Explore detailed types of bolt threads including coarse fine UNC UNF ISO standards and learn how to choose the right thread for your project needs.

Bolt Thread Fundamentals Key Parameters and Anatomy

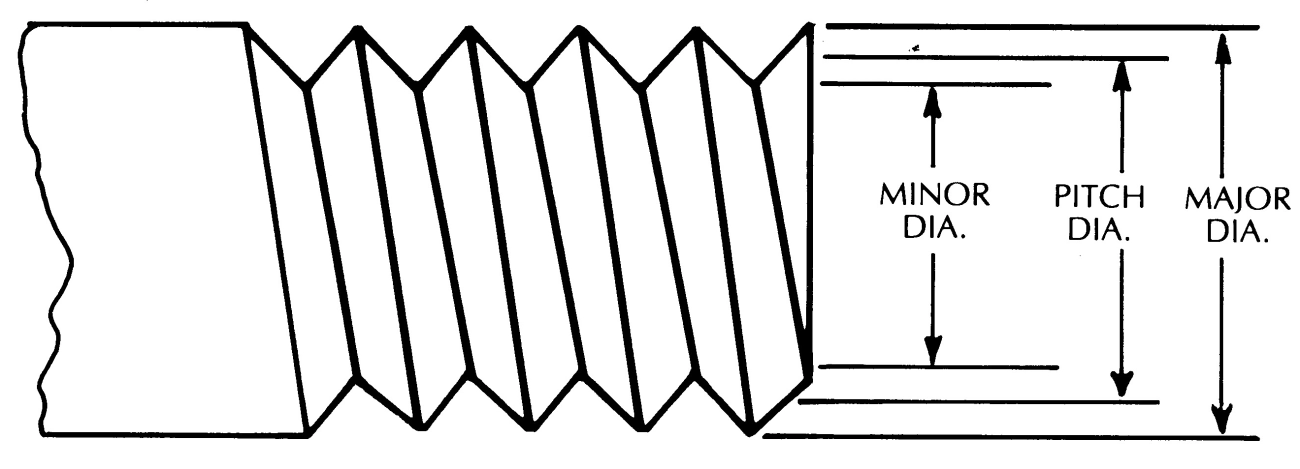

Understanding bolt threads starts with knowing their core components. The major diameter is the largest diameter of the thread, while the minor diameter is the smallest inside diameter. Between these two is the cURL Too many subrequests., which is the distance between corresponding points on adjacent threads. Closely related is the cURL Too many subrequests., the distance a thread advances in one complete turn. The flank angle is the angle between the thread face and its axis, typically 60 degrees in standard threads. The crest is the top edge of the thread, and the root is the bottom groove between threads.

Threads come in two main directions. The most common is right-hand thread, which turns clockwise to tighten. This is the standard for most bolts. On the other hand, left-hand threads tighten counterclockwise and are often found in anti-vibration applications or specific machinery requiring reverse rotation.

Another key feature is the number of starts on a thread. Most bolts have a single start, meaning one continuous thread that spirals around the shank. Multi-start threads have two or more threads running side-by-side, allowing faster engagement and quicker assembly, commonly used in specialized fasteners.

Threads can be internal or external. Nuts feature internal threads tapped inside a hole, while bolts and screws have external threads on their shafts. This internal-external pairing is what allows fasteners to securely join parts.

Quick Reference Glossary of Key Thread Terms

| Term | cURL Too many subrequests. |

|---|---|

| Major Diameter | Largest diameter of the thread |

| Minor Diameter | Smallest diameter (root diameter) |

| Pitch | Distance between threads |

| Lead | Distance thread advances per turn |

| Flank Angle | Angle between thread face and axis |

| Crest | Thread peak or top |

| Root | Thread valley or bottom groove |

| Right-Hand Thread | Tightens clockwise (standard) |

| Left-Hand Thread | Tightens counterclockwise |

| Single Start | One continuous thread on bolt |

| Multi-Start | Multiple threads for faster engagement |

If you want a simple way to identify thread types, measuring pitch and diameter with calipers and comparing to standard charts is a great start. Curious about how to match these to your applications? Stick around as we explore thread types and standards next.

Primary Classifications of Bolt Threads Fastening vs Specialized Types

Bolt threads generally fall into two main categories: fastening threads and specialized threads.

Fastening Threads

These are your standard workhorse threads, most commonly V-shaped with a 60-degree flank angle. This design handles high axial loads well and is typical for structural bolts, nuts, and general fastening. The V shape offers a good balance of strength and ease of manufacturing, making it the go-to choice on most construction and machinery projects.

Power Movement Threads

Power threads are built for motion and force transmission, not just holding parts together. The most common profile here is trapezoidal, including the well-known Acme thread. These threads have a wider, flatter profile, providing smooth linear motion and durability under heavy load. You’ll find them in jackscrews, lead screws, and other machinery where precise, strong movement is key. Round threads (Rd) are similar but rounder, focusing on high force transmission with less wear.

Other Profiles

- Square Threads: Sturdy and efficient for power transmission, but harder to machine and less common.

- cURL Too many subrequests.: Designed for one-sided load support, perfect where force acts mainly in one direction, like in heavy lifting applications.

- Knuckle Threads: Rounded crests, ideal for quick hand assembly with less risk of damage.

- Self-Locking Threads: Special shapes that resist loosening under vibration and torque.

Below is a quick comparison showing typical profiles and their load capacities, helping you decide which thread fits your project best:

| cURL Too many subrequests. | Profile Angle | Common Use | Strength | Special Feature |

|---|---|---|---|---|

| V-Shaped (60°) | 60 degrees | Fastening structural | High axial load | Standard, widely available |

| Acme (Trapezoidal) | ~29 degrees | Linear motion | High load & wear resistant | Smooth power transmission |

| Round (Rd) | Rounded | Heavy force transfer | High fatigue resistance | Good for shock/impact loading |

| Square | 90 degrees | Power transmission | Very efficient | Harder to cut, less common |

| Buttress | Asymmetric | One-direction load | High load on one side | Specialized heavy-duty use |

| Knuckle | Rounded crest | Quick assembly | Moderate | Protects threads from damage |

Understanding these primary classifications helps you pick the right thread type whether your job is about holding parts or powering motion.

Standardized Bolt Thread Types Imperial Metric and Beyond

When it comes to bolt threads, there are a few major standards you’ll see, especially in the U.S. and globally. Here’s a quick look at the most common ones:

Unified Thread Standard (UTS) – Imperial System

- UNC (Unified Coarse): This is the go-to thread for general construction and framing. It has thicker threads, which means faster installation and better durability in softer materials like wood or metal framing.

- UNF (Unified Fine): These threads are tighter, offering better precision and resistance to vibration. You’ll find UNF commonly in automotive and aerospace applications where strength and reliability matter.

- UNEF (Unified Extra Fine): Ultra-fine threads mainly used for precise adjustments in optics and instrumentation where subtle tweaks are necessary.

- UNJ: A modified version of UNF, designed for aerospace. It features rounded thread roots to reduce fatigue and improve durability under high stress.

ISO Metric Threads – Global Standard

- cURL Too many subrequests. M series is the most popular metric thread standard worldwide. It comes in both coarse and fine pitches and is widely used across machinery and manufacturing industries. These threads meet DIN and ISO guidelines, ensuring compatibility internationally.

British and Specialty Standards

- BSW (British Standard Whitworth) and BSF (British Standard Fine): These are older imperial threads still found in vintage machinery and restoration projects in the U.S., especially in automotive and industrial heritage equipment.

- BA (British Association): These are tiny, precision threads mostly seen in instruments and electronics where space and fine control matter.

Thread Comparison at a Glance

| cURL Too many subrequests. | Pitch (TPI) Range | Common Use | Strength & Notes |

|---|---|---|---|

| UNC | Coarser (e.g., 13 TPI for 1/4″) | General construction | Durable, quick install |

| UNF | Finer (e.g., 28 TPI for 1/4″) | cURL Too many subrequests. | Precise, vibration resistant |

| UNEF | Very fine | Optics, instrumentation | Ultra precise, sensitive |

| UNJ | Fine with rounded roots | cURL Too many subrequests. | Fatigue resistant |

| Metric M | Various (coarse/fine) | Machinery worldwide | Standardized internationally |

| BSW/BSF | cURL Too many subrequests. | Vintage UK machinery | Legacy, less common now |

| BA | Very fine | Electronics, instruments | Precision, space-saving |

Knowing these standards helps you pick the right bolt thread for your job, whether you’re fixing a vehicle, building structures, or working on sensitive equipment.

Coarse vs Fine Bolt Threads When to Choose Each

When deciding between coarse and fine bolt threads, it really depends on what you need for the job.

Coarse Threads

- More durable and stronger in tough conditions

- Faster to assemble, which is great on large projects like wood or metal framing

- Better resistance to dirt and corrosion because the threads are deeper

- But they’re more prone to loosening from vibration

Fine Threads

- Provide better precision and a tighter fit

- Stronger in shear (sideways) loads, good for automotive or aerospace use

- Resist vibration loosening better than coarse threads

- However, they take longer to install and are more vulnerable to damage if over-tightened

Stress and Strength

The tensile strength of a bolt depends partially on the stress area of its threads. Fine threads with a higher TPI (threads per inch) offer a larger stress area, which can increase strength. The rough formula to estimate tensile strength shows that more threads per inch can mean better load handling, but only up to a point.

Manufacturing and Tolerances

- Rolled threads are stronger and smoother compared to cut threads because rolling compresses the metal fibers.

- Thread tolerances vary from loose to tight: common classes are 1A/1B (loose fit) and 3A/3B (tight fit). Fine threads often require tighter tolerances to perform well.

Case Study

- Use coarse threads in framing, construction, or anywhere quick, strong fastening is needed.

- Choose fine threads for high torque engines or aerospace parts where precision and vibration resistance matter most.

Picking the right thread type saves time, prevents failures, and makes your project stronger and safer.

Applications and Selection Guide Matching Threads to Your Needs

Choosing the right bolt thread is key to getting the job done right, whether you’re in construction, automotive, aerospace, or plumbing. Here’s a quick look at common industry uses to help guide you:

- Construction: UNC coarse threads are popular because they’re durable and fast to install, perfect for wood or metal framing.

- Automotive: UNF fine threads offer better vibration resistance and higher precision, ideal for engines and vehicle assemblies.

- cURL Too many subrequests.: UNJ threads are designed with rounded roots to reduce fatigue, meeting the demanding standards in aircraft manufacturing.

- cURL Too many subrequests.: NPT tapered threads create tight, leak-resistant seals used in piping and fittings.

When selecting threads, consider these factors:

- Load type: Will your application face shear, tension, or a mix?

- Material: Steel bolts differ from stainless in durability and corrosion resistance.

- Environment: Exposure to moisture or chemicals means choosing corrosion-resistant threads.

- Vibration: Fine threads generally handle vibration better, reducing loosening over time.

How to Measure Threads

Measuring bolt threads accurately is crucial before you buy or install:

- Use calipers to measure the diameter.

- Use a thread gauge to find the cURL Too many subrequests. (the distance between threads).

- Check compatibility with your existing parts to avoid issues like cross-threading.

cURL Too many subrequests.

For unusual or non-standard thread sizes, consider working with custom threading services. They can create bolt threads tailored exactly to your technical specs—something especially useful in specialized equipment or repairs.

Want to find the perfect thread type faster? Try an embeddable quiz or thread selector tool to match your application needs with the right bolt threads every time.

Common Mistakes and Best Practices for Bolt Thread Installation

When working with types of bolts threads, it’s easy to make mistakes that can cost you time and money. Here are some common pitfalls to watch out for:

- Mismatched pitches: Using a bolt with a different thread pitch than the nut or tapped hole can lead to stripping or cross-threading. Always double-check thread pitch before installation.

- Over-torquing fine threads: Fine pitch threads, like UNF or UNEF, are strong but more delicate. Too much torque can strip the thread or cause failure.

- Ignoring thread direction: Don’t forget about left hand bolt threads where applicable. Installing a right-hand bolt where a left-hand is needed will ruin the connection.

Best Practices for Strong, Reliable Threads

- Use thread lockers: Apply a threadlocker to prevent loosening from vibration, especially in automotive or machinery bolts.

- Apply anti-seize compounds: This helps avoid galling or seizing, particularly with stainless steel threads or in corrosive environments.

- Regular inspections: Check bolts for wear, corrosion, or damage to threads during maintenance routines.

When to Replace Threads

- Look out for galling signs—this happens when threads on stainless bolts start to stick or tear under stress.

- Replace bolts that show stripping, wear, or significant corrosion to maintain safety and strength.

By avoiding these mistakes and following proper installation tips, you can get the most out of your bolt threads and keep your projects secure.