Discover 321 stainless steel properties including high temperature resistance corrosion durability and welding tips ideal for aerospace and automotive uses

If you’re dealing with high-temperature environments or need a stainless steel that won’t crack under pressure, you’ve likely heard about 321 stainless steel. This titanium-stabilized alloy isn’t just another version of 304—it’s engineered to resist corrosion and maintain strength even when the heat rises. Whether you’re an engineer, fabricator, or procurement pro trying to choose the right material for aerospace parts, automotive exhausts, or chemical processing equipment, understanding 321 stainless steel properties is key to getting it right. Stick around, because we’re diving deep into what makes this grade a standout choice—and why it might just be the solution you’ve been searching for.

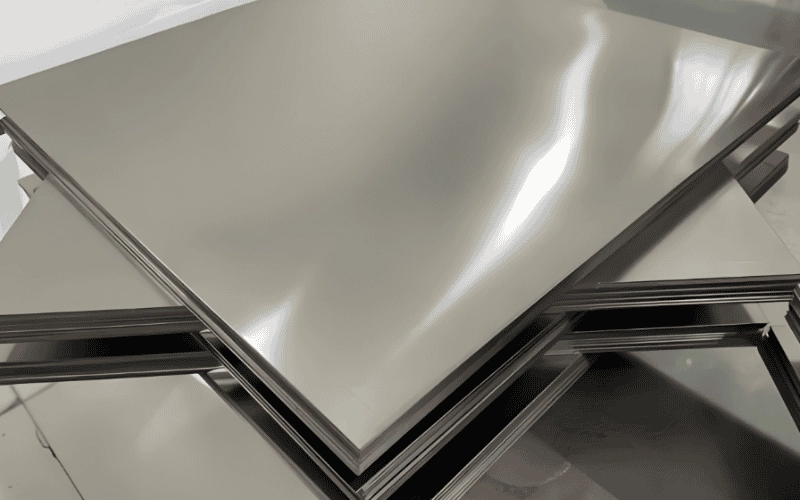

What is 321 Stainless Steel Composition and Key Characteristics

321 stainless steel is an austenitic stainless steel grade known for its excellent high-temperature performance. What sets it apart is its stabilization with titanium, which helps prevent chromium carbide formation during welding or high heat exposure. This stabilization significantly improves its resistance to intergranular corrosion, making it a preferred choice in demanding environments.

The chemical composition of 321 stainless steel typically includes:

- Chromium (Cr): 17-19% — provides corrosion resistance

- Nickel (Ni): 9-12% — enhances toughness and corrosion resistance

- Titanium (Ti): 5x (carbon content) — stabilizes the steel, preventing carbide precipitation

- Carbon (C): max 0.08% — low to reduce carbide formation

- Manganese (Mn): up to 2% — contributes to strength and hardness

- Silicon (Si): up to 1% — adds oxidation resistance

- Iron (Fe): balance

Physically, 321 stainless steel exhibits good ductility and formability due to its austenitic structure. It maintains strength at elevated temperatures, typically up to 1500°F (815°C), with excellent resistance to oxidation and scaling. These traits not only support fabrication but also ensure long-term durability in high-temperature industrial applications, such as exhaust systems or chemical processing equipment.

Understanding these key characteristics helps in selecting the right material for both structural integrity and corrosion resistance in various industries across the United States.

Mechanical and Thermal Properties of 321 Stainless Steel

321 Stainless Steel offers solid mechanical strength and excellent thermal performance, making it a popular choice for demanding environments. Here’s a quick look at its key properties:

- Tensile Strength: Around 75,000 psi (520 MPa)

- Yield Strength: Approximately 30,000 psi (205 MPa)

- Elongation: 40% in 2 inches, showing good ductility

- Hardness: Typically 70 HRB (Rockwell B scale)

Thermally, 321 stainless steel stands out with its ability to resist oxidation and maintain strength at high temperatures, thanks to its titanium stabilization. It performs well up to about 1500°F (815°C) without scaling, making it ideal for high heat applications.

Thermal and Oxidation Resistance Highlights

- Maintains mechanical integrity in hot conditions

- Resists oxidation better than 304 stainless steel

- Suitable for repeated heating cycles without weakening

321 Stainless Steel vs 304 and 316 Stainless Steel

| Property | 321 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|---|

| Tensile Strength (psi) | 75,000 | 73,200 | 75,000 |

| Yield Strength (psi) | 30,000 | 29,000 | 30,000 |

| Elongation (%) | 40 | 40 | 40 |

| Max Service Temp (°F) | 1500 | 870 | 1200 |

| cURL Too many subrequests. | High | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | Excellent | Fair | Good |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- Use sharp, carbide tools

- Employ moderate cutting speeds

- Apply plenty of coolant to reduce heat buildup

- Avoid heavy cuts to prevent tool wear and surface work hardening

Regarding heat treatment, 321 isn’t hardenable by typical methods, so annealing remains the main way to relieve stress and improve ductility. Avoid overheating above 2100°F (1150°C) as it can trigger titanium carbide precipitation, which may reduce corrosion resistance.

Following these guidelines helps ensure smooth fabrication and long-lasting performance of 321 stainless steel in your projects.

321 vs Other Grades When to Choose 321 Stainless Steel

When deciding on 321 stainless steel, it helps to know how it stacks up against other common grades like 304, 316, and 347. Here’s a quick comparison to guide your choice.

321 vs 304 Stainless Steel

- cURL Too many subrequests.: 321 offers better resistance to high temperatures due to titanium stabilization, making it ideal for applications exposed to heat cycling.

- Cost: 321 tends to cost more than 304 because of added titanium and specialized manufacturing.

- Corrosion Resistance: Both perform well in mild environments, but 304 may show signs of intergranular corrosion after welding, which 321 resists better.

321 vs 316 Stainless Steel

- Corrosion Resistance: 316 has superior resistance to chlorides and acidic conditions than 321, which is better suited for high-temperature but less aggressive environments.

- cURL Too many subrequests.: 321 outperforms 316 at elevated temperatures due to its titanium stabilization.

- Cost: 316 is generally more expensive than 321 because of molybdenum content.

321 vs 347 Stainless Steel

- Stabilization Element: 321 uses titanium; 347 uses niobium for stabilization. Both prevent intergranular corrosion after welding effectively.

- Performance: Differences are subtle; 321 is favored in industries focusing on thermal cycling, while 347 may be preferred where niobium offers slight advantages in creep strength.

- Availability: 321 is more widely stocked and commonly requested in the U.S. market.

Quick Selection Guide

| Factor | Choose 321 Stainless Steel | Choose 304 Stainless Steel | Choose 316 Stainless Steel | Choose 347 Stainless Steel |

|---|---|---|---|---|

| High-Temperature Use | Yes, with strong oxidation and scaling resistance | No, limited heat resistance | Moderate, better corrosion resistance | Yes, similar heat resistance to 321 |

| Corrosion in Chlorides | cURL Too many subrequests. | cURL Too many subrequests. | Excellent | cURL Too many subrequests. |

| Welding Stability | Excellent (Ti stabilized, no post-weld anneal) | Moderate (susceptible to sensitization) | Excellent | Excellent (Nb stabilized) |

| Cost | Mid to High | cURL Too many subrequests. | High | Mid to High |

| Market Availability | Widely available in U.S. | cURL Too many subrequests. | cURL Too many subrequests. | Less common |

This comparison shows 321 stainless steel fits best when you need good heat stability and welding performance without the higher cost of 316. For U.S. customers needing parts that handle heat, stress, and corrosion after welding, 321 offers a reliable balance.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. Certified material with full documentation is standard with reputable suppliers.

- Do they supply other titanium stabilized grades? Yes, 347 stainless steel and similar materials are often available.

By choosing a certified, experienced 321 stainless steel supplier in the U.S., you ensure you get reliable material tailored to your project’s thermal, corrosion, and strength requirements.