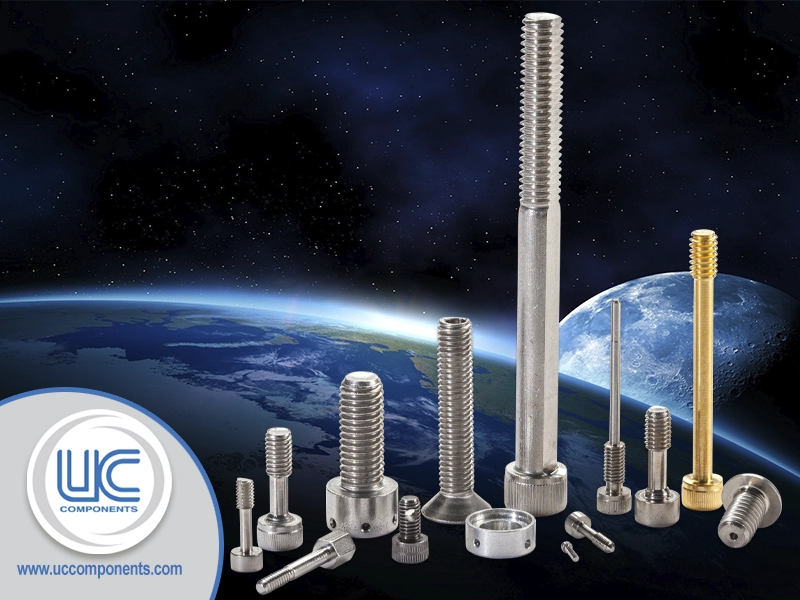

Discover aerospace fasteners types materials and standards trusted for strength vibration resistance and certified quality in aerospace applications.

When it comes to aerospace manufacturing and maintenance, aerospace fasteners are the hidden heroes holding everything together—literally. From withstanding intense pressure and vibration to meeting strict industry standards, these tiny components make a massive impact on safety and performance. Whether you’re an engineer, procurement specialist, or MRO technician, understanding the types of aerospace fasteners, their materials, and compliance requirements isn’t just helpful—it’s essential. In this guide, you’ll get clear, actionable insights to navigate selection challenges and discover how Vast delivers precision-engineered solutions that keep your projects flying smoothly. Ready to tighten your grip on aerospace fastening expertise? Let’s get started.

Analysis and of the Keyword Aerospace Fasteners Search Intent

When users search for aerospace fasteners, their intent typically revolves around finding reliable, high-performance fastening solutions designed specifically for the aerospace industry. This includes engineers, manufacturers, and procurement specialists looking for fasteners that meet stringent safety and quality standards. Often, the goal is to understand the types of fasteners available, their materials, certifications, and how these components perform under demanding aerospace conditions.

Search intent can be grouped into a few key areas:

- Technical information about fasteners like aircraft bolts, blind rivets, and vibration resistant fasteners

- Product sourcing from reputable suppliers offering NAS standards or mil spec screws

- Compliance and certification, including AS9100 certification and other aerospace quality benchmarks

- Innovations and new technologies such as corrosion resistant coatings or titanium aerospace hardware

Ultimately, searchers want trustworthy insights and practical data to help select the right fastener for complex aerospace applications that ensure safety, durability, and regulatory compliance. The keyword signals a need for industry-specific knowledge combined with access to reliable, mission-critical aerospace fastener products.

Analysis and of the Keyword Aerospace Fasteners Local User Search Habits

When looking at search habits for aerospace fasteners in the U.S., users typically focus on specific needs tied to performance, reliability, and compliance. Most searches include terms like aircraft bolts, blind rivets, and mil spec screws, showing a clear preference for high-quality, certified products that meet strict aerospace standards like NAS standards cURL Too many subrequests. AS9100 certification.

Local users often search with an eye on durability keywords such as corrosion resistant coatings cURL Too many subrequests. vibration resistant fasteners, reflecting concerns about parts lasting under tough conditions. Popular searches also highlight materials like titanium aerospace hardware cURL Too many subrequests. high strength alloys, which offer excellent strength-to-weight ratios—critical for aerospace applications.

In , U.S. buyers want fasteners that guarantee safety and long life, backed by strong compliance documentation. They prefer suppliers that offer clear info on certifications, material specs, and test results to ensure mission-critical reliability.

The Critical Role of Fasteners in Aerospace Engineering Withstanding Extreme Conditions Pressure Vibration and Temperature Demands

Aerospace fasteners are key players in holding aircraft together safely and reliably. These fasteners must endure some of the toughest conditions imaginable—extreme pressure changes during flight, constant vibration from engines and airflow, and wide swings in temperature from freezing at high altitudes to intense heat near engines.

Because of these demands, aerospace fasteners like aircraft bolts, vibration resistant fasteners, and high strength alloys are specially designed to maintain their grip without loosening or failing. They have to resist corrosion too, often featuring corrosion resistant coatings to protect against moisture and chemicals, especially during long flights or exposure to harsh environments.

Without fasteners that can handle these pressures, vibrations, and temperature extremes, the structural integrity of airplanes would be at risk. That’s why selecting the right fasteners—whether titanium aerospace hardware or lockbolt systems—is critical for the safety and performance of any aerospace application.

The Critical Role of Fasteners in Aerospace Engineering Impact on Aircraft Performance and Safety

Fasteners in aerospace aren’t just about holding parts together—they directly affect how an aircraft performs and stays safe. Every bolt, screw, or rivet must meet strict standards because even a small failure can compromise the entire structure. High-strength alloys and vibration resistant fasteners help maintain the integrity of the aircraft during flight, resisting stress from constant pressure changes and rough conditions.

These components keep critical systems secure, ensuring stability and reducing wear over time. Using aerospace fasteners designed to handle the harsh environments—like corrosion resistant coatings and mil-spec screws—also prevents failures due to rust or material fatigue. Ultimately, reliable fasteners protect passengers and crew by supporting both structural integrity and system function throughout the lifecycle of the aircraft.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.: Aerospace nuts often feature self-locking designs like prevailing torque or metal locking inserts to ensure they stay tight without additional tools or adhesives.

- Washers: Lock washers, including split, toothed, and conical types, add extra grip and help spread the load evenly to protect parts from damage.

- Inserts: Threaded inserts offer durable, reusable threads in softer materials, perfect for maintenance-heavy areas that require frequent fastening and unfastening.

Using the right combination of these ensures that bolts and screws maintain their grip during flight, contributing directly to aircraft safety and performance. These locking fasteners meet strict standards like NAS standards or mil spec screws, guaranteeing reliability where it counts most.

cURL Too many subrequests.

Pins Collars and Specialty Hardware Precision for Dynamic Loads

Pins, collars, and specialty hardware play a crucial role in aerospace fasteners by providing precise alignment and securing parts that face dynamic and high-stress loads. Aircraft bolts and vibration resistant fasteners handle a lot, but pins and collars ensure components stay exactly where they need to be during intense movement and pressure changes.

Here’s what makes these fasteners essential:

- Pins like taper pins and shear pins maintain alignment while allowing for controlled movement, critical in moving parts like control surfaces and landing gear.

- Collars act as spacers or locking elements that hold pins and shafts firmly in place without compromising ease of assembly or disassembly.

- Specialty hardware often includes custom clips, retainers, and lockbolt systems designed to fit unique applications where standard fasteners won’t work.

These parts often use high strength alloys cURL Too many subrequests. corrosion resistant coatings to withstand extreme aerospace environments and reduce maintenance needs. Their precision machining and adherence to NAS standards ensure reliable performance for every flight.

In short, pins, collars, and specialty hardware provide the fine-tuned control and durability needed for dynamic aerospace loads, helping keep aircraft safe and efficient.

Materials and Manufacturing Building Fasteners That Last

Alloy Selection for Durability and Weight Savings

Choosing the right alloy is critical when it comes to aerospace fasteners. The goal is to find materials that offer both strength and lightness. High strength alloys like titanium aerospace hardware are popular because they provide excellent durability without adding extra weight. Aluminum alloys are another go-to option, especially when weight savings are a priority.

These alloys help fasteners resist corrosion and withstand the intense pressure and vibration aircraft face every day. Using the correct alloy means the fasteners won’t fail under stress, ensuring aircraft stay safe and perform well. For U.S. manufacturers and maintenance teams, sticking to approved materials that meet NAS standards is key to meeting regulatory requirements while optimizing fastener performance.

In short, alloy choice balances toughness and lightness, making aerospace fasteners reliable for the demanding environment of flight.

Materials and Manufacturing Building Fasteners That Last

Advanced Coatings and Treatments

When it comes to aerospace fasteners, coatings and surface treatments are a big deal. They protect against corrosion, wear, and extreme conditions—critical for keeping aircraft bolts, lockbolt systems, and titanium aerospace hardware working strong.

Some common coatings include:

- Corrosion resistant coatings: These prevent rust and deterioration from moisture and chemicals, essential for parts exposed to harsh weather or fuel.

- Anodizing: Often used on aluminum fasteners, it boosts surface hardness and corrosion resistance without adding weight.

- Plating: Zinc, cadmium, or nickel plating add a protective layer to fasteners, enhancing longevity on mil spec screws and vibration resistant fasteners.

- Passivation: This treatment cleans and strengthens stainless steel surfaces, improving durability while keeping the fasteners lightweight.

Advanced treatments help fasteners meet tight NAS standards and AS9100 certification requirements, so you know they’ll perform under tough aerospace demands. They also extend service life, reducing maintenance costs and downtime.

In short, coatings and treatments are a necessary upgrade—not just a nice-to-have—when you’re selecting aerospace fasteners for reliable, long-lasting performance.

Materials and Manufacturing Building Fasteners That Last

Manufacturing Precision From Forging to CNC Machining

When it comes to aerospace fasteners, precision in manufacturing is non-negotiable. Every bolt, rivet, or screw must meet exacting standards to ensure safety and reliability under tough conditions. The process usually starts with forging, where high-strength alloys like titanium aerospace hardware are shaped to form a strong, durable base. Forging improves the metal’s grain structure, giving the fastener the toughness needed to handle vibration and pressure.

After forging, CNC machining takes over to bring the fastener to tight tolerances. This step is crucial because even tiny variations can affect how a fastener performs in an aircraft. CNC machining allows for detailed threads, precise dimensions, and perfect finishes required by NAS standards or mil spec screws specs.

This combined approach—starting with forging and finishing with CNC machining—ensures that aerospace fasteners aren’t just strong but accurate and consistent every time. It’s why engineers trust these components in critical areas where failure simply isn’t an option.

Standards and Compliance Navigating the Regulatory Maze

Key Specifications for Global Compatibility

When it comes to aerospace fasteners, meeting the right standards isn’t optional—it’s critical. These fasteners must comply with strict specifications to perform reliably across different aircraft and countries. In the U.S., that often means following NAS standards and mil spec screws guidelines, which ensure consistency in materials, strength, and durability.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- Corrosion resistance testing cURL Too many subrequests.

- Vibration resistance checks to confirm fasteners won’t loosen or degrade due to constant aircraft vibrations.

- Temperature cycling to test performance across extreme heat and cold like in high altitude flight.

Meeting standards like NAS standards and holding certifications such as AS9100 means these tests are done rigorously and consistently. For anyone in the U.S. aerospace market, insisting on verified testing protocols is essential for mission-critical assurance and overall aircraft safety.

Sustainability in Standards Eco Friendly Fasteners Ahead

The aerospace industry is paying more attention to sustainability, and aerospace fasteners are no exception. New standards now encourage using eco-friendly materials and processes to reduce environmental impact without sacrificing quality or safety. Manufacturers are adopting corrosion resistant coatings that are less toxic and exploring recyclable alloys, which helps cut down on waste.

Alongside meeting strict NAS standards and AS9100 certification, compliance now often includes assessing a fastener’s lifecycle impact—from production to disposal. This shift pushes companies to innovate with greener solutions that still meet the demanding strength and reliability aerospace applications require.

For U.S. customers, this means sourcing fasteners that not only perform under extreme conditions but are also better for the planet. Choosing eco-friendly fasteners aligns with both regulatory expectations and broader industry goals for sustainability in aerospace engineering.

Selecting the Right Fastener A Step By Step Buyers Guide Assessing Application Needs Load Environment and Accessibility

Choosing the right aerospace fastener starts with understanding exactly what your application demands. First, look at the load environment—how much stress, pressure, or vibration will the fastener need to handle? For example, if you’re dealing with high vibration resistant fasteners in engine parts, strength and durability are key.

Next, consider where the fastener will be used. Is it in a tight or hard-to-reach spot? For areas with limited accessibility, blind rivets or lockbolt systems might be better options because they can be installed without needing access to both sides.

Also, think about the material compatibility. Aircraft parts often use titanium aerospace hardware or high strength alloys. Picking fasteners made from matching or compatible materials helps prevent issues like corrosion.

Here’s a quick checklist:

- Load type: Shear, tensile, or dynamic forces

- Environmental factors: Temperature swings, moisture, corrosion risks

- Accessibility: Can you reach both sides or just one side of the joint?

- Material match: Fastener alloys should complement the materials used

- Standards: Ensure fasteners meet NAS standards or mil spec screws for your specific application

By carefully assessing these factors, you get fasteners that boost performance and reliability without wasting time or money on the wrong parts.

Selecting the Right Fastener A Step By Step Buyers Guide

Common Pitfalls and How to Avoid Them

Choosing the right aerospace fasteners can be tricky, and several common mistakes can cost time and money. Here’s what to watch out for and how to avoid these pitfalls:

- Ignoring Load and Environment NeedsFasteners used in aerospace must handle extreme pressure, vibration, and temperature changes. Don’t pick a fastener without fully understanding the load environment or you risk failures or costly rework.

- Overlooking Material CompatibilityUsing fasteners that don’t match the materials they join can lead to corrosion or weakening. For example, pairing titanium aerospace hardware with incompatible alloys can cause galvanic corrosion. Always confirm alloy compatibility.

- Skipping Standards and Certifications ChecksAerospace fasteners must meet strict standards like NAS standards or mil spec screws requirements. Using uncertified or substandard fasteners can lead to safety issues and regulatory trouble. Look for AS9100 certification and proper documentation.

- Neglecting Installation RequirementsSome fasteners need special tools or procedures for correct installation. Blind rivets or lockbolt systems, for example, must be installed precisely to maintain safety and performance. Avoid shortcuts to prevent weakening joints.

- Focusing Only on CostTrying to save upfront by buying cheaper fasteners can backfire with failures or frequent replacements. Balance cost with quality, certification, and supplier reliability to get the best long-term value.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Smart Fasteners with Embedded Sensors

Smart fasteners are changing the game in aerospace by adding sensors right into bolts, rivets, and other hardware. These sensors track the health of a fastener in real time, monitoring stress, vibration, and temperature. This helps spot early signs of wear or failure before it becomes a major issue, improving safety and cutting down on costly maintenance.

For U.S. aerospace customers, smart fasteners mean better reliability and fewer unexpected repairs, especially in commercial and military aircraft operating under tough conditions. These fasteners often include vibration resistant fasteners and titanium aerospace hardware paired with corrosion resistant coatings to handle harsh environments.

Key benefits of smart fasteners include:

- Continuous monitoring of structural integrity

- Data-driven maintenance schedules

- Increased aircraft uptime and safety compliance

- Compatibility with NAS standards and mil spec screws for trusted performance

As this technology advances, expect smart fasteners to become standard in aerospace, combining high strength alloys with cutting-edge sensors to keep aircraft safer and more efficient.

Innovations Driving the Future of Aerospace Fastening Additive Manufacturing and 3D Printed Custom Solutions

Additive manufacturing, including 3D printing, is changing the game for aerospace fasteners. Unlike traditional methods, 3D printing allows for custom-designed fasteners tailored to specific applications—perfect for complex or hard-to-reach areas on aircraft. This tech helps manufacturers cut weight without sacrificing strength by creating intricate shapes that weren’t possible before.

For U.S.-based aerospace companies, this means faster prototyping, reduced waste, and shorter lead times. Plus, 3D printed fasteners can use advanced high strength alloys and titanium aerospace hardware, offering durability and corrosion resistance in one package.

In short, additive manufacturing brings flexibility and efficiency, supporting innovations like smart fasteners and hybrid designs while meeting strict NAS standards and AS9100 certification requirements. This technology is a key part of building the next generation of aircraft that are safer, lighter, and more reliable.

Innovations Driving the Future of Aerospace Fastening Lightweight Composites and Hybrid Designs

In aerospace fasteners, lightweight composites and hybrid designs are transforming how we build aircraft. These innovations focus on cutting weight without sacrificing strength or reliability, which matters a lot for fuel efficiency and overall aircraft performance.

Lightweight composites often use materials like carbon fiber reinforced polymers paired with metal inserts. This mix reduces fastener weight compared to traditional high strength alloys like titanium aerospace hardware, while still handling tough conditions like vibration and temperature swings.

Hybrid designs combine the best of different materials—for example, pairing corrosion resistant coatings on aluminum or titanium fasteners. This approach maximizes durability and lowers maintenance needs, which is crucial for meeting strict NAS standards and mil spec requirements.

These new fasteners not only help aircraft manufacturers meet AS9100 certification standards but also respond to the push for greener, more sustainable aerospace solutions. By using composite and hybrid fasteners, companies can reduce weight and emissions while maintaining mission-critical performance.

For U.S. aerospace customers, these advances mean better options for customizing fasteners to specific applications, whether it’s retrofitting older aircraft or building next-gen models. Working with suppliers who specialize in these materials can lead to smarter sourcing strategies and cost savings over time.

Partnering with Vast Your Reliable Source for Aerospace Fasteners Why Vast Stands Out in a Competitive Market

When it comes to aerospace fasteners, Vast stands out because we combine quality, reliability, and customer focus—all crucial for meeting the tough demands of U.S. aerospace manufacturers. We know the importance of high strength alloys and vibration resistant fasteners in keeping aircraft safe and performing at their best. That’s why every product we offer, from titanium aerospace hardware to mil spec screws, meets or exceeds NAS standards and comes with AS9100 certification.

What really sets us apart is our commitment to consistency and precision. We source materials carefully and partner with manufacturers who follow strict protocols, including corrosion resistant coatings and lockbolt systems. This means fewer delays, fewer replacements, and a fastener you can trust every time.

We also understand local search habits. U.S. buyers need fast turnaround, transparent supply chains, and support that speaks their language. Vast delivers on all fronts, making sure you get the right fastener—whether it’s blind rivets for tight spots or aircraft bolts for structural loads—without hassle. Simply put, Vast is built to be your reliable partner in aerospace fasteners, helping you succeed in a competitive market.

Partnering with Vast Your Reliable Source for Aerospace Fasteners Success Stories from Vast Customers

When it comes to aerospace fasteners, our customers consistently choose Vast for reliable, high-quality solutions. Many have shared how our aircraft bolts, blind rivets, and titanium aerospace hardware delivered exactly what they needed to meet tough NAS standards and AS9100 certification requirements.

One U.S.-based aerospace manufacturer told us that switching to Vast’s vibration resistant fasteners helped reduce downtime and boosted their production efficiency. Another client praised our corrosion resistant coatings, saying those coatings significantly extended the lifespan of their mil spec screws in harsh environments.

We’ve also worked closely with maintenance teams at major airlines who appreciate our quick sourcing and the strong customer support behind each order. They rely on Vast for lockbolt systems and high strength alloys that consistently perform under extreme conditions.

These success stories highlight how partnering with Vast means dependable aerospace fasteners that keep projects on track and aircraft safe—no surprises, just quality you can trust.