Learn the pitch of helix meaning formulas types and applications in engineering biology and design for precise helix calculations and modelling.

Ever wondered what really defines the pitch of a helix and why it matters across everything from mechanical springs to the twists of DNA? Whether you’re an engineer, designer, or simply curious about the science behind these spirals, understanding helix pitch is key to unlocking precise control over shape, function, and performance. In this guide, we’ll break down exactly what helix pitch means, how to calculate it, and why it’s a crucial design parameter in so many fields. Ready to unravel the secrets behind this fascinating geometric property? Let’s get started!

What Is a Helix? Building the Foundation

A helix is a three-dimensional curve winding around an axis, much like a spring or a spiral staircase. It’s characterised by specific core components that make it unique and useful in many fields.

Core Components of a Helix

| Component | Description |

|---|---|

| Axis | The straight line around which the helix coils |

| Radius | Distance from the axis to the helix curve |

| Handedness | Direction of the curve: right-handed or left-handed |

| Turns | The number of complete rotations along the axis |

Helix vs. Spirals and Helicoids

- Helix: 3D curve with constant radius winding around a straight axis.

- Spiral: 2D curve expanding outward on a flat plane.

- Helicoid: A surface formed by twisting a plane along an axis, like a spiral ramp.

Helices extend upward or downward, maintaining a fixed radius, unlike spirals that grow radially on a plane.

Simple Parametric Equations and Diagrams

A typical helix can be described using parametric equations:

[

x(t) = r cos(t), quad y(t) = r sin(t), quad z(t) = frac{p}{2pi} t

]

- r: radius

- p: pitch (vertical advance per turn)

- t: parameter (angle in radians)

This formula visualises the coil winding around the axis with a smooth rise along (z).

Historical Origins and Visual Aids

The concept of the helix dates back to ancient architecture and natural observations, such as snail shells and vines. Over time, studies by mathematicians like René Descartes formalised its geometry. Today, simple diagrams, 3D models, and CAD software help visualise helices clearly, aiding designers and engineers.

Understanding a helix’s basics sets the stage for deeper exploration into the pitch of helix, its measurement, and applications across various industries.

Defining the Pitch of a Helix: The Core Concept

The pitch of a helix is the distance the helix rises along its central axis during one full turn (360 degrees). It basically tells you how “tight” or “stretched out” the coil is. Mathematically, the pitch ( p ) is given by the formula:

[

p = 2pi times text{(rise per radian)}

]

This means the pitch equals the vertical rise of the helix multiplied by ( 2pi ), representing the full rotation in radians.

Pitch vs. Lead

It’s easy to confuse pitch with lead—especially in screws and threads. Pitch is the axial distance the helix advances in one complete turn of the coil, while lead is how far it moves along the axis per turn of the screw thread. For single-start screws, pitch and lead are the same. But for multi-start threads, lead equals pitch multiplied by the number of starts.

Pitch Compared to Radius and Slope

Pitch doesn’t directly depend on the helix’s radius (the circle’s size around the axis). Instead, it’s about how far the helix moves up during a turn, not how far around. The slope or helix angle connects pitch and radius: a steeper helix angle means a larger pitch relative to the radius.

Units and Measurement

Pitch is measured in units of length, usually inches or millimetres, depending on the application. Make sure you’re consistent—mixing units can throw off calculations.

Why Pitch Matters: A Quick Example

Imagine a standard M10 screw with a pitch of 1.5 mm. That means for one full turn, the screw moves 1.5 mm along its axis. Knowing this helps engineers design screws that fit tightly or loosen quickly, depending on the need.

Understanding pitch is key for anything involving helical shapes—from mechanical parts to biological structures like DNA or alpha helices.

Types of Helix Pitch: Constant, Variable, and Beyond

When we talk about the pitch of helix, it mainly falls into a few key types based on how the spacing between each turn behaves.

Constant Pitch: Uniform Spacing and Benefits

- The pitch stays the same throughout the entire helix.

- Each coil or turn rises by the same distance.

- Common in screws, springs, and standard helical gears.

- Easy to design and manufacture.

- Provides steady mechanical performance.

Variable Pitch: Tapered Advance and Interpolation Methods

- The pitch changes gradually along the helix.

- Used when you need tapered or specialised shapes like cams or progressive springs.

- Often designed using interpolation methods for smooth pitch transitions.

- Allows customised stress distribution and function.

Specialised Types: Cylindrical, Conical, Spherical

- Cylindrical helix: Constant radius, typical in most screws.

- Conical helix: Radius changes along the axis, like in tapered springs or threads.

- Spherical helix: Wrapped on a sphere; rare, mostly in specialised physics and geometry.

Edge Cases: Zero and Infinite Pitch

- Zero pitch: Turns overlap vertically, effectively a flat circle, no rise.

- Infinite pitch: Turns are separated infinitely, almost a straight line.

Comparison Table of Helix Pitch Types

| Pitch Type | Pitch Behaviour | Common Uses | Key Feature |

|---|---|---|---|

| Constant Pitch | Uniform rise | Screws, springs, gears | Simple, steady performance |

| Variable Pitch | Gradual change | Cams, tapered springs | Custom rise, stress control |

| Cylindrical | Constant radius | Standard helix shapes | Regular helical structure |

| Conical | Radius changes | Tapered threads, springs | Variable radius and pitch |

| Spherical | Wrapped on sphere | Specialised physics designs | Complex 3D curvature |

| Zero Pitch | No rise per turn | Theoretical/edge cases | Turns overlap vertically |

| Infinite Pitch | Turns infinitely apart | Near straight line | No helical rise, just linear |

Understanding these types helps select the appropriate helix design for your application, whether it’s mechanical parts or scientific models.

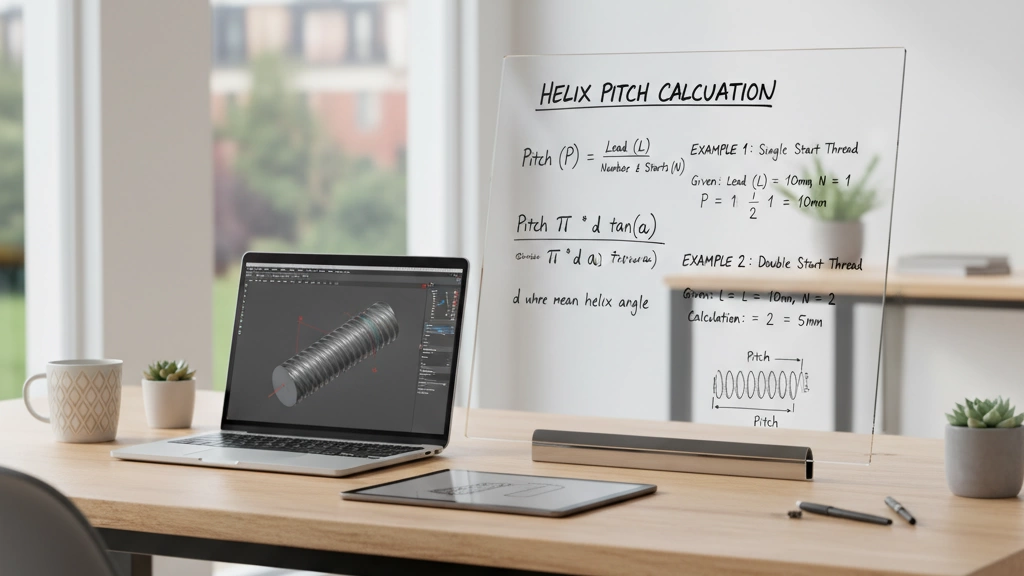

Calculating Helix Pitch: Formulas, Examples, and Tools

When determining the pitch of a helix, it is helpful to understand a few key formulas and how to apply them in real life.

Basic Formula from Arc Length and Turns

The simplest way to calculate pitch (p) is by dividing the total rise by the number of turns. If you know the arc length (L) of one full turn and the helix radius (r), you can use this formula:

[

p = frac{L}{sqrt{1 + left(frac{2 pi r}{p}right)^2}}

]

But this gets simplified usually to:

[

p = text{Rise per full turn}

]

Where the rise is the vertical distance the helix moves in one complete 360° turn.

Calculation Using Helix Angle

The helix angle (α) connects pitch, radius, and slope of the coil. Using the helix angle, pitch can also be calculated as:

[

p = 2pi r tan(alpha)

]

This works when you know the radius of the helix and the angle it makes relative to the base plane.

Advanced Physics Formula for Magnetic Fields

For fields like electromagnetism, where particles move along helical paths, pitch relates to magnetic field strength (B) and particle velocity (v):

[

p = frac{2pi m v_{parallel}}{q B}

]

Here, (m) is particle mass, (v_{parallel}) the velocity component parallel to the field, and (q) the charge. This formula is crucial in physics, especially for cyclotron motion.

Real-World Calculation Examples

- M10 Screw: Standard M10 bolts have a pitch around 1.5 mm—this means the screw threads advance 1.5 mm per full turn.

- Alpha-Helix in Proteins: The pitch is about 5.4 Å (angstroms), corresponding to 3.6 amino acid residues per turn.

Knowing these helps in fields from manufacturing screws to studying protein structures.

Recommended Tools and Software

- CAD Software (AutoCAD, SolidWorks): Great for designing and visualising helices with precise pitch control.

- Helix Pitch Calculators Online: Handy for quick calculations without manual maths.

- Mathematical Software (MATLAB, Wolfram Alpha): Useful for more complex helix pitch problems especially in physics or engineering.

Using the right formula based on your task makes calculating helix pitch straightforward and reliable—whether you’re designing a screw or analysing DNA’s structure.

Applications of Helix Pitch Across Industries

The pitch of a helix plays a crucial role in many industries, shaping how products and processes work efficiently.

Mechanical Engineering: Screws, Gears, Springs

In mechanical engineering, helix pitch defines how screws, helical gears, and springs function. The right pitch ensures screws hold tight and gears mesh smoothly, while springs compress and relax with the proper spacing. For example, standard screw thread pitch is essential for fitting parts correctly without slipping.

Biology and Chemistry: Protein Alpha-Helices, DNA Structures

In biology, the pitch of helix structures like protein alpha-helices and DNA is fundamental. The specific pitch determines how these molecules fold and interact. DNA’s double helix pitch affects how genetic information is stored and read, while protein pitch impacts their shape and function.

Physics and Electromagnetism: Particle Paths, Helical Antennas

Physics uses helix pitch to describe particle paths in magnetic fields and design helically wound antennas. The pitch affects how charged particles spiral and how antennas transmit signals with certain frequencies, improving communication in devices like mobile phones and satellites.

Manufacturing and Design: CNC Milling, 3D Printing

Manufacturers rely on helix pitch to programme CNC milling machines and 3D printers, especially when creating threads or spiralled shapes. Accurate pitch ensures parts fit as designed, reducing waste and speeding up production.

Aerospace: Variable Pitch Gears Case Study

In aerospace engineering, variable pitch gears adjust during operation for optimal performance under different speeds and loads. This adaptability relies on changing helix pitch to balance strength, noise reduction, and efficiency, which is critical in aircraft transmissions.

In short, knowing the correct pitch of a helix helps engineers, scientists, and manufacturers create better, more reliable products across many fields.

Common Challenges and Solutions in Helix Pitch Design

When working with the pitch of a helix, several common problems can arise. Recognising these and knowing how to fix them keeps your design solid and on point.

Misconceptions About Pitch vs. Radius

A common confusion is mixing up pitch with radius. The pitch is the vertical distance the helix moves upwards in one full turn, while the radius is the distance from the centre (axis) out to the edge of the coil. They are related but entirely different measurements. Remember: pitch affects how tightly the turns are spaced vertically; radius controls the overall size of the helix.

Calculation Errors and Overlapping Turns

Sometimes, calculations can be inaccurate, leading to turns overlapping or being too compressed. This usually happens if you miscalculate the rise per turn or do not consider the correct helix angle. To avoid this:

- Double-check your pitch formula.

- Ensure the helix angle correctly correlates with the pitch and radius.

- Use CAD tools to visualise the helix before manufacturing.

Tips for Optimising Strength and Pitch Balance

Getting a helix right involves balancing pitch for strength and function. Too tight a pitch can weaken the structure; too loose wastes space. Some tips:

- For screws and springs, match the pitch to load requirements.

- Use variable pitch when strength needs vary along the helix.

- Test prototypes to fine-tune the pitch-radius combination.

FAQ: Converting Helix Angle to Pitch

Converting the helix angle to pitch can be confusing. Here’s a quick method:

- Use the formula pitch (p) = 2π × radius × tan(helix angle).

- Make sure the angle is in radians or convert degrees to radians first.

- This formula links the helix angle, radius, and pitch directly, saving guesswork.

Keeping these points in mind helps avoid the most common pitfalls in helix pitch design, ensuring your project meets both engineering and practical needs.