Explore precision cast aluminum parts with expert insights on manufacturing, alloys, applications, and sourcing for automotive and aerospace needs.

The Casting Process: From Molten Metal to Mission-Critical Cast Aluminum Parts

When you hear cast aluminum parts, what’s the journey behind turning molten metal into precise, mission-critical components? The casting process varies, mainly through die casting, sand casting, e fusione a investimento—each suited to different needs and complexities.

Die Casting vs. Sand Casting vs. Investment Casting

- Pressure Die Casting (HPDC): Ideal for high-volume precision parts. This method injects molten aluminum into steel molds under high pressure, providing tight tolerances and smooth finishes.

- Gravity/Sand Casting: Best for complex, low-volume geometries. Molten metal is poured into sand molds where it solidifies naturally. This approach handles larger, more intricate shapes but with looser tolerances.

- Investment Casting: Used for fine detail and thin-walled parts; the wax pattern process creates intricate molds not possible with other methods.

Step-by-Step Breakdown of Cast Aluminum Parts Production

- Alloy Melting & Temperature Control: Aluminum alloys like A356 or ADC12 are melted in controlled furnaces. Maintaining precise temperatures (usually between 1150–1220°F) ensures consistent flow and quality.

- Mold Design (CAD/CAM Integration): The mold’s design is critical. CAD and CAM software help engineers optimize mold geometry for strength, cooling, and minimal defects.

- Pouring, Solidification, Ejection: The molten aluminum is injected or poured into the mold. Solidification timing varies by method—pressure casting is faster, sand casting takes longer. Once solid, parts are ejected carefully to avoid damage.

- Trimming, Heat Treatment, Surface Finishing: After casting, excess metal is trimmed off. Heat treatments like T6 improve mechanical properties. Surface finishes—anodizing, powder coating, or machining—upgrade appearance and performance.

Quality Control Milestones

Ensuring precision aluminum castings meet specs involves detailed quality checks:

- X-ray inspection spots internal porosity or cracks.

- Coordinate Measuring Machines (CMM) verify critical dimensions with ±0.1mm accuracy in die casting.

- Spectrometry tests alloy composition to confirm material standards.

This rigorous process guarantees reliability for industries demanding the best—from aerospace to automotive and electronics.

By understanding the casting process in clear, practical steps, it’s easier to match the right method to your project’s volume, complexity, and performance needs.

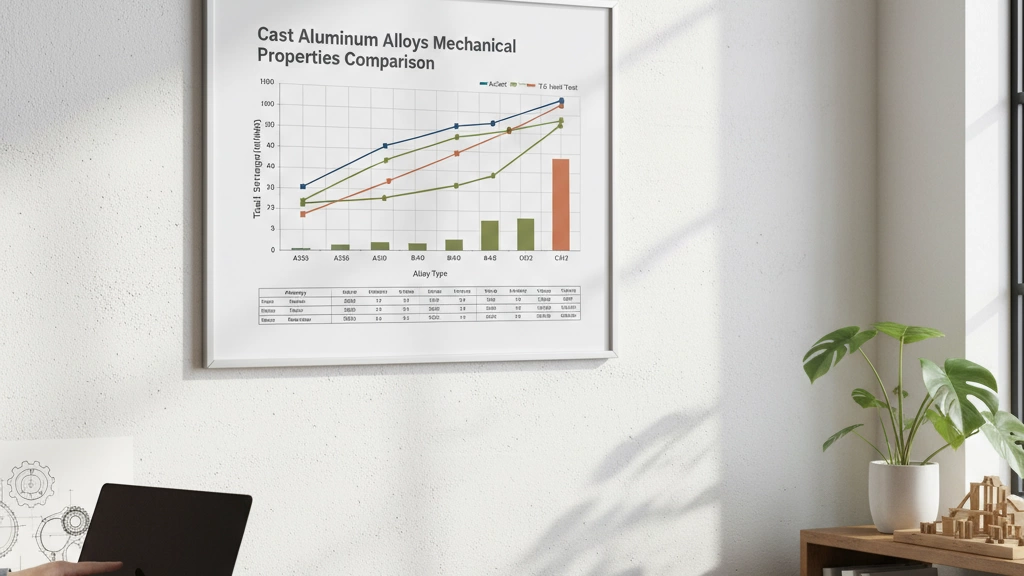

Aluminum Alloys Decoded: Matching Material to Application

When it comes to cast aluminum parts, choosing the right alloy is key to getting the job done. For aerospace structural components, A356 is a go-to alloy because it offers excellent strength and corrosion resistance. In the automotive world, ADC12 shines due to its good mechanical properties and cost-effectiveness, making it ideal for mass production of parts like engine blocks and housings. For electronics, where thermal management is critical, A380 is preferred thanks to its superior thermal conductivity and fine surface finish.

Here’s a quick look at their core traits:

| Leghe | Best For | Tensile Strength | Corrosion Resistance | Thermal Conductivity |

|---|---|---|---|---|

| A356 | Aerospace structures | High | Excellent | Moderate |

| ADC12 | Automotive parts | Good | Good | Moderate |

| A380 | Electronics parts | Moderate | Fair | High |

Heat treatments like T6 e T5 can further boost performance by improving tensile strength and hardness. T6, for example, is common for aerospace and automotive parts where durability is crucial. T5, offering a good mix of strength and ductility, suits parts that need less intensive structural properties but stable performance.

Matching the right alloy with proper heat treatment ensures cast aluminum parts perform reliably in their intended application, whether it’s a tough automotive drivetrain or a sensitive electronic heat sink.

Industry Applications: Where Cast Aluminum Excels

Cast aluminum parts are everywhere, especially in industries that demand lightweight strength and precision. Here’s where they really shine:

- Automotive drivetrain & EV battery housings: Aluminum’s low weight and excellent thermal conductivity help improve fuel efficiency and battery cooling, making it a top choice for electric vehicle components and engine parts.Aerospace landing gear components: High-strength alloys like A356 are used for critical aerospace parts, offering durability without the weight penalty, perfect for landing gear.Electronics heat sinks & enclosures: Aluminum’s ability to dissipate heat quickly makes it ideal for heat sinks and protective casings in electronic devices.Industrial pump housings & valve bodies: Cast aluminum’s corrosion resistance and toughness hold up well in harsh industrial environments.Case Study: vast’s Custom BracketWe developed a custom aluminum bracket for a client that cut their part’s weight by 42% compared to traditional materials—boosting overall system efficiency without sacrificing strength.This versatility across sectors, combined with cost-effective manufacturing, keeps cast aluminum parts as a go-to solution for U.S. manufacturers looking to optimize design and performance.Design for Manufacturability (DFM) Best PracticesWhen working with cast aluminum parts, designing with manufacturability in mind can save time and cost while boosting quality. Here are some solid DFM tips to keep in mind:

- Wall Thickness: Aim for uniform walls between 1.5 and 4mm. This helps avoid defects like warping or porosity and ensures consistent cooling.

- Draft Angles: Include draft angles on vertical surfaces. They make it easier to remove parts from the mold without damage.

- Fillets and Ribs: Use fillets on sharp corners to reduce stress and improve flow. Adding ribs can increase strength without adding too much weight.

- Tolerances: For high-pressure die casting (HPDC), a tight ±0.1mm tolerance is achievable. Sand casting usually allows for ±0.5mm due to its nature.

- Simulation Tools: Software like MAGMA or AnyCasting helps catch issues early by predicting porosity or cooling problems before tooling.

Once cast aluminum parts come out of the mold, surface finishing and secondary operations step in to boost performance and appearance. Here’s what typically happens:

- Anodizing: Adds a protective oxide layer to improve corrosion resistance and wear. It also lets you customize color options for parts seen on the outside.

- Powder Coating & E-Coating: Both provide durable, even coatings that resist chips and scratches. Powder coating is great for thicker layers, while e-coating offers superior coverage, especially in complex shapes.

- CNC Machining: After casting, CNC machining is used to hit tight tolerances (down to ±0.1mm for die cast parts). This is essential for complex geometries and parts needing precise fits.

- Impregnation: For pressure-tight parts like pump housings or valve bodies, impregnation fills tiny pores or micro-cracks. This prevents leaks and extends part life.

When sourcing cast aluminum parts, knowing the right questions to ask your supplier can save time and money.MOQ Flexibility:

- Can they handle low minimum order quantities (as low as 100 pcs) or only large runs (10,000+ pcs)?

- This matters if you need prototypes or small batch production before scaling up.

- Expect 4–6 weeks for tooling setup.

- Production can add extra time depending on volume and finish requirements.

- Make sure they provide clear timelines upfront to avoid surprises.

- Check for industry-standard certifications like IATF 16949 for automotive, AS9100 for aerospace, and ISO 9001 for quality management.

- Certified suppliers ensure consistent processes and traceability.

- Don’t just look at unit costs—factor in freight, tariffs, and potential delays with offshore suppliers.

- Local aluminum casting suppliers in the USA often offer faster turnaround and easier communication, which can be a big plus.

- Sometimes paying a bit more locally means fewer headaches and better quality control.

- Tooling Amortization: The initial mold or die creation is a big upfront investment. The more parts you produce, the lower the cost per piece. That’s why high-volume runs make tooling costs more manageable.

- Alloy Price Volatility: Aluminum prices fluctuate regularly, tracked on the London Metal Exchange (LME). This ups and downs in raw material costs can affect your quotes, especially for alloys like A356 or ADC12.

- Production Volume: Low volumes often mean higher cost per part due to fixed tooling and setup costs.

- Part Consolidation: Design components that combine multiple pieces into one. This cuts down on assembly costs and reduces overall machining and finishing time.

- Design for Manufacturability (DFM): Working with your foundry early to tweak wall thickness, draft angles, and features for casting can lower scrap and improve cycle times.

- Order Planning: Bulk orders spread tooling cost better and may qualify for discounts.

- Alloy Selection: Choosing the right alloy for the performance needed — not over-engineering with expensive grades — helps keep costs in check.

Once cast aluminum parts come out of the mold, surface finishing and secondary operations step in to boost performance and appearance. Here’s what typically happens:

Once cast aluminum parts come out of the mold, surface finishing and secondary operations step in to boost performance and appearance. Here’s what typically happens: When sourcing cast aluminum parts, knowing the right questions to ask your supplier can save time and money.MOQ Flexibility:

When sourcing cast aluminum parts, knowing the right questions to ask your supplier can save time and money.MOQ Flexibility: