Explore titanium alloys including Ti-6Al-4V Grade 5 medical and aerospace grades with key properties strength corrosion resistance and applications.

If you’re working with titanium alloys, you already know they pack steel-level strength at roughly 45% of the weight—a game changer for aerospace, medical, and high-performance engineering. In 2025, titanium alloys continue to lead industries hungry for lightweight durability and corrosion resistance, with the aerospace sector consuming more than half of global supply and medical applications growing rapidly. Whether you’re an engineer, designer, or buyer, mastering the differences between grades like Ti-6Al-4V (Grade 5), Grade 2, and emerging beta alloys is essential for making smart material choices. This guide cuts through the noise, delivering everything you need to know about titanium properties, grades, key applications, and how to select the perfect alloy for your project—with insights drawn from Vast’s premium expertise in custom titanium solutions.

What Are Titanium Alloys and Why They Dominate High-Performance Engineering

Titanium alloys combine titanium with other elements to enhance its natural properties, making them essential in high-performance engineering. While pure titanium offers excellent corrosion resistance and strength, it lacks the mechanical robustness required for demanding applications. That’s where alloying comes in—introducing key elements transforms titanium into a versatile metal with exceptional strength, durability, and performance.

Pure Titanium vs. Alloyed Titanium

- Pure Titanium (Commercially Pure or CP): Known for outstanding corrosion resistance and biocompatibility, but relatively low strength.

- Alloyed Titanium: Adds strength, toughness, and high-temperature resistance to meet rigorous engineering demands. Alloying significantly improves the material’s mechanical properties without compromising its corrosion resistance.

Classifications: Alpha, Alpha-Beta, and Beta Alloys

Titanium alloys are typically grouped into three categories based on their microstructure and phase stability:

- Alpha Alloys: Stable at room temperature; excellent weldability and corrosion resistance; limited strength. Ideal for aerospace components exposed to moderate temperatures.

- Alpha-Beta Alloys: The most widely used, balancing strength, toughness, and formability. Ti-6Al-4V (Grade 5) is the flagship example.

- Beta Alloys: Exhibiting the highest strength and heat-treatability; used where exceptional mechanical performance at elevated temperatures is critical.

Key Alloying Elements and Their Effects

- Aluminium (Al): Strengthens the alpha phase and enhances oxidation resistance.

- Vanadium (V): Stabilises the beta phase, improving strength and toughness.

- Molybdenum (Mo): Enhances beta phase stability and corrosion resistance, especially in marine environments.

- Chromium (Cr): Contributes corrosion resistance and supports beta phase stabilisation.

- Tin (Sn): Improves creep resistance and strength at elevated temperatures.

- Zirconium (Zr): Adds strength and corrosion resistance without affecting biocompatibility.

Together, these elements tailor titanium alloys to meet diverse engineering requirements, which is why titanium alloys remain dominant across aerospace, medical, automotive, and industrial sectors.

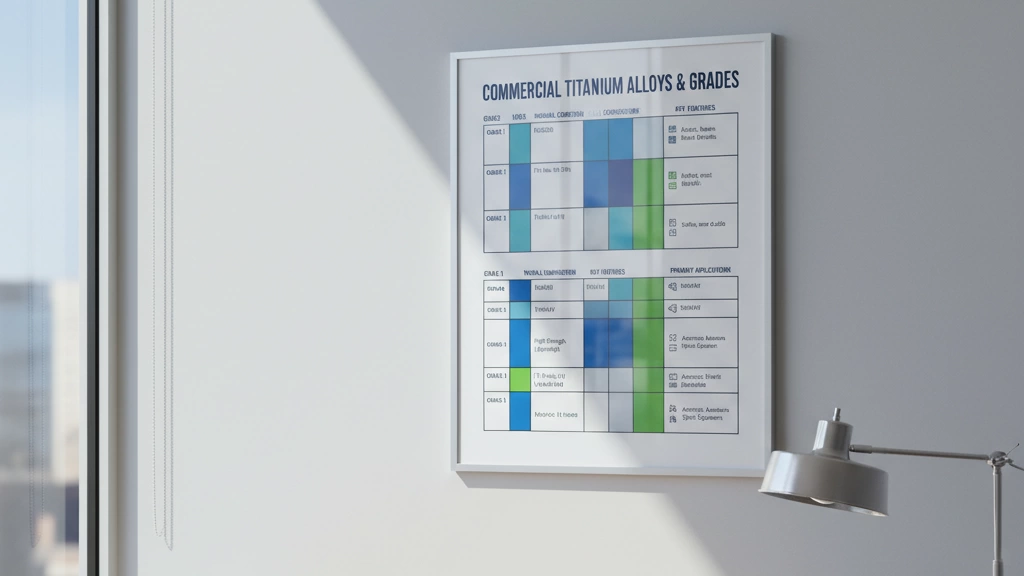

Most Important Commercial Titanium Alloys & Grades

Here’s a quick look at the key commercial titanium alloys that dominate industries, including their common grades and standout features:

| Alloy / Grade | Key Features | Typical Use Cases |

|---|---|---|

| CP Titanium (Grade 1–4) | Pure titanium, great corrosion resistance, good formability | Chemical processing, marine, medical implants (non-load bearing) |

| Ti-6Al-4V (Grade 5) | Most popular, excellent strength-to-weight, versatile | Aerospace, automotive, sports equipment |

| Ti-6Al-4V ELI (Grade 23) | Extra-low interstitials, better fracture toughness | Medical implants, aerospace critical parts |

| Ti-3Al-2.5V (Grade 9) | Balanced strength and formability, better weldability | Bicycle frames, aerospace tubing, marine |

| Ti-6Al-2Sn-4Zr-6Mo (Ti-6246) | High strength, good fatigue resistance, high temperature capability | Aerospace engine components, landing gear |

| Ti-10V-2Fe-3Al (Ti-10-2-3) | High strength beta alloy, good creep resistance | Aerospace structural parts, high-performance motorsport |

| Beta-C, Ti-5553, Ti-17 | New generation beta alloys with superior strength and toughness | Advanced aerospace, defence, high-stress applications |

These alloys cover a wide range of UK market demands, from lightweight and corrosion-resistant pure titanium to high-strength beta alloys for cutting-edge engineering. Titanium’s appeal is in this diversity—matching the right grade to your project’s performance needs.

Mechanical & Physical Properties That Matter

Titanium alloys really shine when it comes to key mechanical and physical qualities. Their strength-to-weight ratio is one of the best around—outperforming materials like 7075-T6 aluminium, 316 stainless steel, and 4340 steel. This makes titanium a go-to choice for projects where weight savings without sacrificing strength is essential, like in aerospace and motorsport.

When it comes to Fatigue strength and fracture toughness, titanium alloys also perform excellently. They resist cracking and fatigue far better than many other metals, which means longer lifespans in demanding conditions.

In terms of corrosion resistance, titanium is tough. It withstands harsh environments—seawater, acids, and even body fluids won’t easily degrade it. This quality makes it ideal for marine applications and especially for medical implants, where durability and safety inside the body are critical.

High-temperature performance is another strong point, especially for beta alloys that can maintain strength and stability at temperatures up to 600°C (about 1112°F). This allows titanium alloys to operate in engines and other high-heat environments without losing their properties.

Finally, titanium alloys boast excellent biocompatibility and osseointegration, meaning they’re safe in the human body and bond well with bone. That’s why they’re the material of choice for medical implants and dental applications across the UK market.

Key Advantages vs Disadvantages of Titanium Alloys

Advantages

- Exceptional strength-to-weight ratio: Titanium alloys are much lighter than steel but offer comparable or better strength.

- Outstanding corrosion resistance: They withstand seawater, acids, and body fluids well, making them perfect for marine and medical uses.

- High temperature performance: Some beta titanium alloys remain strong up to 600 °C, ideal for aerospace engine parts.

- Biocompatibility: Titanium alloys like Grade 23 (Ti-6Al-4V ELI) are widely used in implants because they integrate well with bone and tissue.

- Fatigue and fracture toughness: They resist cracks and fatigue better than many other metals, extending service life.

- Non-magnetic and non-toxic: Useful in medical devices and sensitive electronic equipment.

- Versatility: Suitable across many industries — aerospace, automotive, marine, medical, and consumer goods.

Cons (with Mitigation Strategies)

- High cost: Titanium alloys are more expensive than aluminium or steel.

Mitigation: Use low-cost or powder metallurgy alloys; optimise design to use less material. - Difficult machining (“gummy” behaviour): Tends to stick to cutting tools and generates heat.

Mitigation: Use sharp tools, proper coolant, and slow cutting speeds. - Challenging welding: Sensitive to contamination and cracking during welding.

Mitigation: Controlled environment welding (argon shielding), use of proper filler metals. - Limited availability of some high-strength grades: Can cause lead-time delays.

Mitigation: Partner with suppliers like VAST for vertical integration and inventory flexibility. - Lower modulus of elasticity: More flexible than steel, which can be a disadvantage in structural applications.

Mitigation: Design adjustments to account for flexibility or use of stiffer titanium alloys.

Knowing both sides helps you pick the right titanium alloy for your project without surprises, balancing performance and cost.

Major Applications by Industry (2025)

Titanium alloys are everywhere in high-demand industries thanks to their strength, light weight, and corrosion resistance. Here’s a quick look at where they dominate in 2025:

Aerospace & Defence

Titanium alloys are a staple for aircraft airframes, engine parts, and landing gear. Their high strength-to-weight ratio helps improve fuel efficiency and performance, making them critical for aviation and military gear.

Medical & Dental

Medical-grade titanium, like Grade 23 (Ti-6Al-4V ELI), is the preferred material for implants and surgical instruments. It’s biocompatible, resists body fluids, and supports osseointegration, meaning bones bond well with titanium implants.

Automotive & Motorsport

Lightweight yet strong, titanium alloys reduce vehicle weight and enhance performance. They are used in exhaust systems, engine components, and high-end racing parts where every ounce matters.

Marine & Offshore

Titanium’s corrosion resistance makes it ideal for saltwater environments. It is used in ship components, deep-sea equipment, and offshore oil platforms where durability against seawater is essential.

Chemical Processing

Titanium alloys resist acids and harsh chemicals, making them suitable for heat exchangers, reactors, and piping in chemical plants, ensuring longevity and minimal maintenance.

Consumer Goods

From premium watches and knives to durable eyewear frames, titanium alloys add strength without the weight. Its corrosion resistance also helps these consumer products maintain their appearance for longer.

Emerging Markets: Hydrogen Storage & Additive Manufacturing

New applications such as hydrogen storage tanks benefit from titanium’s strength and lightness. Additionally, additive manufacturing (3D printing) with titanium alloys like Ti-6Al-4V and Beta-Ti enables the production of complex parts in aerospace, medical, and automotive sectors more quickly and with less weight.

In summary, titanium alloys drive critical components across industries, and this trend is only expanding as new applications and technologies develop.

Machining, Welding & Heat Treatment Best Practices for Titanium Alloys

Titanium alloys are known to be “gummy” during machining. This means they tend to stick to cutting tools and generate heat rapidly, which can dull tools quickly and affect surface finish. To machine titanium successfully:

- Use sharp, wear-resistant tools (carbide or coated tips are optimal)

- Maintain relatively low cutting speeds to prevent overheating

- Use ample coolant or lubrication to control temperature

- Opt for shallow cuts and higher feed rates to reduce tool rubbing

Regarding welding, most common titanium grades such as Ti-6Al-4V (Grade 5) and CP titanium weld well with proper shielding gas (argon) to prevent contamination. However, welding requires strict control of heat input and clean conditions to avoid cracking or embrittlement. Beta alloys and some high-strength grades may require preheating and post-weld heat treatment to reduce residual stresses.

Heat treatment is crucial for alpha-beta and beta titanium alloys. The standard approach involves:

- Solution treating: Heating the alloy above the beta transus temperature to create a uniform phase mix

- Aging: Cooling and holding at lower temperatures to precipitate strengthening phases, boosting strength and fatigue resistance

Following the right heat treatment cycles improves mechanical properties and durability, especially for aerospace and medical parts. Always refer to specific grade guidelines to optimise treatment conditions.

By understanding these best practices in machining, welding, and heat treatment, you can get the best performance from titanium alloys without common pitfalls.

Latest Developments in Titanium Alloy Technology (2024-2025)

Titanium alloys keep evolving, especially when it comes to cutting costs and boosting performance. Here’s what’s new in 2024-2025:

Low-Cost Alloys & Powder Metallurgy

Manufacturers are focusing a lot on low-cost titanium alloys that still deliver solid strength and corrosion resistance. Powder metallurgy (PM) plays a big role here—it allows titanium parts to be made with less machining and waste, cutting costs overall. PM is becoming more popular for making complex shapes and reducing lead times, which suits industries like automotive and aerospace looking to save money without compromising quality.

Additive Manufacturing Grades (Ti64, Ti-5553 for 3D Printing)

Additive manufacturing (AM), or 3D printing, is a game changer. The most popular titanium alloys for AM remain Ti-6Al-4V (Ti64) and Ti-5553, thanks to their excellent mechanical properties and printability. New tweaks in powder quality and process control boost the parts’ density and reduce defects, making 3D-printed titanium components more reliable than ever. This trend is huge in aerospace, medical implants, and even motorsports.

High-Entropy Titanium Alloys Research

High-entropy alloys (HEAs) are a hot topic in material science. For titanium, these alloys mix five or more elements in near-equal amounts, offering unique combinations of strength, toughness, and corrosion resistance. While still mostly in the research phase, high-entropy titanium alloys show promise for next-generation aerospace and defence uses, where extreme performance is non-negotiable.

Sustainability & Recycling Trends

Sustainability remains front and centre. New recycling methods for titanium scrap are improving, helping to reduce reliance on expensive raw materials. Companies are also designing alloys and processes with lower environmental footprints. Powder recycling in additive manufacturing is becoming standard practice, minimising waste and saving costs. If you’re aiming for greener production without losing quality, these trends are worth watching.

Staying updated on these latest tech moves can help you pick the right titanium alloy and process for your projects—and keep you competitive in a fast-changing United Kingdom market.

How to Select the Right Titanium Alloy for Your Project

Choosing the right titanium alloy comes down to a few key factors you need to consider upfront:

- Operating temperature: Some alloys handle heat better than others. For example, beta alloys like Ti-6246 can handle up to 600 °C, while others are better around room temperature. Know your part’s working range to avoid performance issues.

- Strength & fatigue requirements: If your project demands high strength and fatigue resistance—think aerospace or motorsport—grades like Ti-6Al-4V (Grade 5) or newer beta alloys like Ti-5553 are solid choices. For lighter loads, CP titanium (Grade 2) might be enough.

- Corrosion environment: Will your alloy sit in seawater, acidic chemicals, or body fluids? Titanium’s corrosion resistance varies by grade—medical grade alloys like Ti-6Al-4V ELI (Grade 23) excel in bio environments, while others might fit better in offshore or chemical processing.

- Biocompatibility needed?: For implants or medical devices, biocompatibility is a must. Medical-grade alloys like Grade 23 are designed for osseointegration and body safety.

- Cost vs performance trade-off: Some high-strength alloys come with price tags. Understand your budget and balance it with performance needs. CP titanium is cost-effective but less strong, whereas advanced beta alloys cost more but pack serious punch.

- Manufacturing method: How you make your component matters. Some alloys machine or weld better than others, and additive manufacturing might limit your alloy options to grades tailored for 3D printing like Ti64 or Ti-5553 powders.

Getting the alloy choice right at the start saves headaches down the line—matching your operating conditions and manufacturing plans to the best titanium alloy makes all the difference.

Partnering with vast for Premium Titanium Alloys & Components

When you work with vast, you’re tapping into a fully vertically integrated mill that handles everything from alloy production to precision machining. This setup means tighter quality control and faster turnaround on complex titanium components — a huge plus for United Kingdom customers who need reliability and speed.

What vast offers:

- Precision machining: Advanced CNC and custom tooling ensure tight tolerances on critical parts.

- Short lead times: Efficient processes keep typical delivery times competitive without sacrificing quality.

- Certifications: vast meets strict industry standards including AS9100 for aerospace and ISO 13485 for medical devices.

- Minimum order flexibility: Whether it’s a prototype batch or full production, vast supports varying order sizes to fit your project needs.

Real-world examples:

- A satellite bracket crafted from Ti-5553, showcasing high-strength beta titanium’s performance in aerospace applications.

- A spinal implant machined from Grade 23 ELI, illustrating vast’s capability in producing top-tier medical-grade titanium components.

Choosing vast means getting premium titanium alloys matched with expert manufacturing — designed for industries where performance and consistency matter most.