Explore the die casting process, materials, methods, and benefits for precise metal manufacturing with cast and die technology.

What Is Die Casting The Fundamentals Explained

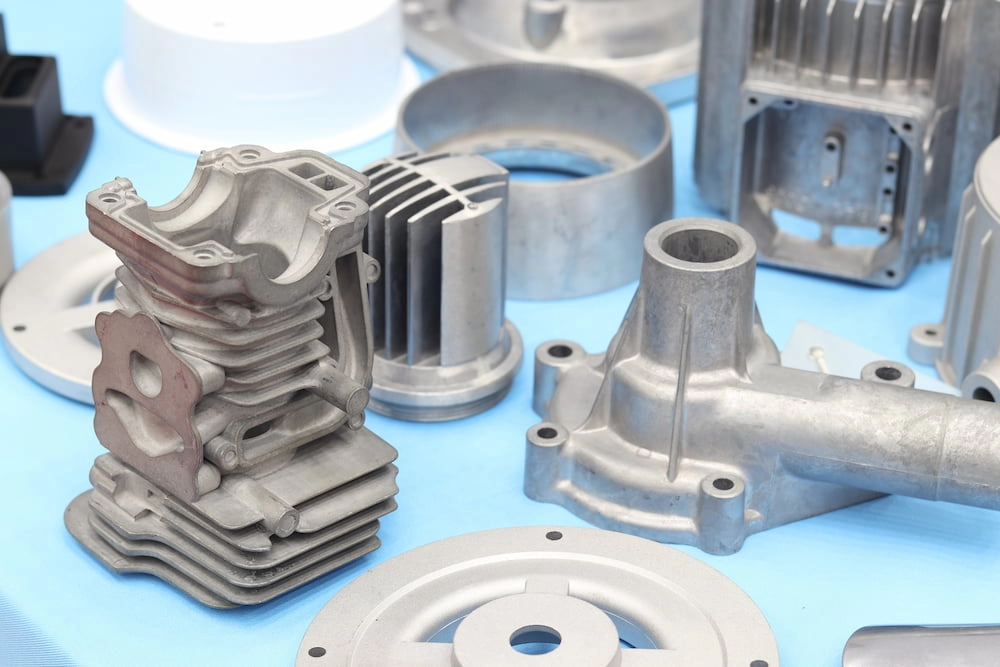

Die casting is a metal casting process where molten metal is injected under high pressure into a reusable mold called a die. This method produces precise, complex shapes with smooth surfaces and tight tolerances. It matters because it combines efficiency and accuracy, making it ideal for industries that demand high-quality parts at scale.

The roots of die casting trace back to the early 19th century when small-scale applications began, evolving significantly with advances in machinery and materials. Today, it supports everything from automotive components to complex electronics housings.

In the United States, die casting plays a crucial role in local manufacturing. It enables faster production cycles, reduces waste, and keeps supply chains close to home. This local focus helps manufacturers stay competitive while meeting strict quality and delivery standards.

The Die Casting Process Step-by-Step Breakdown

Die casting starts with die preparation and tooling investment. Before anything else, manufacturers spend time and money creating or maintaining the steel molds, called dies. These dies need to be precise and durable since they shape every part. Investing in quality tooling upfront saves headaches later on and improves overall product consistency.

Next up is melting and injection. Different metals like aluminum, zinc, or magnesium are melted in specialized furnaces. For example, aluminum often uses a hot chamber process, while zinc usually goes through a cold chamber die casting technique. Once molten, the metal is injected under high pressure into the die, filling every cavity quickly to ensure sharp details.

Once the metal fills the mold, cooling and solidification happen inside the die. Proper cooling is crucial to avoid defects such as shrinkage or porosity. At this stage, quality control checks often occur to catch any early issues.

After solidification, the part is ejected from the die carefully. Then it undergoes trimming and finishing where excess metal, called flash, is removed, and surfaces are smoothed or prepped for secondary operations.

Some of the common defects to watch out for include porosity, cold shuts, and warping. These problems mostly arise from improper temperature control, poor injection speed, or damaged dies. Preventing defects means maintaining equipment and closely monitoring the entire process.

For local manufacturers wanting to reduce downtime, here are some quick tips:

- Schedule regular maintenance for casting machines and dies

- Train operators to spot defects early

- Use quality alloys suited for your casting method

- Optimize injection settings based on metal type and part complexity

Following these steps ensures you get the most from your die casting investment, producing reliable, top-notch components every time.

Types of Die Casting Choosing the Right Method for Your Needs

When it comes to cast and die processes, choosing the right die casting method can make a big difference in quality, cost, and production speed. Here’s a quick look at the main types used in the U.S. manufacturing scene:

High-Pressure Die Casting Applications

This method is popular for mass-producing precision die cast components quickly. It forces molten metal into a steel mold at high speed and pressure. It’s ideal for making automotive die cast parts, consumer electronics, and appliances where detail and surface finish matter. You get fast cycles and good repeatability, but tooling costs can be higher.

Low-Pressure Die Casting Features and Uses

Low-pressure die casting fills the mold slower but more evenly. It’s great for larger or more complex parts requiring stronger bonds and fewer defects. Industries like aerospace and heavy machinery lean on this method because it reduces porosity and improves mechanical strength. This method usually has longer cycle times but better quality control.

Vacuum Die Casting Benefits and Quality Impact

Vacuum die casting removes air and gases from the mold, dramatically cutting down defects like porosity. It’s perfect for aerospace and medical precision parts where structural integrity is critical. While it can be pricier due to equipment and operation time, the quality gains often justify the cost for high-end parts.

Comparison of Methods Pros Cons and Applications

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | Common Uses |

|---|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- Aluminum alloys cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. are even lighter than aluminum, which helps improve fuel efficiency and ease of handling in industries like aerospace and automotive.

- Copper alloys provide excellent thermal and electrical conductivity but are often used in specialized applications due to higher cost.

When picking the right alloy, local manufacturers in the U.S. should consider:

- Cost efficiency: Aluminum and zinc tend to be more budget-friendly for mid to large-volume runs.

- Environmental impact: Aluminum and magnesium are more recyclable and often preferred for sustainable manufacturing.

- cURL Too many subrequests. Strength, weight, thermal resistance, and corrosion resistance should match the product’s use case.

For U.S. industries focusing on automotive, aerospace, or precision electronics, aluminum and zinc cast and die alloys usually offer the best balance of performance, availability, and cost. Staying local with alloy sourcing can also reduce supply chain risks and support domestic manufacturing growth.

Applications of Die Casting Real-World Industries and Case Studies

Die casting plays a big role in many industries here in the United States, especially when you need precision, strength, and fast production.

Automotive Parts Manufacturing

Most cars on the road rely on die cast parts for things like engine blocks, transmission cases, and even structural components. Aluminum and zinc alloys are popular here because they keep vehicles lightweight but durable. The process helps U.S. manufacturers hit tight specs while keeping costs manageable.

Consumer Electronics Components

From smartphones to laptops, consumer electronics use die cast parts for their housings and internal frames. Die casting allows for fine details and a smooth finish — perfect for sleek devices customers expect. It also supports mass production, which is crucial for rapidly changing markets.

Aerospace and Medical Precision Parts

In aerospace and medical fields, die cast components need to be ultra-precise and reliable. This includes parts like brackets, housings, and connectors where safety and high performance are critical. American manufacturers lean on die casting to meet these strict industry requirements without slowing down production.

Case Study Showcasing Vast’s Impact

Vast, a leading U.S. die casting supplier, has worked with automotive and aerospace clients to reduce turnaround times by 30% while improving part consistency. Their use of high-pressure die casting and AI-driven quality checks has set a new standard in local manufacturing efficiency.

Emerging Trends and 3D-Printed Dies

The die casting world is evolving fast. 3D-printed dies are becoming more common, letting manufacturers in the U.S. cut tooling costs and speed up prototype stages. Combined with advanced automation and real-time monitoring, these trends help local shops stay competitive and eco-friendly.

Die casting’s versatility and efficiency make it a go-to choice across multiple U.S. industries, helping keep production sharp and costs smart.

Advantages and Disadvantages of Die Casting Is It Right for You

Die casting offers some big benefits that make it a go-to choice for many manufacturers. First off, it delivers high precision with tight tolerances, which means parts come out consistent and ready to use. The process is also fast, allowing for large production runs without slowing down your schedule. Plus, with the right setup, die casting can be quite cost-effective—especially for medium to high volume runs—because it reduces material waste and minimizes the need for extra machining.

On the other hand, die casting isn’t perfect for every job. One major downside is the high tooling costs—creating the cast and die equipment takes a significant upfront investment. This typically limits the process to larger production runs where those costs can be spread out. Also, because of the machinery involved, die casting works best for certain volume ranges, so if you only need a few parts, other methods like metal injection molding or CNC machining might be more practical.

When comparing die casting with other manufacturing methods:

- Die casting vs metal injection molding: Die casting usually handles larger parts faster, while metal injection molding suits very small, complex components.

- Die casting vs CNC machining: Die casting is faster and cheaper for big quantities, but CNC is better for prototypes or low volumes.

- Die casting vs sand casting: Die casting offers better surface finish and accuracy but comes with higher upfront costs and less flexibility in design changes.

In the U.S. market, if you’re looking for precision, repeatability, and speed—and plan on producing high volumes—die casting could be a solid fit. Just keep in mind the tooling costs and volume needs before you commit.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.