Discover what a pump housing is its key functions materials and how to choose durable casings for efficient industrial pump performance.

The Core Function of a Pump Housing in Fluid Systems

A pump housing, often called a pump casing or impeller housing assembly, serves as the main enclosure that holds and protects the internal components of a pump. Its core function is to contain the fluid under pressure and guide it efficiently through the pump’s flow paths, ensuring smooth operation and effective fluid transfer. By maintaining a sealed environment, the housing prevents leaks, protects internal parts from damage, and helps manage the fluid’s direction and speed, which is crucial for system performance.

Beyond protecting the pump’s inner workings, the housing plays a vital role in preventing system failures. A well-designed casing absorbs and distributes the stresses caused by fluid pressure, reducing the risk of cracks or deformation. It also securely integrates seals and bearings, preventing contamination and wear that can lead to downtime or costly repairs. This protective function helps extend pump lifespan and reliability in demanding industrial environments.

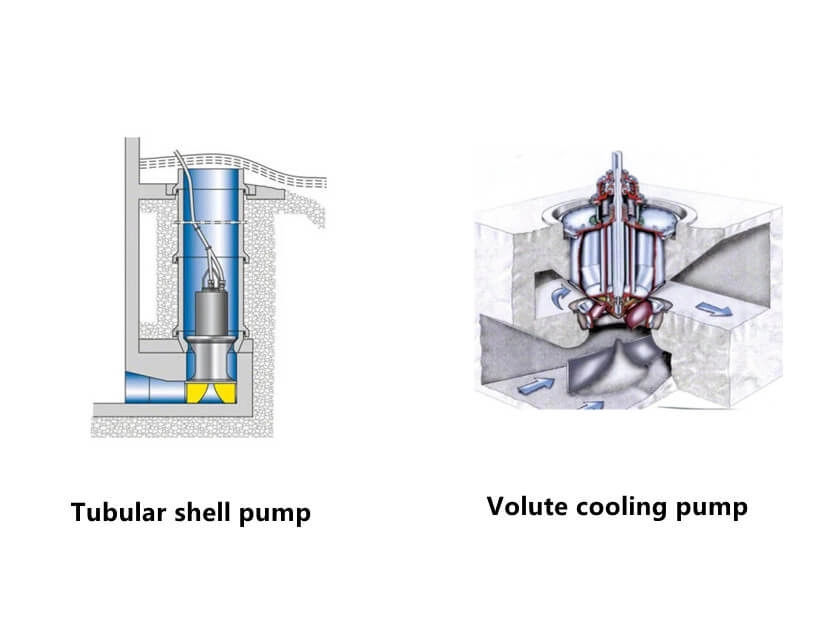

Pump housings are specially designed to fit various pump types such as centrifugal, submersible, and volute pumps, adapting to their specific fluid handling and pressure containment needs. Whether managing water in treatment plants or oil in manufacturing, the right pump housing ensures the overall system runs smoothly, safely, and efficiently.

Key Components and Design Features of Pump Housings

A pump housing is more than just a shell—it holds vital parts that keep your pump running smoothly. Here’s what you’ll typically find inside a pump casing design:

Inlet and Outlet Nozzles

These are the entry and exit points for the fluid. They’re carefully designed to guide flow smoothly into and out of the pump, minimizing pressure loss and improving efficiency. Properly shaped flow paths inside the housing help maintain consistent fluid pressure and reduce turbulence.

Seals and Bearings Inside the Housing

Seals prevent leaks and protect the internal parts from contaminants. They’re crucial for keeping the pump airtight and fluid-tight. Bearings support the rotating parts like the impeller, making sure everything spins freely without extra friction or wear. Good seal and bearing integration ensures longer pump life and fewer breakdowns.

Mounting and Alignment Features

The pump housing includes mounting points and alignment elements that keep everything stable and properly positioned. This is crucial for making sure the pump stays aligned with pipes and motors, reducing vibrations and wear over time. Proper alignment also helps maintain the integrity of internal components.

In short, the design of the pump housing and its components directly impacts the pump’s performance, durability, and ease of maintenance in any fluid system. Whether it’s for a centrifugal pump enclosure or a submersible pump protection setup, these elements are key to reliable operation.

Materials Used in Pump Housing Manufacturing

When choosing a pump housing, the material makes a big difference in durability and performance. Here are the main options:

Cast Iron and Ductile Variants

- Cast iron is popular for pump casings because it’s strong, affordable, and handles most fluids well.

- Ductile iron offers more flexibility and impact resistance, making it a step up for tougher jobs.

Stainless Steel and Alloys

- Stainless steel is ideal when you need corrosion resistance, especially in chemical processing or salty environments.

- Other metal alloys blend strength and corrosion protection, often used in industrial fluid transfer or oil and gas sectors.

Emerging Options Like Composites

- Composite materials are lighter and resist corrosion without metal’s weight.

- They’re gaining traction for submersible pump protection and HVAC where efficiency and cost-saving matter.

Whether you’re buying from China, a custom factory, or local U.S. suppliers, knowing the materials helps you match your pump housing to your system’s pressure, temperature, and fluid type.

Common Applications and Industries Relying on Pump Housings

Pump housings are key in many industries across the U.S., supporting fluid transfer and system reliability. Here are some of the most common areas where they’re essential:

- Water Management and TreatmentPump housings protect components in water supply, wastewater treatment, and irrigation systems. Their corrosion-resistant materials help handle various water types, ensuring smooth fluid pressure containment and lasting performance.

- Automotive and HVAC SystemsIn cars and heating, ventilation, and air conditioning setups, pump housings support coolant circulation and fluid flow. They keep pumps aligned and sealed properly, which prevents leaks and system failures in both engines and climate control units.

- Oil and Gas and ManufacturingThe tough environments in oil drilling, refining, and heavy manufacturing rely on durable pump housings, often made from cast iron or stainless steel. These housings withstand high pressures and harsh fluids, making them vital for safe, continuous operation.

In all these sectors, choosing the right pump housing design and materials is key. Whether it’s a volute pump structure or a centrifugal pump enclosure, the housing’s quality impacts efficiency and maintenance needs. This is why many U.S. businesses look for custom pump housing options from reliable factories to fit their specific fluid systems.

How to Select the Right Pump Housing for Your Needs

Choosing the right pump housing means thinking about how and where you’ll use it. Here are the key factors to consider:

Pressure and Temperature

- Make sure the housing can handle the maximum pressure your system will produce.

- Check the temperature limits, especially if you deal with hot fluids or steam. Some materials perform better under heat.

Fluid Type

- Consider what type of fluid you’ll pump—water, chemicals, or abrasive liquids.

- Corrosion-resistant materials like stainless steel are better for harsh or corrosive fluids.

- Cast iron or ductile iron works well for clean water or less aggressive fluids.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- Reduced pump performance may mean blockages in the impeller housing assembly or flow paths—clean or service these areas.

When to Replace with Vast Upgrades

- If the housing has multiple cracks or severe corrosion, replacement is safer than repair.

- Upgrading to corrosion resistant casings like stainless steel or advanced composites can boost durability and reduce maintenance frequency.

- For older pumps, consider modern designs that improve fluid pressure containment and efficiency.

- Balance cost vs longevity: investing in a high-quality pump housing upfront often saves money in the long run.

By staying on top of maintenance and recognizing early warning signs, you ensure your pump system runs smoothly, avoiding unexpected failures and costly downtime in your industrial or commercial applications.