Explore the different types of washers including flat, spring, and lock washers with tips on selecting the right material and size for your project.

What Are Washers Functions and Core Benefits

Washers are small but crucial components that sit between a fastener—like a bolt or screw—and the surface being fastened. Their core role is to distribute the load of the fastener evenly, protecting the material from damage and preventing the fastener from pulling through. This simple function helps keep your connections strong and stable.

Beyond load distribution, washers offer key benefits:

- Reduce friction between fastener and surface

- Absorb shock and vibrations to protect joints

- Act as spacers to maintain proper alignment

- Seal joints against leaks or dirt

- Enhance overall joint integrity for longer-lasting assemblies

Here’s a quick stat: using washers can extend the life of fasteners by up to 50 percent when working in high-vibration environments, making them essential for durability.

Not all washers are the same. Let’s dive into the three primary categories and find the right type for your project.

The Three Main Types of Washers A Breakdown

Plain Washers Flat Washers

These are simple, flat discs that spread the load evenly across surfaces. They help prevent damage and ensure the fastener holds tight.

- Subtypes

- Standard flat washers: The go-to for most jobs

- Fender washers: Larger outer diameter for soft or thin materials

- Countersunk/bevelled washers: Designed for flush fits with angled screws

- Ideal uses

- General assembly tasks

- Woodworking projects

- Automotive panels

- Pro tip

Pair with Vast’s USS SAE flat washers for better precision in sizing.

Spring Washers

Made in helical or curved shapes, spring washers compress to keep tension on a bolt or screw, preventing it from loosening.

- Subtypes

- Split washers: Crescent-shaped for flexible tension

- Belleville washers: Cone-shaped and stackable, great for heavy loads

- Wave and multi-wave washers: Best for light vibration damping

- Ideal uses

- Machinery and engines

- Thermal expansion situations where parts move or shift

- Pro tip

Vast’s carbon steel split washers are perfect for dynamic and high-vibration jobs.

Lock Washers

These washers have textured or deformed surfaces that stop fasteners from coming loose due to torque or vibration.

- Subtypes

- Internal tooth washers: Teeth grip the inside of the hole

- External tooth washers: Teeth bite around the outside for extra grip

- Star washers: Multi-pronged for strong resistance

- Nylon-insert washers: Use friction from a nylon ring to lock

- Ideal uses

- Construction

- Electronics

- High-security fixtures

- Pro tip

Choose Vast’s stainless steel lock washers for long-lasting outdoor durability.

Specialty Washers Beyond the Basics for Niche Applications

Specialty washers are designed to tackle unique challenges that standard washers can’t handle. These advanced types come in all shapes and materials to fit specific needs in tough environments.

Some popular specialty washers include:

- Shoulder washers – used as insulating spacers, perfect for preventing electrical contact.

- Rubber-bonded washers – great for sealing leaks in plumbing or automotive systems.

- C-washers – adjustable clips that slide into place for easy installation.

- Phenolic washers – non-conductive options ideal for electrical uses, helping prevent shorts.

You’ll often find these washers in plumbing, aerospace, and marine setups where durability and precision are critical.

For a clear comparison, check out the infographic showing how standard washers stack up against specialty washers in terms of function and materials.

Materials Guide Matching Washers to Your Environment

Choosing the right washer material is key to making sure your fasteners hold up and last. Here’s a quick look at common options and when to use them:

Stainless steel

- Pros: Highly corrosion-resistant, great for outdoor and wet environments

- Cons: Higher cost than some others

- Best for: Outdoor projects, marine, and anywhere moisture is a concern

Zinc-plated steel

- Pros: Affordable, decent rust protection

- Cons: Not ideal for long-term outdoor use or harsh conditions

- Best for: Indoor applications and light-duty jobs

Nylon and plastic

- Pros: Low friction, won’t scratch surfaces, non-marring

- Cons: Less durable under heavy loads or heat

- Best for: Electronics, light fixtures, and areas needing insulation

Brass and copper

- Pros: Naturally conductive, decorative finish

- Cons: Softer materials, not for heavy loads

- Best for: Electrical grounding, decorative hardware

High-carbon steel

- Pros: Extra strength for heavy-duty use

- Cons: Prone to rust if not coated

- Best for: Structural work and high-stress fastening

What else to keep in mind

- Avoid mixing metals to prevent galvanic corrosion which can damage both the washer and fastener.

- Consider the environment: moisture, temperature, and load type all matter when choosing materials.

| Material | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Stainless Steel | Corrosion-resistant | More expensive | Outdoor, marine |

| Zinc-Plated Steel | Cost-effective, rust-resistant | Limited outdoor use | Indoor, light-duty |

| Nylon/Plastic | Low friction, non-marring | Not for heavy loads | Electronics, insulation |

| Brass/Copper | Conductive, decorative | Softer, less strong | Electrical, decorative |

| High-Carbon Steel | Strong, heavy-duty | Rust-prone without coating | Structural, high load |

For easy shopping, check out Vast’s material-specific washer kits tailored to your project needs. They make matching the right washer to your environment simple and hassle-free.

How to Choose the Right Washer Step-by-Step

Picking the right washer can save you headaches down the road. Here’s a simple process to follow:

Step 1: Assess the load type

Ask yourself if the load is static (steady) or vibrating. For vibration-prone environments, spring or lock washers work best to keep things tight.

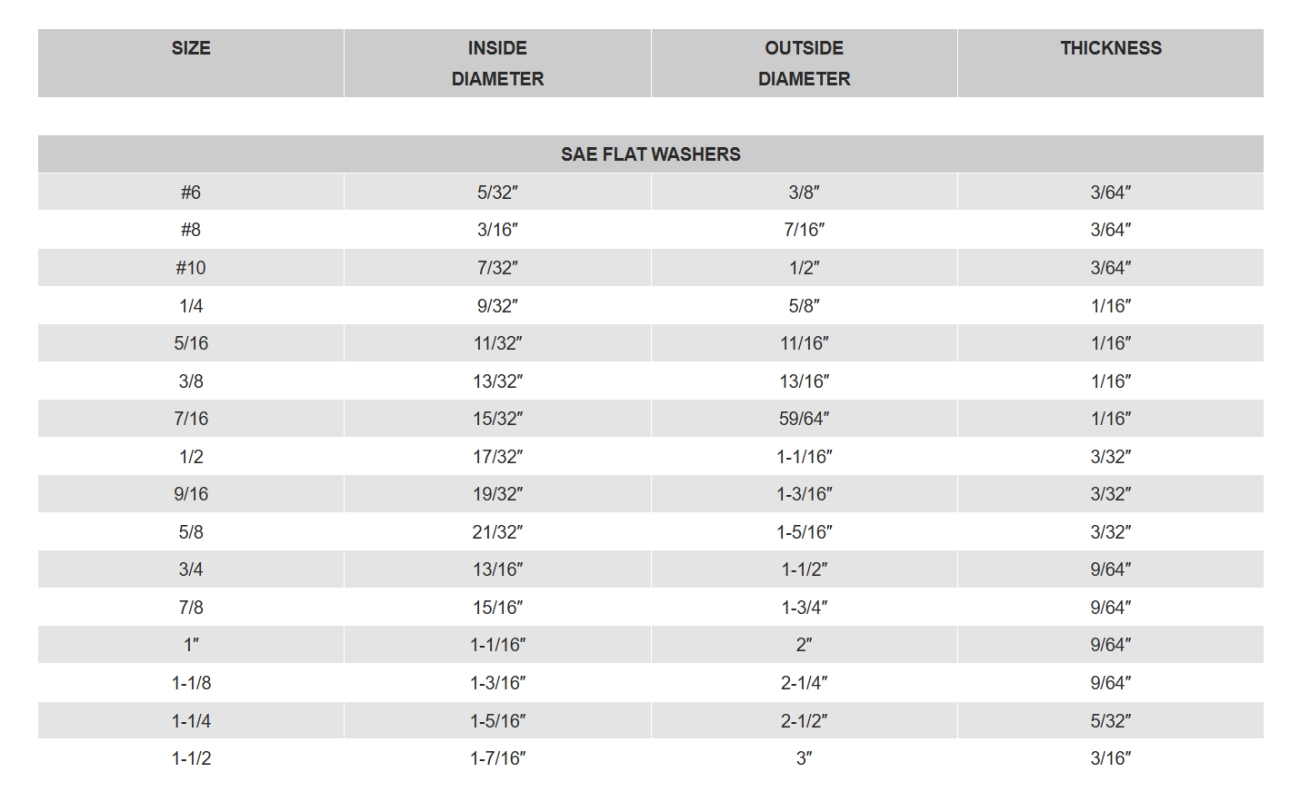

Step 2: Match size to your fastener

Check the washer’s inner diameter (ID) and outer diameter (OD) so it fits your bolt or screw perfectly. Use the ANSI standards chart to ensure accurate sizing.

Step 3: Consider the environment

Think about moisture, temperature, and exposure. Stainless steel washers suit outdoor use because they resist corrosion, while zinc-plated steel might be fine indoors.

Step 4: Test compatibility and torque specs

Make sure the washer material won’t react badly with your fastener to avoid corrosion. Also, check torque recommendations to prevent over-compression or slippage.

Common mistakes to avoid

- Using washers that are too small for the load

- Ignoring protective coatings that prevent rust and damage

For extra help, try Vast’s interactive quiz—it recommends the best washers based on your project specifics and environment.

Washer Installation Best Practices and Maintenance

Installing washers the right way keeps your fasteners secure and lasting longer. Here’s what I recommend:

- Order of assemblyAlways put the washer between the bolt head and the nut—or under the nut if you’re using a lock washer. This helps spread the load evenly and prevents damage.

- Torque tipsUse a calibrated torque tool to tighten bolts. This avoids over-compressing the washer and fastener, which can lead to failure or stripped threads.

- MaintenanceCheck washers regularly for wear or corrosion, especially in damp or outdoor environments. Replace them yearly if exposed to harsh conditions to keep joints safe and tight.

- Safety noteWear proper PPE like gloves and safety glasses during installation, especially with heavy-duty machinery or outdoor projects.

Following these steps will boost your hardware’s performance and prevent costly repairs down the road.