Discover comprehensive insights on bearings and bearings including types, uses, maintenance tips, and expert guidance for reliable mechanical performance.

What Are Bearings The Fundamentals Explained

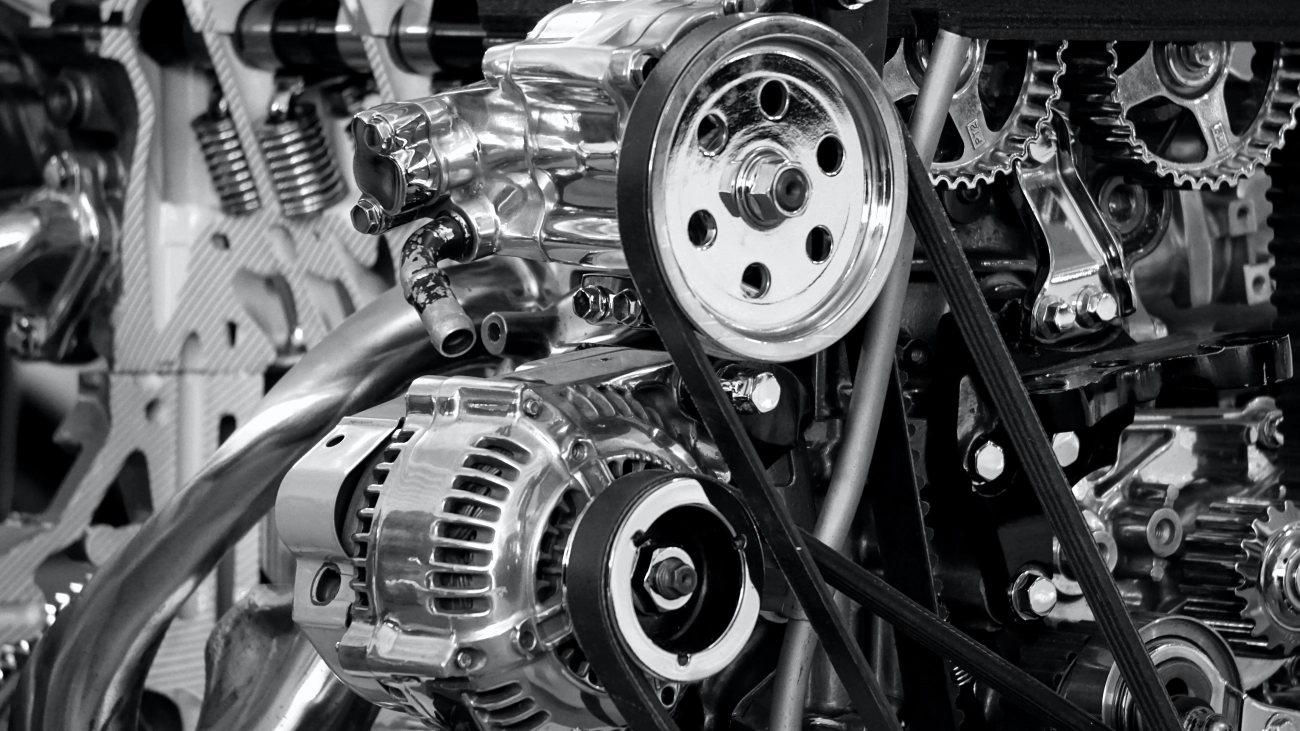

Bearings are essential mechanical components designed to reduce friction between moving parts and support rotational or linear motion. At their core, bearings enable smooth operation by allowing surfaces to move with minimal resistance, which protects machinery from wear and tear while enhancing efficiency.

Historically, the concept of bearings dates back thousands of years, with early applications seen in simple wooden rollers and stone wheels. Over time, advancements in metallurgy and engineering led to the development of precision ball and roller bearings that revolutionized industrial machinery during the Industrial Revolution and continue to do so today.

Bearings serve several key functions in modern machinery, including:

- Reducing friction between rotating shafts and stationary parts

- Supporting mechanical load—both radial and axial

- Maintaining alignment of moving components

- Enhancing wear resistance and extending equipment life

In the local industry context, bearings are vital in sectors such as automotive manufacturing, aerospace, heavy machinery, and renewable energy. Their reliability directly impacts productivity and safety, underscoring the importance of sourcing high-quality bearings from trusted suppliers.

Understanding the fundamentals of bearings sets the foundation for selecting the right type and maintaining them effectively, ensuring smooth and long-lasting equipment performance. Ready to explore the different types of bearings and discover the best fit for your needs?

Types of Bearings Choosing the Right One for Your Needs

When it comes to bearings, picking the right type can make all the difference in your machine’s performance. Here’s a quick look at the main subtypes and what they’re good for.

Ball Bearings

- Deep Groove Ball Bearings

- Pros: Versatile, handle both radial and light axial loads

- Cons: Not ideal for heavy loads or high speeds

- Uses: Common in motors, household appliances, and light machinery

- Angular Contact Ball Bearings

- Pros: Better at supporting axial loads and higher speeds

- Cons: Usually costlier and need more precise mounting

- Uses: Great for pumps, gearboxes, and high-speed applications

Roller Bearings

- Cylindrical Roller Bearings

- Pros: Handle higher radial loads than ball bearings

- Cons: Not designed for axial loads

- Uses: Heavy machinery, conveyors, and electric motors

- Spherical Roller Bearings

- Pros: Accommodate misalignment and shock loads

- Cons: Larger, heavier, and pricier

- Uses: Construction equipment, mining, and steel mills

Specialized Bearings

- Thrust Bearings

- Pros: Support axial loads only

- Uses: Automotive steering, heavy-duty machinery transmissions

- Needle Bearings

- Pros: Compact, handle heavy radial loads with minimal space

- cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | Cost | cURL Too many subrequests. |

|---|---|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | High | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | Very High | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | High radial + misalignment | cURL Too many subrequests. | High | Harsh environments, heavy shock |

| Thrust | Axial only | cURL Too many subrequests. | cURL Too many subrequests. | Axial load focused applications |

| Needle | High radial in tight spaces | cURL Too many subrequests. | cURL Too many subrequests. | Limited space, heavy radial loads |

| Plain | Moderate, low-speed | cURL Too many subrequests. | cURL Too many subrequests. | Slow speed, simple machines |

How to Choose Based on Environment and Precision

- For high-speed electric motors, angular contact ball bearings are ideal.

- In dirty or rough environments, go for spherical roller bearings for durability.

- Tight spaces with heavy loads call for needle bearings.

- If your load is mainly axial, thrust bearings are your best bet.

- For general-purpose or budget-friendly options, deep groove ball bearings work well.

cURL Too many subrequests.

In the US, plenty of industrial bearing suppliers offer a wide range of these bearing types. Look for vendors that provide quick shipping and expert advice to get the right fit. Also, consider suppliers who support local industries, so you get bearings that match American industry standards and your specific needs.

Choosing the right bearing saves you time and money by reducing downtime and maintenance headaches. Keep your machinery running smoother by picking the right one from the start.

Common Applications Where Bearings Keep the World in Motion

Bearings play a crucial role across many industries here in the U.S., from automotive to heavy industrial machinery and everyday consumer products. In cars, you’ll find ball bearings in wheel hubs and angular contact bearings in transmissions, helping to reduce friction and support mechanical loads smoothly. Industrial equipment uses roller bearings and thrust bearings extensively to handle high loads and maintain precision under tough conditions.

In consumer goods, plain and needle bearings appear in everything from home appliances to fitness machines, ensuring quieter, longer-lasting performance. One growing trend we’re seeing locally is the integration of bearings made with eco-friendly materials, alongside innovations tailored for electric vehicles (EVs). These bearings are designed to cope with the high speeds and unique demands of EV motors.

For example, a Midwest manufacturer recently worked with a local supplier to upgrade their production line with precision angular contact bearings. This change improved efficiency and cut downtime, proving how the right bearings make a difference in real-world settings.

Regionally, industries like aerospace in the Pacific Northwest and packaging machinery in the Southeast heavily rely on specialized bearings to maintain their competitive edge. No matter the sector, bearings keep everything moving smoothly across the country.

Maintenance and Troubleshooting Extending Bearing Life

Taking good care of your bearings is key to keeping machinery running smoothly and avoiding costly downtime. Here are the best practices to help extend the life of your bearings:

Best Practices for Lubrication and Alignment

- Lubricate regularly using the right grease or oil as recommended for your bearing type. Proper lubrication reduces friction and wear.

- cURL Too many subrequests. often. Misaligned bearings can cause uneven wear, vibration, and early failure.

- Use quality lubricants designed for your environment—whether it’s high-speed applications or heavy mechanical load support.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Quality Assurance: Every bearing we sell meets strict quality standards, ensuring long-lasting performance and reliable mechanical load support. That reduces downtime and lowers maintenance costs.

- Fast Shipping Nationwide: We understand you need your parts fast. Vast’s quick shipping gets bearings to your door when you need them — no long waits.

- Expert Support: Our team knows bearings inside and out. Whether you are looking for bearing maintenance tips, advice on friction reduction in machinery, or help choosing the right bearing based on your environment, we’re here to help.

- Better Than Generic Suppliers: Unlike generic suppliers, Vast offers genuine, tested products with warranty and support — not just the lowest price.

- Local Store Finder and Shipping Benefits: We have local stores across the U.S., making pickup and returns simple. Plus, shipping rates are competitive, especially for businesses with bulk needs.

Choosing Vast means you’re partnering with a reliable industrial bearing supplier who understands your needs and keeps your operations running smoothly.