Learn essential blind hole drilling techniques, design tips, and machining best practices for precision and efficiency in manufacturing.

If you’ve ever wrestled with drilling holes that don’t go all the way through, you know the unique challenges blind holes present—whether it’s chip build-up, depth precision, or threading headaches. But mastering blind holes is crucial for engineers, machinists, and CNC pros who demand flawless, sealed joints without compromising material strength. In this post, you’ll get clear, practical insights on machining blind holes, from design tips to drilling techniques that keep your tools running smooth and your parts up to spec. Ready to turn tricky blind holes into precision wins? Let’s get started.

Understanding Blind Holes: What Exactly Is a Blind Hole?

A blind hole is a type of hole drilled into a material that does not go all the way through—it has a bottom within the workpiece. Unlike through holes that pass completely through the part, blind holes stop at a specified depth, making them essential for many applications where full penetration isn’t desirable.

Anatomy of a Blind Hole

- Diameter (Ø): This indicates the hole’s width across its cross-section. It’s usually specified with a tolerance, for example, Ø10 mm ±0.05 mm.

- Depth: The vertical distance from the surface to the hole’s bottom. It’s often noted as “ØX × Y deep,” where X is diameter and Y is depth (e.g., Ø10 × 25 mm deep).

- Bottom Profile: The end of the blind hole can have different shapes depending on the drilling method and application.

- Flat bottom: Created using specialised drilling or reaming tools, ideal for seated fasteners or precise seals.

- Pointed (conical) bottom: Typical of standard twist drills, resulting in a tapered end that may affect sealing or fastener fit.

Understanding these elements helps ensure blind holes meet strength, sealing, and assembly requirements precisely.

Blind Holes vs. Through Holes: Quick Comparison

| Feature | Blind Holes | Through Holes |

|---|---|---|

| Penetration | Partial depth; doesn’t go all the way through | Full penetration; goes completely through the material |

| Chip Flow | Chips can build up at the bottom, needing special drilling like peck cycles | Chips exit freely through the hole, easier chip evacuation |

| Applications | Used when sealing, aesthetics, or weight reduction matter (e.g., hidden fasteners) | Common in simple mounting where full holes are no issue |

| Cost Implications | Usually higher due to complex drilling and tool wear | Generally cheaper and faster to produce |

Blind holes are great when you need to keep fasteners hidden or ensure seals in fluid systems. But they require careful machining to deal with chip evacuation and depth accuracy. Through holes are simpler but won’t offer the same benefits in design or function. Understanding these differences helps choose the right hole type for your part.

Why Choose Blind Holes?

Blind holes offer some clear benefits that make them the go-to choice in many designs. Here’s why:

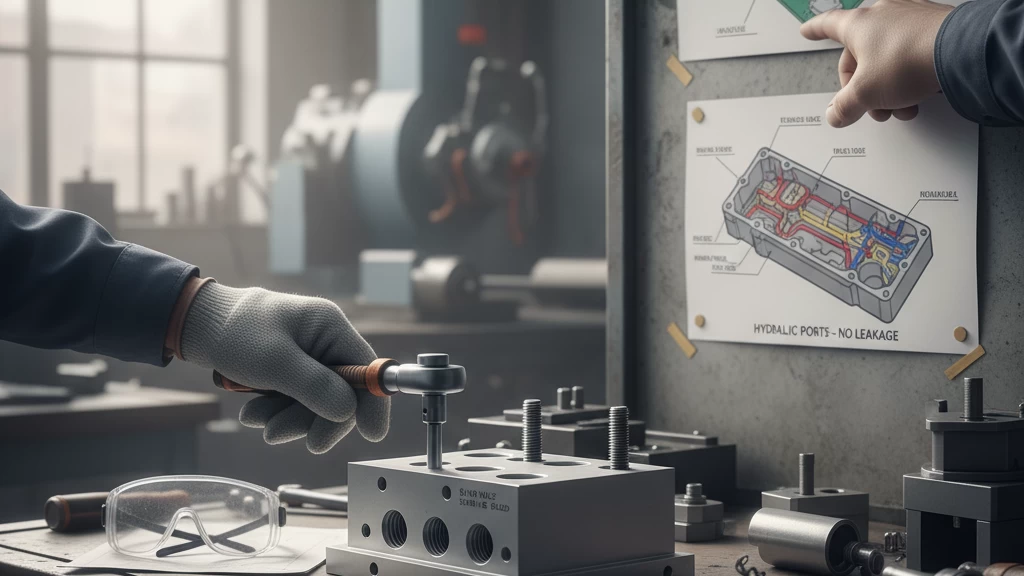

- Better Sealing in Fluid PathwaysBecause blind holes don’t go all the way through, they help prevent leaks in fluid systems. This makes them ideal for parts like hydraulic blocks and engine components where sealing is critical.

- Hidden Fasteners for a Clean LookBlind holes keep screws or bolts out of sight, improving the overall appearance of products. This is great for consumer electronics, automotive interiors, and any design where aesthetics matter.

- Weight ReductionSince the hole depth can be controlled precisely, and it stops short of breaking through, blind holes remove only what’s necessary. This helps reduce weight without compromising strength, especially important in aerospace and EV components.

Quick Benefits Table

| Benefit | Why It Matters | Common Use Cases |

|---|---|---|

| Enhanced Sealing | Prevents Fluid Leaks | Hydraulic, Pneumatic Parts |

| Hidden Fasteners | Cleaner, More Polished Look | Electronics, Automotive Trims |

| Weight Reduction | Saves Material and Cuts Weight | Aerospace, Electric Vehicles |

Choosing Blind Holes Means Balancing Function and Form, Making Your Parts Perform Better While Looking Sharp and Staying Light.

Common Misconceptions About Blind Holes

One Big Myth Is That Blind Holes Are Always Harder to Machine Than Through Holes. While They Can Be Trickier Because the Drill Can’t Pass All the Way Through, Modern Techniques Like Automated Peck Drilling Cycles Make This Much Easier. Peck Drilling Helps Break Up Chips and Clears Them Out Regularly, Reducing the Chance of Tool Breakage and Improving Hole Quality.

So, With the Right CNC Programs and Tooling, Machining Blind Holes Can Be Just as Efficient as Drilling Through Holes. The Key Is Proper Chip Evacuation and Controlling Heat Buildup, Which Peck Cycles Handle Well. This Debunks the Idea That Blind Holes Automatically Mean More Difficult or Slower Machining—Technology Has Levelled the Playing Field.

Design Essentials for Blind Holes: Key Specifications

When Designing Blind Holes, Getting the Specs Right Is Crucial to Avoid Issues Like Stress Cracks or Poor Fit. Here’s What You Need to Keep in Mind:

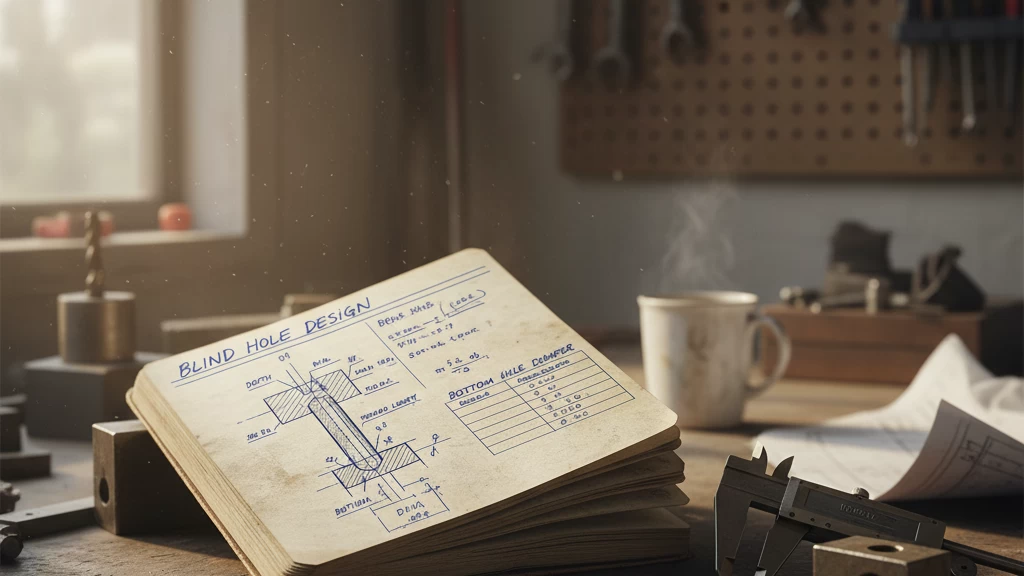

Depth Calculation

- Formula: Depth = Thread Length + Clearance + Tip Allowance

- Tip allowance: Usually 1.5 x thread pitch to prevent bottoming out

- Ensure the depth is neither too shallow (risk of stripped threads) nor too deep (wastes material and time).

Tolerance Callouts

| Feature | Typical Tolerance | Notes |

|---|---|---|

| Diameter (Ø) | ±0.005 in (±0.13 mm) | Precision depends on fit |

| Depth | ±0.010 in (±0.25 mm) | Vital for thread engagement |

| Bottom flatness | Surface finish 32-63 µin | For sealing surfaces |

Placement Strategies

- Avoid stress concentrations by:

- Keeping blind holes a safe distance from edges (at least 2x hole diameter)

- Avoiding hole placement near corners or highly loaded areas

- Using fillets or chamfers around holes to reduce sharp transitions

Keeping these key specifications in check ensures your blind holes function well and last longer without adding extra machining costs.

Material Considerations for Blind Holes: Aluminium vs. Titanium

Choosing the right material plays a significant role in blind hole stability and machining ease. When working with aluminium, you’ll find it’s softer and easier to drill. That means faster feed rates and less tool wear. Plus, aluminium benefits from less aggressive coolant use—usually just a mist or light flood is enough to keep temperatures down.

On the other hand, titanium is tougher and more heat-resistant, which affects how you approach blind hole drilling:

- Slower feed rates are needed to avoid tool breakage and poor hole quality.

- Stronger, more focused coolant flow is essential to manage heat build-up during drilling.

- Watch for work hardening; titanium’s surface can toughen if you go too fast or pause, making it harder for subsequent passes.

In both materials, stability and surface finish depend on controlling chip evacuation and tool wear. Using the right tooling and adjusting speed/feed settings based on material will help keep your blind holes on spec and avoid costly rework.

Bottom line: Aluminium lets you push efficiency, while titanium calls for a careful, patient approach to get the best results with blind holes.

Integration with Fasteners: Sizing and Over-Torquing Risks

When designing blind holes for screws or bolts, getting the size right is crucial. You want a snug fit that holds securely without damaging the material. Here’s what to keep in mind:

- Optimal Sizing: Match the hole diameter and depth exactly to the fastener specifications. Too small, and you risk cracking the part; too large, and the fastener won’t grip properly.

- Consider the thread engagement length — generally, it should be at least 1 to 1.5 times the bolt diameter for strong holding power.

- Use tolerance callouts to ensure consistent fit across production, especially if parts are batch-made or used in safety-critical systems.

Watch out for over-torquing risks when working with blind holes:

- Because the hole doesn’t go all the way through, applying too much torque can cause cracks or strip the threads inside.

- Use torque limiters or controlled power tools to avoid damaging the hole or fastener.

- Remember: blind holes don’t allow for easy visual or physical checking of thread wear, so plan for cautious assembly.

By carefully sizing fasteners and controlling torque, blind holes can deliver reliable, clean connections that keep parts tightly secured without risk of damage.

Design Essentials for Blind Holes: Extensive Tips on Design Review and FEA Simulations

When designing blind holes, taking the time for thorough design review is a smart move to avoid costly mistakes later. Using Finite Element Analysis (FEA) simulations helps you identify potential stress points around the hole, predict how the material will react, and check if the hole’s size and depth meet your structural needs.

Here’s why it matters:

- Identify stress concentrations early: FEA shows where cracks or failures might initiate near the blind hole.

- Optimise hole placement: Ensure your blind hole won’t weaken the part or cause warping.

- Save time and money: Addressing issues during the design phase is better than reworking or discarding parts during production.

- Improve performance: Double-check sealing effectiveness and fastener strength, especially in critical applications.

Bottom line: integrating FEA and design review into your blind hole process gives you confidence in your design’s durability and function—before you even drill the first hole.

Machining Blind Holes: Drilling Methods

When it comes to drilling blind holes, choosing the right method can make all the difference in quality and efficiency.

CNC vs. Manual Drilling

CNC drilling offers precision and repeatability that’s hard to match manually. Automated control ensures consistent depth and diameter, which is crucial for blind holes where you can’t afford to break through. Manual drilling works for simpler jobs or quick fixes but risks over-penetration or inaccuracies.

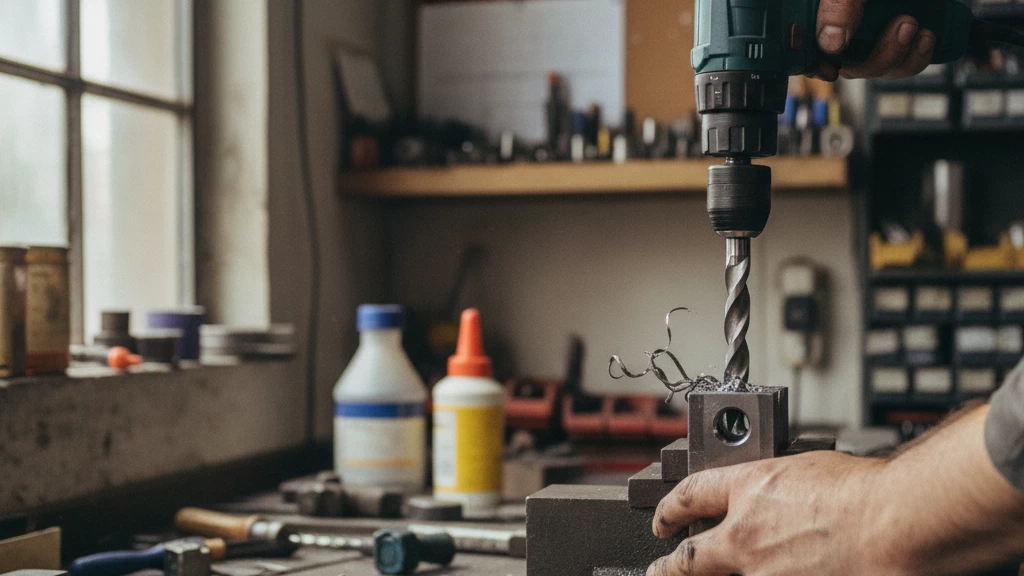

Peck Drilling Cycles

Peck drilling is an essential technique especially for deeper blind holes. Instead of drilling straight down in one go, the drill bit retracts periodically to clear chips. This prevents chip buildup, reduces heat, and lowers the chances of tool breakage. Most CNC machines support automated peck cycles for easier chip evacuation.

Chip Evacuation

One of the biggest challenges in blind hole drilling is clearing chips efficiently. Poor chip removal can cause jamming, tool wear, or even stuck tools. Using coolant or compressed air, combined with peck drilling, is key. Also, selecting drill bits with proper flute design helps chips move out smoother.

Tool recommendations

For blind holes, long drill bits with split points or specialised tip geometries help reduce walking and improve entry. Carbide or cobalt bits handle harder materials better, especially when paired with adequate coolant. Keep tool sharpness in check—dull tools generate more heat and increase breakage risk.

In short, CNC with peck drilling cycles and good chip evacuation strategies will give you the clean, precise blind holes your projects demand.

Threading Blind Holes: Spiral Flute vs. Straight Flute Taps and Troubleshooting Breakage

When it comes to threading blind holes, choosing the right tap is crucial. Spiral flute taps spiral flute taps are usually the top choice because they pull chips out of the hole, which is essential since the hole doesn’t go all the way through. This chip evacuation prevents clogging and reduces the risk of tap breakage. Spiral flute taps work great in softer materials like aluminium or plastics, where chip control is a must.

On the other hand, straight flute taps push chips downward into the hole bottom, which can cause problems in blind holes because chips get trapped. However, straight flute taps might be better for very hard materials or when tapping shallow blind holes.

Tips to Avoid Tap Breakage

- Use peck tapping cycles on your CNC machine to incrementally remove chips.

- Keep coolant or lubricant flowing to reduce heat and friction.

- Avoid aggressive feed rates; slower, steady tapping is safer.

- Select taps with good coating and sharp cutting edges.

- Inspect tools regularly for wear to replace before failure.

If breakage still happens, check for misalignment, worn tools, or material inconsistencies. Threading blind holes calls for patience and the right technique—getting it right saves time and tooling costs.

Machining Blind Holes: Finishing Touches

Once the blind hole is drilled and threaded, the finishing steps are key to ensuring quality and functionality. Here’s what to focus on:

- Reaming: Use a precision reamer to clean up the hole diameter for tight tolerances and better surface finish. This step helps achieve the exact size and smooth walls, which is critical for proper fastening.

- Chamfering: Adding a chamfer at the hole entrance prevents burrs and makes screw insertion easier. A slight bevel also reduces stress concentration around the hole opening.

- Inspection: Check depth and diameter with calibrated gauges and use optical or tactile measurement tools for precise results. Don’t skip checking the bottom profile—whether flat or pointed—as it affects seating and sealing in critical applications.

Finishing blind holes correctly reduces assembly issues and extends the life of fasteners, which ultimately saves time and cost on the shop floor.

Machining Blind Holes: Advanced CNC Strategies

When machining blind holes, advanced CNC strategies can make a significant difference in accuracy, speed, and tool life. Using high-speed parameters—such as increased spindle speeds and optimised feed rates—helps reduce cycle times without compromising hole quality. Combining these with proprietary G-code optimisations allows for smoother tool paths and precise depth control, which is crucial in blind holes to avoid bottoming out the drill or tap.

Some key tips include:

- Use peck drilling cycles with custom retract distances to enhance chip evacuation and reduce heat build-up.

- Program dwell times at the hole bottom to improve surface finish before retracting.

- Implement adaptive feed control to adjust feeds based on material hardness and cutting forces.

- Leverage canned cycles tailored for blind hole drilling and threading for consistent results.

These advanced CNC methods not only improve blind hole precision and reduce tool wear but also help scale production efficiently. For anyone working on blind holes, mastering these strategies can save time and prevent costly rework.

Challenges and Solutions: Chip Accumulation and Tool Breakage

One of the biggest headaches when drilling blind holes is chip build-up inside the hole. Since blind holes don’t go all the way through, chips have nowhere to escape. This can cause tool jams, increased heat, and eventually tool breakage if not handled properly.

Common Causes

- Poor chip evacuation: Chips get trapped at the bottom.

- Incorrect feed rates: Too fast or too slow, both can cause issues.

- Using wrong tools: Standard drill bits or taps not designed for blind holes.

- Lack of coolant or lubrication: Increases friction and heat.

How to Fix It

- Peck drilling cycles: Break chips into small pieces and clear them regularly.

- High-quality tools: Use drill bits and taps made for blind hole drilling, like spiral flute taps for better chip removal.

- Proper coolant flow: Keeps the tool cool and flushes chips out.

- Adjust feed and speed: Optimise based on material and tool.

A Real-World Example: Vast Solutions Case Study

At Vast, we tackled chip accumulation by implementing automated peck drilling combined with high-pressure coolant systems. This approach reduced tool breakage by 40% and cut machining time by 25%. Using spiral flute taps for threading blind holes further improved chip flow, preventing tap fractures and ensuring consistent thread quality.

By focusing on these strategies, we turned a tough machining challenge into a repeatable process that improves production efficiency and tool life.

Depth Accuracy Issues: Thermal Expansion, Vibration, and Solutions

When drilling blind holes, maintaining depth accuracy can be tricky. Two big challenges here are thermal expansion and vibration, both of which can throw off your measurements and cause costly mistakes.

Thermal expansion happens because the drill bit and workpiece heat up during machining. As metal heats, it expands slightly, meaning the hole might end up deeper or shallower than intended if not accounted for. To combat this:

- Use coolant to keep temperatures stable.

- Allow the tool and part to cool down between passes.

- Program CNC machines with thermal compensation if possible.

Vibration during drilling leads to inconsistent depth and poor surface finish. It happens especially with long drill bits or unstable setups. To reduce vibration:

- Secure the workpiece firmly with proper fixturing.

- Use sharp, balanced tools designed for blind hole drilling.

- Opt for peck drilling cycles — these retract the bit regularly to clear chips and reduce chatter.

By addressing thermal expansion and vibration upfront, you get more consistent blind hole depths, saving time and rework. Incorporating these solutions into your process is key for precision and efficiency.

Surface Finish and Burrs: Bottom Polishing and Electrochemical Deburring

When machining blind holes, getting a clean surface finish at the bottom can be tricky. Burrs often form around the edges and the hole bottom, which can cause assembly problems or affect sealing in fluid applications.

Here’s how to tackle surface finish and burr issues:

- Bottom Polishing: Use specialised small-diameter polishing tools or brushes designed for blind holes. These tools smooth out rough spots without changing hole dimensions.

- Electrochemical Deburring (ECD): This process uses an electric current and chemical solution to gently remove burrs, especially in hard-to-reach blind hole bottoms. It’s fast, precise, and reduces the risk of damaging the part.

- Chamfering: Adding a slight chamfer around the hole entrance removes sharp edges, prevents burr formation, and makes it easier to insert fasteners.

- Inspection: Use borescopes or surface profilometers for quality checks. Catching burrs or roughness early helps avoid downstream problems.

By focusing on these finishing steps, you ensure blind holes meet tight tolerances and last longer, especially in high-performance UK-made parts where reliability matters.

Challenges and Solutions: Scaling for Production

When moving blind holes from prototype to full production, efficiency becomes key. Here are some practical ways to scale up without sacrificing quality:

- Batch Efficiency: Group similar parts together to minimise machine setups and tool changes. This speeds up production and lowers costs. Using standardised blind hole depths and sizes across batches helps too.

- Fixture Design: Custom fixtures are a game-changer. They hold parts securely and ensure consistent hole placement. Well-designed fixtures reduce vibration and improve repeatability, which is critical when machining multiple blind holes.

- Multi-Axis Programming: Taking advantage of 3, 4, or 5-axis CNC machines lets you machine complex blind holes in one setup. This cuts down on handling time and reduces errors caused by repositioning. Plus, it improves chip evacuation when combined with peck drilling cycles.

By focusing on batch workflows, smart fixture setups, and advanced CNC programming, manufacturers can effectively scale blind hole production—keeping quality high while controlling time and cost.

Blind Holes in Aerospace and Defence: Sealed Housings and Leak Minimisation

In aerospace and defence, blind holes play a critical role in creating sealed housings that keep systems airtight and leak-free. Because these industries demand top-notch reliability, blind holes help maintain pressure boundaries without risking exposure to contaminants or fluids.

Here’s why blind holes are preferred:

- Leak Prevention: Unlike through holes, blind holes don’t pass through the entire material, reducing the chances of fluid or gas leaks in sensitive avionics or hydraulic components.

- Structural Integrity: By stopping short of breaking through, blind holes maintain part strength, which is essential for withstanding high stresses during flight or combat situations.

- Hidden Fasteners: Blind holes allow for flush, concealed fasteners that improve aerodynamics and reduce corrosion risks from environmental exposure.

- Precision Sealing: When paired with O-rings or threaded plugs, blind holes provide reliable seals that meet stringent aerospace standards.

In short, when aerospace and defence equipment needs airtight, robust, and high-performance assemblies, blind holes often stand out as the smart choice to minimise leaks while preserving strength and durability.

Real-World Applications: Automotive and EV Components – Lightweight Brackets and Hidden Threads

Blind holes play a significant role in automotive and electric vehicle (EV) parts, especially when weight and clean design are important. Using blind holes for lightweight brackets helps reduce material usage without compromising strength. Since these holes don’t go all the way through, they keep components sturdy while lowering overall weight—crucial for EV range and fuel efficiency.

Hidden threads in blind holes also enhance the appearance and functionality of automotive parts. Fasteners remain concealed, resulting in cleaner assemblies and reducing corrosion risks since the threads aren’t exposed. This is essential for parts exposed to harsh road conditions and temperature fluctuations.

In summary, blind holes provide automotive and EV manufacturers with a way to produce lighter, stronger components with sleek, durable finishes—ideal for the United Kingdom market where performance and style are equally valued.

Real-World Applications: Medical Devices – Sterility, Biocompatibility, and Precision Tolerances

In medical devices, blind holes are vital where sterility and precision are non-negotiable. Because these holes don’t go all the way through, they help maintain sealed environments—perfect for fluid pathways or housing sensitive electronics. The design of blind holes minimises contamination risks by reducing open surfaces where bacteria or particles might settle.

Biocompatibility is another key factor. Materials commonly used with blind holes in medical equipment, such as titanium and certain stainless steels, must be compatible with the human body and capable of maintaining tight tolerances without sacrificing strength. This means the hole’s diameter, depth, and bottom profile need to be machined with high accuracy.

Precision tolerances are essential because even minor deviations can impact assembly, functionality, or sterility. Strict control during the drilling and threading of blind holes ensures devices meet rigorous FDA and ISO standards. Employing advanced CNC blind hole drilling techniques and thorough inspection helps prevent costly defects.

In brief, blind holes in medical devices ensure safety, reliability, and performance by combining designs that support sterility and biocompatibility with precise machining practices. This is why they are preferred in surgical tools, implants, and diagnostic equipment.

Consumer Electronics: Compact Enclosures Balancing Aesthetics and Heat Dissipation

Blind holes are important in consumer electronics, especially when designing compact enclosures. These holes allow manufacturers to hide screws and fasteners, giving devices a cleaner, sleeker appearance. This is significant for products like smartphones, laptops, and gaming consoles where every millimetre counts.

Beyond aesthetics, blind holes also assist in managing heat dissipation. By carefully positioning blind holes, designers can avoid creating weak points in the enclosure that might trap heat or disrupt airflow. Achieving this balance is vital—electronic components need to stay cool for longer lifespan, but the casing must remain slim and intact.

In the United Kingdom market, where consumers expect high-quality, slim designs packed with power, effective use of blind holes means achieving a combination of durability, style, and thermal management. It’s about creating enclosures that not only look good but also keep devices functioning smoothly without overheating.

Key points for consumer electronics with blind holes:

- Conceal fasteners for a smooth, modern finish

- Optimise hole depth to prevent weakening thin walls

- Position holes to support airflow and heat dissipation

- Use precise tolerances to ensure tight fits without gaps

This approach keeps devices lightweight and durable while meeting the design demands of today’s competitive electronics market.

Real-World Applications: Emerging Trends with Additive Manufacturing Hybrids and Post-Printed Threading

Additive manufacturing (3D printing) is reshaping how blind holes are created, especially when combined with traditional machining—this hybrid approach brings new possibilities. Instead of drilling blind holes into solid parts, manufacturers can print near-net-shape components with rough hole features already in place. Then, they follow up with precise machining like post-printed threading to achieve exact dimensions and finish quality.

This hybrid method offers:

- Material savings by printing only what’s needed

- Reduced machining time since less metal is removed

- Better design flexibility for complex internal geometries

- Improved accuracy by trimming and threading after printing

Post-printed threading is becoming a go-to for blind holes in aerospace, medical devices, and high-precision electronics, where tight tolerances and surface finishes matter. Using advanced CNC tools with automated threading cycles helps avoid common issues like tap breakage in tricky blind holes.

In the manufacturing sector, this blend of additive and subtractive techniques helps meet demanding specifications faster, reduces waste, and supports innovative design—in line with local industry needs focused on efficiency and quality. If you’re exploring blind hole machining, consider how additive manufacturing hybrids can boost your process without sacrificing precision.

Essential Tooling for Blind Holes

When working with blind holes, having the right tools is key to getting clean, precise results. Here’s a quick rundown of the essential tooling you’ll need:

- Drill Bits: Choose sharp, high-quality drill bits designed for blind hole drilling techniques. Carbide or cobalt bits work well for tough materials like titanium, while HSS bits are fine for aluminium. Look for bits with split points or special flute designs to help with chip evacuation, especially in deeper holes.

- Taps: For threading blind holes, spiral flute taps are your go-to. They pull chips up and out, reducing the chance of breakage inside the hole. Straight flute taps are still useful but generally better for through holes due to slower chip removal. Always match tap size carefully with your hole diameter for best results.

- Holders and Tool Holders: Secure and stable tool holders make a significant difference in precision and surface finish. Use holders designed for your CNC or manual machines that minimise runout and vibration. Quick-change holders improve setup speed, especially in production runs.

- Coolant Delivery Systems: Proper coolant flow helps reduce heat and chip welding, protecting both your tools and the workpiece. External coolant nozzles or through-tool coolant setups are preferred when drilling blind holes.

Investing in these right tools not only boosts your machining quality but also reduces costly tool breakage and rework. If you’re in the UK market, prioritising tool longevity and precision will help keep your operations smooth and competitive.

Tools and Technologies: Software and Automation

When it comes to blind holes, having the right software makes a huge difference. CAD/CAM integration is now standard in many UK workshops, allowing you to design precise hole specifications and directly translate them into CNC programmes. This reduces errors and speeds up setups.

Cloud-based simulation tools are also a game changer. They help you test drilling and threading sequences virtually before running the machine. You can identify potential issues with chip evacuation, tool paths, or depth accuracy early, saving time and money on trial runs.

Benefits of using CAD/CAM and cloud simulation for blind holes:

- Faster programming with fewer errors

- Easy updates to designs and toolpaths

- Real-time collision and chip flow checks

- Better collaboration across design and machining teams

- Optimised cycles that reduce tool wear and machining time

For workshops serving the UK market, investing in these technologies means higher precision, improved throughput, and better consistency when producing blind holes—especially in complex parts. It’s well worth the upgrade if you want to stay competitive.

Tools and Technologies: Safety and Sustainability with PPE and Eco-Friendly Coolants

When working with blind holes, safety and sustainability should never be an afterthought. Using proper personal protective equipment (PPE) is essential to protect against metal chips, coolant splashes, and sharp tools. This includes safety glasses, gloves, and even hearing protection in louder machine shops.

Eco-friendly coolants are also gaining traction in the UK market. These coolants help reduce environmental impact by being biodegradable and less toxic compared to traditional fluids. Plus, they often improve tool life and surface finish, especially in demanding blind hole drilling and threading operations.

Key takeaways:

- Always wear PPE: safety glasses, cut-resistant gloves, and hearing protection.

- Choose biodegradable coolants to reduce waste and keep your workshop greener.

- Eco-friendly fluids help with chip evacuation and reduce heat, extending tool life.

- Using sustainable tools and practices meets both safety standards and evolving UK environmental regulations.

Adopting these measures ensures safer operations and aligns your workshop with modern sustainability goals—good for your team and good for business.