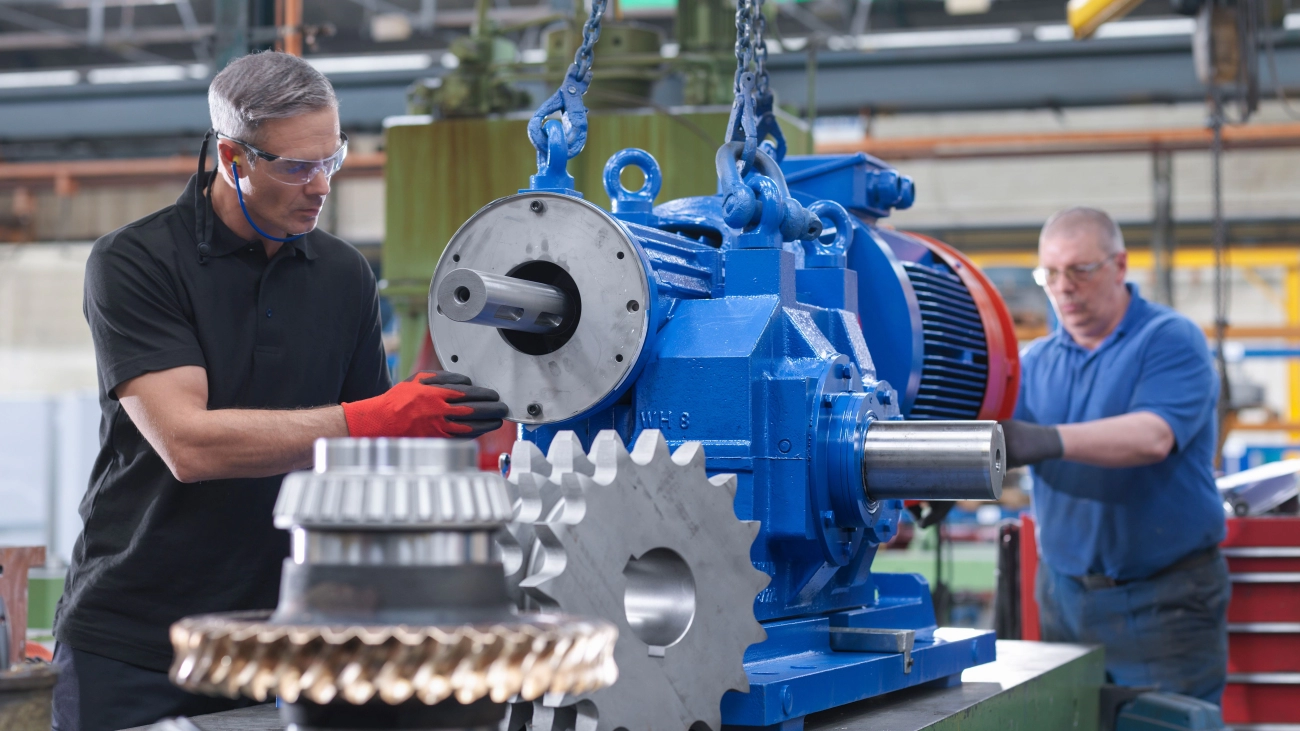

Precision gear manufacturing with customisable types, materials, and high tolerance to ensure durability and quality for industrial applications.

High Quality Gear Manufacturing with Precision and Reliability

At Vast, we deliver gears that meet the toughest demands with high load capacity and tight tolerance standards. Our gear manufacturing processes align with ISO certified quality to ensure every product supports peak performance in your applications. Whether you need spur, helical, bevel, or worm gears, we offer a broad selection built to exact specifications.

Product Specifications at a Glance

| Parameter | Details |

|---|---|

| Gear Types | Spur, Helical, Bevel, Worm |

| Module / DP Range | Module 0.5 – 10 / DP 20 – 64 |

| Diameter Range | 5 mm – 1000+ mm |

| Materials | Steel alloys, plastics, composites |

| Accuracy Grade | AGMA 8 – 14 / ISO 1 – 7 |

| Heat Treatment | Carburising, nitriding, induction |

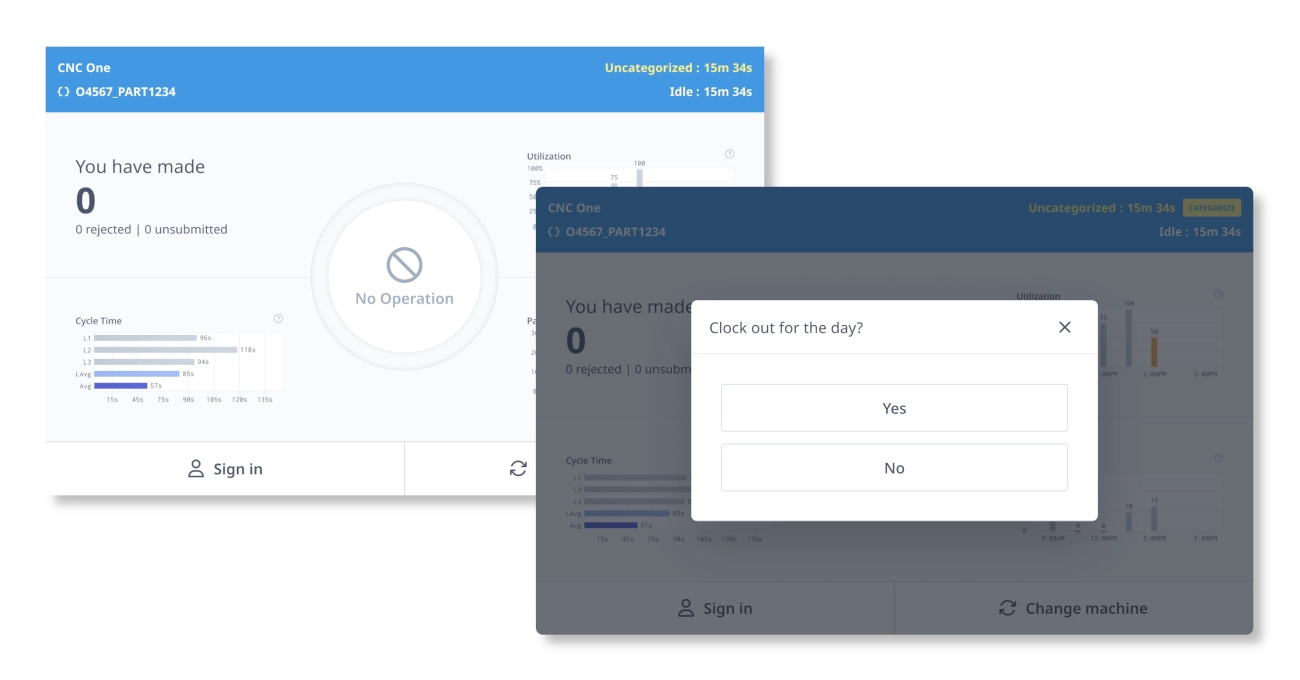

Use our interactive configurator to input your gear specifications and get instant pricing tailored to your project timeline and volume. This tool helps you find the exact gear solution with clear lead times and cost details—making custom gear manufacturing simple and stress-free.

Explore how our expertise turns your gear manufacturing needs into reliable, precision-driven components built to last. Ready to specify your ideal gear? Start with our configurator for accurate quotes and delivery schedules.

Manufacturing Process Breakdown

Our gear manufacturing process is designed for precision and reliability, following clear, step-by-step stages:

- Blank PreparationWe start by preparing gear blanks using methods like casting and forging. Casting is cost-effective for large runs, while forging offers superior strength for heavy-duty applications.

- Tooth CuttingTeeth are formed through CNC gear hobbing, shaping, and milling. Hobbing is ideal for volume production, while shaping suits specialised gear types.

- FinishingProcesses like grinding, deburring, and heat treatment refine gear surfaces, improving durability and reducing noise.

- Quality InspectionOur inspection includes Coordinate Measuring Machine (CMM) checks and gear analyzers to guarantee accuracy and flawless operation.

Material Selection Guide

Choosing the right material affects gear performance:

- SteelStrong, durable, and ideal for high-load gears, but heavier and requires proper lubrication.

- PlasticsLightweight, quieter in operation, and corrosion-resistant — great for low to medium load applications.

Customization Options

We offer flexibility to meet your project needs:

- Prototyping using 3D printing for quick proofs and design testing

- Batch sizes ranging from a single prototype to 100,000+ units for high volume production

Our capabilities ensure you get quality custom gears made in the UK with fast turnaround and competitive pricing.

Applications and Use Cases

Gears are a key part of many industries, playing critical roles wherever precise motion and power transfer are needed. Here’s where you’ll find our custom gear manufacturing solutions working hard for you:

- Automotive: From transmissions to engine timing systems, gears keep vehicles running smoothly and efficiently.

- AerospaceHigh-precision gears used in actuators and control systems help aircraft operate safely and reliably.

- RoboticsGears enable accurate joint movements and precise control in robotic arms and automated machinery.

- Industrial PumpsDurable gears handle heavy loads and continuous use, ensuring long pump life and steady performance.

Case Study

Our vast helical gears helped an industrial pump manufacturer reduce wear by 40%. This means longer service intervals and less downtime, cutting maintenance costs without sacrificing performance. This real-world success demonstrates the impact of quality gear manufacturing on demanding applications.

Quality Assurance and Certifications

We take quality seriously. Our gear manufacturing process meets strict standards like ISO 9001 and AS9100D, ensuring top-tier precision and reliability. Plus, all our products are RoHS compliant, so you know they’re safe and environmentally responsible.

Every gear undergoes thorough testing. We use CMM (Coordinate Measuring Machine) inspection to check exact dimensions, along with noise and vibration analysis to confirm smooth performance. Fatigue simulation tests help us predict how gears will withstand over time, so you receive durable, long-lasting parts.

To support this, we offer a 2-year performance warranty. That means you can have peace of mind knowing your custom gears are built to perform—guaranteed.

Pricing and Lead Times

We offer tiered pricing to suit every stage of your project, whether you need a prototype, low volume, or high volume gear manufacturing. Here’s how it breaks down:

- Prototype PricingIdeal for testing and development runs. Costs are higher per unit but keep your initial investment low.

- Low VolumePerfect for small batch runs, offering a balance between cost and flexibility.

- High VolumeBest for large orders, where you get significant price savings per gear.

Typical delivery times range from 2 to 4 weeks, depending on order size and complexity. Need it faster? We provide expedited options to meet tight deadlines.

Factors That Affect Your Cost

Several things influence your final price and lead time:

- Complexity: More intricate gear designs take extra time and precision.

- Volume: Bigger orders lower your cost per unit but might increase lead time.

- Material: Steel, plastics, or special alloys impact both cost and production speed.

By choosing us, you get transparent pricing and delivery schedules tailored to your specific gear manufacturing needs in the UK market.

Related Products and Upsells

When you choose our gear manufacturing services, we also offer a range of related products to complete your system:

Cross-sells:

- Gearboxes designed for smooth power transmission

- Shafts tailored for precise fit and durability

- High-quality bearings that reduce friction and extend component life

Accessories:

- Advanced lubricants formulated for long-lasting gear performance

- Mounting hardware customised for easy installation and secure fit

These complementary products ensure your gears operate efficiently and reliably, making us a one-stop solution for your gear needs in the UK market.

Footer CTA Section

Hear from our clients: “Vast delivered flawless custom spur gears right on schedule,” says an engineering lead at a major auto firm.

Ready to get started?

- Request a Quote (RFQ)

- Upload Your CAD Files

- Sign up for Our Newsletter

Need help? Contact us anytime by phone, email, or live chat. We’re here to support your gear manufacturing needs with quick, expert service.

What Is Gear Manufacturing and Why It Matters for Your Projects

Gear manufacturing is the process of creating gears—essential parts that transmit power and motion in machines. It has evolved significantly, moving from hand-forged methods to advanced CNC machining. This evolution means better precision, consistency, and faster turnaround times for your projects.

One of the biggest challenges in gear manufacturing is achieving the perfect involute profile. This profile ensures smooth gear meshing under load with minimal backlash, preventing noise and inefficient power transfer.

At Vast, we bring over 20 years of experience in precision gear components, having served more than 500 clients worldwide. Our expertise ensures you get reliable, high-quality gears built to your exact specifications.

For buyers in the United Kingdom, sourcing gears from United Kingdom-based manufacturers like Vast helps reduce tariffs and shipping delays. This local insight means faster delivery and more competitive costs to keep your projects on track.

Common Types of Gears and Their Manufacturing Requirements

Here’s a quick look at the most common types of gears, what they’re used for, and how hard they are to make:

| Gear Type | Profile | Best Applications | Manufacturing Complexity |

|---|---|---|---|

| Spur Gears | Straight Teeth | Automotive, Basic Drives | Low |

| Helical Gears | Angled Teeth | Quieter operation, Robotics | Medium |

| Bevel Gears | Angular Teeth | Aerospace, Industrial Pumps | High |

| Worm Gears | Spiral Worm Teeth | High ratio reductions, Actuators | High |

- Spur gears are the simplest to produce using standard hobbing. They’re perfect for basic automotive and machinery uses.

- Helical gears have angled teeth that run smoother and quieter but need specialised shaping tools for precision.

- Bevel and worm gears involve complex shapes and often require precise EDM (Electrical Discharge Machining) or special cutting to get the high ratio reductions they offer.

Use a selection flowchart based on your load and speed needs to pick the right gear type for your project. This makes sure you get the best fit for performance and manufacturing efficiency.

Step by Step Gear Manufacturing Processes Explained

Blank Preparation Methods

We start with preparing the gear blanks, which can be made through casting, forging, or powder metallurgy. Each method comes with its benefits and trade-offs:

| Method | Advantages | Disadvantages |

|---|---|---|

| Casting | Cost-effective for large runs | Lower strength and precision |

| Forging | Superior strength and durability | Higher cost, longer lead times |

| Powder Metallurgy | Good for complex shapes and tight tolerances | Limited size options |

Tooth Forming Techniques

The gear teeth are formed using several methods, depending on the type and volume of the gear:

- Hobbing: Ideal for high-volume production. It’s fast and cost-effective for spur and helical gears.

- Shaping: Great for internal gears and complex profiles but slower than hobbing.

- Milling: Best suited for prototypes or low volume runs due to its flexibility.

- Broaching: Typically used for internal gears and splines, offering precise profiles.

Finishing and Heat Treatment

After tooth forming, gears undergo finishing processes to enhance durability and precision:

- Grinding: Provides a smooth surface, reduces noise, and improves gear accuracy.

- Carburising and Heat Treatment: These increase surface hardness and improve fatigue resistance by over 30%, extending gear life in demanding applications.

Vast Manufacturing Tip

We use hybrid CNC combined with AI-powered inspection systems. This ensures a 99.9% defect-free output, giving you confidence in every gear we produce.

When you need reliable, precise gears that last, understanding these manufacturing steps helps you choose the right process for your project’s needs.

Essential Materials for Gear Production Choosing the Right One

Picking the right material for gear manufacturing is key to getting the job done right. It affects strength, noise, durability, and cost — all important for UK buyers looking for reliable, long-lasting gears.

Common Gear Materials

- Steel AlloysHigh tensile strength and durability

Ideal for heavy load applications and long life

Widely used in automotive and industrial gears - PlasticsLow friction and quieter operation

Great for light-load or noise-sensitive environments

Often used in consumer products and electronics - CompositesLightweight and corrosion-resistant

Suitable for specialised uses needing a balance of strength and weight

Factors to Consider

- EnvironmentCorrosive or wet conditions call for stainless steel or treated alloys

Choose materials that resist rust and wear - Cost vs PerformanceSteel is the workhorse — robust but can be pricier

Plastics and composites offer savings with some trade-offs in strength

Balance your budget with the gear’s operating needs - SustainabilityVast offers recycled alloy options to cut environmental impact

We align with local regulations promoting eco-friendly manufacturing

Choosing the right materials upfront saves time and costs later, ensuring your gears meet performance requirements for your specific projects.

Quality Control and Standards in Gear Manufacturing

Quality control is crucial in gear manufacturing to ensure every gear meets strict performance and reliability standards. We use advanced inspection tools like Coordinate Measuring Machines (CMM) and gear analyzers to measure gear dimensions and tooth profiles accurately. These tools help us detect even the smallest deviations that could cause problems down the line.

Vast follows key industry certifications, including AGMA, DIN, and other recognised testing protocols. These certifications guarantee our gears meet or exceed the highest quality benchmarks for strength, precision, and durability.

One common issue we see is misalignment during manufacturing, which can reduce gear efficiency by up to 20%. This often leads to premature wear and energy loss. At Vast, we prevent this through tight process controls, real-time monitoring, and multiple quality checkpoints throughout production. Our hybrid CNC and AI inspection systems help us deliver 99.9% defect-free gears consistently.

By adhering to these strict standards, we ensure your gears perform reliably in the toughest applications and last longer, saving time and cost over the life of your equipment.

Applications of Manufactured Gears Across Industries

Gears are essential in many industries, powering critical machinery and systems. Here’s where our custom manufacturing makes a real difference:

- Automotive: Used in transmissions, steering, and engine components for smooth, reliable performance.

- Aerospace: Precision gears ensure safety and efficiency in aircraft actuators and control systems.

- Turbines: Heavy-duty gears handle extreme loads in wind and gas turbines.

- Renewables: Gears play a big role in wind gearboxes, converting natural energy into power.

Case Study

We worked with a United Kingdom-based robotics firm to create custom bevel gears that boosted their assembly speed by 25%. Our precise gear manufacturing cut down wear and improved reliability, helping them stay ahead in a competitive market.

Cost Factors Lead Times and Scaling Production

When it comes to gear manufacturing, understanding the cost and timing is key—especially if you’re planning to scale up. Here’s a clear breakdown for United Kingdom customers:

Low Volume Prototypes

- Price per unit is higher due to setup and tooling costs

- Typical lead time: 2 to 4 weeks

- Great for testing and custom jobs before full production

High Volume Bulk Orders

- Significant cost savings per part as volume increases

- Lead times can stretch 4 to 8 weeks depending on complexity

- Ideal for ongoing production runs, automotive suppliers, and industrial clients

Local Trends and Shipping Benefits

- Many Midlands-based manufacturers offer expedited shipping options to meet tight deadlines

- Domestic sourcing reduces tariffs and import delays, saving time and money

- Tariff-free quotes are common when working with UK factories, giving you a clear edge over overseas suppliers

Planning your order size carefully and factoring in these timelines helps optimise your investment in custom gear manufacturing.

Partner with Vast for Custom Gear Manufacturing

When it comes to custom gear manufacturing, Vast is your reliable partner in the UK. We offer in-house prototyping, so you get quick turnaround and can test your designs before full production. Our global materials sourcing means we have access to high-quality steel, plastics, and composites that fit your project needs and budget.

We provide 24/7 support to keep your order on track and answer any questions anytime. Whether you need spur, helical, bevel, or worm gears, our experienced team is ready to deliver precision with fast lead times.

Get started today with a free consultation. Download our PDF Gear Spec Checklist to make your specifications clear and get an accurate quote faster. Partner with Vast and experience smooth custom gear production tailored for the UK market.

FAQs on Gear Manufacturing

What is gear manufacturing?

Gear manufacturing is the process of producing gears through methods like casting, forging, and CNC gear hobbing. It involves shaping gear blanks and cutting precise teeth to meet specific load, speed, and accuracy requirements.

What types of gears do you produce?

We manufacture a range of gears including spur gears, helical gears, bevel gears, and worm gears. Each gear type is made using specialised methods like shaping, grinding, or EDM to ensure durability and performance.

How do you ensure quality in gear production?

Our gears go through rigorous quality control using CMM inspection, gear analyzers, and fatigue simulation. We hold ISO 9001 and AS9100D certifications to deliver reliable, defect-free products.

Can you handle custom gear fabrication?

Yes, we offer custom gear manufacturing with options like 3D printing for prototypes and batch sizes from 1 to 100,000+. Our interactive configurator provides instant pricing based on your specifications.

What materials are available for gears?

We use high-strength steel alloys, durable plastics, and composites. Each material is selected based on strength, noise reduction, and environmental conditions to match your application.

What lead times and pricing can I expect?

Lead times typically range from 2 to 4 weeks, with expedited options available. Pricing depends on volume, complexity, and material, with tiered rates for prototypes, low volume, and high volume orders.

How do you handle heat treatment and finishing?

We apply heat treatments like carburising and grinding to enhance gear lifespan and fatigue resistance by up to 30%. Our precision finishing ensures smooth operation and less wear.

Are your gears compliant with industry standards?

Yes, all gears comply with AGMA, DIN, and RoHS standards. We continually test for noise, vibration, and durability to meet your performance goals.

What industries do you serve?

Our gears power automotive transmissions, aerospace actuators, robotics joints, and industrial pumps, addressing demanding applications across sectors.

How can I order or get a quote?

Use our online form to request a quote or upload CAD files. Our team offers free consultations and personalised support every step of the way.