Find a local CNC wire EDM shop offering precision machining with ±0.0001 accuracy fast turnaround and expert support near you.

What Is CNC Wire EDM and When Do You Need It

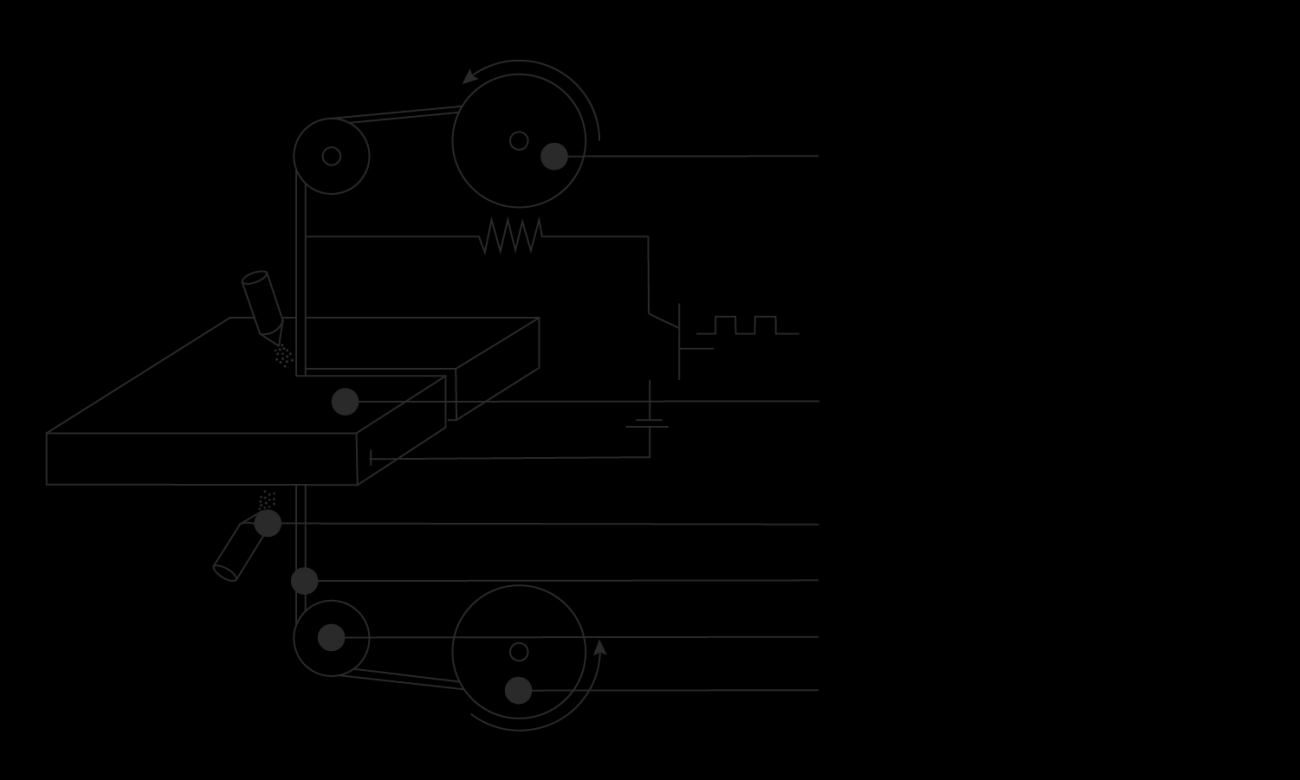

CNC Wire EDM (Electrical Discharge Machining) is a precision cutting process that uses a charged brass wire to erode material from a workpiece. This happens in a dielectric fluid, which acts as a coolant and flushes away debris. Because the wire doesn’t touch the material directly, there’s no mechanical force involved, resulting in burr-free cuts with minimal heat-affected zones. This makes Wire EDM ideal for delicate and complex parts.

Compared to traditional CNC milling, Wire EDM offers several advantages:

- Cuts fragile, heat-treated metals without distortion

- Creates sharp internal corners impossible with milling tools

- Can cut multiple stacked sheets simultaneously for high efficiency

Common applications of CNC Wire EDM include aerospace components, medical implants, automotive dies, and mold making. These are industries where high repeatability and precision in large volume runs are critical to meet strict quality and tolerance standards.

However, Wire EDM has its limits. It works best with conductive metals such as steel, aluminum, and copper, and can cut materials up to about 7 inches thick. It is not suitable for non-conductive materials like plastics or ceramics.

Here’s a quick comparison to clarify when to choose Wire EDM:

| Feature | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|---|

| Material Type | Conductive metals | Conductive metals | Metals & non-metals |

| Max Thickness | Up to 7 inches | Up to 12 inches | Depends on tool |

| Cut Quality | Burr-free, sharp corners | Complex cavities | Good for surfaces |

| Mechanical Force | None | None | Mechanical cutting force |

| Best for | Thin precision cuts, stacks | Internal cavities | Fast material removal |

Understanding how CNC Wire EDM fits your project needs will help you choose the right local shop for speed, quality, and cost efficiency.

The Benefits of Choosing a Local CNC Wire EDM Shop

Picking a local CNC wire EDM shop comes with clear perks that can really boost your project’s success.

Speed and LogisticsShipping locally means faster delivery—days instead of weeks—so you can get quick turnarounds.

This is huge for quick prototypes or last-minute fixes where waiting weeks isn’t an option.Cost SavingsLocal shops save on expensive shipping fees, especially for heavy or delicate parts.

You can meet face-to-face for design for manufacturability (DFM) reviews, which helps avoid costly redesigns later.Quality AssuranceVisiting the shop onsite is easier, letting you inspect work firsthand and build trust.

Most reputable local shops hold certifications like ISO 9001 or AS9100, guaranteeing consistent quality.Community ImpactSupporting nearby shops helps keep local economies strong and skilled jobs within your region.

Many local shops specialize in industries common to their area—like automotive clusters in the Midwest—so they understand your specific needs better.Local Search Tips

When searching “CNC wire EDM shop near me”:

- Check how fast they respond—quick replies usually mean better service.

- Look at reviews and ratings to see who delivers on promises.

- Confirm they have the right machines and materials for your job, especially if you need exotic metals like titanium or Inconel.

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.: Search with terms like “CNC wire EDM [your city]” or “precision EDM cutting near me.” Check out reviews, ratings, and photos.

- Check Portfolios and Machine Fleets: Look for shops that showcase their work, especially in your industry. Make sure they use respected wire EDM machines like Makino or AgieCharmilles for accurate, consistent results.

- Watch for Red Flags:

- Shops without automation may struggle with high-volume orders.

- Limited stock of key materials such as titanium or Inconel can cause delays.

- Lack of detailed case studies or project examples can signal inexperience.

Use this checklist to evaluate potential shops:

| Criteria | cURL Too many subrequests. |

|---|---|

| Certifications | ISO 9001, AS9100 or similar |

| Lead Times | Quotes in 1-5 days |

| Software Compatibility | Support for CAD uploads (e.g., STEP, DXF) |

| Project Documentation | Case studies or references |

| Machine Capabilities | Automation and hybrid CNC + EDM services |

Download our free PDF checklist to keep track of your options and compare shops side by side.

Pro tip: Choosing a shop that offers both wire EDM and CNC milling can save you time and money by consolidating processes under one roof. This is a big plus for reducing turnaround time and complexity in your projects.

Spotlight on Vast Your Trusted Local CNC Wire EDM Partner

Vast brings over 20 years of experience in precision machining, specializing in advanced CNC wire EDM services. Whether you need prototypes or large production runs exceeding 100,000 pieces, Vast supports local businesses across key U.S. regions like the Midwest, Raleigh, and St. Louis.

What sets Vast apart? They offer 30 percent faster cut times thanks to cutting-edge wire EDM generators, backed by a 99 percent on-time delivery rate. Plus, with local hubs nationwide, you get quicker shipping and free design-for-manufacturability (DFM) feedback to help avoid costly errors before production begins.

For example, a local aerospace client recently partnered with Vast and cut complex gear production costs by half—showing real savings and quality improvements in a demanding industry.

Ready to get started? Visit vastmachining.com to upload your CAD files and receive an instant custom quote for your next CNC wire EDM project.