Discover the key bronze and copper differences including composition, strength, conductivity, uses, and cost to choose the right metal for your project.

Chemical Composition & Alloys: Bronze vs Copper

Let’s start with the basics: what exactly are copper and bronze made of?

Copper is nearly pure metal—about 99.9% copper (Cu). It’s soft, highly conductive, and easy to shape, making it ideal for wiring, plumbing, and decorative uses.

Bronze, on the other hand, is an alloy—mainly copper mixed with tin, typically around an 88% copper to 12% tin ratio. This mix gives bronze its extra strength and resistance to wear. But that’s not the only variety out there. Some common bronze types include:

- Phosphor Bronze: Adds phosphorus for better stiffness and fatigue resistance, often used in electrical springs and bearings.

- Aluminum Bronze: Contains aluminum instead of tin (up to 12%), improving corrosion resistance and strength; widely used in marine environments.

Here’s a simple breakdown table to visualize their composition:

| Metal | Copper (Cu) | Tin (Sn) | Other Elements |

|---|---|---|---|

| Pure Copper | 99.9% | 0% | Trace impurities |

| Bronze | ~88% | ~12% | Phosphorus, aluminum, nickel |

Knowing the makeup helps explain why copper and bronze behave so differently in practical use—and why picking the right one depends on your project’s goals.

Physical Properties Comparison

Here’s a quick look at how copper and bronze differ physically:

| Property | Copper | Bronze |

|---|---|---|

| Color & Appearance | Bright reddish-orange | Duller gold-brown, often with a greenish patina over time |

| Density (g/cm³) | 8.96 | ~8.8 |

| Melting Point (°F) | 1,984 | 1,675 – 1,750 |

| Hardness (Brinell) | ~35 | 60 – 170 |

| Ductility & Malleability | High (great for wiring and shaping) | Lower (more resistant to deformation) |

Color & Patina: Copper’s shiny reddish look is iconic, but it darkens and turns greenish (patina) with exposure. Bronze has a more muted, brownish-gold tone and also develops a protective patina, especially outdoors.

Density & Weight: Copper is just a bit denser than bronze, but both materials feel heavy and solid.

Melting Point: Copper melts at a higher temperature, which is useful for some manufacturing processes.

Hardness: Bronze is much harder—this makes it better for parts that face wear and tear.

Ductility: Copper’s softness and flexibility make it ideal for electrical wiring, while bronze’s sturdiness limits how much you can bend or shape it without damage.

Use these basics to pick the right metal based on your project’s needs!

Mechanical & Durability Differences

When it comes to strength, bronze clearly has the upper hand. Its tensile strength can reach up to 120 ksi, compared to copper’s 30–50 ksi. This means bronze parts hold up better under heavy loads or stress.

Both copper and bronze develop protective patinas that help resist corrosion. But in harsh marine environments, bronze outperforms copper thanks to its tin content and special alloys like phosphor bronze or aluminum bronze. This makes bronze a top choice for boat parts and marine bearings.

In terms of wear resistance, bronze shines again. Bronze bearings are standard in machinery because they resist friction and last longer. Copper, on the other hand, is more common in electrical contacts due to its excellent conductivity but doesn’t wear as well under mechanical stress.

| Property | Copper | Bronze |

|---|---|---|

| Tensile Strength | 30–50 ksi | Up to 120 ksi |

| Corrosion Resistance | Good (patina forms) | Excellent (especially marine) |

| Wear Resistance | Moderada | High (ideal for bearings) |

For U.S. buyers, this means bronze offers better durability for heavy-duty and outdoor applications, while copper is preferred where electrical performance is key.

Electrical & Thermal Conductivity

When it comes to conductivity, copper is the top dog. It has a 100% IACS rating (International Annealed Copper Standard), making it the best choice for electrical wiring and components where maximum conductivity is a must. Copper also performs very well in thermal conductivity, which is why it’s often used in cookware and heat exchangers.

Bronze, on the other hand, has a lower conductivity, generally ranging from 15% to 40% IACS depending on the alloy type (like phosphor bronze or aluminum bronze). This means it doesn’t carry electricity or heat as efficiently as copper. But bronze makes up for that with its greater strength and corrosion resistance, which is why you’ll see it in applications where durability matters more than conductivity, such as marine parts and bearings.

Conductivity vs. Cost Trade-Off

| Metal | Electrical Conductivity (IACS) | Typical Cost (per pound) | Best Use Case |

|---|---|---|---|

| Copper | 100% | ~$4.50 | Electrical wiring, plumbing |

| Bronze | 15% – 40% | $2.80 – $3.50 | Bearings, marine hardware |

So if your project needs the best flow of electricity or heat, copper is the go-to. But if strength and corrosion resistance come first, bronze offers a more cost-effective solution even with less conductivity.

Common Applications of Bronze and Copper

Copper is a go-to metal in the US for roofing, plumbing pipes, electrical wiring, and cookware. Its excellent electrical conductivity makes it perfect for wiring, while its corrosion resistance lends well to plumbing and roofing jobs where durability matters.

Bronze, on the other hand, shines in applications needing strength and wear resistance. You’ll often find bronze in statues, bells, marine propellers, bushings, and medals. Marine bronze alloys are especially popular for underwater parts because they resist corrosion better than copper.

There’s some overlap too. For example, musical instruments use both metals: bronze for cymbals and copper wiring for electric instruments. In US plumbing, Type L copper tubing is common, but bronze fittings are often used to connect pipes where extra strength or corrosion resistance is needed, keeping everything code-compliant.

This balance lets you pick the right metal based on the job—copper where conductivity and flexibility matter, and bronze for toughness and longevity.

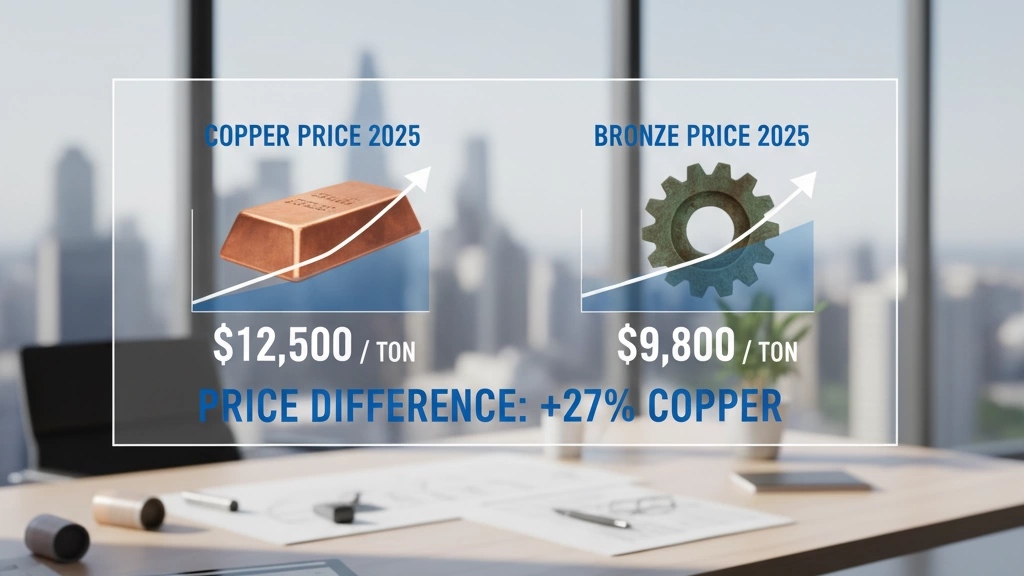

Cost & Market Factors (2025 US Pricing)

When it comes to pricing, copper and bronze differ quite a bit. As of 2025, copper trades around $4.50 per pound on the COMEX market. Bronze is generally cheaper, with prices ranging from $2.80 to $3.50 per pound, depending on the specific alloy mix like phosphor bronze or aluminum bronze.

Scrap value: Copper holds higher scrap value due to its pure metal content, making it more attractive for recycling. Bronze scrap prices can fluctuate more, influenced by tin and other alloy metals.

For those tracking metal prices closely, you might want to check out Vast’s real-time metal price widget — it’s a handy tool to keep an eye on shifts in copper and bronze costs right here in the US.

Bronze and Copper Difference: Pros & Cons

| Característica | Copper | Bronze |

|---|---|---|

| Resistencia | Lower tensile strength (30–50 ksi) | Higher tensile strength (up to 120 ksi) |

| Costo | Higher price (~$4.50/lb COMEX) | Generally cheaper ($2.80–$3.50/lb) |

| Apariencia | Bright reddish color, develops green patina | Duller gold-brown, forms stable bronze patina |

| Corrosion | Good in indoor use; corrodes outdoors | Better corrosion resistance, especially marine |

| Wear Resistance | Less wear-resistant, soft surface | Excellent for bearings, bushings, and wear parts |

| Electrical Conductivity | Best conductor (100% IACS) | Lower conductivity (15–40%), trade-off for strength |

| Maintenance | Requires regular cleaning to prevent tarnish | Easier upkeep, patina protects from damage |

| Ductility | Very ductile; ideal for wiring | Less ductile; not preferred for electrical wiring |

| Recyclability | 100% recyclable, retains high resale value | Also 100% recyclable but resale value varies by alloy |

Both metals have clear strengths depending on your project. Choose copper if you need top electrical and thermal performance or a bright finish. Go with bronze for durability, wear resistance, and outdoor or marine use—plus, it’s usually easier on the budget.

How to Identify Bronze vs. Copper

Telling bronze and copper apart isn’t always obvious, but here are some easy tricks:

- Visual cues: Copper has a bright, reddish-orange shine, while bronze shows a duller, brownish-gold tone. Over time, copper develops a greenish patina, but bronze usually darkens to brown or black.

- Magnet test: Neither copper nor bronze is magnetic, so this won’t help much—be careful not to rely solely on magnets.

- Spark test: When ground down with a grinder, copper sparks are short and dull, while bronze gives off brighter, longer sparks because of its tin content.

- Acid test: Applying a drop of nitric acid can help—copper will turn green, whereas bronze reacts differently, often showing a darker or no significant color change. This test requires caution and safety gear.

Pro tip: Use a file or scratch test on an edge—copper will show a fresh red color beneath the surface, but bronze will appear more yellowish or brass-like under the scratch.

These simple methods can help you quickly spot whether you’re dealing with copper or bronze in the field or at the job site.

Sustainability & Recycling

Both bronze and copper are 100% recyclable, making them great choices for environmentally conscious projects. Copper holds its value longer in secondary markets, so recycled copper often fetches a better price than bronze scrap. This makes copper a smart pick if you’re looking to minimize waste and maximize resale.

However, keep in mind that bronze contains tin, and mining tin has a notable environmental impact. Tin extraction can disrupt ecosystems and use significant energy, which adds to bronze’s overall footprint. If sustainability is a top priority, choosing pure copper or recycled materials can be a greener option.

Quick Recap:

- Both metals recycle fully without quality loss

- Copper scrap is typically more valuable and easier to resell

- Tin mining for bronze alloys poses higher environmental concerns

- Using recycled metals reduces mining impacts regardless of type

FAQs about Bronze and Copper Differences

Is bronze more expensive than copper?

Generally, bronze costs less per pound than pure copper, but prices vary depending on the type of bronze alloy. Some specialty bronzes like phosphor bronze can be pricier due to added elements.

Can you weld bronze and copper together?

Welding bronze to copper is possible but tricky because of their different melting points and alloy compositions. Brazing or soldering is often recommended instead of direct welding.

Which is better for outdoor sculptures?

Bronze is the top choice for outdoor sculptures. It resists corrosion and weathers beautifully with a protective patina, while copper tends to develop a greenish layer faster and can be softer.

Does bronze turn skin green like copper?

Bronze is less likely to turn your skin green compared to pure copper. Copper oxidation causes that green tint, but in bronze, tin and other alloy metals reduce this effect.

Are bronze fittings allowed in US potable water systems?

Yes, many bronze fittings meet US plumbing codes and are widely used, especially marine bronze fittings. They offer corrosion resistance and durability for safe potable water applications.