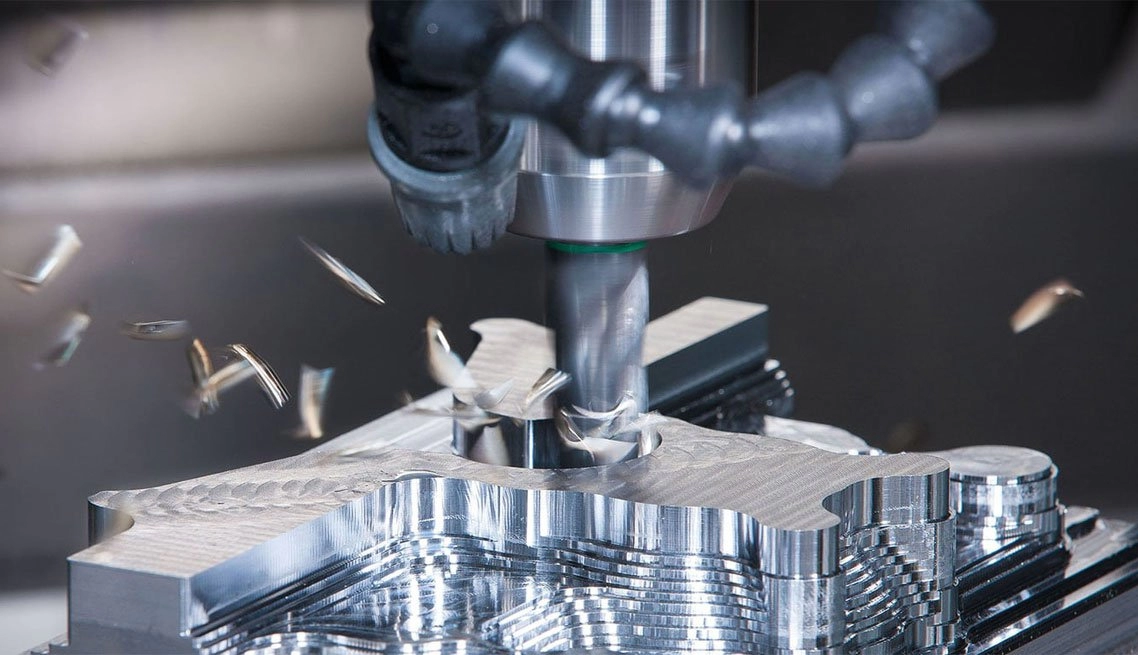

Discover machinability insights including rating systems, material factors, and how vast’s alloys boost CNC efficiency and extend tool life.

Core Factors Influencing Machinability

Machinability depends on several key factors that affect how easily a material can be cut, shaped, or drilled. Understanding these helps you optimise tooling and process parameters for better results.

Material Properties

- Hardness: Harder materials resist cutting, wearing tools faster.

- Tensile Strength: Higher strength usually means tougher machining.

- Ductility: More ductile metals tend to form continuous chips, which can affect tool wear.

- Thermal Conductivity: Materials that dissipate heat well reduce tool overheating and extend tool life.

Microstructure

- Grain Size: Finer grains generally improve machinability by making the material more uniform to cut.

- Phases: Different phases influence chip formation and surface finish.

- Inclusions: Non-metallic particles can cause abrasive wear on tools or lead to unstable cuts.

Work Hardening and Chip Formation

- Work Hardening: Some metals harden rapidly under cutting stress, making subsequent passes harder.

- Shear Angle: Higher shear angles can reduce cutting forces and improve surface quality.

- Chip Breaker Geometry: Proper chip breaker design helps control chip shape and evacuation.

- Built-Up Edge (BUE): This layer of material adheres to the tool and can cause poor surface finish and increased wear.

Thermal Effects

- Heat Generation: Machining produces heat from friction and deformation.

- Heat Dissipation: Materials with higher thermal conductivity cool more quickly, protecting tools.

- Coefficient of Thermal Expansion: Materials that expand significantly under heat can affect dimensional accuracy.

Chemical Composition

- Free-Machining Additives: Elements such as sulphur (S), lead (Pb), bismuth (Bi), and tellurium (Te) enhance machinability by promoting easier chip breaking and reducing tool wear.

Understanding how these factors interact enables you to select the appropriate tools, speeds, and feeds for optimal machining performance.

Machinability Rating Systems

Machinability ratings assist you in comparing how easy or difficult a material is to machine. One common system is the AISI SAE B1112 rating, which establishes a standard reference at 100 percent, typically based on a free-machining steel like B1112. If a material scores 50 percent, it means it is twice as difficult to machine compared to the reference.

Remember, these ratings offer a general guide but have their limitations. They do not always account for specific cutting conditions or newer tooling materials.

Another widely used standard is the ISO 3685 tool life testing method. This method measures how long a cutting tool lasts under fixed cutting speeds and feeds — often reported through V30 or V60 values. These metrics are particularly useful for evaluating tool life on modern high-speed steel (HSS) and carbide tools common in today’s workshops.

When looking beyond just tool life, surface finish and dimensional accuracy also matter. Metrics like Ra (average roughness) and Rz (peak-to-valley height) give a clear picture of the quality produced at different speeds and feeds. For example:

- Increasing cutting speed often lowers Ra, improving surface finish

- Feed rate adjustments can impact both Ra and Rz, balancing smoothness with productivity

These machinability rating systems, combined with surface finish data, are essential when setting up your machine parameters or selecting materials in the CNC process for the best balance of performance and cost.

Material-Specific Machinability Guide

Machinability varies widely depending on the material you’re working with. Here’s a quick breakdown based on common metals used in manufacturing in the United Kingdom:

- Carbon SteelsRelative machinability rating: 50–70%

These steels are low cost and widely used. They tend to work harden, which can affect tool life, but popular grades like vast C-Series hold a solid 65% machinability rating. Great for many general machining tasks. - Stainless Steels (300 Series)Relative rating: 35–45%

Known for corrosion resistance, these steels are tougher to machine due to gummy chip formation that can build up on tools. For example, vast 316L-FM scores about 52%, showing some improvements but still challenging. - Aluminium 6000 SeriesRelative rating: 300–500%

Much easier to machine than steels, aluminium is lightweight and produces continuous chips that might cause built-up edge (BUE) on tools. Vast 6061-MAX leads here with an impressive 450% machinability rating, speeding up production and improving tool life. - Titanium 6Al-4VRelative rating: 15–25%

Titanium is strong and light but generates high heat and stresses cutting edges. The vast Ti64-EZM alloy holds about 28% machinability, which is low but typical, requiring careful tooling and coolant strategies. - Brass and BronzeRelative rating: 200–400%

These materials machine very well, producing soft, easy-to-manage chips and excellent surface finishes. Vast CuZn-FM is a standout with a 380% machinability rating, making them preferred choices where finish quality is critical.

Understanding these material machinability ranges helps in planning tooling, cutting speeds, and cooling to optimise shop-floor efficiency and tool life.

Testing Machinability in Practice

Testing machinability isn’t just theory—it’s about real-world results. In the lab, common methods include turning tests following the ISO 3685 standard, which measures tool life under controlled cutting conditions. Drilling tests monitor torque and thrust, while milling tests focus on power consumption and tool wear patterns. These metrics give precise, comparable data on how materials behave.

On the shop floor, quick checks help operators make fast decisions. They look at chip colour and length, inspect tool wear after about 10 minutes, and listen for changes in the cutting sound signature—these clues reveal how smoothly the machining is running and if adjustments are needed.

Software tools have become a huge asset too. Advanced machinability prediction programmes integrate with CAM systems, like the vast Material Selector plugin, helping choose the best cutting parameters and tools upfront. This data-driven approach saves time and reduces guesswork in machining diverse materials.

Testing machinability combines lab precision, shop-floor experience, and digital tools—giving a full picture to optimise your process every step of the way.

optimisation Strategies for Machinability

Improving machinability isn’t just about selecting the right material—it’s also about how you run the process. Here are some key areas to focus on:

Cutting Parameters

Adjusting speed, feed, and depth of cut can make a big difference. Use these quick reference tables to get started:

| Parameter | Effect on Machinability | Tip |

|---|---|---|

| Cutting Speed (Vc) | Higher speed can reduce tool life but improve finish | Find balance per tool specifications |

| Feed Rate | Higher feed increases material removal but raises tool wear | Use moderate feeds for tough materials |

| Depth of Cut | Too deep causes chatter; too shallow wastes time | Optimize for stable cuts |

Tooling and Coolant

Using the right tools and coolant can extend tool life and improve surface finish:

- Coated Carbides: Better wear resistance and heat control.

- Minimum Quantity Lubrication (MQL): Cuts down coolant use, reduces heat.

- High-Pressure Coolant: Flushes chips effectively, prevents built-up edge.

Process Selection

Choosing the right machining process is key for cost and quality:

- Switch from Milling to Turning When:

- Parts have symmetric shapes.

- Surface finish and dimensional accuracy are priorities.

- Turning often offers better cycle times and tool life on cylindrical parts.

Cost Modelling

Understand your total cost by factoring in machinability:

Total Cost Per Part =

(Material Cost) + (Machining Time × Labour Rate) + (Tooling Cost per Part) + (Setup and Overhead)

Include a Machinability Index to predict effects on tool wear and cycle time, helping optimise cost against quality.

These strategies help maximise efficiency on the shop floor, saving time and lowering expenses while maintaining high quality. Tailor them to your parts and tools for best results.

Case Studies from Vast Customers

Vast’s machinability solutions have delivered impressive results across different industries in the UK aerospace sector saw a 38 percent cycle time reduction using Vast Ti64-EZM alloy. This improvement is a game-changer for tight production schedules and cost control on tough titanium parts.

In automotive manufacturing, Vast 4140-FM helped achieve a 22 percent increase in tool life. Longer tool life means fewer interruptions, less downtime, and better overall efficiency on the shop floor.

These examples show how selecting the right material with a reliable machinability rating can lead to real savings and better process stability. Whether you’re working with aerospace-grade titanium or high-strength steels, Vast’s materials give UK manufacturers a serious edge in productivity.