Explore the different types of gears their functions and applications in machinery with this comprehensive guide on gear and types.

If you’ve ever wondered how machines transfer power so smoothly, gears and their types hold the answer. Whether it’s the engine in your car or the robot on a factory floor, choosing the right gear can mean the difference between peak performance and costly breakdowns. In this guide, you’ll get a straightforward yet detailed look at the most common types of gears, their unique functions, and where they shine best. Ready to unlock the mechanics behind motion? Let’s dive into the world of gears and types—made simple, practical, and essential for anyone curious about how things move.

What Are Gears? A Quick Overview

Have you ever wondered how machines transfer motion and power smoothly? That’s where gears come in. Gears are mechanical components with teeth designed to mesh with one another, transmitting motion and torque between shafts. They play a crucial role in adjusting the speed and force in countless machines—from your car’s transmission to everyday appliances.

At their core, gears consist of several key parts:

- Teeth: The ridges that interlock with another gear’s teeth to transmit motion.

- Pitch: The distance between corresponding points on adjacent teeth, which determines smoothness.

- Diameter: The size of the gear, usually measured at the pitch circle, affecting speed ratios.

When two gears mesh, they can either increase torque while reducing speed or increase speed while reducing torque, depending on the size and arrangement. This ability to precisely control mechanical advantage makes gears vital in many systems.

Materials matter a lot, too. Steel is common for its strength and durability, plastic is used when noise reduction and cost savings are important, and brass offers a balance for light-duty applications. Choosing the right material ensures the gear withstands wear, pressure, and environmental factors, extending its service life.

Understanding these basics helps you appreciate why gears are essential in everyday machines and complex industrial equipment alike.

Why Understanding Gear Types Matters

Knowing the different types of gears is key to picking the right one for your project. Each gear type affects how efficiently power is transferred, how much load the system can handle, and how the overall design shapes up. Using the wrong gear can lead to wasted energy, faster wear, or even complete failure.

Different industries depend on specific gear types for their unique needs. In automotive, gears are crucial for smooth transmissions and efficient power delivery. Aerospace relies on specialized gears for durability and precision under extreme conditions. Machinery and manufacturing use gears to keep production running without hiccups. Even everyday consumer products, like appliances or power tools, count on the right gear choice for reliable performance.

Take car transmissions for example: they often use helical and planetary gears to balance speed, torque, and quiet operation. Meanwhile, wind turbines use large bevel and worm gears to handle heavy loads and convert slow blade movement into useful energy. Understanding gear types helps ensure the gear matches your application’s load, speed, and space requirements perfectly.

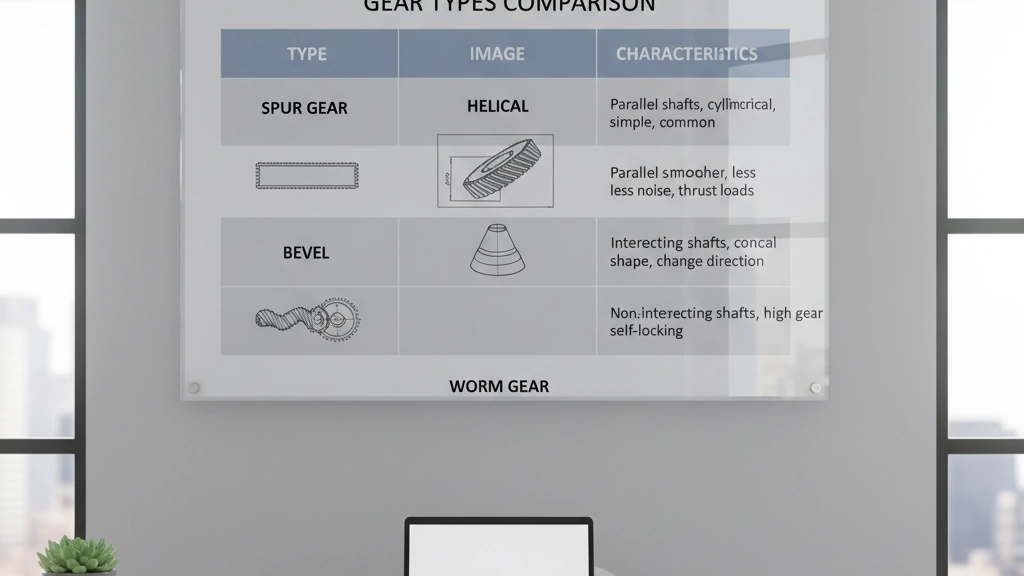

Major Types of Gears and Their Characteristics

Spur Gears

Spur gears are the simplest and most common type. They have straight teeth and are used to transmit motion between parallel shafts. You’ll find them in things like clocks, washing machines, and conveyor systems.

Pros: Easy to make, efficient, cost-effective.

Cons: Can be noisy at high speeds, less smooth compared to other gears.

Helical Gears

Helical gears have angled teeth, which engage more gradually than spur gears, making them quieter and smoother. They’re often used in cars and industrial machinery where noise reduction is important.

Pros: Quieter, handle more load, longer lifespan.

Cons: More complex to manufacture, produce axial thrust which needs support.

Bevel Gears

Bevel gears connect shafts at angles, typically 90 degrees. There are three main types: straight bevel, spiral bevel, and hypoid bevel gears. These are common in automotive differentials and power tools.

- Straight Bevel: Simple, less noisy but less smooth.

- Spiral Bevel: Smoother operation, handles more power, common in vehicles.

- Hypoid Bevel: Allows shaft offset, very quiet and powerful but more expensive.

Pros: Efficient power transfer at right angles.

Cons: Complex design, higher cost.

Worm Gears

Worm gears consist of a screw-like worm and a gear wheel. They’re useful when a high gear ratio is needed with compact size, like in elevators or conveyors.

Pros: High reduction ratios, self-locking capability.

Cons: Lower efficiency due to sliding contact, can wear faster.

Planetary Gears

Planetary gears have a central “sun” gear, planet gears that rotate around it, and a ring gear. This setup is compact and great for high torque in limited space—common in automatic transmissions and robotics.

Pros: High torque density, compact, distributes load evenly.

Cons: Complex design, higher manufacturing costs.

Rack and Pinion Gears

Rack and pinion convert rotational motion into linear motion. You often see them in vehicle steering systems and industrial machines.

Pros: Precise linear control, simple design.

Cons: Limited to linear movement, wear concerns with heavy loads.

Other Specialized Gears

- Internal Gears: Teeth are inside a ring, used in planetary gear sets.

- Herringbone Gears: Double helical gears that cancel axial thrust, used in heavy machinery.

- Non-Circular Gears: Designed for variable speed or torque; niche industrial uses.

Each gear type has its place depending on what you need—whether it’s efficiency, quiet operation, or handling tough loads. Understanding these helps you pick the right gear for your projects or machines.

Comparing Gear Types: Which One Suits Your Needs?

When choosing the right gear, it’s important to consider factors like efficiency, noise, cost, and application. Here’s a quick comparison to help you decide:

| Gear Type | Efficiency | Noise Level | Costo | Common Uses | Complexity |

|---|---|---|---|---|---|

| Spur Gears | Alta | Moderada | Low | Simple machinery, clocks | Low |

| Helical Gears | Very High | Low | Moderada | Automotive, conveyors | Medium |

| Bevel Gears | Moderada | Moderada | Moderada | Differentials, tools | Medium |

| Worm Gears | Low | Low | Moderada | Elevators, tuning devices | Alta |

| Planetary Gears | Alta | Low | Alta | Robotics, autos | Alta |

| Rack and Pinion | Alta | Moderada | Moderada | Steering systems, rails | Low |

Choosing Gears Based on Load, Speed, and Environment

- Load: Heavier loads need stronger, more durable gears like planetary or bevel gears.

- Speed: For high-speed operations, helical gears are often preferred because they run smoother and quieter.

- Environment: Harsh or dirty conditions may favor worm or bevel gears due to their ability to handle misalignment and shock loads.

Example: Automotive Gears

In cars, helical gears are popular because they offer high efficiency and much quieter operation compared to spur gears. This makes them ideal for transmissions where smooth, fast gear changes matter.

By matching gear types to your specific needs—whether load, speed, or environment—you can optimize performance and extend the life of your system.

Applications of Gears in Modern Industries

Gears play a huge role in many industries across the U.S., powering everything from cars to renewable energy systems. Here’s a quick look at where gears matter most:

- Automotive: Gears are essential in transmissions, differentials, and steering systems. They help control speed, torque, and direction, making cars run smoothly and efficiently on American roads.Aerospace: In planes, gears operate actuators and landing gear mechanisms. Their reliability is crucial for safety and performance in flight.Manufacturing: Gears drive conveyors, robotics, and CNC machines. They keep production lines moving fast and accurately in factories nationwide.Consumer Products: Everyday items like watches, kitchen appliances, and power tools depend on specialized gears for precise motion and durability.Renewable Energy: Wind turbines and hydroelectric plants use gears to convert natural forces into electricity efficiently, supporting America’s green energy goals.Case Study: Vast’s EngineeringAt Vast, we integrate advanced gear technology to improve durability and performance in complex systems. By selecting the right types of gears and materials, we help clients across these sectors boost efficiency and reduce maintenance.In short, understanding gear applications helps you choose the right gear type for your business, whether it’s building reliable machines or supporting clean energy initiatives.Key Considerations for Gear Selection and MaintenanceWhen choosing gears, the material matters a lot. Steel gears are durable and handle high loads, while plastic or brass gears are quieter and lighter but might wear faster. Lubrication is crucial to keep gears running smoothly and avoid overheating. Proper alignment ensures the teeth mesh correctly, preventing early wear and noise.Common problems to watch for include:

- Wear from friction

- Misalignment causing uneven load

- Overheating due to poor lubrication or excessive speed

- Regularly lubricate with the right grease or oil

- Perform routine inspections for damage or misalignment

- Follow correct installation procedures to avoid stress on parts