Master press fit tolerance with ISO and ANSI standards, calculation formulas, material tips, and solutions to prevent failures for reliable interference fits.

Press Fit Basics: Key Terminology You Must Know

Let’s start with the essentials. Press fit is all about joining two parts by interference—the shaft is slightly bigger than the hole, creating a tight, non-slip connection. Getting your terminology straight is key to designing and measuring these fits correctly.

Nominal Size

This is your starting point—the basic or “design” diameter before applying any tolerance. For example, a nominal shaft diameter might be 50 mm, which you then adjust with clearance or interference values.

Allowance

Allowance is the intentional difference between the shaft and hole sizes, dictating the fit type. In press fits, allowance is negative clearance (interference), meaning the shaft is purposely larger than the hole.

Interference (Minimum and Maximum)

The heart of press fit tolerance:

- Minimum interference is the smallest difference between shaft and hole diameters—this ensures a snug fit at worst.

- Maximum interference is the largest difference—your tightest fit point.

Interference guarantees the parts stay locked together without slipping.

Hole Basis vs Shaft Basis Systems

These are two ways to control fits:

- Hole Basis System: The hole size stays consistent, and the shaft size changes to create clearance or interference. Handy for mass production.

- Shaft Basis System: The shaft size is constant, and the hole size varies. Often used when shaft standardization is critical.

Knowing which system you’re using influences your tolerance stack-up and manufacturing approach.

Least Material Condition (LMC) and Maximum Material Condition (MMC)

These concepts describe the extremes of feature size:

- MMC is when a part contains the most material—for shafts, it’s the largest diameter; for holes, the smallest diameter.

- LMC is when the part contains the least material—smallest shaft or largest hole.

MMC and LMC are crucial when calculating tolerances because they affect your interference and allowance.

Takeaways:

- Nominal size is your baseline dimension.

- Allowance determines the degree of interference for press fits.

- Minimum and maximum interference set your fit boundaries.

- Hole basis vs shaft basis affects how you assign tolerances.

- MMC and LMC conditions help define extreme size limits.

Master these terms—you’ll be ready to tackle any press fit tolerance calculation or specification with confidence.

Standard Press Fit Tolerance Classes (ISO & ANSI/ASME)

When it comes to press fit tolerance, the industry mainly uses two standards: ISO 286 e ANSI B4.1 / ASME B4.2. ISO 286 defines interference fits with classes ranging from FN1 (light interference) to FN5 (very heavy interference). Here’s a quick rundown of ISO 286 interference fits:

- FN1: Light press fit, suitable for easy assembly.

- FN2: Medium interference.

- FN3 & FN4: Heavy interference for strong, permanent fits.

- FN5: Maximum interference, often for high-load or shock conditions.

On the other side, the American standards ANSI B4.1 and ASME B4.2 use preferred fit classes like LC, LT, LN, which roughly correspond to ISO’s FN series. For example, ANSI’s LN class often matches ISO’s FN2 or FN3 in interference level.

To help choose the right tolerance, engineers often use direct comparison tables between ISO FN e ANSI LN classes. These tables clearly show which ANSI class aligns with ISO’s light to heavy fits, helping you pick the most suitable interference based on your application.

For quick reference, tolerance charts covering diameters from Ø6 mm up to Ø500 mm are widely available. These charts make it easy to find the allowable interference range without diving deep into complex formulas.

Understanding these standards is key for designing reliable press fits, especially when working with different suppliers or international projects. If you’re interested in assembly best practices, consider checking out resources on counterbore symbol guide for engineering drawings and machining to complement your press fit knowledge.

How to Calculate Press Fit Interference

Calculating the right interference is key for a solid press fit that won’t slip or damage parts. Start with the minimum and maximum allowable interference formulas:

- Minimum interference = Hole’s Minimum Material Condition (MMC) – Shaft’s Maximum Material Condition (MMC)

- Maximum interference = Hole’s Maximum Material Condition (MMC) – Shaft’s Minimum Material Condition (MMC)

These define your interference range, ensuring a tight fit without overstressing components.

Diameter Impact on Interference

Keep in mind: larger diameters require proportionally larger interference to maintain the same holding power. A common rule-of-thumb for steel-on-steel fits is:

- 0.0005 to 0.0015 inches of interference per inch of diameter

For example, a 2-inch steel shaft would need between 0.001 and 0.003 inches of interference.

Quick Calculation Tips

- Always verify interference against material specs and operating conditions.

- Use shaft basis or hole basis system formulas depending on design preference.

- For critical assemblies, consider thermal expansion adjustments.

Free Tool Available

To simplify calculations, you can use the vast-branded downloadable Excel calculator or access the free online calculator to quickly find interference values based on your shaft and hole sizes. It saves time and boosts accuracy on the shop floor.

Getting interference right avoids excessive press force and prevents failures down the line. For a deeper understanding of fit classes, check out our detailed guide on ISO press fit classes.

Material Pairs & Their Impact on Tolerance

When dealing with press fit tolerance, the choice of materials plays a huge role in determining the right interference allowance. Different material pairs require different tolerances due to their mechanical properties and thermal behavior.

- Steel shaft into steel hub: This is the most common and straightforward pair. Steel-on-steel usually requires moderate interference fits because both materials have similar thermal expansion rates and hardness. This pair offers reliable, predictable fits.

- Steel into cast iron, aluminum, or bronze: These pairs behave differently. Cast iron and bronze are softer than steel, so the interference can often be a bit lighter to avoid cracking or deformation. Aluminum, being softer and having a higher thermal expansion rate, generally needs tighter tolerances to maintain a solid fit during operation.

- Aluminum shaft into aluminum hub: Aluminum-on-aluminum fits usually require even higher interference than steel because aluminum expands more with temperature changes and is softer. Designing too loose here risks movement or fretting.

- Thermal expansion considerations: It’s crucial to factor in operating vs assembly temperatures. For example, if you fit parts together at room temperature but they will operate at higher heat, the materials’ different expansion rates can cause the joint to loosen or overstress. Proper press fit tolerance must account for this by slightly adjusting the interference to maintain the fit throughout the temperature range.

Choosing the right interference based on material pairs prevents common issues like cracking, loosening, or increased wear. For precision applications, consulting material-specific guides or tools helps nail down the optimal tolerance. For more on selecting materials and mechanical properties, check out our detailed steel yield strength guide with typical values and applications.

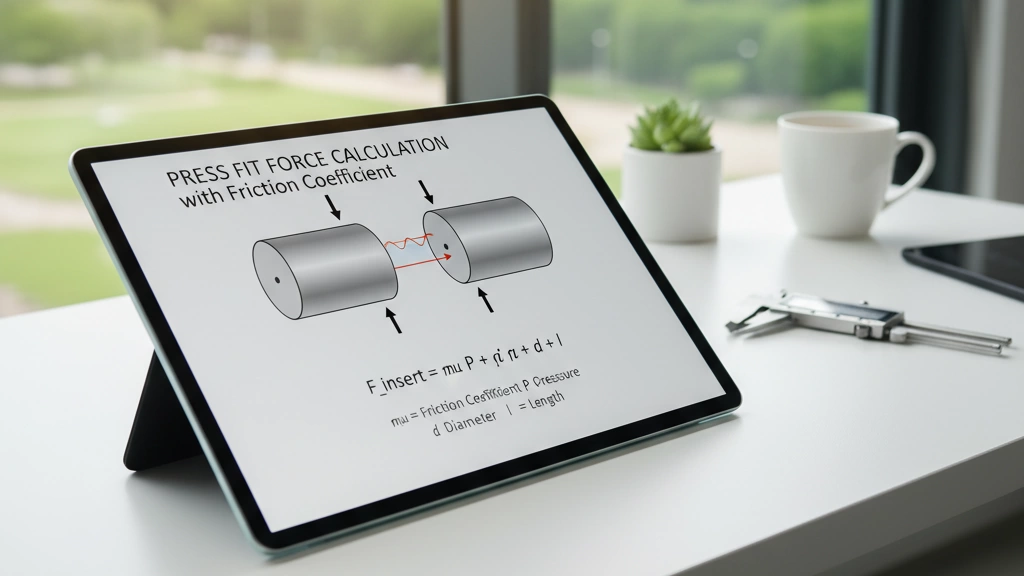

Force Required for Press Fitting

Calculating the force needed for a press fit is crucial to ensure proper assembly without damaging parts. The basic press force formula incorporates the interference amount, shaft diameter, length of engagement, and friction coefficient (μ). It typically looks like this:

F = π × d × L × p × μ

Where:

- F = Required press force

- d = Shaft diameter

- L = Length of the interference fit

- p = Contact pressure from interference

- μ = Friction coefficient between the mating surfaces

Typical Friction Coefficients (μ)

- Dry steel-on-steel: 0.15 to 0.20

- Lubricated steel-on-steel (oil, MoS₂): 0.05 to 0.10

- Lubricated steel on aluminum or bronze: 0.03 to 0.08

Using lubrication significantly reduces the required force, which can help prevent part damage during assembly.

Ton-Force Examples for Common Diameters

| Diameter (in) | Interference (in) | Length (in) | μ (dry) | Approx. Force (tons) | Notes |

|---|---|---|---|---|---|

| 1.0 | 0.001 | 2 | 0.18 | ~1.5 | Steel-on-steel dry |

| 2.0 | 0.0015 | 3 | 0.10 | ~5.2 | With lubrication |

| 4.0 | 0.002 | 4 | 0.05 | ~10 | Large assemblies |

Note: This is a rough guide—always calculate or test for your specific materials and fit.

For highly precise fits or larger diameters, hydraulic or arbor presses are preferred to apply consistent force safely.

If you want a quick way to calculate your press fit needs, you can find tools like the vast press fit calculator that simplify these calculations based on your parameters. Using these can ensure you get the force right without over-pressing or risking part damage.

Surface Finish, Lead-ins & Assembly Best Practices

Getting the surface finish right is crucial for a solid press fit. For shafts and holes, aim for a surface roughness (Ra) around 0.8 to 1.6 microns. This helps ensure proper contact without excessive friction or risk of galling. Chamfers and radius lead-ins on both the shaft and bore edges are must-haves—they guide the parts together smoothly and prevent damage during assembly.

To reduce wear and avoid galling, consider using lubricants like molybdenum disulfide (MoS₂), anti-seize compounds, or even alcohol-based options depending on your materials and environment. Proper lubrication not only eases assembly but also helps maintain a reliable fit.

When it comes to the assembly method, hydraulic presses offer controlled, consistent force that’s ideal for most applications. Arbor presses are good for smaller parts or lighter fits, but they have less control. Thermal assembly—cooling shafts or heating hubs—can simplify the fit by temporarily expanding or contracting parts, reducing press force and minimizing stress.

For more on related metal finishing and machining techniques that affect fit quality, check out our detailed guide on precision metal castings and top suppliers.

Common Press Fit Failures & How to Prevent Them

Press fits are reliable when done right, but there are common failures you should watch out for:

- Galling & Seizure: This happens when metal surfaces stick and tear during assembly, often due to poor lubrication or rough surface finishes. Prevent it by using proper lubricants like MoS₂ or anti-seize compounds, and keeping surface Ra values smooth.

- Hub Cracking or Bursting: Too much interference or using brittle materials can cause cracks or even explode the hub. Choose interference values carefully based on material strength and always check for stress limits. Using a thermal assembly can reduce stress, lowering this risk.

- Shaft Scoring: If the shaft surface isn’t finished right or the fit is excessive, deep scratches or grooves can appear from micromovements during press-in. Chamfers and lead-ins help guide components and avoid scoring, along with proper lubrication.

- Relaxation / Loss of Interference Over Time: Some materials may settle, deform, or creep under load causing the fit to loosen after assembly. To prevent this, pick stable materials and consider using keyways or adhesives for critical applications.

Spotting these risks early and following best practices will keep your press fits tight and trouble-free. For more detailed assembly techniques, you might find our guide on precision CNC turning services helpful.

Design Tips from 20+ Years Shop Floor Experience

After two decades on the shop floor, here are some solid tips for choosing press fit over other fastening methods like adhesives, keys, or set screws:

- When to choose press fit:Press fits are great for permanent, high-strength joins without complex hardware. Use them when you need precise alignment and reliable torque transfer without the extra parts or risk of loosening. They outperform adhesives when you expect temperature or chemical exposure that might degrade glue.

- When to consider alternatives:Keys and set screws work better if you want easier disassembly or if the parts are subject to vibrations that could cause interference fits to loosen. Adhesives suit lightweight, low-stress joints.

- Selective assembly tricks:Sometimes, not all parts are identical; matching slightly oversized shafts with slightly undersized holes can optimize the fit. This “selective assembly” improves consistency when dealing with manufacturing variances.

- Go/no-go gauge strategy:Use go/no-go gauges to quickly check if the shaft and hole dimensions meet tolerance. This speeds production and ensures parts won’t fail in assembly—especially important for press fits where even small deviations can cause rejection.

These tips can save headaches, reduce scrap, and boost reliability in your press fit assemblies. For precision finishing that helps press fits slide and seat better, check out our complete guide to aluminum finishing techniques for durable surfaces.

Downloadable Resources for Press Fit Tolerance

To make your press fit projects easier and more precise, we offer a set of downloadable resources tailored for U.S. manufacturers and engineers:

- vast Press Fit Tolerance Chart 2025 (PDF)Quickly reference ISO and ANSI press fit classes, interference limits, and tolerance values for diameters ranging from 6 mm to 500 mm. Perfect for on-the-fly decisions in design or shop floor checks.

- Excel Calculator for Interference & Press ForceAn easy-to-use spreadsheet that lets you input shaft and hole sizes, material pairs, and friction coefficients to calculate minimum and maximum interference and required press fitting force. This handy tool saves time and reduces guesswork — ideal for steel, aluminum, and bronze combos.

- Material-Specific Quick-Reference CardsThese concise cheat sheets highlight press fit allowances and force factors for common material pairs like steel-on-steel, steel into cast iron, and aluminum shafts into aluminum hubs, including thermal expansion tips.

These tools are designed for practical use, enabling better control over assembly quality and reducing costly errors. To build your press fit knowledge further, check out our detailed guide on precision casting molds and explore insights on optimizing manufacturing with CNC processes via our mastering the CNC process guide.

Download these resources today and boost your press fit confidence and accuracy for 2025 and beyond!

Press Fit Tolerance FAQ

Here are quick answers to common questions about press fit tolerance, interference fits, and related topics:

| Question | Answer |

|---|---|

| What tolerance is typical for locating dowel pins? | Usually, a close running or locational fit like H7/g6 or H7/h6 to ensure precise alignment without too much force. |

| How much interference is needed for a gear on a steel shaft? | Around 0.0005 to 0.0015 inches per inch of diameter is common for steel-on-steel press fits, depending on size and load. |

| Can you press fit stainless steel into aluminum? | Yes, but higher interference is needed because aluminum is softer and more prone to deformation; thermal expansion differences must be considered. |

| Is H7/p6 a press fit? | Yes, H7/p6 is considered an interference fit suitable for press fitting, often providing a strong, permanent joint. |

| What’s the difference between press fit and force fit? | Press fit generally means fitting parts together with interference to hold by friction alone; force fit can be a broader term that includes press fits but may also involve other joining methods (keys, adhesives). |

Need more detailed info on using precise fits or surface finish tips? Check out our guides on master CNC fixturing techniques e brushed finishing benefits.