Discover everything about pump housing including design, materials, types, maintenance, and how the right pump housing enhances efficiency and durability.

What Is a Pump Housing? Core Functions and Why It Matters

A pump housing, often called a pump casing, is the outer shell that encloses the moving parts of a pump. It plays a crucial role in protecting internal components like the impeller and shaft while directing fluid flow efficiently. Think of it as the backbone of the pump—it holds everything together and ensures the pump operates smoothly.

At its core, the pump housing performs three main functions:

- Protects internal parts from damage and contaminants

- Directs fluid flow in and out of the pump to maximise performance

- Contains pressure and prevents leaks during operation

Understanding the anatomy of a pump housing helps clarify its importance. Most housings feature an inlet, outlet, and volute or diffuser shape depending on the pump type. This design impacts how fluid moves through the pump, directly influencing efficiency.

A well-designed pump casing improves not just performance but also pump longevity. When the housing withstands pressure and resists corrosion, the pump runs reliably with less wear and tear. On the other hand, poor housing design or material choice can lead to inefficiencies, vibration, or even early failure.

In short, the right pump housing is a key factor in delivering optimal pump efficiency and durability, especially in demanding industrial environments.

Want to improve your pump system? Start by choosing the right pump housing for your application.

Types of Pump Housings Matching Design to Application

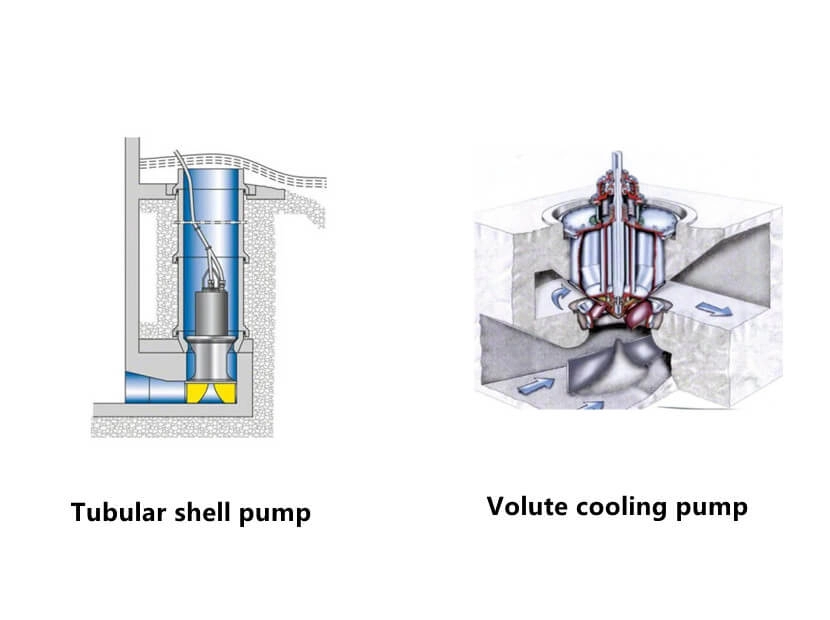

Choosing the right pump housing depends a lot on what the pump needs to do and where it will be used. Different designs work better for different jobs, so understanding types like volute and diffuser housings helps you pick what fits best.

Volute vs Diffuser Housings for Centrifugal Pumps

Volute housings are common for centrifugal pumps in the United Kingdom. They have a spiral shape that helps direct fluid smoothly out of the pump. This design boosts efficiency, especially when handling clear liquids. Diffuser housings, on the other hand, use stationary vanes around the impeller. They slow down the fluid more evenly, which is great for high-pressure applications and reducing vibration.

Submersible and Positive Displacement Housings

Submersible pump housings are sealed tight since they work underwater—for example, in wells or drainage systems. These housings often prioritise corrosion resistance and water-tight seals, making materials like cast iron or corrosion-resistant alloys a smart choice.

Positive displacement pump housings are built differently to handle fluids with varying viscosity or solids. These pumps move a fixed amount of fluid per cycle, so their housings need to be strong and precise, often found in oil, chemical, or food processing industries.

Specialised Variants for Automotive Water Pumps and Modular Pump Houses

Automotive water pump housings are usually compact and designed to fit tight engine spaces. Aluminium housings are popular here for being lightweight and heat-resistant.

Modular pump houses used in industrial settings are built to be adaptable and easy to maintain. These pump casings in factory setups often have standardised parts and easy-access covers for quick repairs or customisation.

By matching pump housing types to the application—whether it’s a submersible pump cover for heavy-duty waterwork or a volute housing for efficient industrial fluid movement—you ensure the pump runs longer, performs better, and saves money in the long term.

Materials for Pump Housings Durability Meets Performance

Choosing the right material for a pump housing is essential for balancing durability, performance, and cost. In the United Kingdom market, where pumps are used in everything from industrial plants to domestic water systems, having a reliable housing material can make all the difference.

Cast Iron and Stainless Steel The Industry Standards

Cast iron remains a top choice for many because of its strength, wear resistance, and ability to handle high pressure. It’s the go-to for heavy-duty pump casings, especially in industrial and municipal water systems. Stainless steel offers excellent corrosion resistance, which is key for pumps dealing with harsh or corrosive fluids. Its durability and resistance to rust make stainless steel pump bodies popular in chemical processing, food-grade applications, and outdoor environments.

Aluminium and Advanced Alloys Lightweight Innovations

For applications where weight matters—like automotive water pumps or portable units—aluminium and other advanced alloys come into play. These materials reduce overall pump weight without sacrificing strength. Aluminium housings also offer good resistance to corrosion, making them suitable for both fresh and saltwater scenarios, and they help improve pump efficiency by reducing energy costs linked to excessive weight.

Casting Processes From Mould to Finished Housing

The manufacturing process affects housing quality just as much as the material itself. Most pump housings are made through sand casting or precision casting methods. Sand casting is cost-effective and widely used for cast iron parts, while precision casting can produce complex shapes with tight tolerances, which is important for specialised pump casings. After casting, the housings undergo finishing steps like machining and coating to improve durability and ensure a perfect fit.

Understanding these materials and how they’re made helps you select a pump housing that fits your specific needs—whether you want long-lasting performance in tough conditions or lightweight efficiency for more mobile setups.

Selecting the Right Pump Housing Key Considerations and Best Practices

Choosing the right pump housing is crucial for achieving optimal performance and durability from your pump. Here’s what you need to keep in mind:

Factors Influencing Your Choice

- Pressure Requirements: Ensure the housing can withstand the system’s pressure. Pumps operating under high pressure require stronger, more durable housings like cast iron or stainless steel.

- Fluid Type: Is the fluid corrosive, abrasive, or containing solids? Corrosion-resistant pump body materials like stainless steel or special alloys are ideal for harsh fluids.

- Environment: Outdoor or indoor use? Harsh environments might require weatherproof or submersible pump covers that protect against dirt, water, and temperature fluctuations.

Installation and Integration Tips

- Verify the dimensions and mounting points match your existing setup to avoid costly modifications.

- Check for compatibility with seals and bearings to ensure smooth operation.

- If you’re upgrading or replacing an old pump housing, confirm that the new housing fits the same pump model or is customizable to your system’s specifications.

Cost vs Value Avoiding Common Mistakes

- Don’t just choose the cheapest option; balance upfront cost with long-term durability and ease of maintenance.

- Avoid underestimating housing strength – a weaker housing can lead to early failures and costly downtime.

- Work with suppliers that offer custom pump housing options if your application is specific. Factories in China offer customisation at competitive prices but always verify quality standards.

By focusing on these points, you’ll find a pump housing that matches your needs, prolongs pump life, and keeps your operation running smoothly.

Maintenance and Troubleshooting Pump Housings Pro Tips for Longevity

Keeping your pump housing in good condition is key to ensuring your pump runs smoothly and lasts longer. Here are some practical tips for routine maintenance and troubleshooting, specifically for pump housings used in the UK market.

Routine Inspections and Cleaning Protocols

- Regular visual checks: Look for cracks, corrosion, or any signs of physical damage on the pump casing design. Early detection can save costly repairs.

- Clean the housing: Especially for submersible pump covers or centrifugal pump enclosures, remove debris and buildup to avoid flow issues.

- Check seals and fasteners: Tighten any loose bolts and replace seals showing wear to prevent leaks.

- Lubricate bearings: Many pump housings include bearing housings that require routine lubrication to reduce friction and extend life.

Common Issues and Fixes

- Corrosion and rust: Cast iron pump parts often face corrosion, especially in harsh environments. Use corrosion-resistant pump bodies or coatings and regularly inspect for rust.

- Cracks and leaks: Hydraulic pressure and vibrations can cause cracks. If small, some cracks might be welded or sealed temporarily, but larger damage calls for replacement.

- Overheating: Poor circulation caused by blockages in the volute housing can lead to overheating. Clean the housing and ensure proper installation.

- Misalignment: Causes vibration and premature wear. Realignment during installation keeps everything running smoothly.

When to Replace Signs and Vast Replacement Options

- Persistent leaks that won’t stop with seal replacement.

- Extensive cracks or damage that affect pump efficiency.

- Severe corrosion weakening the pump housing.

- If repairs cost more than a new housing, replacement makes sense.

At Vast, we offer a wide range of replacement pump housings customised to fit various pump types and applications. Our durable cast iron and aluminium pump housings are engineered to meet UK industrial standards, ensuring you get strong performance and reliability. When you need a replacement, choosing Vast means fast turnaround and high-quality parts built to last.

Future Trends in Pump Housing Technology

The pump housing market is evolving rapidly, and Vast is at the forefront of these changes. As industries push for smarter, more sustainable solutions, pump housing designs are adapting too.

Smart Sensors and Sustainable Materials

One major trend is integrating smart sensors directly into the pump housing. These sensors can monitor temperature, pressure, and vibration in real-time, helping to prevent breakdowns before they occur. It’s a game-changer for reducing downtime and maintenance costs.

On the materials front, Vast is exploring eco-friendly options that don’t compromise strength or durability. Sustainable materials like advanced composites and corrosion-resistant alloys are becoming popular, especially in applications where reducing environmental impact is critical. These innovations help extend pump housing lifespan while maintaining high efficiency.

Vast’s Role in Next Generation Designs

Vast is leading the way in customising pump housing solutions that meet the unique needs of industries in the UK. Their factories specialise in combining traditional cast iron and stainless steel parts with cutting-edge materials, ensuring performance and reliability. Whether it’s for industrial pump casting or lightweight aluminium pump housing, Vast brings modern design practices and customisation options to the table.

This focus on innovation means Vast’s next-generation pump housings are not just durable—they’re smarter, more efficient, and designed to last longer in tough UK environments. For anyone seeking a reliable pump casing design that leverages the latest technology, Vast’s offerings are worth a close look.