Discover comprehensive slip fit tolerance tables with ANSI and ISO standards for precise shaft and hole fits in mechanical engineering designs.

Understanding Slip Fits Fundamentals and Fit Classifications

If you’ve ever struggled with parts that are either too tight or too loose, understanding slip fits is your first step to fixing that. Slip fits are all about finding the sweet spot where two parts—usually a shaft and a hole—fit together smoothly without binding or wobbling.

Clearance vs Interference Fits

- Clearance fit means there’s always a gap between the shaft and hole for easy sliding or assembly.

- Interference fit means the shaft is slightly larger than the hole, requiring force or press-fitting to assemble.

- Slip fits sit between these two: parts are close enough to avoid play but still slide together without force.

Hole-Basis vs Shaft-Basis Systems

- In a hole-basis system, the hole size stays constant and the shaft size varies.

- In a shaft-basis system, the shaft size stays constant and the hole size varies.

This concept helps engineers standardise fits and ensure parts are interchangeable.

ANSI B4.1 Fit Classes RC1 to RC9

ANSI B4.1 defines fit classes from RC1 (very tight) to RC9 (very loose):

- RC1–RC3Close running or sliding fits, tight but still moving.

- RC4–RC6Precision slip fits, common in bearings and machinery.

- RC7–RC9Loose fits, easy assembly, less precision needed.

ISO 286 Tolerance Grades and Letters

The international standard ISO 286 uses tolerance grades (IT grades) and letters:

- The letter H typically designates the hole tolerance.

- The letter g or f usually applies to the shaft tolerance.

- For slip fits, common pairs are H7/g6 or H7/f7, balancing clearance and tightness.

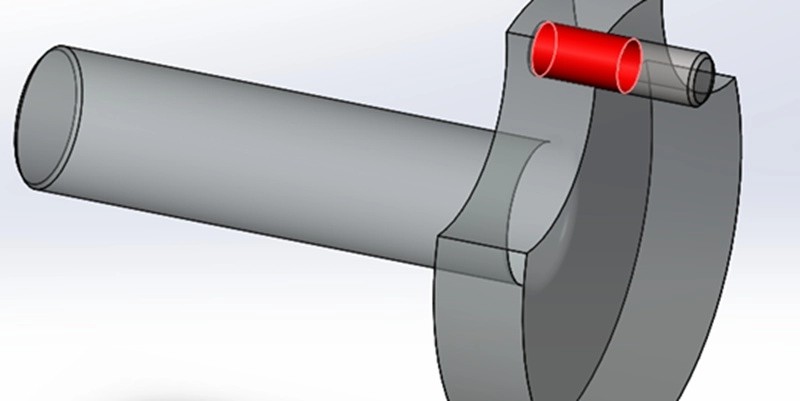

Visualising Fit Types

Imagine an infographic showing:

- Slip fit: slight positive clearance, smooth sliding.

- Transition fit: clearance or slight interference, depends on exact sizes.

- Interference fit: shaft larger than hole, force required.

Pro Tip: What Influences Your Fit Choice?

- Material type: Steel expands less than aluminium, so tolerances differ.

- Thermal expansion: Operating temperature changes sizes.

- Lubrication: Can reduce friction and allow tighter fits.

Understanding these basics helps you choose the right slip fit class for your application—saving time and avoiding costly mistakes.

The Essential Slip Fit Tolerance Table ANSI and ISO Standards

When working with slip fits, having quick access to tolerance tables is a must. We provide dual-format tables in both imperial and metric units for easy reference, making it simple to find the right fit for your project.

ANSI RC Fits Table

This table covers shaft and hole limits for sizes ranging from 0.04 to 18 inches. It’s organised by:

- Basic size

- Fit class (RC1 through RC9)

- Hole tolerance

- Shaft tolerance

- Minimum and maximum clearances

These clearances define the range where parts will slip fit smoothly without being too loose or tight.

ISO 286 Slip Fits Table

For metric sizes between 10 and 50 millimetres, the table lists slip fits such as H7 (hole) and h6 (shaft). You’ll find:

- Standard deviation values

- Tolerance limits for holes and shafts

- Precise clearance ranges based on ISO standards

Downloadable PDF

For convenience, you can download a comprehensive slip fit tolerance table PDF from Vast. This allows you to work offline and keep the reference handy anywhere—ideal for machining workshops or shop areas with limited internet access.

How to Read and Use the Tables

Understanding how to calculate maximum clearance is essential:

- Max clearance = Maximum hole limit – Minimum shaft limit

- Use this to ensure proper slip fit without excessive play

Helpful Tools

To make your work even easier, check out Vast’s online ISO tolerance calculator. This tool allows you to input your specific size and fit class to get customised tolerance values instantly.

Visual and Interactive Help

Our responsive tables come with hover tooltips and alt text descriptions, making navigation simple whether on desktop or mobile. This enhances your experience in finding and confirming the correct slip fit data quickly.

This table setup ensures you have everything needed for accurate engineering fits following ANSI and ISO standards, helping you achieve smooth, reliable slip fits for your projects.

Applications of Slip Fits in Engineering and Manufacturing

Slip fits play a vital role across many industries, providing reliable and efficient connections where a controlled clearance is necessary. Here are some top real-world examples and industry uses:

- Dowel pins in jigs: Slip fits allow dowel pins to slide easily into holes during assembly, ensuring precise alignment without forcing parts.

- Bearings in low-speed machinery: The slight clearance of slip fits reduces friction and wear, making them ideal for bearings that don’t see high-speed operation.

- Automotive shafts: Slip fits enable smooth rotation while allowing easy shaft installation or removal during maintenance.

Industry Breakdown

- Aerospace: Aerospace applications often require tight slip fits such as ANSI RC2 or RC3 classes. This helps resist vibrations and maintain alignment under extreme conditions.

- Automotive: The automotive sector typically uses RC5 or RC6 slip fits, striking a good balance between cost and performance for parts that need reliable sliding but easy assembly.

- Consumer Goods: For consumer products, looser slip fits like RC8 or RC9 make assembly quick and simple, reducing manufacturing time and cost.

Case Study

One of Vast’s clients optimised their prototype by switching to H8/f7 slip fits, a popular ISO fit choice. This small change cut assembly errors by 40%, improving both product quality and throughput.

Troubleshooting Common Slip Fit Issues

- Over-clearance: Too much gap can cause misalignment or movement between parts.

- Surface finish: Rough finishes increase friction and may prevent the fit from sliding properly.

- Solution Tips: Specify tighter tolerances where needed and ensure proper surface treatments or lubrication.

Related SEO Topic

For engineers focused on slip fit tolerances in CNC machining, understanding these principles helps avoid costly reworks. Precise tolerance control directly impacts machining accuracy and final product quality.

How to Select and Implement Slip Fit Tolerances in Your Designs

Choosing the right slip fit tolerance is all about matching your design needs with real-world conditions. Here’s a simple step-by-step approach:

Step by Step Guide

- Determine functional needs: Think about how fast the parts will move, the load they’ll carry, and how often you’ll need to take them apart. These factors drive whether you want a tighter or looser slip fit.

- Use reference tables: Consult slip fit tolerance tables like ANSI RC or ISO 286 to find the right hole and shaft limits. Also, calculate stack-up tolerances to ensure everything fits together perfectly when combined.

- Specify in your drawings: Use standard fit notations such as Ø25 H7 g6 when marking your part drawings. This helps machinists and quality teams understand exactly what you need.

- Validate with prototyping: Before full production, create prototypes and check dimensions with CMM (Coordinate Measuring Machines) or other precise measurement tools. This ensures the slip fits work as expected.

Advanced Considerations

- Account for thermal expansion by using formulas that factor in material types—steel, aluminium, or hybrid combos. This helps avoid fit issues caused by temperature changes in parts during use.

Best Practices

- Apply GD&T positional tolerances alongside slip fits. This tightens control on how parts align and move together.

- Consider working with custom machining services like Vast, which specialise in nuts-and-bolts tolerance optimisation for precise builds.

Including a visual flowchart in your workflow can simplify picking the right slip fit class by laying out decision points from clearance needs to load expectations.

Following these steps makes selecting and implementing slip fit tolerances straightforward and tailored to your project’s success.

Advanced Topics Custom Tolerances and Emerging Trends

Sometimes, standard slip fit tolerances just don’t suffice. When working with exotic materials like composites or speciality alloys, you might need to customise fits to handle unique expansion rates, surface finishes, or strength requirements. These custom tolerances ensure your parts fit perfectly even under unusual conditions.

Technology is changing how we approach slip fit tolerance. AI-driven tools and plugins for CAD programmes like SolidWorks are making it easier to optimise tolerances on the fly. This means you can get precise fit recommendations based on your design, materials, and manufacturing process without guessing.

Sustainability is also playing a bigger role. Using precise slip fits reduces scrap and rework, which saves material and energy—especially important in additive manufacturing. The tighter the control on tolerance, the less waste you create.

Looking ahead, Industry 4.0 is pushing fit monitoring into real-time. Smart sensors and digital twins allow manufacturers to track fits during assembly, catching any issues early and adjusting processes immediately. This data-driven approach boosts quality and lowers costs.

For anyone needing advanced slip fit tolerance calculations, these trends offer powerful tools plus better control, helping you stay ahead in precision engineering and manufacturing.