Discover what is forged aluminum its high strength lightweight properties and how it compares to cast aluminum for automotive aerospace and cookware uses.

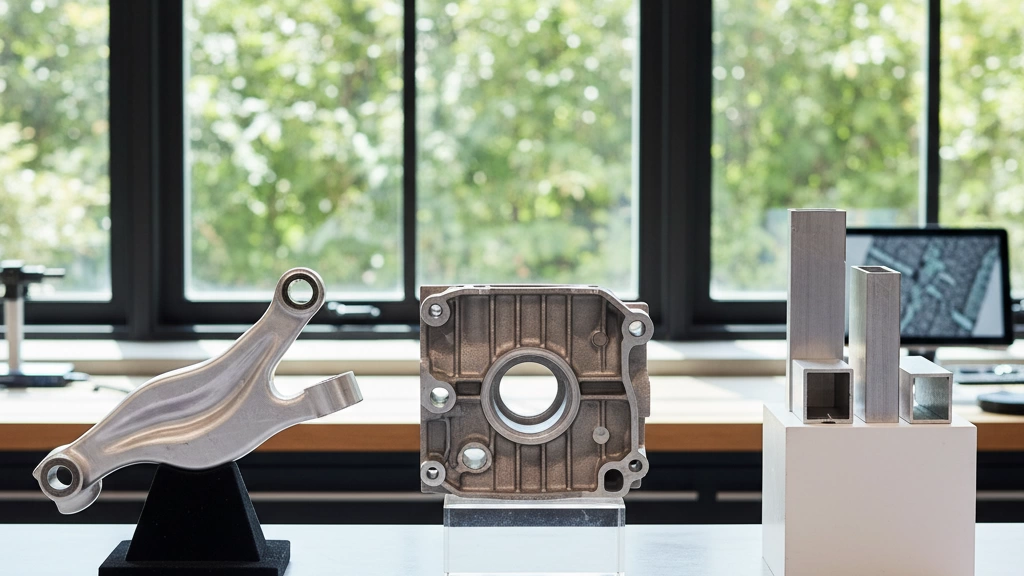

The Forging Process: How Forged Aluminum Is Made

Forged aluminum starts with selecting the right aluminum alloys, commonly 6061 y 7075 series. These alloys are chosen for their strength, durability, and workability during forging.

Step 1: Selecting Aluminum Alloys

- 6061 alloy: Known for good corrosion resistance and weldability

- 7075 alloy: High strength, often used where extra toughness is needed

Step 2: Heating Billets for Plasticity

The selected aluminum billets (solid chunks) are heated to 400–500°C (752–932°F). This high temperature makes the aluminum soft and malleable, allowing it to be shaped without cracking.

Step 3: Die Forging Techniques

Forging employs different methods to form the billet into the desired shape:

- Open-die forging: The billet is worked between flat or simple-shaped dies, good for large, simple shapes.

- Closed-die forging: Also called impression-die forging, the aluminum is pressed into a die cavity closely matching the final shape, producing detailed parts with excellent strength.

- Roll forging: The billet is passed through rollers to reduce thickness and elongate the material, ideal for certain profiles.

Step 4: Trimming, Heat Treatment, and Finishing

- After forging, any excess metal is trimmed off to achieve precise dimensions.

- The aluminum then undergoes heat treatment, commonly T6 tempering, which involves solution heat treatment and aging to maximize strength and hardness.

- Finally, finishing processes like machining, anodizing, or polishing refine the parts for performance and appearance.

This controlled process ensures forged aluminum parts have superior structural integrity, making them stronger and more reliable than cast or extruded alternatives.

Key Properties of Forged Aluminum

Forged aluminum stands out because of its strong mechanical, physical, and thermal properties — making it a top choice across many industries.

Mechanical Strength

- High tensile strength: Forged aluminum can reach up to 83 ksi, which means it can handle heavy loads without breaking.

- Excellent fatigue resistance: It resists cracking and failure, even under repeated stress over time. This makes it reliable for parts that see constant use, like automotive and aerospace components.

Physical Benefits

- Lightweight: With a density around 2.7 g/cm³, it’s much lighter than steel but still tough enough for demanding applications.

- Superior corrosion resistance: Forged aluminum naturally fights rust and corrosion, making it ideal for outdoor and marine environments.

Thermal Performance

- Good conductivity: It efficiently disperses heat, which is great for cookware and heat-sensitive components.

- Enhanced heat dissipation: The forging process optimizes the grain flow, improving thermal management over cast or extruded aluminum.

Yield Strength Comparison

| Aluminum Type | Yield Strength (ksi) |

|---|---|

| Forged Aluminum | 50–83 |

| Cast Aluminum | 15–40 |

| Extruded Aluminum | 30–60 |

This clear difference shows why forged aluminum often outperforms cast and extruded variants in strength and durability.

Forged vs. Cast vs. Extruded Aluminum: Direct Comparison

When choosing aluminum for your project, knowing how forged, cast, and extruded aluminum stack up is key. Here’s a simple breakdown:

Grain Structure

- Forged aluminum: Grains are aligned and compressed, creating stronger, more uniform metal.

- Cast aluminum: Has a porous, uneven grain structure that can lead to weak spots.

- Extruded aluminum: Grains flow along the length, offering good strength but not as uniform as forged.

Performance Metrics

| Property | Forged Aluminum | Cast Aluminum | Extruded Aluminum |

|---|---|---|---|

| Tensile Strength | Up to 83 ksi | 20–45 ksi | 35–65 ksi |

| Fatigue Resistance | Excellent | Poor | Moderada |

| Impact Resistance | Alta | Low | Moderada |

| Weight-to-Strength | Best | Heaviest | Good |

Cost and Production

- Forged aluminum: Costs more upfront due to complex die forging, but lasts longer and performs better. Worth it for critical parts.

- Cast aluminum: Cheapest and quick to produce, but less durable.

- Extruded aluminum: Mid-range price, good for long shapes but less strength than forging.

Pros/Cons At-A-Glance

| Type | Pros | Contras |

|---|---|---|

| Forged | Superior strength, fatigue resistance, consistent quality | Higher cost, shape limits |

| Cast | Low cost, complex shapes | Porosity, weaker structure |

| Extruded | Cost-effective, good uniformity | Lower strength than forged |

In short, forged aluminum is your go-to when strength, durability, and performance matter—perfect for automotive, aerospace, and high-end consumer goods. Cast and extruded aluminum fit well for budget-friendly or non-critical uses.

Common Applications of Forged Aluminum

Forged aluminum is everywhere you look, especially when strength and light weight matter most. Here’s where you’ll find it:

- Automotive: Forged aluminum is huge for wheels, pistons, and suspension parts. Lightweight truck rims made from forged aluminum help improve handling and reduce unsprung weight, boosting overall performance.

- Aerospace: You’ll find forged aluminum in structural frames and landing gear because it delivers reliable strength without adding extra bulk—critical for flight safety and efficiency.

- Consumer Goods: Many quality cookware brands use forged aluminum for pans—thanks to its even heat distribution and durability. It’s also popular in sporting goods, like bike frames and baseball bats, where lightweight and toughness are key.

- Industrial: Forged aluminum parts are common in tools, valves, and machinery where lasting durability and fatigue resistance keep things running smoothly.

Case Study: Weight Reduction in Vehicles

By switching to forged aluminum parts, some automakers cut vehicle weight by up to 40%. This drop not only improves fuel efficiency but also enhances acceleration and handling—making forged aluminum a smart choice for greener, high-performance vehicles.

If you’re in the market for stronger, lighter parts, forged aluminum offers clear advantages across industries here in the U.S.

Advantages and Limitations of Forged Aluminum

Advantages:Exceptional durability: Forged aluminum is tough and stands up well to wear and tear, making it reliable for heavy-duty use.

Reduced failure rates: The forging process aligns the grain structure, which means fewer cracks and longer-lasting parts.

Eco-friendly recyclability: Aluminum is easy to recycle without losing strength, so forged aluminum is a greener choice compared to other metals.Limitations:Higher initial cost: Forging aluminum costs more upfront than casting or extrusion, so it’s usually reserved for parts that need extra strength.

Shape restrictions: Forging works best with simpler shapes, so complex designs can be challenging or expensive to make this way.Myth-busting:

Is forged aluminum safe for cooking? Yes, it is—especially when properly anodized. Anodizing creates a hard, non-reactive surface that makes forged aluminum cookware safe and long-lasting in your kitchen.

How to Identify and Choose Forged Aluminum Products

When picking forged aluminum, knowing what to look for makes all the difference. Here are the key points to keep in mind:

Hallmarks of Forged Aluminum

- Smooth finish: Forged aluminum typically has a clean, polished look without rough spots.

- No porosity: Unlike cast aluminum, forged pieces won’t have tiny holes or bubbles.

- Certification stamps: Look for marks like ASTM B247; these confirm the forging standards were met.

Quick Buying Guide

- Choose brands known for premium forged products—they often highlight their forging process prominently.

- Avoid no-name or generic items that don’t mention forging or certifications.

- Ask retailers or manufacturers about alloy type (6061 or 7075 are common forgings) to ensure quality.

Maintenance Tips

- Clean forged aluminum with mild soap and water—avoid harsh chemicals.

- Prevent thermal shock by warming cookware slowly; sudden temp changes can damage the metal’s surface.

- Regularly check for dents or cracks, especially if used in automotive or aerospace parts.

| Característica | Forged Aluminum | Cast Aluminum | Extruded Aluminum |

|---|---|---|---|

| Surface Finish | Smooth, polished | Rough, porous | Smooth |

| Resistencia | High, aligned grain | Lower, porous | Moderada |

| Certification | Often stamped (ASTM) | Rarely stamped | Sometimes |

| Price | Premium | Lower | Mid-range |

By focusing on these signs, you’ll confidently select forged aluminum products that last longer and perform better.

Future Trends in Forged Aluminum Technology

Forged aluminum is evolving fast thanks to new tech and materials. One big innovation is additive forging hybrids, which combine traditional forging with 3D printing. This lets manufacturers create complex shapes while keeping the strength and durability forged aluminum is known for. It’s a game-changer for industries that need lightweight yet strong parts without wasting materials.

Another trend is the rise of sustainable aluminum alloys. These are designed to reduce environmental impact by using more recycled content or alloys that require less energy to produce. This shift aligns perfectly with the growing focus on eco-friendly manufacturing.

Looking ahead, the demand for forged aluminum is booming, especially in the electric vehicle (EV) market and green manufacturing sectors. EV makers need lightweight but tough components to boost range and performance, making forged aluminum a top choice. Plus, its excellent recyclability fits well with the goals of sustainable production.

In short, the future of forged aluminum blends cutting-edge technology with eco-conscious materials, driving growth across automotive, aerospace, and beyond.