Discover everything about shaft splines including design, types, manufacturing, and applications for reliable torque transmission in machinery.

Imagine your heavy machinery grinding to a halt because of a simple torque slip—frustrating, costly, and avoidable. That’s where shaft splines come into play. These precision-engineered ridges and grooves aren’t just mechanical details; they’re the backbone of reliable torque transmission and seamless alignment in everything from automotive drivetrains to industrial equipment. Whether you’re an engineer, technician, or DIY enthusiast, understanding shaft splines’their design, types, and applications is crucial to preventing failures and optimising performance. Ready to dive into the essentials of shaft splines and how they keep your systems running smoothly and strongly? Let’s get started!

What Are Shaft Splines A Core Breakdown

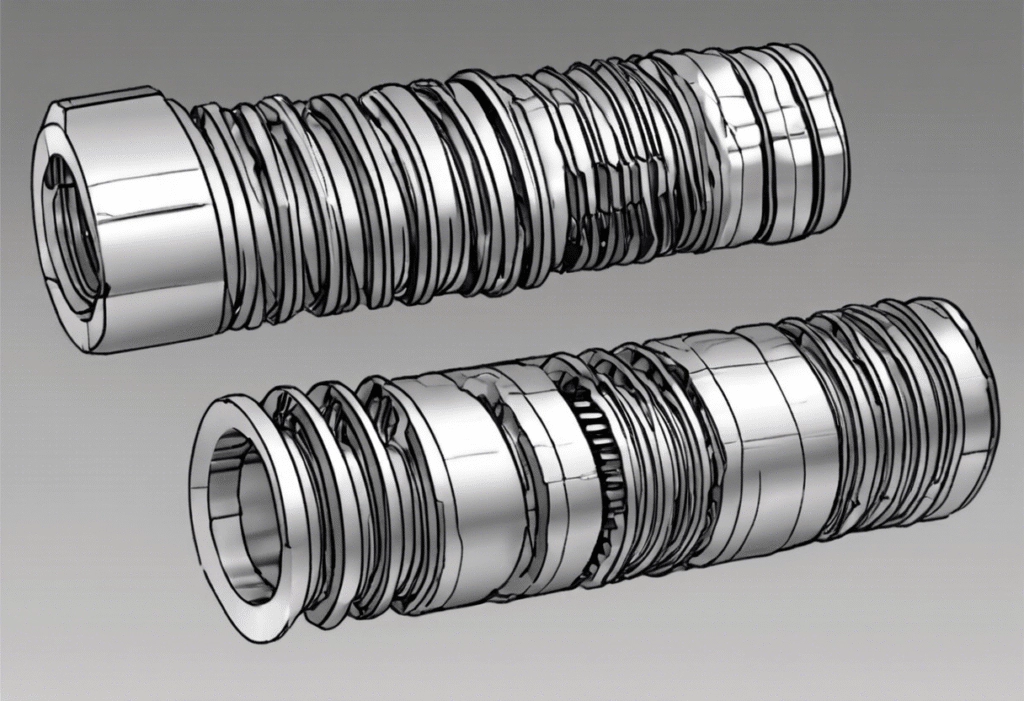

Shaft splines are a fundamental mechanical feature used to transfer torque between a shaft and a mating component, such as a gear, hub, or coupling. At their core, shaft splines consist of a series of ridges or teeth cut into the shaft’s surface. These teeth fit precisely into corresponding grooves on another part, creating a secure and reliable connection that allows rotary motion and power to be transmitted efficiently.

The Basic Anatomy and Function of Spline Shafts

A typical spline shaft includes several key components:

- Teeth: Raised ridges evenly spaced around the shaft.

- Root diameter: The diameter at the base of the grooves.

- Major diameter: The diameter across the tips of the teeth.

- Flanks: The angled sides of each tooth that engage the mating part.

Together, these features ensure a tight engagement that resists slipping under load. The main function of shaft splines is torque transmission without the backlash or wear often seen in keyed shafts, making them ideal for high-precision or high-stress applications.

Why Shaft Splines Outperform Traditional Keyed Shafts

Spline shafts outperform traditional keyed shafts in several important ways:

- Better Load Distribution: Unlike a single keyway, splines distribute torque evenly across multiple teeth. This reduces stress concentration and improves the lifespan of both the shaft and mating parts.

- Increased Torque Capacity: By spreading the load, splines can handle significantly higher torque levels without deformation or failure.

- Precision Alignment: Splines provide more uniform alignment and reduce backlash, which enhances mechanical efficiency and smooth operation.

- Improved Durability: The larger contact surface and multiple load points reduce wear and potential for shaft fretting compared to keyed shafts.

Because of these advantages, shaft splines have become the go-to solution for applications requiring reliable torque transmission splines with minimal maintenance and high performance, especially in automotive, industrial, and aerospace sectors.

This solid understanding of what shaft splines are and why they outperform traditional keyed shafts sets the stage for exploring the different spline types, manufacturing considerations, and their real-world applications.

Types of Shaft Splines Choosing the Right Profile for Your Needs

When it comes to shaft splines, picking the right type makes all the difference. Each profile handles torque and wear a bit differently, so matching your application is key.

Straight-Sided Parallel Splines Ideal for Simplicity

These splines have straight sides and are easy to cut or roll. They’re great for basic torque transmission where loads aren’t extreme. If you want a simple, cost-effective solution for industrial or agricultural equipment, straight-sided parallel splines often fit the bill.

Involute Splines The Gold Standard for High Performance

Involute splines feature curved teeth that match the involute shape—a design that improves load distribution and reduces stress points. This makes them perfect for automotive spline shafts and heavy-duty industrial uses where smooth torque transmission is critical. Their precise spline tolerances, often compliant with AGMA standards, mean they handle high performance better than most alternatives.

Other Specialized Types Serrations Ball Splines and Beyond

Beyond the basics, there are more specialised spline options:

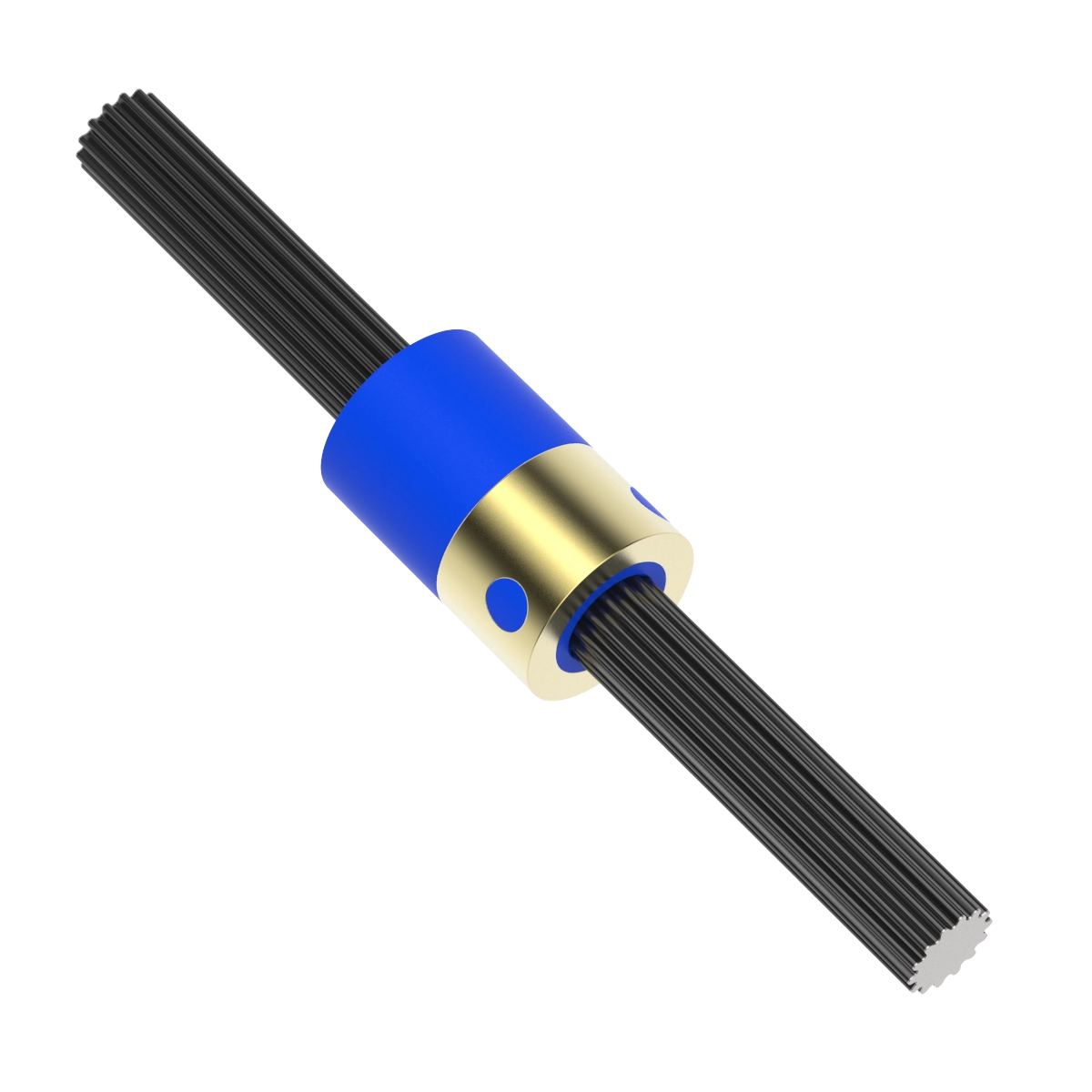

- Serrations: Used when a compact design with smaller torque requirements is needed.

- Ball Splines: These use ball bearings to allow smooth movement along the shaft, perfect for heavy-duty precision applications or complex machinery.

- Custom Profiles: Sometimes, custom spline rolling or broaching produces tailored solutions for unique engineering challenges.

Choosing the right shaft spline profile depends on the torque needs, alignment tolerances, and movement required. Knowing these types helps you decide what fits your project best.

Manufacturing and Material Considerations for Durable Shaft Splines

When it comes to making shaft splines that last, the manufacturing process and material choice are a big deal. Getting this right ensures your spline shafts handle torque transmission splines effectively and stay reliable over time.

Common Production Methods From Rolling to Broaching

There are a few popular ways to produce shaft splines, each with its pros:

- Spline Rolling: This cold-forming process is fast, creates strong external spline designs, and keeps material grain flow intact. It’s great for high-volume automotive spline shafts because it reduces waste and boosts strength.

- Broaching: This is a precise cutting method, perfect for complex spline profiles like involute splines or specialised serrations. It’s slower but offers tight spline tolerances AGMA standards require, making it ideal for aerospace or precision engineering uses.

- Milling and Grinding: Used when high precision is key or for prototypes/custom spline rolling isn’t practical. It’s more flexible but slower and often more costly.

Material Selection and Heat Treatment Essentials

Choosing the right material sets the foundation for durability:

- Most shaft splines use high-grade alloy steels designed to withstand high torque and stress.

- Heat treatment—like carburising or induction hardening—is critical. It hardens the spline surface, boosting wear resistance while keeping the core tough to avoid cracks or fractures.

- Proper heat treatment also helps maintain spline tolerances, especially in demanding industrial spline maintenance situations.

Quality Control Avoiding Common Pitfalls

Ensuring quality means catching issues early:

- Dimensional checks on spline tooth profiles prevent fit problems in mating parts.

- Monitoring surface finish to reduce friction and wear during operation.

- Using non-destructive testing like magnetic particle inspection to detect possible cracks.

- Focusing on consistent spline shaft manufacturing processes reduces defects and improves long-term performance.

By combining solid manufacturing methods, the right materials, and strict quality control, shaft splines deliver reliable strength and smooth torque transfer for countless applications across the UK market.

Real World Applications Where Shaft Splines Drive Success

Shaft splines play a critical role across several industries in the UK, making torque transfer smoother and more reliable.

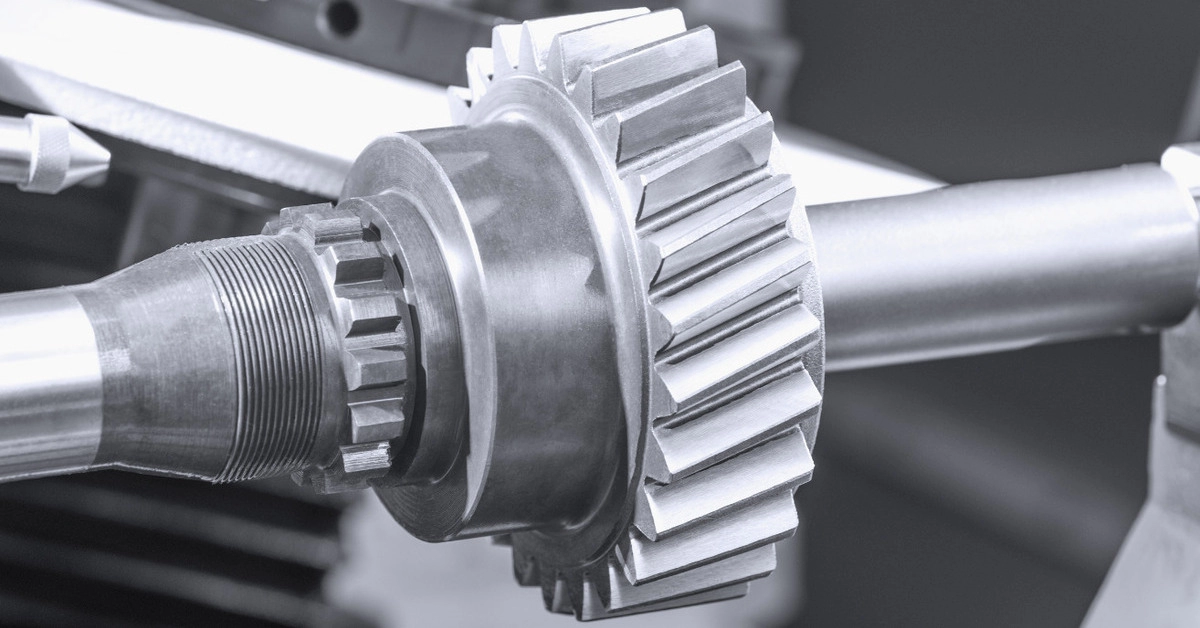

Automotive and Driveline Innovations

In automotive manufacturing, splines are everywhere—from transmission shafts to drive axles. Automotive spline shafts help deliver consistent power and handle high torque loads, improving vehicle performance and durability. They outperform traditional keyed shafts by reducing play and wear, which is essential on modern cars where precision matters.

Industrial and Agricultural Powerhouses

Heavy machinery in industries like construction and agriculture relies on shaft splines for robust torque transmission. Equipment such as tractors, harvesters, and industrial mixers use splines to handle tough loads without slipping. The durability of these splines, often made from heat-treated steel, keeps machines running longer with less maintenance.

Aerospace and Precision Engineering Uses

In aerospace, precision is key, and so is weight reduction. Shaft splines in aircraft components enable precise alignment and efficient power transfer while maintaining lightweight designs. Aerospace spline shafts must meet strict tolerances and quality standards, ensuring safety and performance during demanding conditions.

Across these sectors, the combination of strong materials, careful design—like involute splines—and precise manufacturing makes shaft splines a trusted choice for reliable torque transfer and long-lasting performance.

Maintenance Troubleshooting and Best Practices for Longevity

Keeping shaft splines in good shape is key to making sure your machinery runs smoothly. Here’s how to spot trouble, maintain your splines, and know when it’s time to upgrade.

Signs of Spline Wear and Failure Modes

- Noise and Vibration: Unusual sounds or vibrations often point to worn spline teeth or loose fits.

- Visible Wear: Look for rounding or deformation of the spline teeth.

- Corrosion: Rust or pitting can weaken spline surfaces, leading to premature failure.

- Excessive Backlash: Too much play between the shaft and mating part means the fit is no longer tight.

- Cracks or Fractures: These are serious and need immediate attention to avoid breakdowns.

Pro Tips for Installation and Upkeep

- Clean and Inspect: Always clean splines before installation and check for damage.

- Proper Lubrication: Use the right grease or oil to reduce friction and prevent corrosion.

- Correct Alignment: Misaligned splines can wear quickly — make sure shaft and hub are correctly positioned.

- Follow Manufacturer Specs: Stick to recommended torque and spline tolerances to avoid stress.

- Regular Checks: Schedule routine inspections to catch wear early.

When to Upgrade Scaling with Vast Expertise

Knowing when to upgrade is just as important as maintenance. Consider upgrading your shaft splines if you notice:

- Repeated wear or damage despite regular upkeep.

- Increased torque demands in automotive or industrial applications.

- Changes in operating conditions such as heavier loads or higher speeds.

- Newer spline designs offering enhanced performance or durability.

By addressing these points, you will extend the lifespan of your spline shafts and keep your equipment operating at peak performance.