Discover what is the HPDC high pressure die casting process its benefits applications and materials for precise high volume metal parts manufacturing.

What is High Pressure Die Casting HPDC

High Pressure Die Casting, or HPDC, is a manufacturing process where molten metal is injected at high pressure into a steel mold, called a die, to create precise metal parts quickly and efficiently. This process stands out for its ability to produce complex shapes with thin walls and tight tolerances, making it ideal for mass production.

Historically, metal casting began with gravity casting, where molten metal simply filled molds by gravity alone. Over time, the need for faster production, better surface finish, and stronger, lighter parts led to the development of modern HPDC. Unlike earlier methods, HPDC uses high injection speed and pressure to force molten alloys into detailed cavities, allowing parts to solidify quickly and maintain dimensional accuracy.

Key characteristics of HPDC include:

- High injection speed and pressure which ensure the molten metal fills every detail of the die

- Rapid solidification enabling quick cycle times and efficient production

- Use of lightweight alloys like aluminum, zinc, and magnesium designed for strength and durability

- Capability to produce thin wall designs which reduce material usage and weight without sacrificing performance

HPDC has become essential in industries where lightweighting and performance matter, such as automotive and aerospace. By enabling manufacturers to produce strong yet lightweight parts at high volumes, HPDC supports the growing demand for fuel efficiency, emission reduction, and cost-effective production.

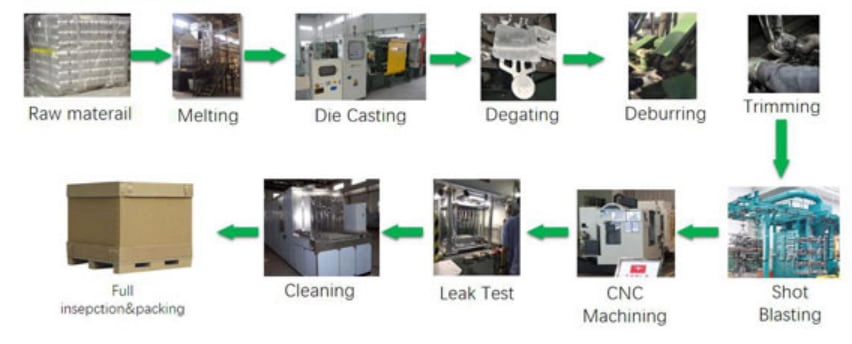

How Does the HPDC Process Work Step by Step

High Pressure Die Casting (HPDC) works through a series of well-coordinated steps to quickly produce high-quality metal parts.

1. Preparation and Mold Design

Before anything, the mold is designed with precision to match the part’s shape. The metal—usually aluminum, zinc, or magnesium—is melted in a furnace and kept at the right temperature for casting.

2. Injection of Molten Metal

Once the metal is ready, it’s injected into the mold cavity at very high pressure. This pressure forces the molten metal to fill even the tiniest corners quickly. Controlling pressure and reducing turbulence during injection is key to avoiding air pockets and defects.

3. Solidification and Ejection

As the metal fills the mold, it solidifies rapidly because the mold is cooled. Once solid, the mold opens, and the part is ejected smoothly and efficiently without damage.

4. Post-Processing and Quality Checks

After ejection, parts go through trimming to remove any excess metal, finishing for surface quality, and thorough inspections to ensure they meet standards.

Variations like Vacuum-Assisted HPDC

Sometimes vacuum systems are added to reduce air entrapment and improve part density. HPDC also boasts shorter cycle times compared to other casting methods, making it ideal for large-scale production.

This step-by-step process delivers fast, precise, and repeatable results for high-volume metal parts manufacturing.

Materials Used in HPDC Choosing the Right Alloy

When it comes to HPDC, picking the right alloy is a big deal. The main choices are cURL Too many subrequests., zinc, and cURL Too many subrequests.. Each one has its own set of strengths, costs, and ideal uses.

Aluminum

- Pros: Lightweight, good strength, corrosion-resistant

- Cons: Higher melting point means more energy to cast, can be pricier

- Great for automotive parts where weight matters.

Zinc

- Pros: Lower melting point saves energy, excellent for detailed parts, cost-effective

- Cons: Heavier than aluminum, not as strong

- Perfect for consumer goods and electronics housings.

Magnesium

- Pros: The lightest metal option, strong for its weight

- Cons: More expensive, flammable in powder form—needs careful handling

- Used where every ounce counts, like aerospace parts.

cURL Too many subrequests.

- Melting Point affects how easy and fast the casting is.

- Strength and Weight Ratio cURL Too many subrequests.

- Cost cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- AerospacecURL Too many subrequests.

- Electronics and Consumer GoodscURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

A U.S.-based automotive supplier switched to HPDC for engine blocks. This change cut production time by 30%, lowered scrap rates, and reduced the overall material cost by 15%. The investment paid off quickly, showing how HPDC boosts efficiency and return on investment for manufacturers focused on high-volume metal production.

If you’re looking to optimize parts with strong, lightweight materials and precise detail, HPDC offers proven benefits across many industries here in the U.S.

HPDC vs Other Die Casting Methods When to Choose What

When choosing a die casting method, it helps to know how High Pressure Die Casting (HPDC) stacks up against Low Pressure Die Casting (LPDC) and gravity casting. Each process fits different needs, so picking the right one depends on your part’s specs and production goals.

Comparing HPDC, LPDC, and Gravity Casting

- HPDC (High Pressure Die Casting)

- Best for high-volume runs

- Produces parts with thin walls and complex shapes

- Fast cycle times for quick turnaround

- High precision and smooth surface finish

- Common for aluminum, zinc, and magnesium alloys

- LPDC (Low Pressure Die Casting)

- Uses lower pressure to fill molds gradually

- Ideal for thicker-walled parts

- Better for parts needing less porosity and higher density

- Slower cycle but stronger mechanical properties

- Common in automotive engine parts and aerospace components

- Gravity Casting

- Mold fills by gravity, no pressure involved

- Best for low-volume or large, simple parts

- Slower and less precise

- Typically lower tooling costs

- Often used when thin walls or intricate features aren’t required

When to Choose Which Method

- Go with HPDC if you want fast, reliable mass production of lightweight, detailed parts like automotive brackets or consumer electronics housing.

- Pick LPDC when strength and reduced porosity are top priorities, especially with thicker parts or aerospace components.

- Choose gravity casting for prototypes, large simple parts, or when budget limits tooling costs.

Common Pitfalls and How to Avoid Them

- HPDC: Risk of porosity or cold shuts if mold design or injection speed isn’t right. Mitigate with careful mold engineering and turbulence control.

- LPDC: Slower cycle times can hurt deadlines; optimize cycle times where possible but expect trade-offs.

- Gravity Casting: Less precision and more scrap waste. Best saved for parts where this is acceptable.

Knowing these differences helps you pick the most cost-effective and quality-driven method for your project.

Challenges and Limitations of HPDC

While HPDC is a powerful manufacturing method, it comes with some challenges. One common issue is porosity—tiny air pockets that can weaken parts. Tooling costs can also be high since precision molds need to be made for each design, which means upfront investment is significant.

Controlling pressure cURL Too many subrequests. turbulence during molten metal injection is tricky but important to reduce defects. This requires skill and careful machine setup.

To tackle these issues, many companies use vacuum-assisted die casting, cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

Looking ahead, cURL Too many subrequests. cURL Too many subrequests., hybrid processes cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. speed, cURL Too many subrequests., and cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.