Discover durable sharp fasteners including zinc-coated sharp point screws ideal for wood metal and cement board projects with easy installation.

Understanding Sharp-Point Fasteners Key Features and How They Work

Sharp-point fasteners are designed to pierce materials cleanly and quickly, making them a go-to choice for many projects. Let’s break down what makes them tick.

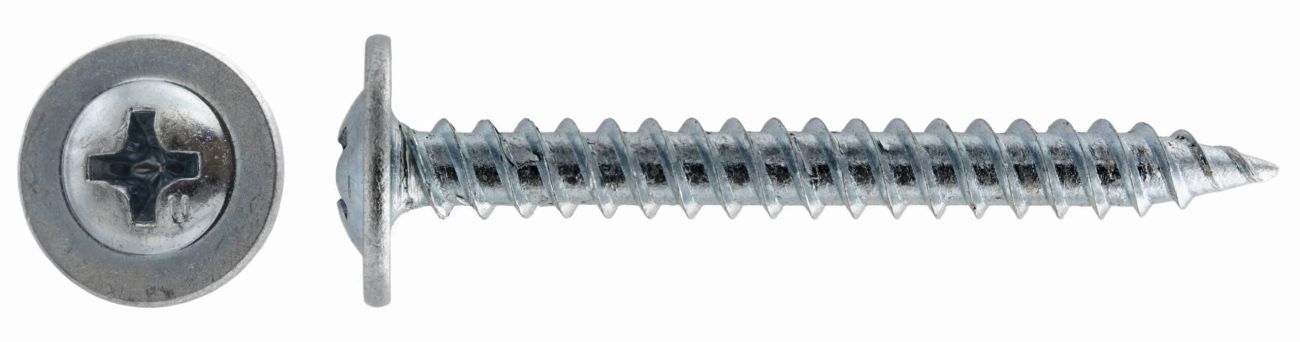

Core Anatomy

- Point Geometry: The defining feature is the sharp tip that easily penetrates wood, metal, or masonry without pre-drilling.

- Thread Design: Threads grip tightly, often with deep cuts for better hold and reduced pull-out risk.

- Head Styles: Common heads include Phillips, wafer, flat, or hex, each suited for specific tools and applications.

Material Options

- Steel: Strong and versatile but prone to rust if untreated.

- Stainless Steel: Corrosion-resistant and great for outdoor use, though typically costlier.

- Zinc-Coated: Offers a balance with some corrosion protection at a lower price point.

Each material has pros and cons in durability, weather resistance, and price, so choose based on your environment.

How They Differ

Sharp-point fasteners stand apart from blunt or self-drilling fasteners because they don’t require pre-drilling or a separate cutting edge. While blunt fasteners need pilot holes and self-drilling screws have built-in drills, sharp points excel in speed and ease on softer materials.

U.S Standards for Sourcing

When buying sharp fasteners locally, look for products meeting ASTM or ANSI standards. These certifications ensure consistency in size, strength, and coating quality, important for safety and performance in your projects.

Understanding these basics will help you pick the right sharp-point fastener every time.

Types of Sharp Fasteners Matching the Right One to Your Project

Choosing the right sharp-point fastener can make all the difference in your project’s success. Here’s a quick guide to the main types you’ll find and when to use them:

- Woodworking screwsThese usually have fine thread options that grip wood fibers tightly. They’re perfect for everything from furniture making to deck building. Vast offers plenty of choices in sizes and head styles, including Phillips drive sharp screws for easy use.

- Metal lath and sheet metal screwsDesigned for fastening thin metal to metal or metal to wood, these screws often have low-profile heads that sit flush. Their sharp points make piercing metal easier without pre-drilling, saving you time.

- Cement board and masonry fastenersThese often come ceramic coated to resist corrosion and wear. They’re ideal for installing cement board, brick, and other masonry materials, ensuring a durable, rust-free hold outdoors or in damp areas.

- Specialty variantsNeedle point framing screws are great when you need precision and speed on framing jobs. These specialty fasteners reduce splitting and give a strong grip in dense wood.

- Selection matrixVast’s extensive SKUs make picking the right size, length, and drive type simple whether you’re working on light carpentry or heavy construction. Always match the fastener to your material thickness and project demands.

By knowing these types and their uses, you’ll save time and avoid mistakes on your local projects. For more on selecting the best screws, check related guides on self-tapping wood screws and corrosion-resistant hardware.

Benefits of Using Sharp-Point Fasteners in Real-World Applications

Sharp fasteners make a real difference on the job, especially when speed and strength matter. Because their sharp points pierce materials easily, installation is faster—this means less wear and tear on your tools and less time spent on each screw. The deep threads also provide a superior hold, reducing the chance of pull out even under heavy loads.

From a cost perspective, using sharp-point screws lowers labor time and return visits, saving money over the long haul. Safety is another plus; these fasteners minimize splitting in wood and other materials, keeping your projects structurally sound. Plus, many sharp fasteners come in recyclable materials or with eco-friendly coatings, supporting sustainability efforts.

A great local example is a DIY backyard fence upgrade where sharp-point screws cut installation time in half. The fence stayed solid through seasonal changes with no signs of fastener failure—proving these fasteners are worth the investment for both pros and weekend warriors.

How to Choose the Best Sharp-Point Fasteners for Your Needs

Picking the right sharp fasteners can save you time and headaches. Here’s a simple step-by-step guide to help you get it right:

Assess Material Thickness and Load

- Measure the materials you’ll fasten to choose the correct length.

- Consider the load—whether the fastener needs to handle heavy weight or just hold pieces together.

Size and Gauge Tips

- Thicker materials usually need thicker screws (higher gauge).

- Use a screw long enough to grip firmly without poking through the other side.

Coating Considerations

- For outdoor or moisture-prone projects, go with corrosion-resistant options like zinc-coated or stainless steel fasteners.

- Zinc-coated screws offer good rust protection at a lower price.

- Stainless steel fasteners last longer but can cost more upfront.

Budget Versus Quality

- Don’t skimp on quality for critical jobs—invest in precision-engineered sharp point screws from trusted brands like Vast for durability and performance.

- For less demanding tasks, budget options might work, just check reviews for reliability.

Watch Out for Common Pitfalls

- Match drive types correctly. For example, Phillips drive sharp screws are common, but make sure your tools fit perfectly to avoid stripping.

- Avoid mixing blunt fasteners when the job calls for sharp point screws, especially in wood or thin metal.

Following these tips will help you find the perfect sharp fasteners for your project, whether you’re fixing up a fence or working on a metal frame.

Step by Step Installation Guide Pro Tips for Flawless Results

Getting sharp fasteners installed right is key to a strong, lasting job. Here’s a simple guide to make it smooth and hassle-free.

Prep Checklist

- Tools: Use the right screwdriver or drill bit—Phillips drive sharp screws usually work well with a quality drill.

- Surface: Clean and mark your surface to avoid mistakes.

- Safety: Always wear safety glasses and gloves to protect yourself during installation.

Driving Techniques and Torque Settings

- For wood, keep the drill speed moderate and apply steady pressure. Sharp point screws cut through smoothly with less effort.

- With metal, start at a low speed to avoid stripping the threads. Use torque settings on your drill if possible—too much force can strip or break the fastener.

- Let the screw do the work instead of forcing it. If it feels stuck, back out and try again.

Troubleshooting Common Issues

- Cam out: This happens when the driver slips out of the screw head. Use a driver bit that fits tight and keep it aligned straight.

- Stripping: Avoid over-tightening. If threads strip, you may need a bigger size or a different drive type.

- Misalignment: Always start screws square to the surface to prevent bending or weak holds.

Advanced Hacks

- Pair sharp fasteners with Vast anchors for tougher materials like cement board or masonry. It gives extra grip and security.

- Pre-drill pilot holes on very hard wood or metal to reduce splitting and make driving easier.

- Use a tilt angle tool or guide for angled placements to keep everything flush and precise.

Following these tips will get your sharp-point screws into place cleanly and efficiently every time, saving you time and frustration on your projects.

Maintenance and Longevity Keeping Your Sharp Fasteners Performing

To get the most out of your sharp fasteners, proper care after installation is key. Start by regularly inspecting for any signs of corrosion or loosening, especially in outdoor projects exposed to weather. If you spot rust or wear, replace the affected fasteners promptly to keep your structure solid.

Organize your fasteners well when storing—use labeled containers or kits to quickly find the right size and type. Keep them dry and away from moisture to prevent premature rusting, even if they are zinc-coated or stainless steel.

From an eco-friendly angle, consider recycling old fasteners whenever possible. Buying sharp fasteners from brands focused on sustainable sourcing helps reduce environmental impact. This way, you keep your projects sturdy and support greener practices.