Explore comprehensive CNC machine types including milling lathes routers and more to find the perfect fit for precision manufacturing needs.

The Fundamentals of CNC Machines

CNC machines are the backbone of modern manufacturing. At their core, they combine several key components: a controller that reads instructions, axes that guide movement, spindles that hold and rotate cutting tools, and cURL Too many subrequests. that tells the machine what to do step-by-step. These parts work together seamlessly to carve, cut, and shape materials with incredible accuracy.

The story of CNC (Computer Numerical Control) begins in the 1940s with the first Numerical Control (NC) machines, which used punched tape to control tool paths. Since then, CNC technology has evolved dramatically, moving from simple two-axis machines to today’s sophisticated, multi-axis systems capable of complex, automated operations.

The benefits of CNC machines are clear and compelling. They offer unmatched precision, consistently producing parts to exact specifications. Scalability is a huge plus—CNC machines can handle everything from one-off prototypes to large-volume production without sacrificing quality. Plus, CNC machining significantly reduces waste by optimizing material use, saving money and resources in the long run. Whether you’re crafting aerospace parts or custom components, CNC machines bring efficiency and reliability to the shop floor.

Core Types of CNC Machines CNC Milling Machines The Versatile Workhorse

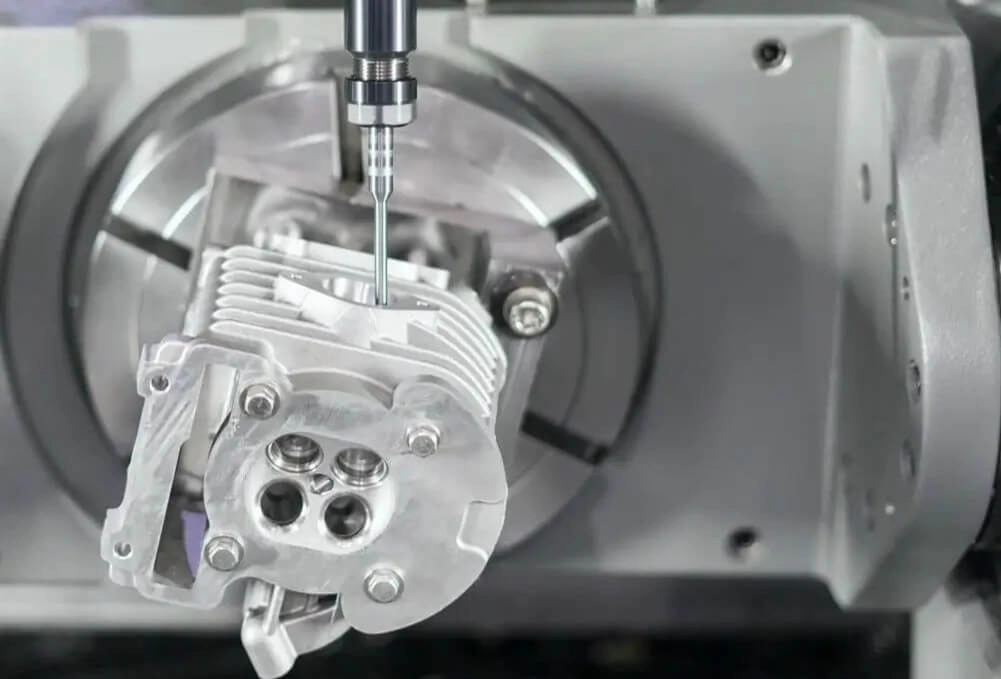

CNC milling machines are some of the most common and versatile machines you’ll find in workshops across the U.S. They use rotary cutters to remove material from a workpiece, shaping complex parts with high precision. These machines come in two main styles: horizontal and vertical. Vertical mills have a spindle that moves up and down, ideal for detailed cuts and quick tool changes, while horizontal mills are better for heavy-duty cuts and larger surface areas.

Milling machines excel in prototyping and producing complex geometries, making them popular for industries like aerospace, automotive, and manufacturing. They handle metals, plastics, and composites efficiently.

Pros

- Great precision and surface finish

- Suitable for complex shapes and contours

- Versatile for many materials and projects

- Wide range of axis options from 3 to 5 axis for more freedom

Cons

- Can be costly for small shops or simple parts

- Requires operator skill for advanced setups

- Larger footprint for heavier machines

Axis Variants

- 3-axis mills: Standard for basic cutting (X, Y, Z directions)

- 4-axis mills: Adds rotary movement, good for angled cuts

- 5-axis mills: Simultaneous rotation and positioning, ideal for very complex parts

Vast Tip

If your projects demand precision and flexibility for different materials, investing in a CNC milling machine, especially one with 4 or 5 axes, will boost your productivity and part quality without needing multiple setups.

Core Types of CNC Machines CNC Lathes and Turning Centers Masters of Rotation

CNC lathes and turning centers are all about rotation. Instead of the tool moving around the workpiece like on a mill, here the workpiece spins while stationary cutting tools shape it. This setup is perfect for creating round or cylindrical parts like shafts, bolts, and bushings.

Swiss-style lathes add precision for tiny, complex parts often used in electronics and medical devices. These machines can handle detailed work on small diameters with tight tolerances.

Typical applications:

- Automotive shafts and pins

- Fasteners like bolts and screws

- Watch components and small mechanical parts

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

Benefits

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

Limitations

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

If your job involves woodworking, plastics, or composites and you want speed plus precision on larger pieces, CNC routers are a smart, practical choice. For manufacturers in the US looking to customize or source CNC router types from China or local factories, focusing on machine size, spindle power, and software compatibility will save time and cost down the line.

Core Types of CNC Machines CNC Drilling Machines Targeted Hole-Making Experts

CNC drilling machines specialize in creating precise holes quickly and consistently. They use rotating drill bits controlled by CNC to drill into various materials, from metal to plastic. Many CNC drilling machines come with multi-spindle setups, letting you drill several holes simultaneously to speed up production, perfect for assembly line prep.

Key applications

- Making holes in automotive and aerospace parts

- Preparing materials for fasteners and bolts

- PCB and electronic component drilling

Pros

- Extremely fast and efficient for hole-making

- High repeatability with tight tolerances

- Multi-spindle options boost throughput

Cons

- Limited mainly to drilling and simple hole patterns

- Not suitable for complex shaping or milling

Vast Tip

If your primary task is drilling a large number of precise holes, especially for assembly or structural parts, CNC drilling machines are cost-effective and reliable. For more versatility, consider combining drilling with milling operations in one machine.

Core Types of CNC Machines CNC Grinding Machines Finishing for Ultimate Surface Quality

CNC grinding machines specialize in finishing and refining surfaces to a high degree of smoothness and precision. They use abrasive wheels to polish or sharpen parts, making them essential when tight tolerances and fine finishes are required. Grinding is commonly applied to cylindrical parts like shafts and bearings, as well as surface grinding for flat components like metal plates and tooling.

Key Features

- Uses abrasive wheels for precise material removal

- Can handle cylindrical grinding and surface grinding

- Ideal for finishing hardened materials and complex shapes

Common Applications

- Bearings and automotive parts

- Cutting tools and molds

- Aerospace components demanding tight surface quality

Pros

- Produces extremely smooth and accurate finishes

- Great for working on hardened metals that other tools can’t handle

- Extends tool life by perfecting edges and surfaces

Cons

- Typically slower than milling or turning

- Requires careful setup and maintenance for consistent results

- Can be costly upfront and for wheel replacements

Vast Tip

For businesses in the US looking to improve product quality, CNC grinding machines offer reliable precision finishing that can lower rejection rates and boost customer satisfaction. When customizing or sourcing from China, always check wheel compatibility and machine support to ensure long-term productivity.

Advanced and Specialized CNC Machine Types Electrical Discharge Machines EDM Spark Precision for Hard Materials

Electrical Discharge Machines (EDM) use electrical sparks to shape hard materials that are tough to machine with traditional CNC tools. Instead of cutting with force, EDM removes material by creating tiny sparks between a wire or shaped electrode and the workpiece. This process doesn’t apply mechanical stress, making it perfect for intricate molds, dies, and complex parts where fine detail and precision are crucial.

How EDM WorksA thin wire (wire EDM) or a shaped electrode (sinker EDM) moves near the part.

Electrical sparks jump the gap, eroding material bit by bit.

No direct contact means no distortion or damage to delicate parts.Main ApplicationsIntricate mold making

Hard metals like tungsten carbide

Components with complex internal shapes and fine detailProsCan machine extremely hard materials

Creates highly precise, clean cuts and corners

No mechanical force reduces risk of part deformationConsSlower than traditional cutting methods

Limited to electrical conductive materials

Usually higher operating costsVast Tip

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Pros

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

Cons

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

Vast Tip

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- Food industry cutting

Pros

- No heat-affected zones – preserves material integrity

- Can cut thick and layered materials

- Environmentally friendly – no harmful gases or dust

- Excellent precision for complex shapes

Cons

- Slower cutting speed compared to plasma or laser for thin metals

- Higher operating costs due to abrasives and water treatment

- Requires regular maintenance to avoid nozzle wear

Vast Tip: If your projects involve materials sensitive to heat or complex multi-layer cuts, a CNC waterjet cutter from a trusted China factory with customization options can save time and reduce waste while keeping quality high. Always balance upfront costs with long-term durability and maintenance plans to get the best ROI.

Advanced and Specialized CNC Machine Types Multi-Axis and Hybrid Machines The Future of Complexity

Multi-axis CNC machines take precision and flexibility to the next level. These machines range from 4 to 12 axes, allowing tools and workpieces to move simultaneously in multiple directions. This means they can handle complex shapes and tight tolerances that simpler 3-axis machines can’t manage. Hybrid machines combine milling and turning processes within the same setup, reducing the need for multiple machines and cutting down production time.

Applications

- Aerospace parts like turbine blades

- Medical implants with intricate geometries

- Complex automotive components

- Prototyping and custom manufacturing where detail matters

Pros

- Handles highly complex parts in one go

- Improved accuracy with fewer setups

- Saves space and boosts workflow efficiency

- Ideal for hard-to-machine materials

Cons

- Higher upfront cost than standard CNC machines

- Requires skilled operators and advanced programming

- More maintenance due to mechanical complexity

Vast Tip

If your production involves intricate parts or you want to optimize time by reducing setups, multi-axis or hybrid CNC machines are worth the investment. They offer the flexibility and power needed for cutting-edge manufacturing, especially in industries where precision and speed are non-negotiable.

Explore different axis configurations and machine capabilities to find the right fit for your project complexity and budget.

Axis Configurations How They Define CNC Capabilities

Understanding axis configurations is key to picking the right CNC machine type for your project. The number of axes determines the complexity and precision of the parts you can create.

- 3-Axis CNC Machines: The most basic setup. Moves the tool or workpiece along the X, Y, and Z linear axes. Perfect for simple cuts, drilling, and milling on flat or moderately curved surfaces. These machines are cost-effective and widely used for prototyping and standard parts.

- 4 and 5-Axis CNC Machines: Add rotational movement to the 3-axis system. This extra freedom allows the tool to approach the workpiece from multiple angles. Ideal for complex shapes like aerospace parts, turbine blades, and molds. 5-axis machines reduce or eliminate the need for repositioning, boosting accuracy and efficiency.

- Multi-Axis CNC Machines (6 to 12 Axis): These advanced systems offer simultaneous movement along multiple linear and rotational axes. They handle highly intricate components and hybrid processes combining milling and turning in one setup. Great for industries needing tight tolerances and complex geometries.

Here’s a quick comparison to guide your choice:

| Axis Count | Capabilities | Ideal Applications | Cost Range |

|---|---|---|---|

| cURL Too many subrequests. | Basic linear movement | Simple parts, basic milling | Low to Mid |

| cURL Too many subrequests. | Adds rotary movement on one axis | Medium complexity parts | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Production volume: For large runs, invest in machines with higher automation and faster cycle times. Smaller batches might be handled by versatile mills or lathes.

- Budget: CNC machines vary widely in price. Factor in the initial cost plus ongoing maintenance and tooling expenses.

- Software compatibility: Make sure your CNC machine works smoothly with the CAD/CAM software your team uses. This helps avoid costly workflow disruptions.

Common Pitfalls to Avoid

- Ignoring maintenance needs: Regular maintenance is crucial to keep your CNC machine running smoothly and avoid costly downtime.

- Overlooking scalability: Think about whether your machine can grow with your business—adding axes or upgrading controllers can save money in the long run.

- Misjudging complexity: Don’t overbuy. A simple 3-axis mill might be all you need instead of a pricey 5-axis model.

ROI Calculation Example

Say you invest $100,000 in a CNC mill that boosts production speed by 30%, reduces waste by 15%, and cuts labor costs by 20%. Over a year, these savings can quickly cover your investment, especially for high-volume metal parts manufacturing.

Vast Recommended CNC Mills for U.S. Customers

- Robust 3-axis mills for entry-level precision

- Advanced 4-5 axis mills for complex parts

- Customizable CNC machines from trusted U.S. and Chinese factories offering local support and tailored options

Make your choice based on what fits your current needs but leaves room for future growth. Ready to upgrade your workshop? Explore our selection of reliable, scalable CNC machines designed for American manufacturers today.