Discover what billet aluminium is, its production process, benefits, and applications in automotive and aerospace for stronger high-precision parts.

The Basics: Defining Billet Aluminium and Its Role in Manufacturing

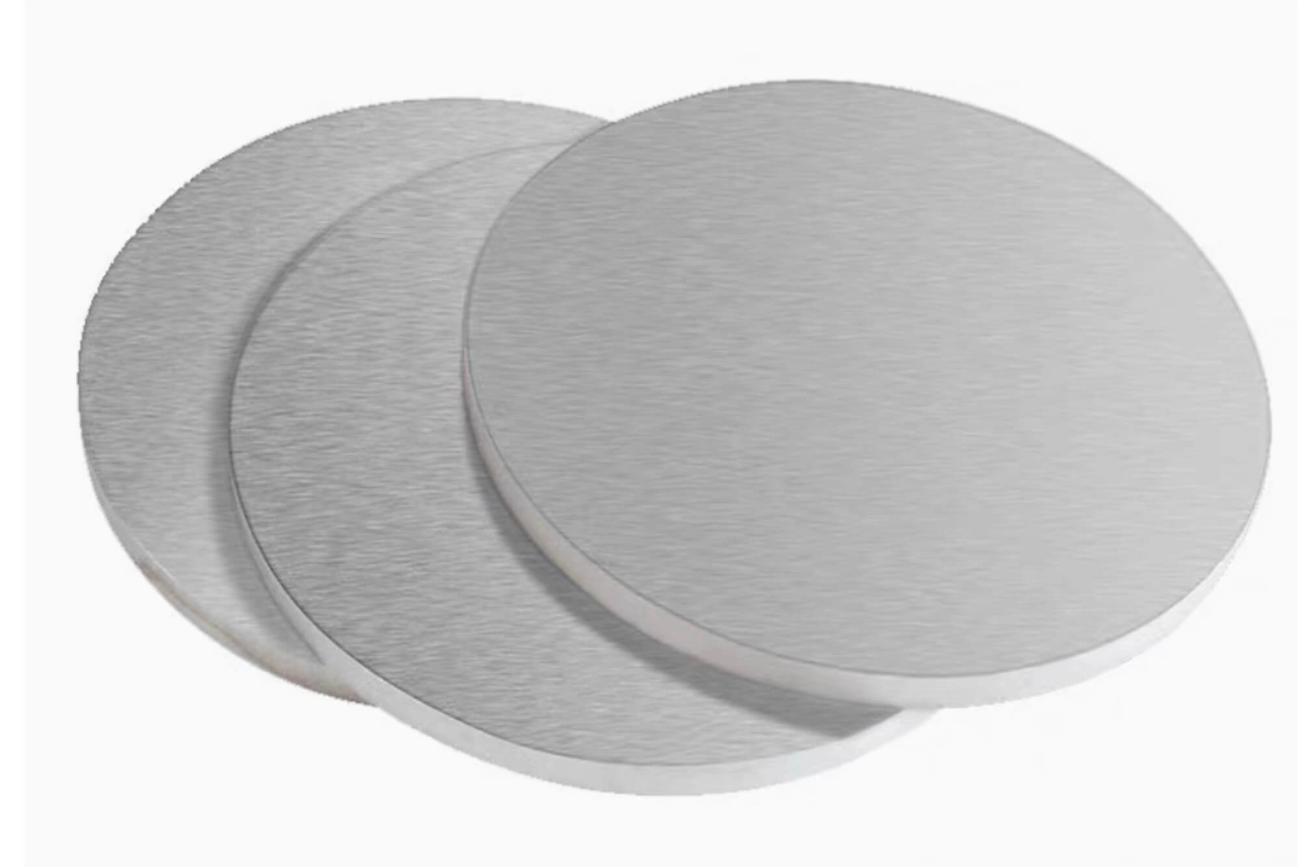

What exactly is billet aluminium? Think of a billet as a solid block of high-quality aluminium that serves as the starting point for precision manufacturing. Unlike cast aluminium, which is melted and poured into moulds, billet aluminium is created by cooling molten aluminium into large, dense bars. These bars are then cut into smaller pieces called billets, which are prized for their consistent grain structure and mechanical properties.

Billet aluminium plays a crucial role in industries where strength, precision, and reliability matter—everything from aerospace components to custom automotive parts. Because billets offer a uniform, defect-free base material, manufacturers can machine complex, detailed parts with excellent accuracy.

Common alloys used in billet aluminium vary depending on the application but often include:

- 6061-T6: Known for its excellent strength-to-weight ratio and corrosion resistance, popular in CNC billet parts.

- 7075: High-strength aluminium used when durability is a top priority.

- 2024: Favoured in aerospace for its toughness and fatigue resistance.

Choosing the right alloy is key to balancing strength, machinability, and cost, making billet aluminium an incredibly versatile solution in modern manufacturing.

How Is Billet Aluminium Produced Step-by-Step Process

Producing billet aluminium starts with raw aluminium metal, usually recycled or newly refined. Here’s a simple breakdown of the process from start to finish:

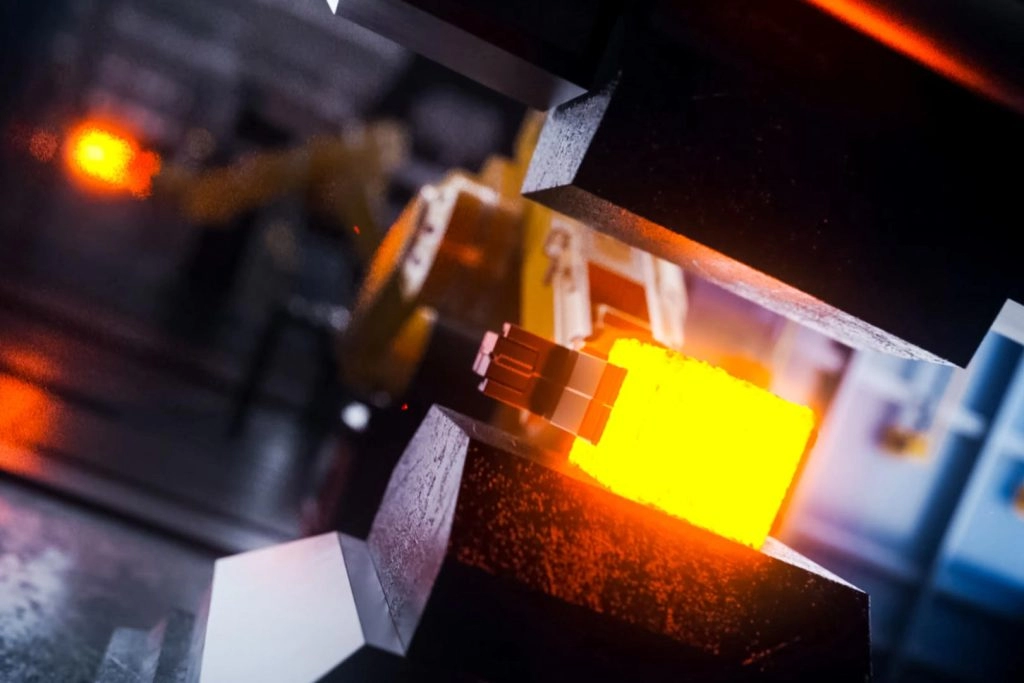

- Melting and Purifying: The raw aluminium is melted in a furnace. Impurities are removed to ensure the metal is clean. This step is crucial for strong, high-quality billet aluminium.

- Alloy Mixing: Specific elements like magnesium and silicon are added to create the desired aluminium alloy, such as popular 6061-T6. This defines the billet’s strength and properties.

- Casting into Logs: The molten aluminium alloy is poured into large moulds, forming solid cylindrical logs or ingots. These are the “billets” — solid blocks of aluminium ready for further processing.

- Cooling and Solidifying: The moulds are cooled slowly and carefully to prevent internal stresses and defects like porosity often seen in cast aluminium parts.

- Extrusion or Rolling: Sometimes billets undergo extrusion, where they’re pushed through a shaped die to form aluminium profiles. Otherwise, they can be cut into smaller pieces for machining.

- Quality Control Checks: Throughout production, equipment like ultrasonic testers and X-ray machines check for defects or consistency issues. Maintaining tight quality control is key to producing reliable billet aluminium.

Key Equipment Used

- High-temperature furnaces for melting

- Alloy mixers for precise composition

- Heavy-duty moulds for casting

- Automated cooling systems

- Inspection tools for material testing

This step-by-step approach ensures the billet aluminium is tough, defect-free, and ready for high-precision uses like CNC billet parts or automotive components.

Billet Aluminium vs Cast and Forged Key Differences Explained

When deciding between billet aluminium, cast aluminium, or forged aluminium, it helps to know the key differences in strength, cost, and durability.

Billet vs Cast Aluminium

- Strength: Billet aluminium is made by machining from a single solid block of high-strength aluminium stock. This results in a more consistent, dense metal with fewer impurities. Cast aluminium, on the other hand, is poured into moulds and can have tiny air pockets (porosity) that weaken the metal, making it less durable under stress.

- Cost: Cast aluminium is generally cheaper because the process is faster and requires less machining. Billet aluminium parts take more time and precision to make, so they come with a higher price tag.

- When to Choose: Choose billet aluminium for performance parts where strength and precision are critical, like CNC billet parts used in motorsports. Cast aluminium works well for budget-friendly, less demanding applications.

Billet vs Forged Aluminium

- Density and Durability: Both billet and forged aluminium start with solid aluminium stock, but forging involves shaping the metal under heat and pressure. This aligns the metal grains, increasing strength and fatigue resistance. Billet aluminium is machined from a solid block but doesn’t get the grain structure benefits of forging.

- Application Differences: Forged aluminium is typically stronger and more resistant to impact and fatigue. Billet aluminium offers precise machining freedom, excellent surface finish, and is less expensive than forging.

- Choosing Between Them: Opt for forged aluminium if you need maximum durability and toughness, especially in high-stress aerospace or automotive parts. Billet aluminium is great when you want detailed shapes and tight tolerances without the expense of forging.

Understanding these differences helps you select the appropriate material for your project, balancing performance, cost, and manufacturing requirements.

Advantages and Disadvantages of Billet Aluminium

Top Benefits for Performance and Precision

Billet aluminium is valued for its high strength and precision. Since it’s produced from a solid block of high-quality aluminium alloy, the material is dense and uniform throughout. This provides several key advantages:

- Superior Strength: Billet aluminium components are stronger and more durable compared to cast aluminium, which can contain pores and weak spots.

- Precision Machining: CNC billet components can be manufactured with very tight tolerances, making them ideal for applications where exact fit and finish are crucial.

- Better Surface Finish: The smooth, uniform structure of billet aluminium allows for cleaner cuts and more attractive final products.

- Customization: It’s easier to customise billet aluminium for specific needs, whether for automotive, aerospace, or industrial applications.

- Reduced Defects: The billet manufacturing process minimises defects such as cracks or inclusions, enhancing reliability.

Potential Drawbacks and How to Mitigate Them

Even with these advantages, billet aluminium isn’t perfect. Here are some disadvantages and ways to address them:

- Higher Cost: Billet aluminium is generally more expensive than cast or extruded alternatives. This is due to the extra material quality and machining time required.

- Mitigation: Use billet aluminium only where strength and precision justify the higher cost, such as critical engine parts or aerospace components.

- Longer Production TimeMachining billets can take longer than casting or forging, as removing material from a solid block requires careful work.

- MitigationPlan ahead in manufacturing schedules and consider CNC process optimisation.

- Material WasteCutting parts out of a solid billet can create excess scrap material.

- MitigationRecycle scrap aluminium to improve overall efficiency and reduce costs.

In the United Kingdom, billet aluminium offers top-notch performance and precision, especially in the market where demand for high-strength aluminium stock is strong in industries like automotive and aerospace. Its disadvantages mainly revolve around cost and production speed, which can be managed with smart design and process planning.

Real-World Applications Where Billet Aluminium Shines

Billet aluminium is a go-to material in many high-performance and precision industries across the United Kingdom, thanks to its strength, consistency, and machinability. Here’s where it really stands out:

Automotive and Motorsports

- Engine parts and custom componentsBillet aluminium machining is perfect for making strong, lightweight parts like piston heads, valve covers, and throttle bodies.

- Performance upgradesRacers and car enthusiasts favour billet parts because they hold up better under high stress and heat, improving performance and reliability.

- Custom CNC billet partsFrom gear knobs to suspension components, billet aluminium allows custom designs that boost both looks and function.

Aerospace

- High-strength aluminium stockAircraft parts need materials with exceptional strength-to-weight ratios. Billet aluminium alloys like 6061-T6 are popular in making critical structural components.

- Precision and safetyThe uniform grain structure helps ensure parts meet tight tolerances and safety standards in aerospace construction.

Construction and Beyond

- Durable structural components: In construction, billet aluminium is used for custom fittings and structural supports where strength and corrosion resistance are essential.

- Industrial machinery: Custom machined billet parts help improve the lifespan and efficiency of equipment.

- Recreational gear: High-quality sports and outdoor gear makers use billet aluminium for parts that require toughness without extra weight.

In all these fields, billet aluminium delivers reliability, precision, and performance that often outperform cast or forged alternatives. It’s a trusted choice for anyone needing high-quality aluminium parts made right here in the UK and worldwide.

Billet Aluminium in 2025 Market Trends and Future Outlook

The billet aluminium market in 2025 is shaped by rising demand for high-strength aluminium stock, especially in the UK automotive and aerospace industries. Here’s what’s happening right now:

Pricing and Supply Chain Insights

- Prices are gradually increasing due to higher raw material costs and tighter supply chains.

- Supply chain disruptions have pushed many manufacturers to seek more local sources and improve inventory strategies.

- UK producers focus on reducing dependency on overseas suppliers to keep delivery times predictable.

Sustainability Efforts

- More companies are prioritising eco-friendly billet manufacturing methods, like increased recycling of aluminium scrap.

- The push for lightweight vehicles and fuel efficiency fuels interest in billet aluminium with better strength-to-weight ratios.

- Sustainable production practices are becoming a key selling point for buyers looking to reduce their carbon footprint.

Innovations Impacting the Market

- Advanced CNC billet parts machining is getting more precise and cost-effective, enabling quicker turnaround on custom orders.

- Researchers are developing new alloys, including updated versions of the common 6061-T6 alloy properties, to enhance durability and machinability.

- Automation and AI-driven quality controls minimise billet manufacturing defects, improving overall product reliability.

Overall, billet aluminium remains a strong choice for manufacturers in the United Kingdom seeking high-performance, reliable aluminium solutions while adapting to pricing changes and environmental goals. The market continues to evolve with technology and sustainability at the forefront.

Frequently Asked Questions About Billet Aluminium

What is billet aluminium used for?

Billet aluminium is popular in industries that require strong, precise, and lightweight parts. You’ll find it in automotive components, aerospace parts, motorsports gear, and even custom CNC billet parts for machines and tools.

How is billet aluminium different from cast or forged aluminium?

Billet aluminium starts as a solid block of high-strength aluminium alloy, offering better uniformity and fewer defects than cast aluminium, which can have porosity. Forged aluminium is shaped under pressure and is tough too, but billet often allows for more precise machining.

What alloys are common in billet aluminium?

6061-T6 is a top choice because of its excellent balance of strength, corrosion resistance, and machinability. Other alloys like 7075 are used when more strength is required.

Can billet aluminium have manufacturing defects?

While billets are solid and typically defect-free, issues can occur if the raw aluminium isn’t properly processed or if the cooling isn’t controlled during casting. Quality controls during production help prevent this.

Is billet aluminium more expensive?

Yes, billet aluminium usually costs more than cast or extruded aluminium due to the machining and quality involved. However, the investment pays off with better performance and durability.

Why choose billet aluminium over other processes?

If you need high precision, strength, and reliability without the variability of cast parts, billet aluminium is the ideal choice. It’s especially useful in high-performance and safety-critical applications.

Where can I buy billet aluminium in the United Kingdom?

Many suppliers in the United Kingdom specialise in aluminium billet with quick shipping options. Look for sellers that offer certification and support for aerospace-grade or automotive-grade aluminium stock.

If you’re curious about how billet aluminium compares to other materials or want a deeper dive into manufacturing, check out our article on [billet vs cast aluminium] for a detailed comparison.