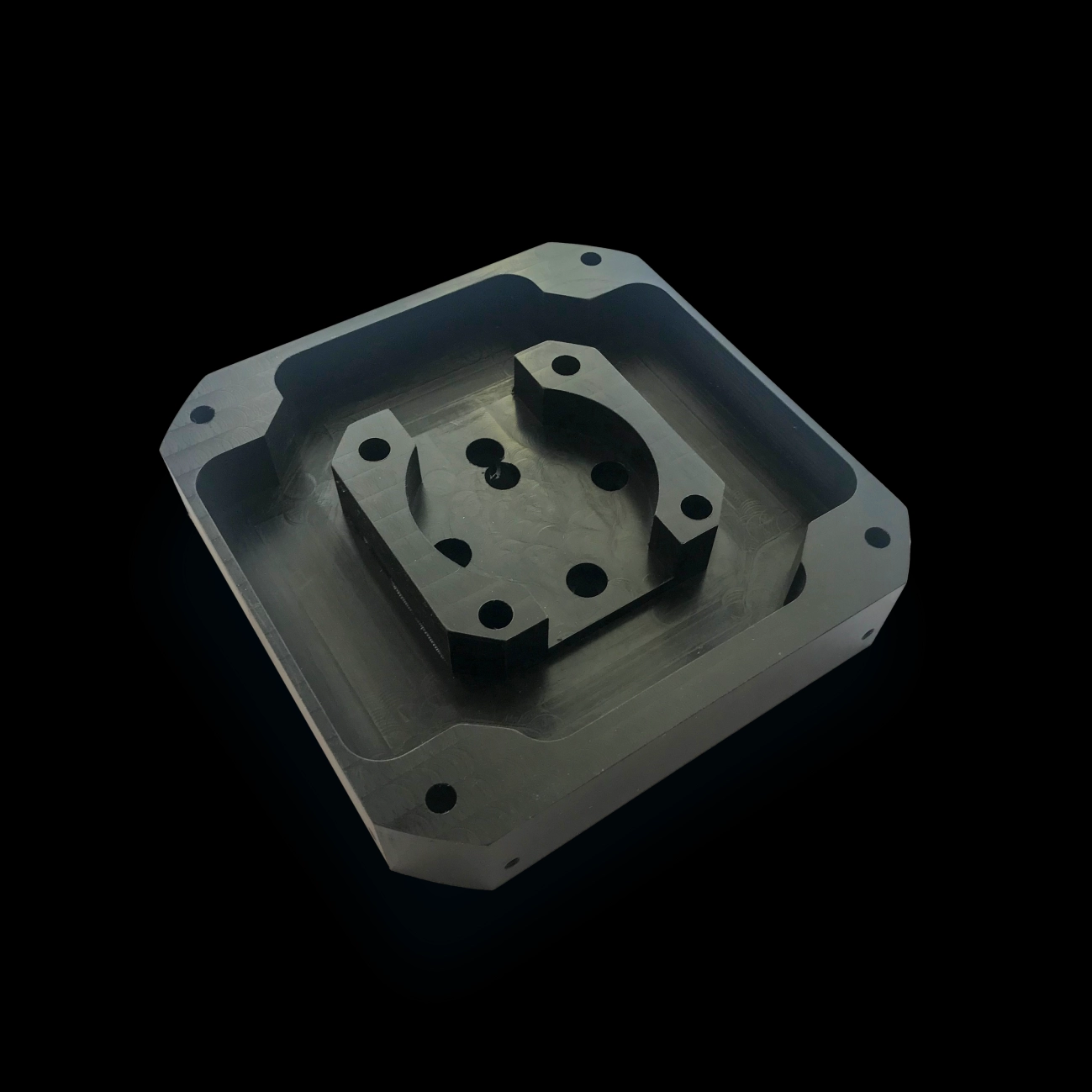

Discover high-precision CNC machined parts made in the USA with fast turnaround custom prototypes and production using advanced milling and turning.

What Are CNC Machined Parts The Fundamentals Explained

CNC machined parts are components created through Computer Numerical Control (CNC) machining, a precise manufacturing process that uses automated machines to cut, shape, and finish metal or plastic materials. These parts are essential in many industries where tight tolerances and complex designs matter. Whether you need a custom CNC prototype or production-quality components, CNC machining ensures accuracy and repeatability.

How CNC Machining Works From CAD to Finished Prototype

The process begins with a detailed CAD (Computer-Aided Design) file that defines the part’s dimensions and geometry. This digital design is converted into a set of instructions for the CNC machine using CAM (Computer-Aided Manufacturing) software. The machine follows these instructions with precision to remove material from a solid block or billet through milling, turning, or other techniques. The result is a highly accurate, finished prototype or production part ready for testing or assembly.

Types of CNC Machined Parts Prototypes vs Production Runs

CNC machining serves both rapid prototyping and full-scale production needs.

- Prototypes: These are one-off or small batch parts made to validate design concepts quickly. Custom CNC prototypes allow engineers to test form, fit, and function before mass production.

- Production Runs: For larger quantities, CNC machines create consistent, repeatable parts at high speed. Production runs can range from dozens to thousands of units, with strict adherence to specifications.

Choosing between prototype or production CNC machined parts depends on your project stage and quantity requirements. Understanding these basics will help you select the right CNC machining strategy for your needs.

Materials for CNC Machined Parts Choosing the Right One for Your Project

Picking the right material for your CNC machined parts is key to making sure your project works well and lasts. Depending on what you need—strength, weight, flexibility, or cost—different materials fit different jobs. Here’s a quick guide to help you decide.

Metals for Durability Aluminum Stainless Steel and Titanium

- Aluminum CNC parts are lightweight, strong, and resist corrosion. Great for aerospace, automotive, and electronics where weight matters.

- cURL Too many subrequests. offers excellent strength and corrosion resistance. Perfect for medical devices, food processing, and rugged industrial parts.

- Titanium is strong like steel but lighter, plus it handles extreme temperatures and corrosion. It’s ideal when top durability meets weight savings.

Plastics and Composites Nylon ABS and Carbon Fiber

- Nylon is tough and flexible, often used in gears and mechanical parts that need to absorb impact.

- ABS is an affordable plastic that’s easy to machine. It’s good for prototypes and parts not under heavy stress.

- Carbon fiber composites combine light weight with exceptional strength. They’re used in high-performance products like sports equipment and robotics.

Material Selection Checklist

When choosing materials, ask yourself:

- What strength and durability do I need?

- How important is weight for this part?

- Will the part face heat, chemicals, or wear?

- What’s my budget?

- Do I need a prototype or a long production run?

- What surface finish and tolerance levels am I targeting?

Answering these helps steer you toward the best CNC machining materials for your custom machined components. If you’re working with a local CNC machine shop, they can also recommend materials based on your project’s needs.

The CNC Machining Process Step by Step Breakdown

CNC machining starts with designing your part, usually in a CAD program. Once the digital design is ready, it’s loaded into the CNC machine, which reads the file and controls precise cutting tools to shape the material.

Milling and Turning Core Techniques for Complex Geometries

- cURL Too many subrequests. uses rotary cutters to remove material, perfect for creating flat surfaces, slots, and complex 3D shapes.

- cURL Too many subrequests. spins the raw material on a lathe while cutting tools shape its outer surface, great for cylindrical parts.

Both are essential for handling complex geometries and precision features in custom CNC prototypes or production runs.

Advanced Methods EDM Swiss Machining and Grinding

- Electric Discharge Machining (EDM) cURL Too many subrequests.

- Swiss Machining cURL Too many subrequests.

- Grinding cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- TolerancescURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

- Use cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. 3D models in common formats (STEP, IGES, or native CAD files) so your local CNC shop can process them easily.

- Include detailed notes on dimensions, materials, and finishes directly in your CAD file or accompanying documentation.

Cost Saving Strategies

- Simplify geometries when possible. Complex curves and tight corners require more machining time.

- Choose standard material sizes to reduce waste and expense.

- Consolidate parts or features to reduce assembly time and cost.

- Work with a local CNC machining partner who can advise on design tweaks that save money without sacrificing quality.

Following these tips helps ensure your custom CNC prototypes and production runs come out right the first time—saving you time and money.

Applications of CNC Machined Parts Real World Industries

CNC machined parts are the backbone of many industries across the United States, known for their precision and reliability. From aerospace to medical devices, these parts ensure the high-quality standards that modern manufacturing demands.

Aerospace and Automotive High Stakes Precision

In aerospace and automotive sectors, precision is everything. Custom CNC prototypes and production runs must meet tight tolerances to ensure safety and performance. Aluminum CNC parts, stainless steel, and titanium are popular here because they offer strength without adding too much weight. Whether it’s engine components or structural parts, CNC machining guarantees consistent accuracy critical to these high-stakes industries.

Medical and Electronics Reliability Meets Innovation

Medical devices and electronics rely heavily on custom CNC machined components. Precision CNC milling helps create small, complex parts for surgical tools, implants, and electronic housings, where reliability can’t be compromised. Materials like nylon, ABS, and advanced composites ensure durability while maintaining lightweight properties. The ability to produce rapid prototyping CNC parts allows quick innovation cycles, speeding up product development in these fast-moving fields.

Emerging Uses Robotics and EVs

Robotics and electric vehicles (EVs) are rapidly growing markets where CNC machining plays an important role. Complex geometries and tight CNC machining tolerances make 5-axis CNC machining and CNC turning services ideal for producing parts in these areas. From motor housings to robotic arms, CNC machining supports the durability and precision needed for cutting-edge technology, making local CNC machining services a smart choice for U.S.-based developers and manufacturers.

Whether you’re looking for aerospace-grade precision or custom machined components for the latest tech, CNC machined parts deliver the accuracy and quality that today’s industries demand.

Why Choose Local CNC Machining Services Insights for US Users

When it comes to CNC machined parts, choosing a local provider in the US offers clear advantages. Local CNC machining services mean faster turnaround times, easier communication, and better quality control. Whether you need rapid prototyping CNC work or full production runs, having a near me partner helps keep your project on schedule without shipping delays or customs hassles.

Benefits of Near Me Providers Speed and Compliance

- Faster Delivery – Local shops cut down shipping times dramatically, so you get your CNC parts quicker.

- Better Communication – Being in the same time zone and region makes it easier to discuss design tweaks or urgent needs.

- Regulatory Compliance – US-based manufacturers understand domestic standards and regulations, ensuring your parts meet all required specs.

- Support Local Economy – Using American CNC machining materials and labor supports local businesses and helps maintain industry standards.

Vast Your Partner for Custom CNC Machined Parts

At Vast, we specialize in custom CNC machined parts made right here in the US. From precision CNC milling to complex 5-axis CNC machining, we handle projects of all sizes. Our focus is on quality, speed, and clear communication, so you get exactly what your business needs without the headaches of overseas production.

Choosing local CNC machining services means you get the reliability and flexibility required for today’s fast-paced industries. Whether it’s aerospace, automotive, or medical, working with a trusted local partner like Vast ensures your custom CNC prototypes and components come out right the first time.