Discover slip fit tolerances and applications for precise engineering assemblies and comfortable slip-on footwear with top design tips and product picks.

Slip Fit in Engineering The Foundation of Flawless Mechanical Assemblies Core Concepts and Tolerance Basics

Have you ever wondered how parts in machines fit together smoothly without being too tight or too loose? That’s where slip fit comes in. In engineering, slip fit refers to a type of fit between two mating parts—usually a shaft and a hole—designed to slide together easily with minimal friction. This kind of fit is essential for assemblies that need to move or be assembled quickly without force.

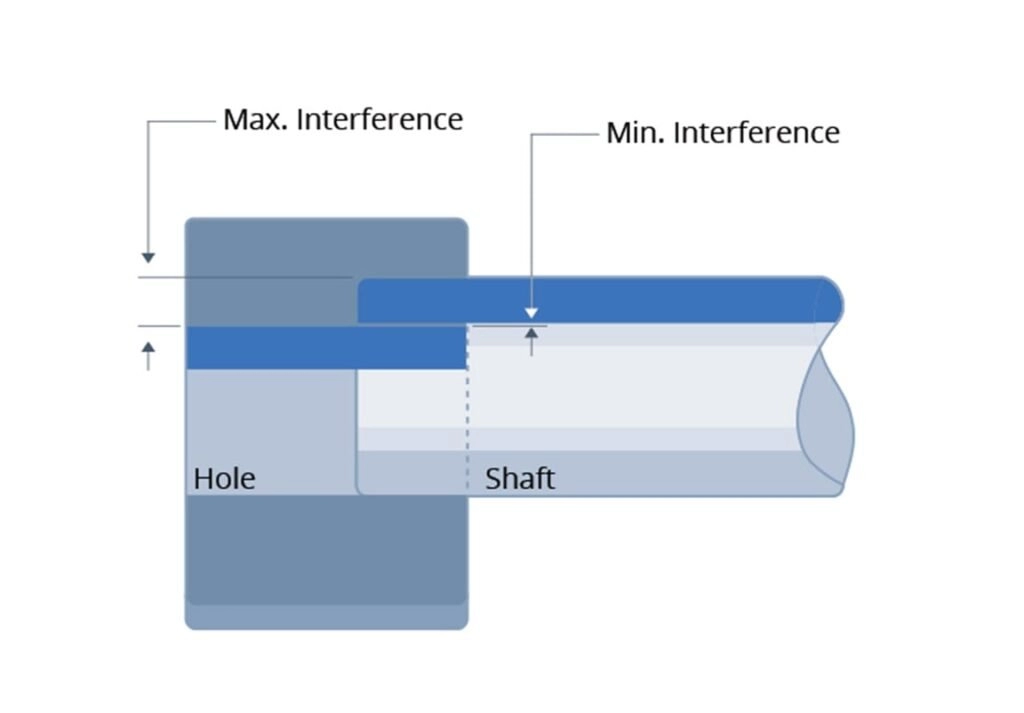

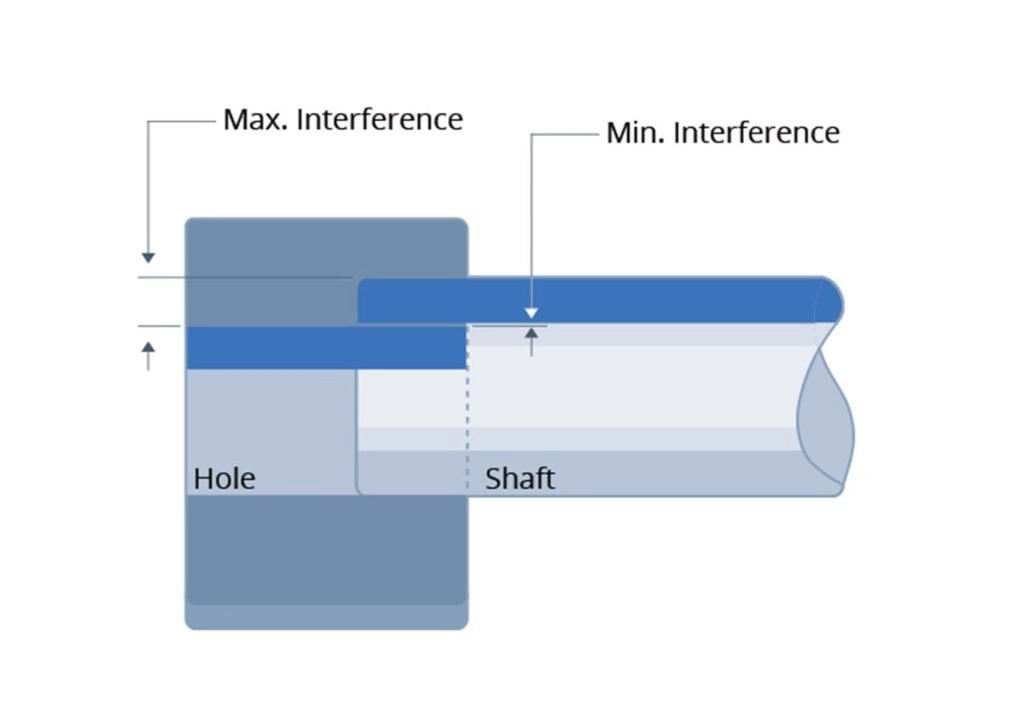

At its core, slip fit is all about clearance fit tolerances. These tolerances define the precise gap between the hole and the shaft to ensure parts slide effortlessly without wobbling. Understanding these tolerances is key to preventing common issues like unwanted vibration or difficulty during assembly.

Here are some core concepts to keep in mind:

- Clearance Fit: The hole is slightly larger than the shaft, allowing free movement.

- Tolerance Range: Tight control of manufacturing tolerance ensures the parts stay within allowable limits.

- ISO Engineering Fits: International standards like ISO and ANSI provide detailed charts for fits including slip, press, and interference fits.

- Basic Measurements: Knowing the exact diameter of shafts and holes is critical for achieving the right slip fit.

Slip fits provide a reliable foundation for flawless mechanical assemblies by allowing easy assembly and disassembly while maintaining functional alignment. This balance helps engineers design durable systems that work smoothly without wear or excess stress.

Are you dealing with shafts and holes that need to fit just right? Understanding slip fit basics could save you time and headaches in your next project. What’s the toughest part about getting mechanical parts to fit perfectly in your experience?

Slip Fit in Engineering The Foundation of Flawless Mechanical Assemblies Types of Slip Fits and When to Use Them

Slip fits come in a few different types, each designed to meet specific needs in mechanical assemblies. Understanding these types helps you choose the right slip fit for your project, ensuring smooth shaft-hole assembly without issues like too much play or tightness.

Types of Slip Fits

- Light Slip Fit Offers minimal clearance, just enough for easy assembly and slight movement. Ideal for parts that need to slide or adjust without wobbling.

- Standard Slip Fit Provides moderate clearance that balances easy assembly with a firm hold. Common in applications like dowel pin clearance and sliding fit uses.

- Loose Slip Fit Gives generous room between parts for free movement or quick assembly and disassembly. This type suits situations where quick maintenance or flexible positioning matters.

When to Use Each Type

- Use light slip fits when precision is important but you still want parts to join without force.

- Opt for standard slip fits in everyday mechanical assemblies where components like shafts and holes come together regularly.

- Choose loose slip fits for parts that need to move freely or be removed often, like in certain machinery or adjustable devices.

Knowing which slip fit to pick prevents issues like binding or excessive play, helping your projects run smoother and last longer. Following basic tolerance guidelines, including references from ISO engineering fits and ANSI tolerance charts, ensures you’re on the right track.

Slip Fit in Engineering The Foundation of Flawless Mechanical Assemblies Design Best Practices for Slip Fit Success

Getting slip fit right means focusing on a few key design principles to ensure smooth assembly and reliable performance. Here’s what I keep in mind when working with slip fits:

- Define Clearances CarefullyUse clearance fit tolerances that provide just enough gap for easy assembly without causing wiggle or misalignment. Reference ANSI tolerance charts or ISO engineering fits standards to pick the right shaft-hole assembly dimensions.

- Choose the Right Type of Slip FitThere are several slip fit categories—like running fits or sliding fits—each suited for different applications. Knowing when to use a light slip fit or a looser fit can prevent issues like binding or excessive wear.

- Consider Material BehaviorAccount for thermal expansion or material swelling that could tighten or loosen the fit in real-world conditions. This is especially true for metals and plastics exposed to varying temperatures.

- Avoid Surface ImperfectionsSmooth finishes on mating surfaces reduce friction and help components slide easily. Rough surfaces can cause sticking, defeating the purpose of a slip fit.

- Plan for Assembly and DisassemblyDesign slip fits so parts can be put together and taken apart without damage. This includes checking dowel pin clearance and considering how much force is needed to connect or separate parts safely.

- Test Early and OftenPrototype with real parts before full production. Even small differences from drawings can impact the fit, so hands-on testing lets you catch problems early.

Following these practices offers a solid foundation for flawless mechanical assemblies that rely on slip fits. In the United Kingdom, they help keep production efficient and products dependable.

Slip Fit in Engineering The Foundation of Flawless Mechanical Assemblies Real-World Applications and Case Studies

Slip fit plays a significant role in many real-world mechanical assemblies, especially where easy assembly and disassembly are important. For example, in shaft-hole assemblies, slip fit ensures the shaft slides smoothly into the hole without force, avoiding damage. This is common in motors and gearboxes where parts may need quick replacement.

Another case is the use of dowel pin clearance in manufacturing. Slip fit allows dowel pins to align parts accurately but still permits easy removal, making it ideal for jigs and fixtures used on the workshop floor. It balances precision with flexibility.

In heavy machinery, sliding fit applications depend on slip fit for components that must move freely while remaining aligned. This prevents wear and extends the lifespan of parts such as bearings or guide rails.

One notable example comes from the automotive industry, where slip fit tolerances ensure that parts like transmission shafts slide together properly without being too tight (press fit) or too loose. Using ANSI tolerance charts and ISO engineering fits assists engineers in designing the perfect clearance.

These cases demonstrate how slip fit principles help create reliable, easy-to-maintain machines that meet UK industry standards and customer expectations for durability and performance.

Slip Fit in Footwear Why It’s a Game Changer for Modern Lifestyles

Slip fit isn’t just an engineering term—it’s also transforming how we wear shoes every day. Forget the hassle of laces or straps; slip-on shoes with a well-designed slip fit offer the perfect balance of comfort and convenience. This type of fit allows your foot to slide in easily while still providing enough snugness to keep the shoe in place throughout your daily routine.

Thanks to advances like memory foam insoles and stretchy uppers, slip fit footwear adapts to your foot’s shape without feeling tight or loose. This relaxed fit style is especially popular for hands-free slip-on shoes, making them ideal for busy lifestyles where quick on-and-off wear is essential.

Slip fit in footwear supports everything from casual walks to quick errands, and it’s particularly appreciated by those who value comfort without sacrificing style. Whether you’re at home, running errands, or heading to the office, slip fit shoes enhance mobility while reducing foot fatigue—making them a true game changer in modern footwear.

Top Slip Fit Footwear Recommendations

When it comes to everyday comfort, slip fit footwear is a game changer. These shoes are designed for easy on and off, thanks to a relaxed fit that doesn’t compromise support. If you’re in the UK market looking for slip fit options, here are some top picks that combine convenience with comfort.

1. Hands-Free Slip-On Shoes

Brands like Skechers and Vionic offer slip-on shoes that perfectly match the slip fit concept. With memory foam insoles and breathable materials, these shoes fit just right—no squeezing or wrestling required.

2. Casual Slip Fit Sneakers

Look for sneakers with clearances designed for sliding fit applications. Nike and New Balance have models that allow a little extra space around the foot, making daily wear painless while supporting natural movement.

3. Relaxed Fit Boots

Timberland and Clarks provide relaxed fit boots with enough clearance fit tolerances to slide on smoothly but stay secure. Great for people who want easy-to-wear boots without sacrificing durability.

4. Orthotic-Friendly Slip Fit Shoes

For those needing extra foot support, many brands like Orthofeet design slip fit shoes with removable insoles. These accommodate memory foam or custom orthotics, blending health benefits with convenience.

Key Benefits to Look For

- Easy slip-on design cuts down hassle.

- Comfortable fit reduces foot fatigue.

- Quality materials ensure breathability and durability.

- Styles suited for work, casual, or outdoor needs.

If you want more info on how fit impacts footwear performance, check out our guide on relaxed fit footwear for deeper insights. These slip fit shoes are perfect for busy lifestyles where comfort and convenience come first.

Slip Fit Beyond the Shop Comfort and Convenience in Everyday Products Broader Consumer Applications

Slip fit isn’t just for engineering or footwear—it shows up in many everyday products that make life easier and more comfortable. You’ll find slip fit technology in items like kitchen tools, electronic devices, and even furniture, where parts need to slide together smoothly but stay secure without extra effort.

Here are some common consumer products using slip fit principles:

- Battery compartments: Devices like remote controls and toys use slip fit joints so you can easily open and close the compartment without tools.

- Removable handles: Kitchen appliances often have slip fit handles that snap on and off for cleaning or storage.

- Phone cases and accessories: Cases use slip fit designs to stay snug without scratching your device while still allowing quick on/off.

- Adjustable furniture parts: Chairs or tables with sliding mechanisms rely on slip fit for smooth movement and easy adjustments.

- Recreational gear: Things like hiking poles and sporting equipment use slip fit for quick assembly and breakdown.

The key benefit here is convenience. Slip fit offers just the right amount of clearance so parts fit together easily by hand but don’t wobble or fall apart during use. It blends function with user-friendly design—something every product striving for ease of use should aim for.

In the UK market, where customers value practical, durable, and easy-to-use products, slip fit designs help brands stand out by providing that smooth, hassle-free user experience.

Advanced Tips Optimising Slip Fit for Your Needs Troubleshooting Common Issues

Even with the best design, slip fit assemblies can hit a few bumps. Knowing how to spot and fix common issues can save time and keep your projects running smoothly.

Common Slip Fit Problems and How to Fix Them Too Tight to Slide

This usually means your clearance fit tolerances are off. Double-check the shaft-hole assembly dimensions and compare them with ANSI tolerance charts or ISO engineering fits standards. To fix it, slightly increase the hole diameter or decrease the shaft size.

Too Loose and Wobbly

If your parts slide too easily and feel shaky, you might have a larger-than-needed clearance. Adjust by reducing the hole size or increasing the shaft diameter within your tolerance range.

Parts Sticking Due to Dirt or Debris

Even small contaminants can affect slip fit performance. Always clean parts thoroughly and apply a light lubricant if recommended for sliding fit applications.

Material Expansion or Contraction

Changes in temperature can affect metal fits, creating unexpected tightness or looseness. Consider the operating temperature range during design and select materials accordingly.

Wear Over Time Affecting Fit

Repeated use may loosen the fit. Look into harder materials or surface treatments, and plan for maintenance checks.

Pro Tips for Better Slip Fit Performance

- Use precision measuring tools like micrometers or callipers for accurate dimensions.

- Follow industry standards such as ANSI or ISO fit guidelines for reliable results.

- Test with prototypes before full production to catch fit issues early.

- Document your fit tolerances and assembly process for consistency.

By proactively troubleshooting these common issues, you can optimise your slip fit assemblies for durability, ease of use, and a flawless mechanical experience every time.

Advanced Tips Optimising Slip Fit for Your Needs

Tools and Resources from Vast

When it comes to getting the perfect slip fit, having the right tools and resources can make all the difference. Whether you’re working on a shaft-hole assembly or designing footwear with memory foam insoles, precision matters. Here are some essentials to help you optimise slip fit:

- Precision Measuring Tools: Calipers and micrometers help you check clearance fit tolerances accurately. Keeping within ISO engineering fits ensures your parts slide smoothly without excess play or tightness.

- Tolerance Charts: ANSI tolerance charts and guides provide standards to quickly determine the right clearance or sliding fit applications for your project.

- 3D Modelling Software: Tools like CAD programmes let you simulate slip fit scenarios to spot potential issues early in design.

- Supplier Resources: Reputable manufacturers often provide detailed specs and recommendations for dowel pin clearance and other slip fit components. Use their catalogues to match parts perfectly.

- Online Calculators: Handy for quick checks on press fit vs slip fit decisions and to adjust dimensions effectively.

By combining these tools with the right know-how, you can avoid common slip fit issues and create durable, user-friendly assemblies or products. For UK engineers and designers, investing time in these resources means better-quality results that fit manufacturing tolerances and real-world use.

If you want to explore more about fit types and what works best in mechanical design, checking out resources on ISO engineering fits can be a smart next step.