Discover high-speed, durable laser marking solutions for industrial traceability with advanced fiber and CO2 systems tailored for metals and plastics.

What Is Laser Marking Understanding the Basics

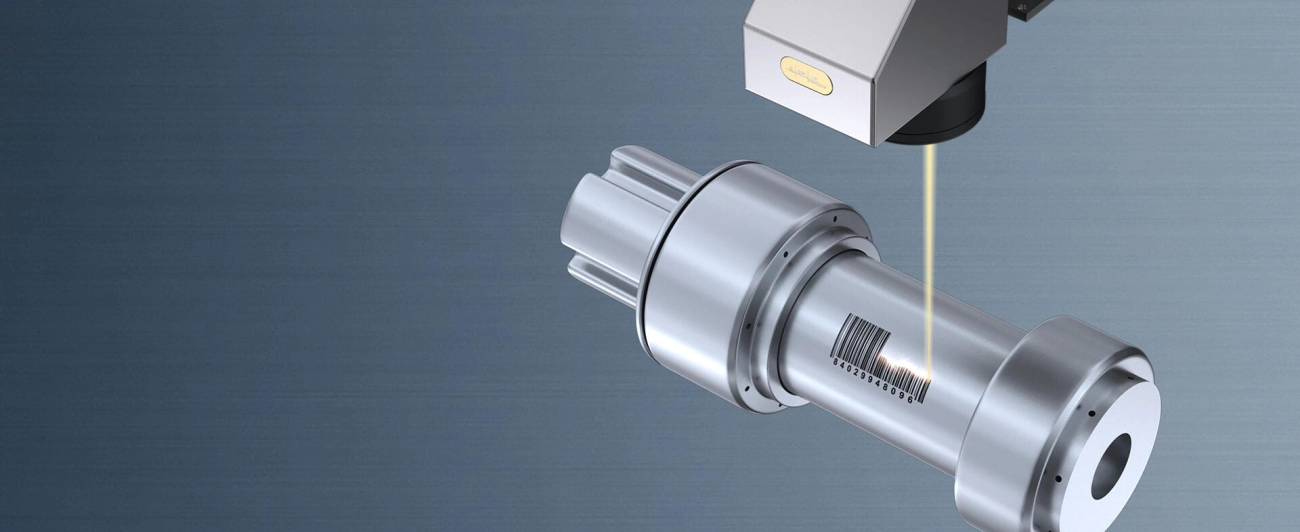

Laser marking is a precise and permanent process that uses focused light to create clear, high-contrast marks on various materials. Unlike traditional printing or stamping, laser marking does not require ink or physical contact, making it clean and highly durable. It’s widely used to add traceability codes, logos, serial numbers, and barcodes directly onto surfaces without damaging the material.

How Laser Marking Machines Work

Laser marking machines operate by directing a laser beam onto the material’s surface. The light energy alters the surface in one of several ways, depending on the material and laser settings. Common effects include color change, surface annealing, or slight ablation (removal of a thin layer) to reveal a mark. The entire process is controlled by computer software, which guides the laser to produce detailed and repeatable patterns at high speed. This non-contact method reduces wear on equipment and ensures consistent results even with complex designs.

Differences from Etching and Engraving

Laser marking is often confused with etching or engraving, but there are key differences:

- Laser Marking typically modifies the surface color or texture without cutting deep into the material. It’s fast, clean, and ideal for fine details.

- Laser Etching involves removing a thin layer of material to create a shallow mark that can be felt. It is deeper than marking but not as deep as engraving.

- Laser Engraving cuts deeply into the surface, removing material to create a prominent, tactile design. It’s slower and used when depth and durability are critical.

Understanding these distinctions helps in choosing the right laser technology based on the application, material, and desired finish. Laser marking often strikes the best balance between efficiency and quality for industrial part traceability and compliance needs.

Types of Laser Marking Technologies Choosing the Right Fit

When it comes to laser marking, picking the right technology is key to getting the best results for your materials and applications. Here’s a quick look at the main types of lasers and what they’re best for:

Fiber Lasers for Metals

Fiber laser engraving is your go-to for metals. These lasers offer high precision and speed, making them perfect for industrial part traceability, metal surface annealing, and automotive VIN coding. They work great on steel, aluminum, and other metals, delivering sharp, durable marks.

CO2 Lasers for Non Metals

CO2 laser etching is ideal for marking non-metal materials like wood, plastics, glass, and leather. These lasers produce clean, clear marks without damaging the surface, making them popular in packaging, consumer goods, and decorative items.

UV and Green Lasers for Sensitive Materials

UV laser marking and green lasers are designed for delicate or heat-sensitive materials like electronics, medical devices, and some plastics. They work gently but precisely, ideal for high-resolution marks without affecting the material’s properties.

Pulsed vs Continuous Wave

Choosing between pulsed and continuous wave lasers depends on your marking needs. Pulsed lasers deliver short bursts of energy, which is great for detailed, precise marks and reducing heat impact. Continuous wave lasers provide a steady beam, better suited for deeper engraving or faster marking speeds.

Understanding these options helps you match the right laser marking method to your materials, saving time and money while boosting quality.

Benefits of Laser Marking for Modern Manufacturing

Laser marking offers clear advantages for manufacturers looking to improve quality and efficiency. One of the biggest benefits is enhanced traceability and compliance. With precise laser marking, you can easily add barcode serialization, automotive VIN coding, or part numbers right on the product surface. This makes tracking industrial parts much simpler and helps meet strict regulatory standards quickly.

On top of that, laser marking delivers cost savings and efficiency. Unlike traditional marking methods, it’s a non-contact process that doesn’t wear down tools, which means less downtime and lower maintenance costs. High-speed laser systems also speed up production lines, allowing you to mark batches without slowing down operations.

Finally, laser marking gives you an environmental edge. It uses less energy and avoids harmful chemicals or inks, making it a cleaner choice for your factory. The process creates minimal waste, supporting sustainability goals that local U.S. manufacturers are increasingly focused on.

In , laser marking improves product quality, cuts costs, and supports eco-friendly practices — all essential benefits for modern manufacturing in the United States.

Laser Marking Applications Across Industries

Laser marking is a versatile solution used across many industries in the U.S., offering precision and durability that traditional methods can’t match.

Automotive and Aerospace

In these fields, laser marking plays a big role in automotive VIN coding e industrial part traceability. It helps manufacturers mark metal and plastic parts with serial numbers or data matrix codes that survive harsh conditions, ensuring quality and safety compliance.

Electronics and Medical Devices

For electronics and medical devices, laser marking delivers clean, non-contact material marking that won’t damage sensitive components. It’s perfect for creating permanent labels, barcodes, and identifiers on small parts, including circuit boards and surgical tools.

Consumer Goods and Packaging

In consumer goods, laser marking offers fast, readable barcode serialization and branding on packaging and products. It adapts well to different materials, from plastics to glass, helping brands meet tracking needs without slowing down production.

Emerging Uses

New industries are adopting laser marking for custom jobs, including metal surface annealing for unique finishes and high-speed laser systems for large-scale production. Green and UV lasers open up options for delicate materials like electronics or luxury goods.

Laser marking is clearly moving beyond traditional applications and becoming a must-have for manufacturers aiming for efficiency, traceability, and durability.

Integrating Laser Marking into Your Workflow

Bringing laser marking into your production line doesn’t have to be complicated. To get the best results, focus on setup, integration, and handling common challenges efficiently.

Best Practices for Setup and Integration

- Assess Your Materials: Choose the right laser type—fiber laser for metals, CO2 for non-metals—to match your products.

- Plan Your Layout: Position the laser marker where it fits naturally in the process, minimizing movement and handling.

- Automate When Possible: Use conveyor belts or robotic arms to feed parts, boosting speed and consistency.

- Train Your Team: Ensure operators know how to run and maintain the system safely and effectively.

Common Challenges and Solutions

- Material Variation: Some materials react differently—test samples first to adjust settings and avoid errors.

- Marking Speed vs Quality: Balance laser speed and power to maintain high-quality marks without slowing production.

- Maintenance Needs: Regular cleaning and servicing prevent downtime in your high-speed laser systems.

- Traceability Accuracy: For barcode serialization or automotive VIN coding, double-check your markings with scanners to ensure compliance.

Local SEO

If you’re searching for a trusted local partner, prioritize manufacturers with hands-on experience and customization options near you. A nearby laser marking manufacturer can provide faster support and tailored setups, fitting your specific industry needs.

Integrating laser marking smoothly saves time, cuts costs, and enhances product traceability—key for staying competitive in U.S. manufacturing.

Why Choose Vast for Your Laser Marking Needs Local Support and Customization

When it comes to laser marking, Vast stands out because we combine advanced technology with real local support. We understand the unique needs of manufacturers and businesses across the United States, and we make sure our solutions fit your exact requirements. Whether you need fiber laser engraving for industrial part traceability or CO2 laser etching for non-metal materials, we offer customized systems that deliver reliable, high-speed laser marking every time.

Here’s why working with Vast makes a difference:

- Local Service You Can Trust: Our team is right here in the U.S., ready to provide hands-on support and quick response times. No waiting for overseas tech help or complicated communication.

- Tailored Solutions: We don’t offer one-size-fits-all laser marking machines. Instead, we customize setups for your specific industry needs—whether it’s automotive VIN coding, barcode serialization, or metal surface annealing.

- Easy Integration: Our experts guide you through setup and help streamline laser marking into your existing workflow, improving efficiency without disruption.

- Quality and Compliance Focused: Vast ensures your laser marking meets industry standards for traceability and regulatory compliance, critical for sectors like aerospace, electronics, and medical devices.

- Environmentally Friendly Options: We prioritize green laser marking solutions that reduce waste and energy use, aligning with sustainable manufacturing goals.

Choosing Vast means you’re getting more than just a laser marking manufacturer or factory — you’re getting a partner committed to your success through smart, customized laser marking technology and unmatched local support.