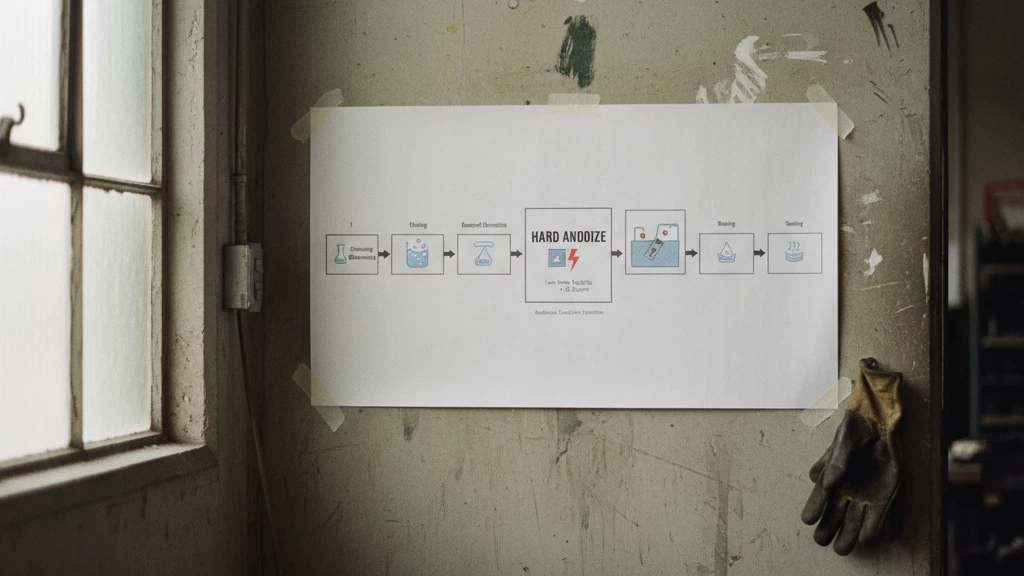

The Hard Anodising Process: Step-by-Step Breakdown

Hard anodising starts with pre-treatment, which is key to getting the coating to stick well. The aluminium parts are thoroughly cleaned to remove oils and dirt, then etched to smooth the surface. After that, a deoxidising step ensures the metal is free of any surface contaminants, setting the stage for a strong bond.

Next is the electrolytic setup. The aluminium acts as the anode, submerged in a cold sulphuric acid bath—usually kept around 32°F (0-5°C) to control the reaction. A cathode made of lead or stainless steel completes the circuit. Voltage and current density are carefully regulated, typically with low voltage (around 12-18 volts) and high current density to build a thick, dense oxide layer.

During coating formation, aluminium ions move towards the surface and react with the acid to form aluminium oxide. This oxide layer is much thicker and harder than natural oxidation because the low temperature and controlled current slow the reaction, producing a denser finish.

After the anodising bath, post-treatment seals the pores of the oxide layer. Sealing options can include hot water or steam, improving corrosion resistance. Dyeing may be applied if colour customisation is needed, although hard anodising typically leaves a natural matte grey finish. Finally, the process complies with standards like MIL-PRF-8625F Type III, ensuring the coating meets military-grade performance for abrasion and corrosion resistance.

Hard Anodising vs. Other Methods: Making the Right Choice

When choosing anodising, it helps to know how hard anodising compares to other types. Here’s a quick comparison of the main anodising methods (all common in the United Kingdom market):

| Feature | Hard Anodising (Type III) | Regular Anodising (Type II) | Chromic Acid Anodising (Type I) |

|---|---|---|---|

| Coating Thickness | 0.0012″ to 0.005″ (30–125 μm) | 0.0001″ to 0.0010″ (2.5–25 μm) | 0.00005″ to 0.0003″ (1–8 μm) |

| Hardness | 60–70 HRC (very hard) | 15–25 HRC | Softer, less protective |

| Wear Resistance | Excellent | Moderate | Low |

| Corrosion Protection | Very good | Good | Good, but less durable |

| Colour Options | Limited (mostly natural or black) | Can be dyed various colours | Limited |

| Best Use | Industrial, heavy wear parts | Decorative, colour finishes | Aerospace parts needing thin coatings |

| Cost | Higher | Lower | Moderate |

When to Choose Hard Anodising

- You need a tough, abrasion-resistant finish in harsh environments.

- Parts face heavy wear, like in automotive, aerospace, or industrial gear.

- You want strong corrosion protection for marine, petrochemical, or outdoor use.

- Electrical or thermal insulation benefits are critical.

- A longer-lasting coating justifies a bit more upfront cost.

When to Consider Other Anodising or Thin Films

- You want bright, colourful, or decorative surfaces—Type II is more flexible.

- Coatings need to be very thin or lightweight, such as aerospace or optics.

- Cost is a big concern and durability demands are low.

- Thin, flexible coatings like chromic acid anodising work better on tight tolerance components.

Emerging Eco-Friendly Alternatives

The market is promoting greener treatments to reduce waste and energy consumption. New methods include:

- Low-voltage hard anodising which reduces power consumption.

- Hybrid coatings combining hard anodising with more environmentally friendly layers like PVD (Physical Vapor Deposition).

- Use of Non-toxic dyes and sealing agents to minimise pollution.

These alternatives aim to comply with environmental regulations while maintaining high performance.

Choosing the right anodising depends on your part’s needs, budget, and durability expectations. Hard anodising excels when toughness and wear resistance are priorities.

Key Benefits: Unlocking Superior Performance with Hard Anodising

Hard anodising offers several performance advantages that make it a top choice for demanding applications. Here’s why it stands out:

Abrasion Resistance and Wear Reduction

- Creates an extremely hard aluminium oxide coating (up to 60+ HRC hardness)

- Significantly reduces surface wear in high-friction environments

- Extends component lifespan, reducing replacement frequency

Corrosion Protection

- Provides excellent protection against rust and corrosion—ideal for marine and petrochemical applications

- Protects aluminium from harsh chemicals and saltwater exposure

- Helps maintain structural integrity in extreme conditions

Electrical and Thermal Insulation

- The oxide layer is non-conductive, offering strong electrical insulation

- Assists in heat management by providing thermal resistance where needed

Lubricant Retention and Low Friction

- Porous surface holds lubricants well, boosting low-friction performance

- Beneficial for moving parts like gears or pistons to reduce wear and energy loss

Cost Savings and Environmental Advantages

| Benefit | Explanation |

|---|---|

| Longer service life | Less downtime for repairs or replacements |

| Lower maintenance needs | Durable finish keeps parts functional for longer |

| Energy-efficient process | Uses less energy compared to other surface coatings |

| Environmentally friendly | No heavy metals or toxic chemicals in the coating process |

In the UK market, these benefits translate into greater reliability and lower total costs, especially for aerospace, automotive, and industrial users who demand both strength and longevity in aluminium parts.

Real-World Applications: Where Hard Anodising Excels

Hard anodising is a go-to solution for industries that demand tough, wear-resistant aluminium parts. In aerospace and defence, it’s used on components exposed to harsh conditions, offering scratch resistance and long-lasting performance. Automotive and robotics industries rely on hard anodising for gears, pistons, and parts where durability and low friction matter. Medical devices benefit from the corrosion protection and biocompatibility of hard coat anodising too.

In optics and electronics, hard anodising helps protect sensitive parts while maintaining electrical insulation. Niche markets, like sporting goods and heavy machinery, also use hard anodising to extend product life.

Industry demand for hard anodising is growing steadily, driven by the push for high-performance components in renewable energy, electric vehicles, and aerospace technology. For example:

- Aerospace: Landing gear and engine parts

- Automotive: Suspension components and brake parts

- Robotics: Wear pads and sliding surfaces

- Medical: Surgical tools and implants

- Electronics: Heat sinks and connectors

Visual examples include anodised pistons with a matte grey finish, rugged camera housings, and corrosion-resistant marine fittings. These applications demonstrate why hard anodising remains the top choice for durable, high-performance aluminium parts in the United Kingdom market.

Standards, Specifications, and Quality Assurance

When it comes to hard anodising, following industry standards ensures quality and performance. The main specifications to know are:

| Specification | Description |

|---|---|

| MIL-A-8625F Type III | U.K. military standard for hard coat anodising with strict thickness and wear requirements |

| AMS 2469 | Aerospace material specification focused on hard anodised coatings |

| ISO 7599 | International standard covering anodic oxidation of aluminium |

Thickness Measurement and Testing

- Typical thickness ranges from 25 to 125 microns for Type III anodising.

- Testing uses electrical impedance, microscopic cross-section, or magnetic induction gauges.

- Uniformity and density are key factors checked to meet specifications.

Common Issues & Solutions

- Overheating during anodizing can cause porous, weak coatings. To avoid this:

- Use refrigerated electrolyte baths

- Monitor current density carefully

- Vast’s advanced monitoring and cooling techniques help prevent such failures, ensuring consistent coating density and hardness.

Compliance and Certification

Meeting MIL-A-8625F and other relevant certifications is crucial, especially for aerospace and defence customers in the United Kingdom. It guarantees:

- Reliable wear and corrosion protection

- Repeatable manufacturing quality

- Confidence in product performance under demanding conditions

Following these standards and quality checks protects your investment and keeps your anodized parts performing reliably for years.

Challenges, Limitations, and Best Practices in Hard Anodizing

Hard anodizing is a fantastic way to boost durability, but it comes with some challenges you should know about before making the switch. Here are the key points:

Dimensional Changes and Tolerance Planning

- The hard coat process adds a thicker aluminium oxide layer, usually between 0.001–0.004 inches.

- This extra thickness can cause small dimensional shifts, so you need to plan machining tolerances carefully.

- It’s common to machine parts slightly undersized before anodizing, then finish with light post-anodize machining if precision is critical.

Colour Limitations and Alloy-Dependent Hues

- Unlike decorative anodizing, hard anodizing mostly results in natural silver-gray or matte black finishes.

- The colour depends a lot on the aluminium alloy and process parameters—expect limited colour options here.

- Trying to add vibrant colours isn’t ideal, since it can affect the hardness and durability of the coating.

High Initial Costs vs Lifespan ROI

- Setting up hard anodising can be pricier upfront compared to regular anodising or painting. Equipment, bath control, and strict process conditions drive costs.

- But on the flip side, the wear resistance and corrosion protection offer long-term ROI by extending part life and reducing maintenance.

Best Practices for Success

- Choose the right alloys: 6xxx and 7xxx series aluminium alloys work best for hard anodising. Avoid alloys with high copper or manganese content.

- Integrate CNC machining: Precision machining before and after anodising helps manage tolerances and ensures consistent quality.

- Work with certified providers: Compliance with MIL-A-8625F Type III spec ensures high-quality coatings you can trust. Look for providers comfortable with tight specs and testing protocols.

Troubleshooting Common Failures

- Overheating during anodising: Can cause soft coatings or discolouration. Proper cooling and low temperature baths prevent this.

- Uneven coatings: Often caused by poor cleaning or inadequate electrical contact; strict pre-treatment steps are key.

- Cracking and flaking: Linked to too thick coatings or wrong alloy choice. Managing thickness and selecting engineered anodising alloys helps.

Understanding these challenges and sticking to best practices will help you get the most from your hard anodising projects in the UK market — durable, cost-effective parts with proven performance.

The Future of Hard Anodising: Innovations and Trends

Hard anodising is evolving rapidly, especially with a strong push towards greener, more efficient processes. One key innovation is using low-voltage rectification during the sulphuric acid anodising process. This reduces energy consumption while maintaining the tough, abrasion-resistant finish expected from Type III anodising. It’s a smart move for workshops aiming to cut costs and comply with stricter environmental regulations.

We’re also seeing hybrid coatings, where hard anodising layers are combined with PVD (Physical Vapour Deposition) films. This combination enhances hardness and wear resistance beyond what traditional hard coats offer, making components even more durable for aerospace, automotive, and defence applications.

Looking ahead, growth in renewable energy and 3D printing is shaping demand for hard anodising. Lightweight, durable aluminium parts with corrosion protection are essential in wind turbines, solar panels, and customised 3D-printed components requiring reliable surface treatment.

Locally in the UK, companies like Vast are leading eco-anodising R&D, developing cleaner, water-saving anodising methods that still meet MIL-A-8625F Type III specifications. This is excellent news for manufacturers seeking to offer sustainable, high-performance aluminium oxide coatings without compromising quality.

In short, the future of hard anodising is about smarter, greener technology and hybrid options, tailored for new industries and stricter UK market standards.