Discover how plastic automotive components enhance vehicle performance with lightweight, durable materials and advanced manufacturing processes.

The Rise of Plastics in Automotive Design Why They’re Essential Today

Historical Context and Shift from Metal to Polymer

For decades, automotive manufacturing relied heavily on metal parts such as steel and aluminum for building car bodies and components. However, the rise of plastics in automotive design represents a major shift driven by changing industry demands. Starting in the mid-20th century, manufacturers began exploring plastic automotive components to address critical needs like weight reduction, cost efficiency, and design flexibility.

This shift from metal to polymer materials accelerated as plastics evolved to meet stricter performance and safety standards. Early applications included simple trims and interior panels, but today plastics are fundamental across vehicle systems — from bumpers made of polypropylene to instrument panels incorporating ABS blends.

Several factors have fueled this transition:

- Lightweighting: Plastic parts reduce overall vehicle weight, improving fuel efficiency and lowering emissions.

- Design freedom: Polymers allow for complex shapes and integration of multiple functions in a single piece.

- Cost savings: Injection molded plastics often reduce manufacturing time and material waste compared to metal fabrication.

- Corrosion resistance: Unlike metals, many plastics resist rust and chemical degradation, enhancing durability.

Today, plastic automotive components are no longer just alternatives to metal; they are essential materials designed specifically for automotive thermoplastics applications. This evolution reflects the industry’s broader shift towards innovation and sustainability, setting the stage for new technologies in electric vehicles and smart automotive systems.

How can manufacturers continue optimizing the balance between plastics and traditional materials to meet future automotive challenges?

The Rise of Plastics in Automotive Design Why They’re Essential Today Core Applications Across Vehicle Systems

Plastic automotive components have become key players in nearly every part of a vehicle. From the exterior to the interior, plastics offer flexibility and performance that metals can’t always match. Here’s where you’ll typically find them:

- Exterior parts: Bumpers, grilles, side mirrors, and fender liners often use polypropylene (PP) and other thermoplastics. These materials are lightweight yet tough, helping improve fuel efficiency without sacrificing durability.

- Interior components: Dashboards, door panels, and consoles rely heavily on ABS plastic blends and polycarbonate for their strength and aesthetic appeal.

- Under-the-hood: Engine covers, air intake manifolds, and battery enclosures are often made from nylon and PVC, which handle heat and chemical exposure well.

- Lighting systems: Polycarbonate and acrylic plastics are popular here because they provide clear lenses that resist yellowing.

- Fuel systems: Plastic fuel tanks and fuel line components use resistant polymers that contribute to lighter vehicles and better efficiency.

Across these systems, injection molded car parts dominate because they offer precision, repeatability, and cost-effective production at scale. For anyone looking into plastic automotive components, understanding their widespread use is key to appreciating why plastics have become essential in today’s vehicles.

Top Types of Plastics for Automotive Components Properties and Best Uses Polypropylene PP The Versatile Workhorse

Polypropylene (PP) is one of the most widely used plastics in automotive components, thanks to its balance of strength, flexibility, and cost-effectiveness. It’s lightweight, which helps improve fuel efficiency by reducing overall vehicle weight. This plastic is commonly found in bumpers, interior trims, battery cases, and even under-the-hood parts where moderate heat resistance is needed.

Why it stands out:

- Durability: PP resists impact and fatigue, making it ideal for parts exposed to daily wear.

- Chemical resistance: It handles exposure to oils, fuels, and cleaning chemicals without breaking down.

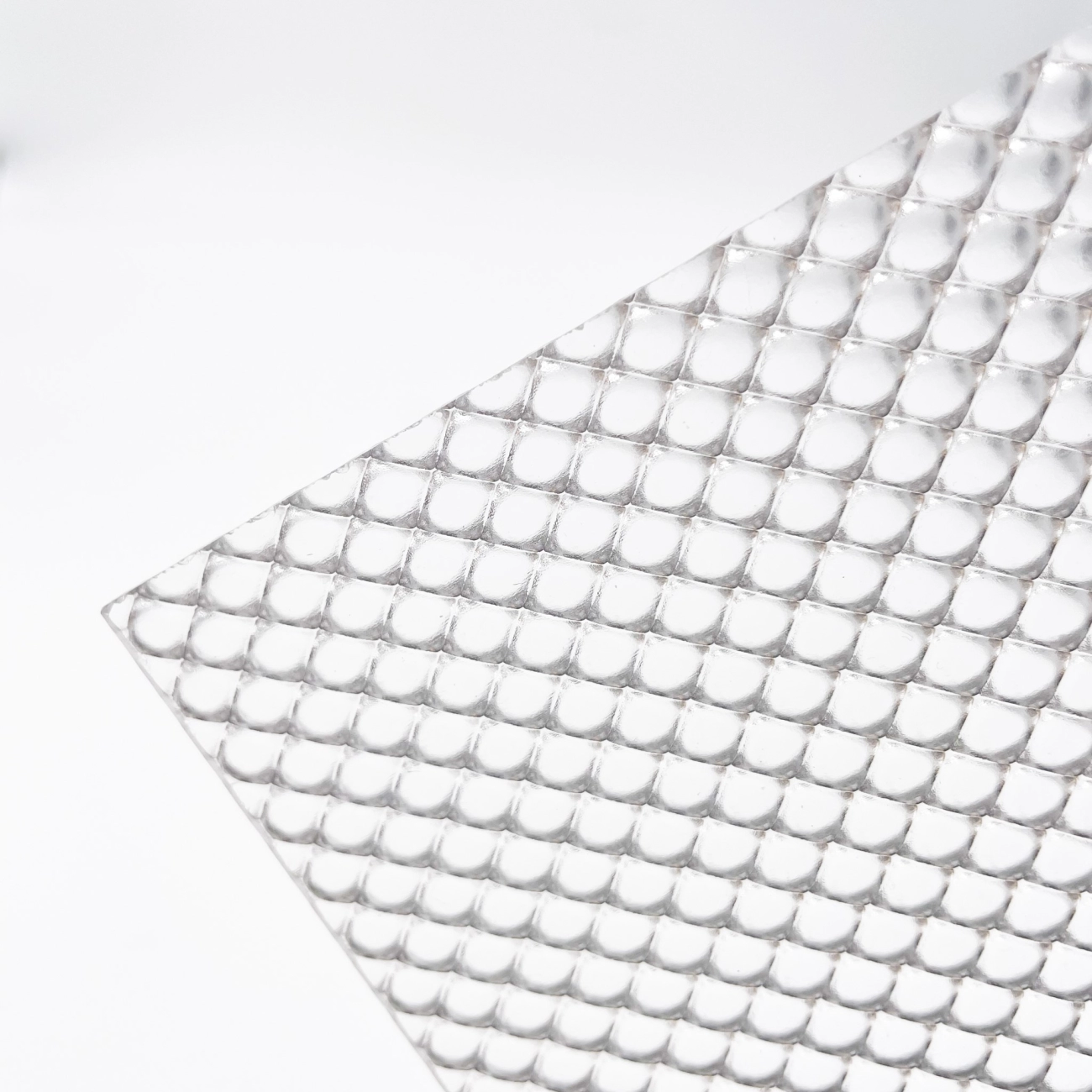

- Easy to mold: Injection molded car parts made from polypropylene allow for complex shapes and consistent quality.

- Cost-effective: It offers a good mix of performance and affordability for large-scale production.

Polypropylene’s versatility also makes it a top choice for manufacturers in the U.S., especially those looking for lightweight vehicle materials that do not sacrifice strength. Plus, it’s recyclable, supporting sustainability goals in automotive design. Whether it’s bumpers that need impact absorption or interior panels requiring flexibility, polypropylene remains a reliable, everyday option in plastic automotive components.

ABS and Polycarbonate Blends for Durability and Clarity

ABS (Acrylonitrile Butadiene Styrene) and polycarbonate blends are go-to plastics when automotive components need both toughness and clarity. ABS offers great strength and impact resistance, making it ideal for durable parts like dashboards, interior trims, and exterior moldings. Polycarbonate adds transparency and higher heat resistance, which is why you see it used in clear or semi-clear components like headlamp covers and instrument panels.

When combined, ABS-polycarbonate blends deliver the best of both worlds. They provide robust impact protection while maintaining a smooth, glossy finish that resists scratching. This makes them perfect for visible parts that have to take a beating but still look good over time.

In the US market, these blends are common in injection molded car parts, balancing cost and high performance. Plus, they handle temperature swings well, important for vehicles operating in varied climates around the country. This combination also supports lightweight vehicle materials efforts—helping improve fuel efficiency without sacrificing safety or design flexibility.

Top Types of Plastics for Automotive Components Properties and Best Uses Advanced Options Nylon PVC and Acrylic

When it comes to plastic automotive components, advanced materials like Nylon, PVC, and Acrylic play important roles. These plastics offer unique properties that suit specific parts under the hood and inside the car.

Nylon is known for its toughness and resistance to wear. It’s great for parts like engine covers, air intake manifolds, and fuel system components because it handles heat and chemicals well. Its strength also helps in moving parts that need durability over time.

PVC (Polyvinyl Chloride) stands out for its flexibility and excellent weather resistance. It’s widely used in interior trims, door panels, and wiring insulation. PVC’s ability to resist UV light and moisture makes it a go-to plastic for long-lasting vehicle interiors, especially in varying climates across the U.S.

Acrylic is prized for its clarity and impact resistance. You’ll often find acrylic in automotive lighting, like headlamp lenses and signal covers. It’s also used in instrument panels where a clear, durable surface is needed.

In , choosing the right plastic depends on the part’s demands—whether it’s the heat and wear-resistance of Nylon, the flexibility and weather-proofing of PVC, or the clarity and toughness of Acrylic. These advanced options support the U.S. automotive industry’s push for reliable, lightweight, and cost-effective plastic automotive components.

Top Types of Plastics for Automotive Components Material Selection Guide

Choosing the right plastic for automotive components depends on where and how the part will be used. Different plastics offer unique benefits, so it’s important to match material properties with performance needs. Here’s a quick guide to help you understand which plastics work best in specific areas:

1. Polypropylene (PP)

- Lightweight and cost-effective

- Great for bumpers, interior trims, and battery housings

- Resistant to chemicals and fatigue

2. ABS and Polycarbonate Blends

- Tough and impact-resistant

- Perfect for dashboards, instrument panels, and headlamp covers

- Offers clarity where visibility matters

3. Nylon (Polyamide)

- Strong and heat-resistant

- Often used in under-the-hood parts, fuel lines, and connectors

- Handles high stress and temperature well

4. PVC (Polyvinyl Chloride)

- Flexible or rigid options

- Ideal for door panels, wiring insulation, and tubing

- Good weather and chemical resistance

5. Acrylic (PMMA)

- Clear with excellent light transmission

- Common in light covers and decorative trims

- UV resistant and scratch resistant

When selecting plastics for automotive applications, consider:

- Mechanical requirements: strength, flexibility, impact resistance

- Environmental exposure: heat, chemicals, UV light

- Manufacturing methods: compatibility with injection molding or thermoforming

- Cost and availability: balance performance and budget

- Weight: lighter materials contribute to fuel efficiency and EV range

Using this guide ensures that plastic automotive components meet both performance demands and cost expectations, keeping vehicles safe, durable, and efficient.

Manufacturing Processes for High Performance Automotive Plastics

Injection Molding Precision at Scale

Injection molding is the go-to method for producing plastic automotive components quickly and with high precision. This process involves melting thermoplastic material, like polypropylene or ABS, then injecting it into molds shaped exactly like the part needed. Once cooled, these parts come out ready for use in everything from bumpers to dashboards.

Why injection molding works so well for automotive manufacturers in the US:

- High Volume Efficiency: It’s perfect for producing thousands of consistent parts fast, meeting the strict demands of car makers.

- Design Accuracy: Complex shapes and fine details are easily achieved, helping parts fit perfectly and function reliably.

- Material Versatility: Works with popular automotive thermoplastics like PP, ABS blends, and nylon, allowing tailored properties for different applications.

- Cost-Effective at Scale: While initial mold costs can be high, costs per part drop significantly when making large quantities, helping reduce overall production expenses.

For plastic automotive components manufacturers and factories, especially those sourcing in China or local US suppliers, injection molding remains essential. It balances quality and speed, supporting lightweight vehicle materials that boost fuel efficiency and performance. This technique is a backbone for turning raw plastic materials into durable, precise car parts that meet industry standards and customer expectations.

Manufacturing Processes for High Performance Automotive Plastics Emerging Techniques Overmolding Gas Assist and Thermoforming

As automotive designs push for lighter and stronger plastic components, new manufacturing methods are coming into play alongside traditional techniques like injection molding. Let’s break down three emerging processes making a difference in plastic automotive components production:

Overmolding

- Combines two or more materials in one part

- Creates complex, durable components like dashboards with soft-touch grips or multi-material bumpers

- Offers improved bonding and design flexibility without extra assembly steps

Gas Assist Injection Molding

- Injects gas into molten plastic during molding

- Produces hollow or partially hollow parts that are lighter but maintain strength

- Reduces cycle times and material use, boosting production efficiency and fuel economy benefits

Thermoforming

- Heats flat plastic sheets to mold them over shapes

- Ideal for large panels like door trims or interior linings

- Enables cost-effective mass production with excellent surface finish

These advanced methods help automotive thermoplastics meet the high standards for durability, weight savings, and complex shapes that today’s vehicles demand—especially in the U.S. market where performance and cost go hand in hand. Partnering with plastic automotive components manufacturers and factories in China who specialize in these techniques can also ensure quality and scale for OEMs and aftermarket suppliers alike.

Manufacturing Processes for High Performance Automotive Plastics Quality Assurance in Production

Ensuring top quality is crucial when making plastic automotive components. In the U.S. market, customers expect parts that are reliable, durable, and precise. That’s why quality assurance (QA) plays a big role throughout the entire manufacturing process.

Here’s how quality is ensured:

- Material InspectionEvery batch of automotive thermoplastics like polypropylene or ABS is tested before production. This avoids using substandard materials that could affect performance.

- Process MonitoringDuring injection molding or other automotive molding techniques, key factors like temperature and pressure are closely tracked. This helps keep parts consistent and free from defects.

- Dimensional ChecksPrecision measuring tools verify that parts meet exact size and fit requirements. This is vital for components like dashboards or bumpers where tight tolerances matter.

- Visual and Functional TestingPlastic parts go through visual inspections to catch surface flaws and functional tests to confirm they meet strength and durability standards.

- Traceability and DocumentationRecording production data and material sources ensures accountability and makes tracking easier if issues pop up later.

These QA steps benefit manufacturers and U.S. customers by delivering plastic automotive components that perform well and last longer. It also supports cost savings by reducing waste and rework, which is key when choosing plastic automotive components manufacturers or factories in China or locally. Quality assurance keeps everything running smoothly and meets the growing demand for lightweight vehicle materials that don’t compromise on strength or appearance.

Key Benefits and Challenges of Plastic Automotive Components Advantages Lightweighting Cost Savings and Design Freedom

Plastic automotive components offer clear advantages that have reshaped vehicle design and manufacturing in the U.S. market. One of the biggest benefits is lightweighting. Plastics like polypropylene and ABS are much lighter than traditional metals, helping cars improve fuel efficiency and meet stricter emission standards. This is crucial for American drivers who want both performance and better gas mileage.

Cost savings are another strong point. Plastic parts are generally cheaper to produce, especially with injection molded car parts made at scale. The reduced weight also means less wear on tires and brakes, cutting maintenance costs over time. For automakers in the U.S., this balance of lower material and operating costs is a key selling point.

Design freedom is a big plus too. Plastics can be molded into complex shapes that metals can’t easily match. This allows for more streamlined, aerodynamic designs, better fits, and enhanced interior styling—think of durable ABS plastic dashboards and sleek polypropylene bumpers. Plus, plastics can integrate multiple functions into a single part, cutting down assembly time and improving durability.

In , plastic automotive components provide lightweight solutions, lower costs, and design flexibility—helping manufacturers meet American consumer demands for efficient, stylish, and affordable vehicles.

Key Benefits and Challenges of Plastic Automotive Components Sustainability Edge Recyclability and Circular Economy

Plastic automotive components offer a big sustainability advantage, especially for U.S. automakers focused on reducing environmental impact. Many plastics used in cars today, like polypropylene (PP) and ABS, are recyclable, which helps cut down on landfill waste and supports a circular economy. Using recycled materials in manufacturing also lowers the demand for new raw materials, saving energy and reducing carbon emissions.

Here’s how plastics contribute to sustainability in vehicles:

- Recyclability: Thermoplastics like PP and nylon can be melted down and reused multiple times, making recycled automotive plastics a practical option.

- Lightweighting: Plastic parts weigh less than traditional metal ones, improving fuel efficiency and lowering emissions for gasoline vehicles. For EVs, lighter materials help extend battery range.

- Circular Economy: Many manufacturers in China and the U.S. are adopting circular models, reclaiming scraps from production and recycling used components into fresh parts.

At the same time, there are challenges. Recycling automotive plastics isn’t always straightforward because parts often contain mixed materials or coatings. Industry innovators are working on better sorting and processing technologies to improve recyclability rates. Additionally, some plastics degrade after repeated recycling, so maintaining quality is key.

Overall, the sustainability edge of plastic automotive components is strong but requires ongoing effort in recycling infrastructure and material innovation to meet U.S. market demands and environmental goals.

Overcoming Drawbacks Heat Recycling and Durability Hurdles

Plastic automotive components come with clear benefits, but there are challenges to tackle. Heat resistance is a big one. Some plastics soften or lose strength under the high temperatures found near engines or exhausts. That’s why selecting materials designed to handle heat or using special additives is crucial for parts under stress.

Recycling is another challenge, especially since cars use many different plastic types. Sorting and processing these materials can be complex and costly. Still, the industry is improving recycling methods to boost sustainability and support a circular economy—this means more recycled car components make it back into new parts, reducing waste.

Durability also matters. Plastics can crack or degrade over time if not chosen or treated properly. But advances like improved blends, coatings, and reinforced polymers are helping plastics stand up better to daily wear and tear.

In short, while plastics have downsides like heat sensitivity, recycling complexity, and durability issues, ongoing innovations and smarter material choices keep pushing the benefits higher for U.S. car makers and drivers looking for lightweight, cost-effective, and sustainable vehicle parts.

Future Trends Plastics in EVs and Beyond EV Specific Innovations Battery Housings and Aerodynamics

As electric vehicles (EVs) continue to grow in the U.S. market, plastics play a bigger role in making them lighter, safer, and more efficient. One of the biggest areas is battery housings. These need to be tough, heat-resistant, and lightweight to protect expensive battery packs while improving overall range. Advanced automotive thermoplastics like nylon and reinforced polypropylene are popular choices here because they offer strength without adding weight.

Plastics also help improve aerodynamics, which is crucial for EVs to maximize their driving range. Designers use molded plastic components to create smooth, streamlined shapes that cut wind resistance. Parts like underbody panels, spoilers, and grille covers made from injection molded car parts help EVs glide more efficiently on the road.

In short, plastics are essential in pushing EV innovation forward by:

- Reducing vehicle weight to boost fuel efficiency

- Enhancing battery protection with durable materials

- Enabling sleek designs that improve aerodynamics

For U.S. buyers, this means better-performing EVs with longer range and lower costs—thanks in large part to smart use of plastic automotive components.

Future Trends Plastics in EVs and Beyond Regulatory Shifts and Smart Materials

The future of plastic automotive components is closely tied to evolving regulations and smart material innovations, especially as electric vehicles (EVs) grow in popularity across the U.S. New government standards are pushing for lighter, more energy-efficient materials to improve fuel economy and reduce emissions. This means automotive thermoplastics need to be not just lightweight but also meet stricter safety and environmental guidelines.

Smart plastics are stepping up to meet these demands. Materials with self-healing, heat resistance, or sensor-friendly features are becoming more common. For example, plastics that can monitor battery health or adjust to temperature changes help boost EV performance and reliability. Meanwhile, regulations are encouraging recyclability and the use of sustainable automotive polymers, aligning with the circular economy goals many U.S. carmakers are adopting.

These shifts make it essential for manufacturers, especially those sourcing from plastic automotive components factories in China or locally, to stay ahead by integrating smart materials that meet compliance without sacrificing durability or design flexibility. In a nutshell, the coming years will see plastics playing a bigger, smarter role in making vehicles safer, greener, and more efficient.

Partnering with Vast Your Source for Custom Plastic Automotive Solutions Why Choose Vast

When it comes to plastic automotive components, Vast stands out as a reliable partner for custom solutions tailored to the U.S. market. We understand the demand for lightweight, durable, and cost-effective automotive thermoplastics that meet strict quality standards.

Here’s why choosing Vast makes sense:

- Expertise in Manufacturing: Vast works with advanced injection molding and automotive molding techniques, ensuring precision in every part—from bumpers using polypropylene to ABS dashboards.

- Local Market Focus: We know what American automotive manufacturers need, delivering components that enhance fuel efficiency and meet safety regulations.

- Flexible Customization: Whether it’s plastic fuel efficiency parts or EV battery enclosures, Vast adapts materials and designs to your specific requirements.

- Sustainability Commitment: We prioritize sustainable automotive polymers and recycled car components, helping you reach your eco-friendly goals without compromising performance.

- Quality Assurance: Rigorous quality control in manufacturing guarantees that every plastic automotive component will perform reliably on the road.

Choosing Vast means partnering with a manufacturer that combines experience, innovation, and a strong understanding of the U.S. automotive industry’s needs for plastic automotive components.

Partnering with Vast Your Source for Custom Plastic Automotive Solutions Success Stories

When it comes to custom plastic automotive components, Vast stands out as a trusted partner for manufacturers and suppliers across the United States. Our success stories speak volumes about how we deliver reliable, high-quality parts tailored to meet the exact needs of the automotive industry.

We’ve worked with clients who needed lightweight, durable plastic parts for everything from bumpers to dashboard assemblies. One major manufacturer switched to our polypropylene bumpers, significantly improving fuel efficiency without compromising strength. Another client benefited from our expertise in injection molding, gaining precision parts for EV battery enclosures that support safety and aerodynamics.

Vast’s commitment to sustainable automotive polymers also helped several customers implement recycled car components, aligning their production with the growing demand for eco-friendly vehicles. Throughout every project, we focus on material selection, manufacturing techniques, and quality assurance to ensure top performance and cost-effective solutions.

If you’re searching for plastic automotive components manufacturers in China or local factories equipped to handle your production needs, partnering with Vast means access to seamless communication, fast turnaround times, and components built for the evolving US market. We’re proud of our proven track record in helping businesses innovate with plastic automotive solutions that match today’s industry standards.

Choosing Vast means choosing a partner who understands your challenges and delivers results every time.