Discover the top advantages of laser beam machining including precision, speed, low heat impact, and versatility for advanced manufacturing.

What Is Laser Beam Machining and How Does It Work

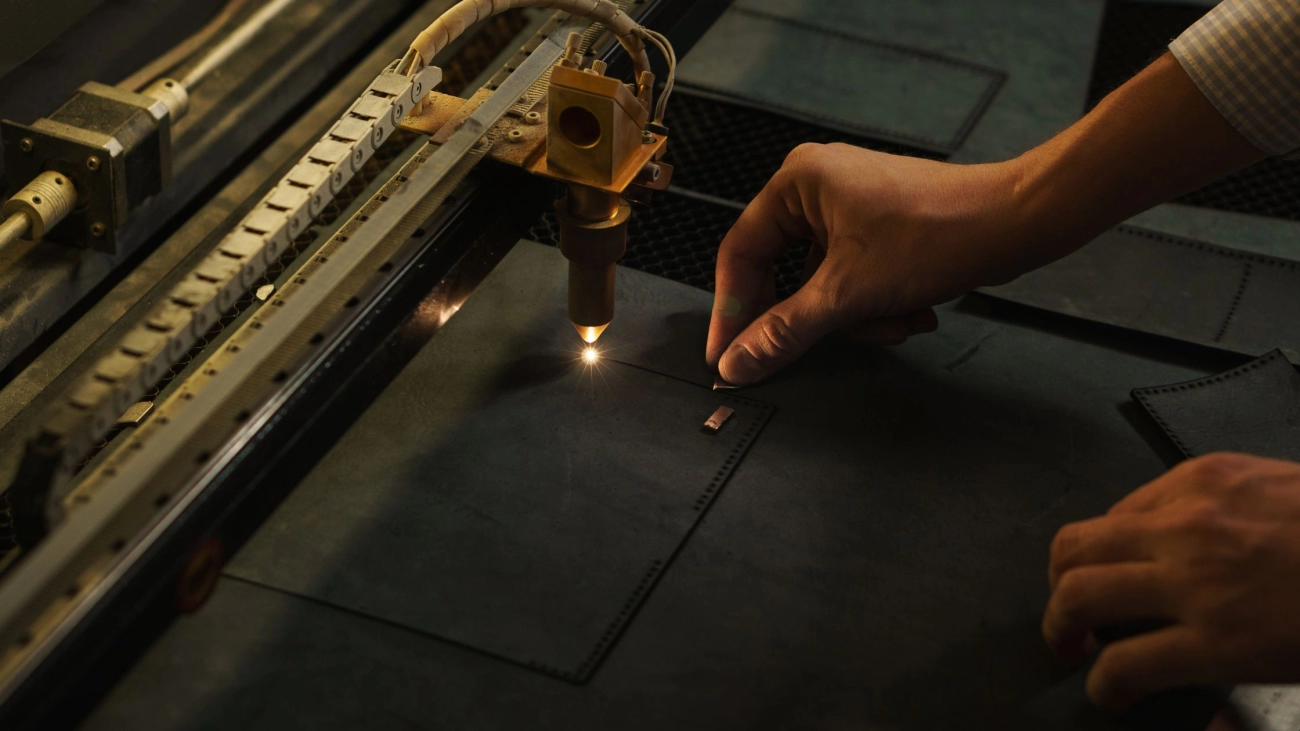

Laser beam machining (LBM) is a modern manufacturing process that uses a concentrated laser beam to cut, drill, or shape materials with incredible precision. Instead of traditional tools making contact with the workpiece, LBM relies on a focused light source to remove material by melting, vapourising, or ablating it. This non-contact approach means there’s no physical wear or mechanical stress on the material, making it ideal for delicate or complex parts.

Core Principles of Laser Beam Machining

At its core, LBM involves generating a high-energy laser beam through a specialised laser source. This beam is directed via mirrors and lenses onto the material surface. The laser’s intense heat alters the material, causing it to melt or vapourise right where the beam touches. The surrounding areas remain mostly unaffected, which significantly reduces the heat-affected zone. The process allows for fast and precise material removal with minimal damage.

Types of Lasers in Machining CO2, Fibre and Nd:YAG Compared

Choosing the right laser depends on the material and desired results. The most common laser types in machining include:

- CO2 Lasers: Best for cutting non-metal materials like wood, plastic, and glass. They emit infrared light and offer deep penetration.

- Fibre Lasers: Known for their high efficiency and excellent precision, fibre lasers work well on metals like steel and aluminium. Their shorter wavelength allows for fine, detailed cuts.

- Nd:YAG Lasers: These solid-state lasers are versatile and effective on metals and some plastics. They’re often used for precision welding and drilling.

Each laser type brings unique benefits, but all share the advantage of enabling high-speed, precise cutting and shaping without physical contact. This makes laser beam machining a standout technology for many industries.

The Standout Advantages of Laser Beam Machining Over Traditional Methods

Laser beam machining offers several clear advantages compared to traditional cutting and shaping methods, making it a top choice for many industries.

Unmatched Precision and Accuracy for Intricate Designs

With laser cutting precision, LBM delivers incredibly fine, detailed work. It’s perfect for intricate designs where small tolerances matter. This precision is tough to match with mechanical tools, especially when you’re working with complex shapes or tiny parts.

High Speed Processing and Automation Ready Efficiency

Laser machines cut materials much faster than traditional methods. Combined with CNC laser integration, this means job turnaround times drop, and production lines can run automatically with minimal supervision. Faster cutting means more parts done in less time, keeping projects on schedule and budgets tight.

Versatility Across Diverse Materials and Applications

Laser beam machining works across a wide range of materials — metals, plastics, ceramics, even composites. From aerospace aluminium to automotive steel, this method suits pretty much any job. It’s also handy for applications beyond cutting, like precision welding techniques and drilling.

Minimal Heat Affected Zone and No Mechanical Stress

One of the biggest perks is how laser machining minimises the heat-affected zone. This keeps surrounding areas safe from damage and preserves material integrity. Plus, since it’s a non-contact machining process, there’s no mechanical stress or tool pressure that could warp or weaken the workpiece.

Cost Effective with Low Waste and No Tool Wear

Laser machining doesn’t rely on physical blades or bits that dull and break. That means no tool wear advantages translate to saved costs on replacements and maintenance. Also, the focused beam causes less waste material, making it a more cost-efficient and eco-friendly choice over time.

In short, laser beam machining blends speed, precision, and versatility better than traditional methods — ideal for UK manufacturers looking to stay competitive.

Real World Applications Where Laser Beam Machining Excels

Laser beam machining (LBM) has proven its value across many industries here in the UK, especially where precision and efficiency matter most. From aerospace to automotive and beyond, this technology is reshaping how companies handle complex manufacturing tasks.

Industry Spotlights Aerospace, Automotive and Beyond

- Aerospace: In aerospace, laser cutting precision and minimal heat-affected zones are critical. LBM helps create lightweight, intricate parts without compromising structural integrity. The non-contact machining benefits mean less stress on sensitive materials, which is a big deal for safety and performance.

- Automotive: For car manufacturers, speed and accuracy are everything. LBM delivers high-speed material removal with CNC laser integration, speeding up production while maintaining tight tolerances. It’s also key in precision welding techniques used in electric vehicle battery components and body frames.

- Medical and Electronics: Beyond big industries, LBM works great for tiny, detailed parts in medical devices and electronics. Its versatility across materials ensures reliable cuts on metals, plastics, and composites without tool wear or the waste issues found in traditional machining.

Emerging Trends Hybrid LBM and Sustainability Gains

- Hybrid Laser Beam Machining: Combining LBM with other processes like additive manufacturing or mechanical methods is becoming popular. This hybrid approach boosts overall efficiency and opens the door to even more complex designs with fewer steps.

- Sustainability Gains: UK manufacturers are also focusing on greener processes. LBM’s low waste and energy-efficient operation align with sustainable goals, cutting down on scrap and rework. Plus, the minimal heat input reduces harmful emissions during production, making it a cleaner choice.

In short, laser beam machining isn’t just high-tech; it’s practical and adaptable for a wide range of real-world applications that demand precision, speed, and reliability.

Potential Limitations and How to Overcome Them

While laser beam machining offers many advantages, it’s important to recognise a few challenges before getting started.

Initial Costs

One of the biggest obstacles is the upfront investment. High-quality laser machines, especially fibre lasers and CO2 systems, can be expensive. This may be a concern for smaller workshops or startups. However, you can offset this by considering the long-term savings from low maintenance, no tool wear, and faster processing speeds. Leasing options and scaled-down models also help reduce initial financial pressure.

Handling Reflective Materials

Reflective metals like aluminium and copper can be tricky because they reflect a lot of the laser energy, leading to inefficient cuts and potential damage to the machine. To overcome this, using fibre lasers instead of traditional CO2 lasers is a smart move since fibre lasers handle reflective surfaces better. Adjusting laser settings and employing assist gases also improve cut quality on these tough materials.

Other Considerations

- Some materials may produce fumes or require ventilation systems.

- Complex shapes sometimes need programming expertise and precise CNC laser integration.

By being aware of these limitations and investing in the right technology and training, you can maximise the benefits of laser beam machining while minimising downtime and costs.

Why Choose Vast for Your Laser Beam Machining Needs

When it comes to laser beam machining advantages, Vast stands out by delivering customised solutions that fit your unique business needs. We understand that no two projects are the same, so our team works closely with you to tailor the laser cutting precision, ensuring every detail meets your exact standards.

Our expert support means you’re never alone. From setup to ongoing CNC laser integration, we provide hands-on assistance to keep your operations running smoothly and efficiently. Whether you’re after high-speed material removal or want to minimise heat-affected zone impacts, we bring the expertise to get the job done right.

Choosing Vast means investing in:

- customised laser machining solutions that align with your production goals

- Reliable service and technical support whenever you need it

- Access to the latest fibre laser efficiency and precision welding techniques

- Cost-effective laser beam machining benefits including no tool wear and minimal waste

For businesses in the United Kingdom looking to upgrade their manufacturing with versatile laser applications, Vast offers a practical, local partner to help you get the most out of every project.